Page 8

Tower 3 (Alarm) Switch Adjustment

Threshold Alarm Switch

1. Position platform at the fully raised

(floor level) position using the pen-

dant control.

2. Place pressure on the threshold

warning plate (base plate). Con-

tinue applying pressure to threshold

plate and turn switch adjustment

screw clockwise until alarm sounds.

If alarm sounds when pressure is

first applied go to Step 3.

3. Continue applying pressure to

threshold plate and slowly turn

switch adjustment screw coun-

terclockwise until the alarm stops

sounding.

Tower 4 (Fold) Switch Adjustment

Partial Fold

1. Position platform at 45˚angle using

the manual hand pump or pendant

control.

2. View the Tower 4 microswitch inside

the lift tower (see Photo B). Turn

the switch adjustment screw in or

out as needed until the radius of the

microswitch blade rides on the apex

of the activation plate.

3. Verify proper adjustment. Criteria

below must be met.

Proper Adjustment Criteria:

• Apply pressure (push down) on

outboard end of platform by press-

ing the hand pendant FOLD switch.

The platform should not fold (stow)

with light pressure applied.

• When folding fully, the platform

should stow tightly (snug with stow

blocks).

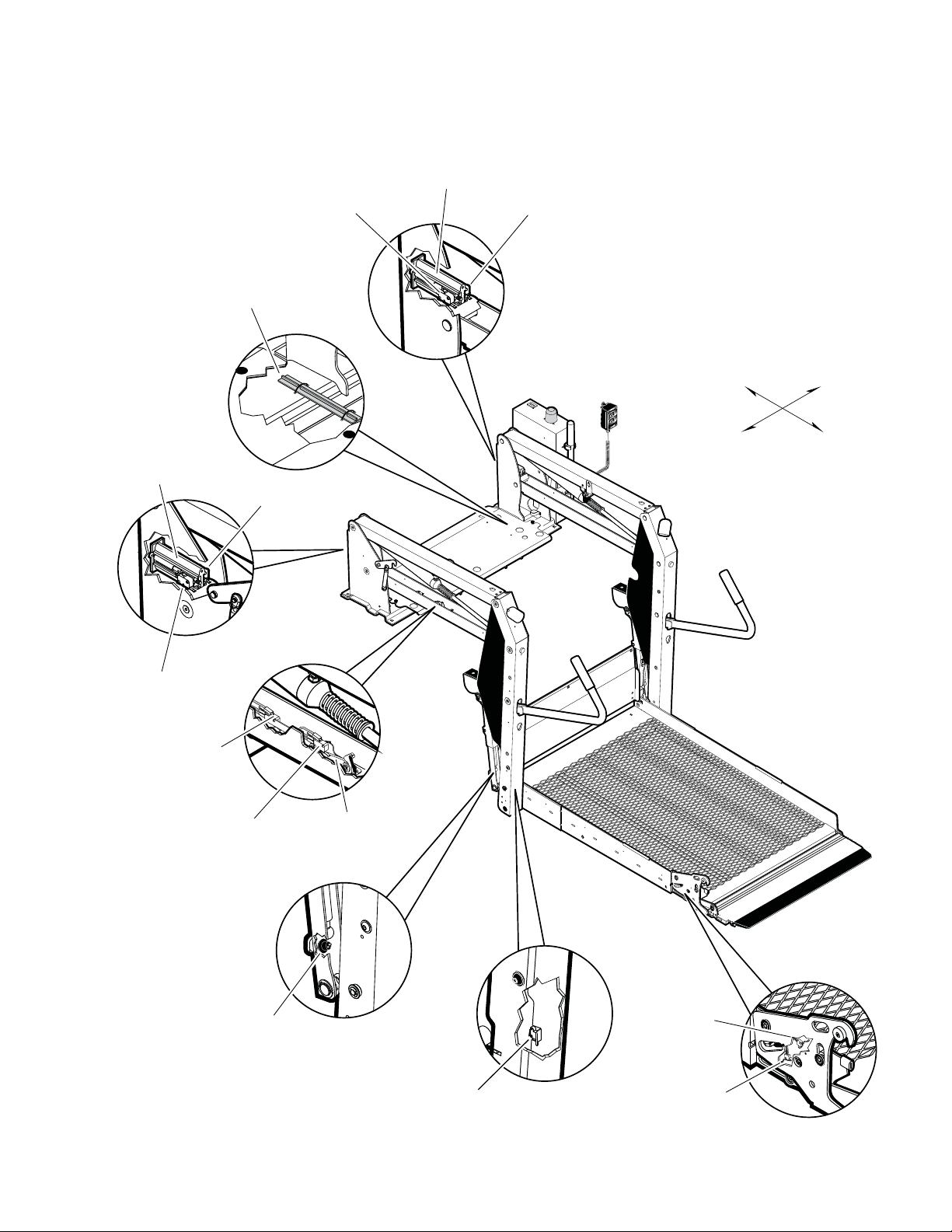

Figure E Note: Left (rear) pump lift de-

picted. Right (front) pump

lift is a mirrored image.

Note: Review adjustment

procedures below and adjust

as needed only.

Tower 1 (Unfold) Switch Adjustment

Floor Position from Stow

1. Position platform at the fully stowed

position using the manual hand

pump or pendant control.

2. Turn switch adjustment screw clock-

wise 3 full turns.

3. Press pendant UNFOLD switch (con-

tinue pressing switch until platform

stops unfolding).

4. When platform stops unfolding, turn

switch adjustment screw coun-

terclockwise while pressing the

pendant UNFOLD switch. Platform

position will change. Repeat adjust-

ment until criteria below is met.

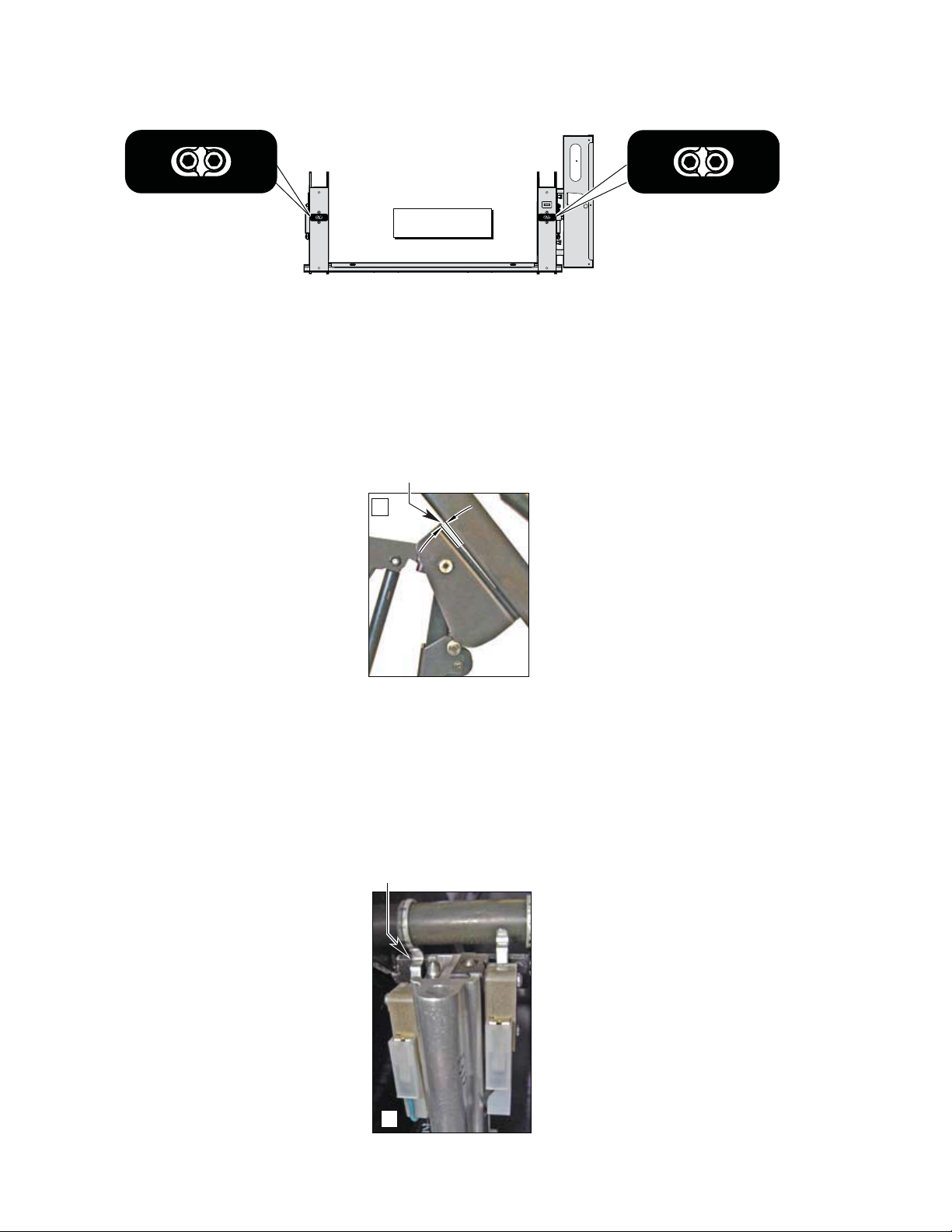

Proper Adjustment Criteria:

• Bridge plate should just rest on

threshold plate (base plate).

• Should be an approximate 1/8˝

clearance between outboard end of

rotating pivot slide arm saddle and

the lower parallel arm. See Photo

A.

Tower 2 (Up) Switch Adjustment

Floor Position from Below Floor

1. Lower platform a minimum of 6˝

below floor level position using the

manual hand pump or pendant

control.

2. Turn switch adjustment screw coun-

terclockwise 3 full turns.

3. Press pendant UP switch (continue

pressing switch until platform stops).

4. When platform stops, turn switch

adjustment screw clockwise while

pressing the pendant UP switch.

Platform position will change. Ad-

just platform to meet criteria listed

for Tower 1 Proper Adjustment

Criteria.

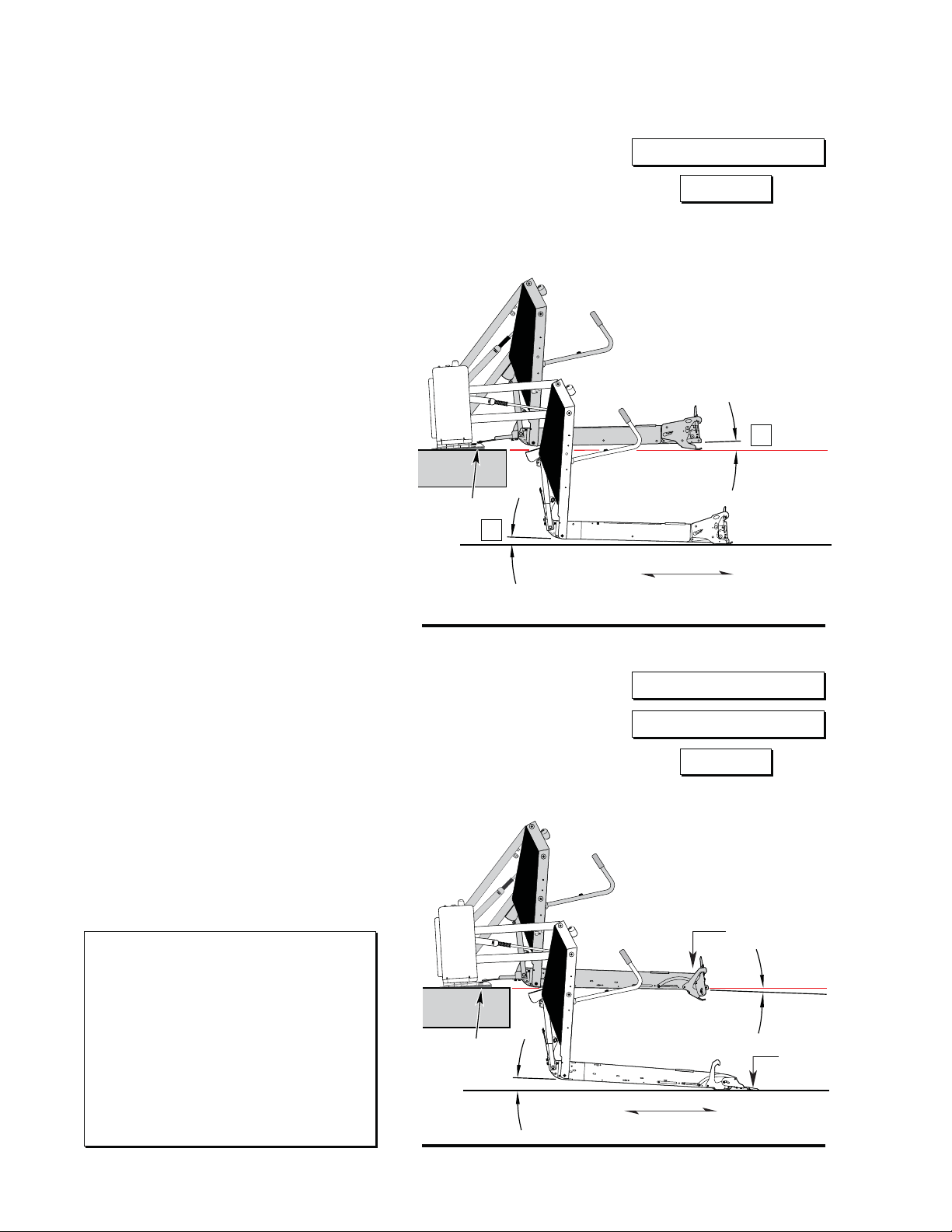

TOWER

2

TOWER

1

32942

TOWER

4

TOWER

3

32943

A

B

Radius of Tower 4 Micro-

switch Blade activated by

Apex of Activation Plate.

1/8"

TOWER

2

TOWER

1

32942

TOWER

4

TOWER

3

32943

Tower Microswitch Adjustment