Brave PRO BRPS105H User manual

OPERATORS

MANUAL

SURFACE FINISHING SCREED

BRPS105H

1

TableofContents

1. SAFETYINFORMATION.. 2

1.1SafetyPrecautions .. 2

1.2OperatingSafety 3

1.3OperatorSafetywhileusing InternalCombustion Engines .. ..3

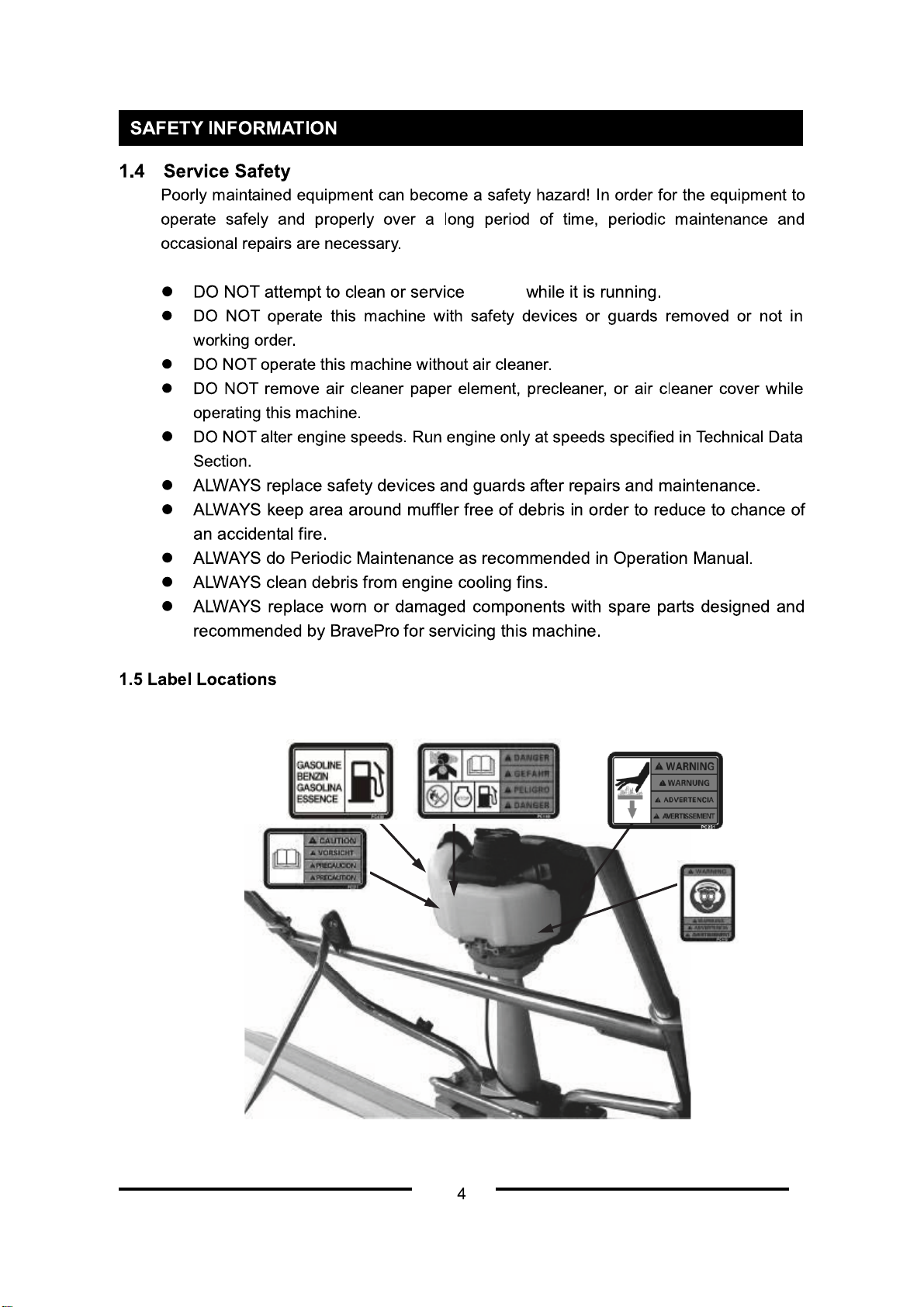

1.4ServiceSafety .. .4

1.5LabelLocations .. 4

1.6SafetyandOperatingLabels ....5

2. OPERATION ..... 6

2.1Assemblethe screed ..6

2.2Pre-Operation Check .. ..... 6-7

2.3ToStart .. .. ..7

2.4Operation and useoftheSCREED ... 7-8

2.5 Operation .8

2.6ToStop .. ..8

3. MAINTENANCE .. ... . 9

4.TECHNICALDATA ... .. ... .. .. .. 10

WARRANTY ..... .. .. .11

MAINTENANCERECORD .. .... .. ..12

.

ECDECLARATION .. ...13

3

SAFETYINFORMATON

1.2OperatingSafety

Familiarityandpropertrainingarerequired forthesafeoperation ofequipment!

Equipmentoperated improperlyorbyuntrainedpersonnelcan bedangerous!Read the

operatinginstructionsand familiarizeyourselfwiththe location and properuseofall

instrumentsandcontrols.Inexperienced operatorsshouldreceiveinstruction from

someone familiarwiththe equipment beforebeingallowed tooperatethemachine.

lNEVER allowimproperlytrained personneltooperatethis machine.

lNEVER leavearunningmachine unattended.

lNEVER usechoketostopengine.

lNEVER operatethemachine inareaswhereexplosionsmayoccur.

lALWAYS read,understand,andfollowproceduresinOperationManualbefore

attempting tooperateequipment.

lALWAYS besureoperatorisfamiliarwithpropersafetyprecautionsandoperation

techniquesbeforeusingthismachine.

lALWAYS wearprotectiveclothingwhileoperating.Weargogglesorsafetyglasses,

hearingprotection, andsafetyshoes.

lALWAYS remainawareofmovingpartsand keephands,feet, andlooseclothing

awayfromthe movingpartsofthe machine.

lALWAYS turnengine OFF when the machine isnotbeingoperated.

1.3OperatorSafetywhileusing InternalCombustion Engines

lDONOTsmokewhenrefuelingtheengineorduring anyotherfuelhandling

operation.

lDO NOTrefuelahot orrunningengine.

lDO NOTrefueltheenginenearanopenflame.

lDO NOTspill fuelwhen refuelingthe engine.

lDO NOTrunthe enginenearopenflame.

lALWAYSrefill fueltankinwell-ventilatedarea.

lALWAYScheck fuellines,fuelcap,andfueltankforleaksandcracks before

startingengine.Donot runmachineiffuelleaks arepresent, orfuelcaporfuel

linesareloose.

lAvoidprolongedbreathingofexhaust gases.

lAvoidcontactwithhot exhaustsystemsandengineparts.

lAllowengine tocoolbeforeperforming anyrepairsorservice.

lALWAYStransportandhandlefuelonlywhencontainedinapprovedsafety

containers.

lALWAYSkeeptheareaaroundthemufflerfreeof debrissuchasleaves,paper,

cartons,etc.Ahot mufflercouldignitethedebrisand startafire.

screed

BravePro

Serial No.

Manuf. Yr.

Model

SURFACE FINISHING SCREED

kW hp lb

kg

Brave

Ph.800-350- 8739 www.braveproducts.com

Made in China

7

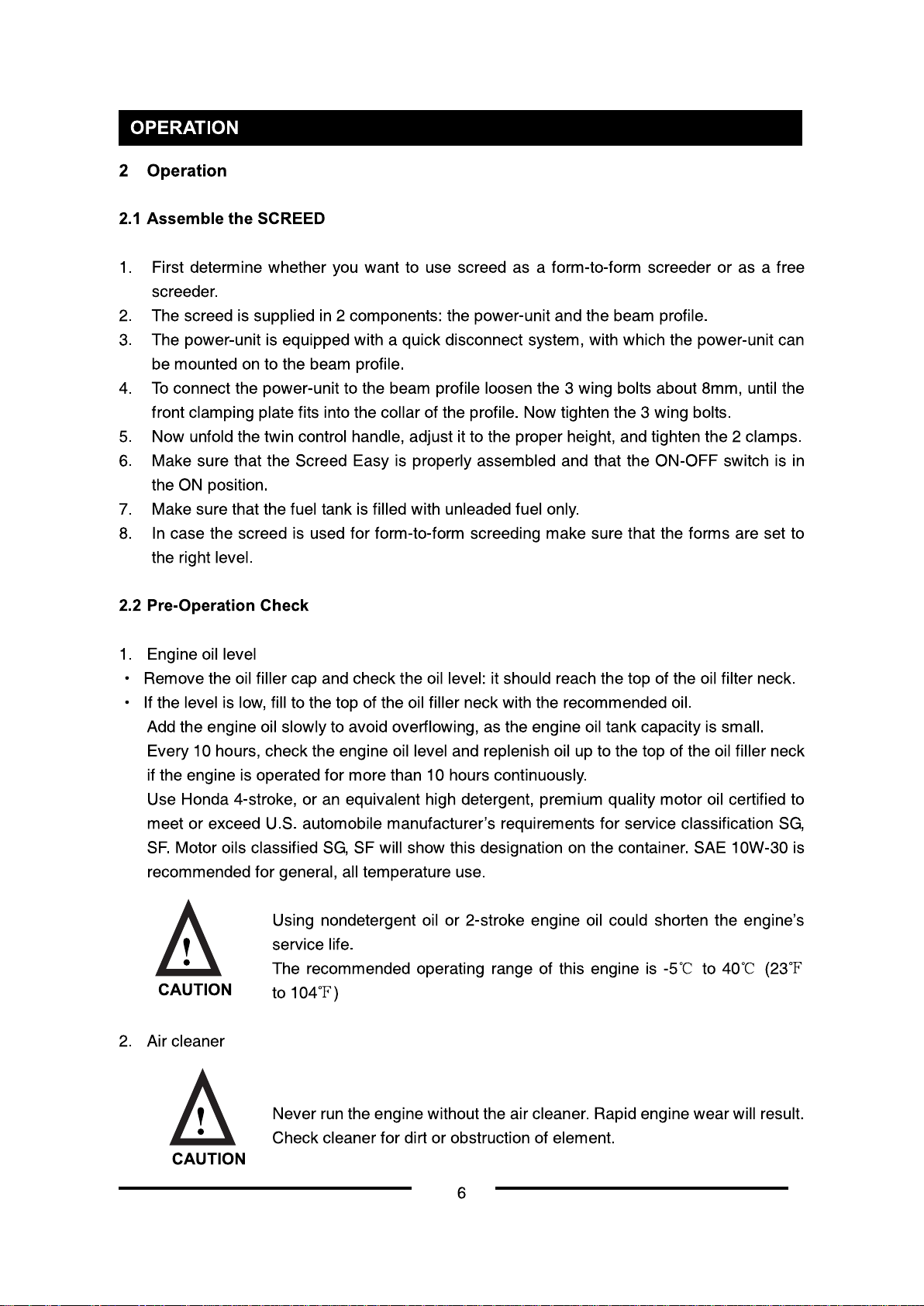

OPERATION

3.Fuel

Useautomotivegasoline (Unleaded orlowleadedispreferred tominimizecombustion

chamberdeposits).

Neverusean oil/gasoline mixtureordirtygasoline.Avoidgetting dirt, dustorwaterinthe

fueltank.

4.Retighteningboltsand nuts

Check forlooseboltsand nuts.Tighten theboltsand nutsproperlyandsecurely,if

necessary.

2.3ToStart

1.Turnthe engine switchtothe ONposition (on the equipment side).

2.Movethe chokelevertotheCLOSEDposition.

Note: Donot usethe chokeifthe engine iswarmorthe airtemperatureishigh.

3.Press the primingpumpseveraltimesuntil afuelflowinthe fuelreturntubeisvisually

noticed.

4.Pull the startergriplightlyuntil resistanceisfelt, thenpull briskly.

5. Graduallymovethe chokelevertothe OPENposition.Warmupthe engine until itrun

smoothly.

6.Position thethrottlecontrolleverforthe desired engine speed (onthe equipment side).

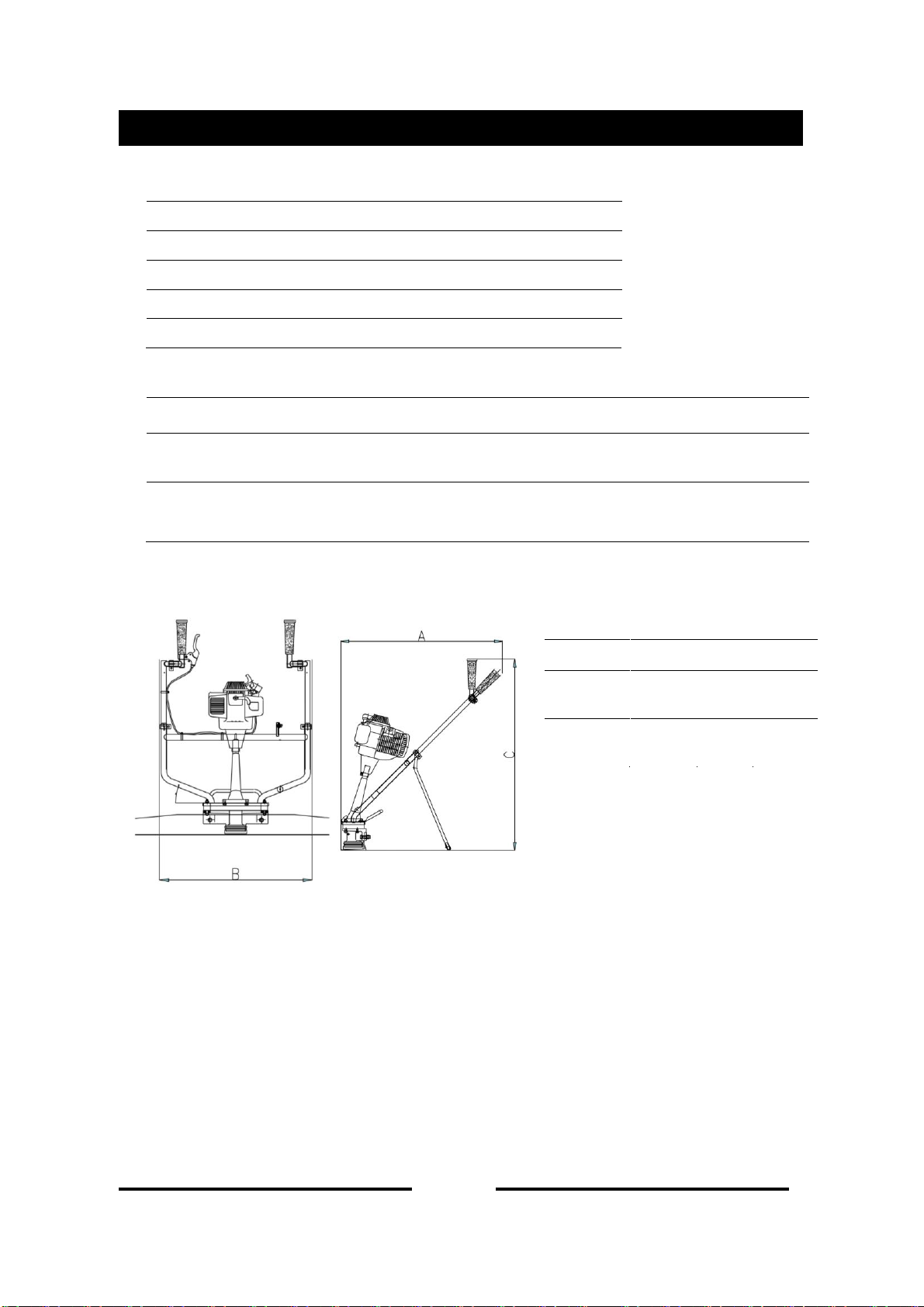

2.4Operation and use oftheSCREED

1. Place the screedbeamon the rail supports orifyou wanttouse the screed as afree screed,

directlyonthe freshlypouredconcretesurface.

2. Nowstart the engine and allowathree minutewarming-upperiod beforesettingthe throttle

handletothe desired engine speed.

3. Aftersettingthe engine speed startmovingthe screed backwards, the travel-speed

depends ontheconsistency ofthe concrete.

4. Afterthe jobis finished,removethe Screedfromthe concreteand switch offthe engine.

5. Afteruse,clean the screed accordingtothe instructions described inthe maintenance

section ofthis manual. Place thescreed on adry, clean andstablesurface.

6. Ifyou donotexpect tousetheengine foralongperiod oftime,drainthe fueltank and let the

engine run at idlespeed unitlthe fuelinthe carburetoris usedand the engine stops.

8

OPERATION

NOTE:

lMakesuretorefill the fueltankintime.Donotletthe engine runsoall thefuelisused. This

might causestartingproblems.

lPreventthescreed ofsinkingintothe concrete.Aftertheenginehasbeen switched on,

immediatelymovethe Screed Easybackwards.

lWhen usingalowslumpconcrete,movethe screed slowlyacross thesurfaceofthe

concrete. When usingahighslumpconcrete, movethe screedfasteracross thesurfaceof

the concrete.

lWhen the screed isused asawetscreed itisrecommended tofirstcompactthe freshly

poured concretewithapokervibratorwhileatthe sametimesetthe heightofthe floorby

meansofalaserdevice.

2.5Operation

Thedrive-unitofthe screedisstartedbypullingthe recoil-starterofthe engine.The

vibratingbeamof the screedcompacts,levelsandsmoothsfreshlypoured concreteinone

operation.Thescreedfeaturesadualpurposebeamand canbeusedforform-to-form

screedingorforfree screeding.

Byrotatingthe power-unit180 degrees,the operatorcan choosebetween screeding,using

forms/rails, orfree screeding.

2.6ToStop

Tostopthe engine inan emergency,turnthe engine switchtothe OFF position (on the

equipment side). Undernormalconditions, usethefollowingprocedure:

1.Position thethrottlecontrolleverfullytoLOW(on the equipment side).

2.Turnthe engine switchtothe OFF position (on the equipment side).

9

MAINTENANCE

3MAINTENANCE

Thescreedisdesignedtogivemanyyearsoftroublefree operation. It isrecommended that

an approved dealercarriesoutall majormaintenanceandrepairs.Alwaysuseourgenuine

replacement parts, the useofspuriouspartsmayvoidyourwarranty.

It isrecommended tospraythealuminumblade andquick disconnectorpriortooperation,

withahighqualityformoil.

Clean the quick disconnectorand beamon adailybasis.

Onlyqualified personnel, familiarwiththecontentsof thisoperation manual,areallowed to

carryout maintenanceand repairjobstothe screed.

Afterusestorethescreed inaclean, dryand dust free place.

DailyService

Inordertoachieveamaximumcoolingeffectthe ventilation openingsmuststayfree from

dirt, greaseand concrete.Check thematthe end ofeachworkingday.Ifnecessaryclean

themwithabrushoradampcloth.Fordetailed engine servicinginstructions,pleaseread

the operationinstructionssupplied bythe manufacturer.

10

TECHNICAL DATA

4. TECHNICAL DATA

Model

BRPS105H

Engine type

Honda GX35

Engine Max. Rated Speed rpm

7000

Power kw (hp)

1.2 (1.6)

Weight without blades kg (lb)

12.7 (28.0)

Blades

Model

BRSB4 BRSB6 BRSB8 BRSB10 BRSB12 BRSB14 BRSB16

Blade Size

m (ft)

1.2 (4)

1.8 (6)

2.4 (8)

3.0 (10)

3.7 (12)

4.3 (14)

4.9 (16)

Weight

kg (lb)

2.90

(6.40)

4.36

(9.4)

5.81

(12.80)

7.27

(16.00)

8.72

(19.20)

10.16

(22.40)

11.61

(25.60)

Working Size mm:

Model

A

B

C

PCDH

450

660

1000

Hand-Arm vibration Specification (According to ISO 5394, EN 1033 and EN500-4):

7.8m/s2

11

12

MAINTENANCERECORD

PREVENTATIVE MAINTENANCEAND ROUTINESERVICEPLAN

BravePro screedhasbeenassembledwithcareand will provideyears ofservice.

Preventative maintenanceandroutineservice areessentialtothelonglifeofyourscreed.

Afterreadingthrough this manualthoroughly, youwill findthat youcandosomeofthe

regularmaintenance yourself.However, wheninneedof parts ormajorservice,be sureto

seeyourdealer. Foryourconveniencewehave providedthis spacetorecordrelevant

data aboutyourscreed.

InvoiceNumber: Type of Machine:

DatePurchased: DealerName:

SerialNumber: DealerPhone:

REPLACEMENTPARTSUSED MAINTENANCELOG

PARTNO. DESCRIPTION

QTY COST DATE DATE OPERATION

BRPS105H

Table of contents

Popular Construction Equipment manuals by other brands

Kemper

Kemper KHS Hygiene Flush Box PRO Installation and operating instructions

Red Rhino

Red Rhino 4000 Series Operation & Maintenance Handbook

Urrea

Urrea 2493 User manual and warranty

BAUER Südlohn

BAUER Südlohn SB operating instructions

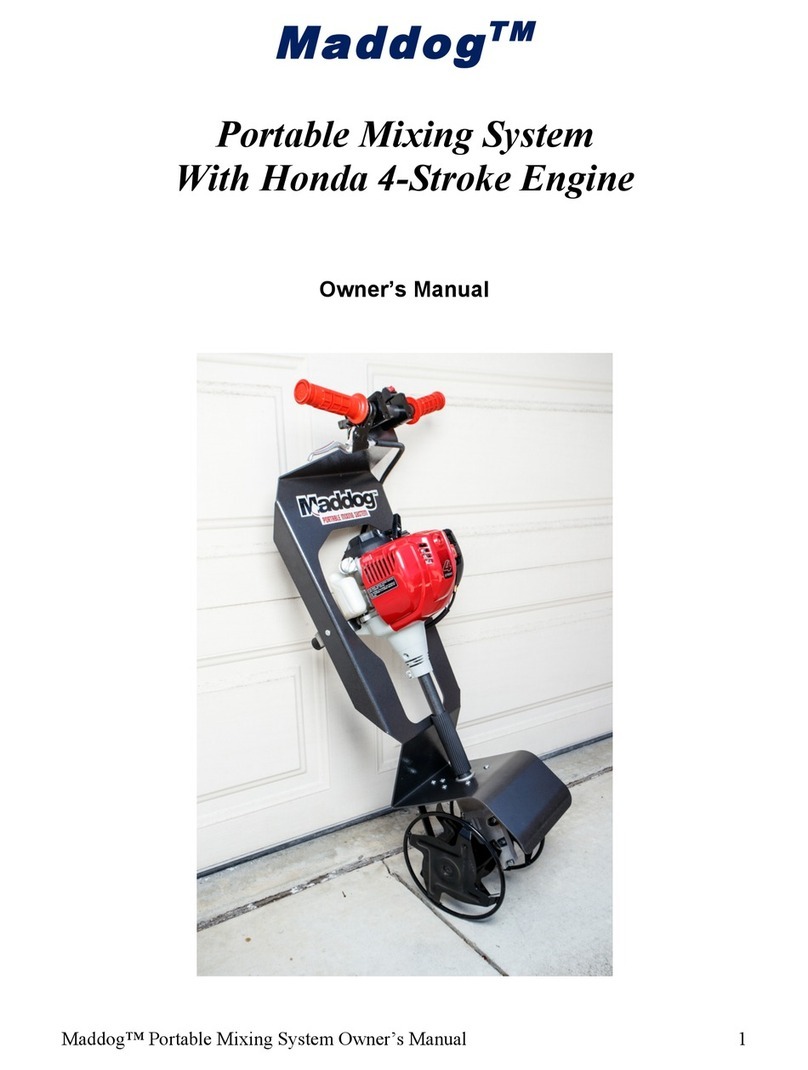

Maddog

Maddog MDGX17l owner's manual

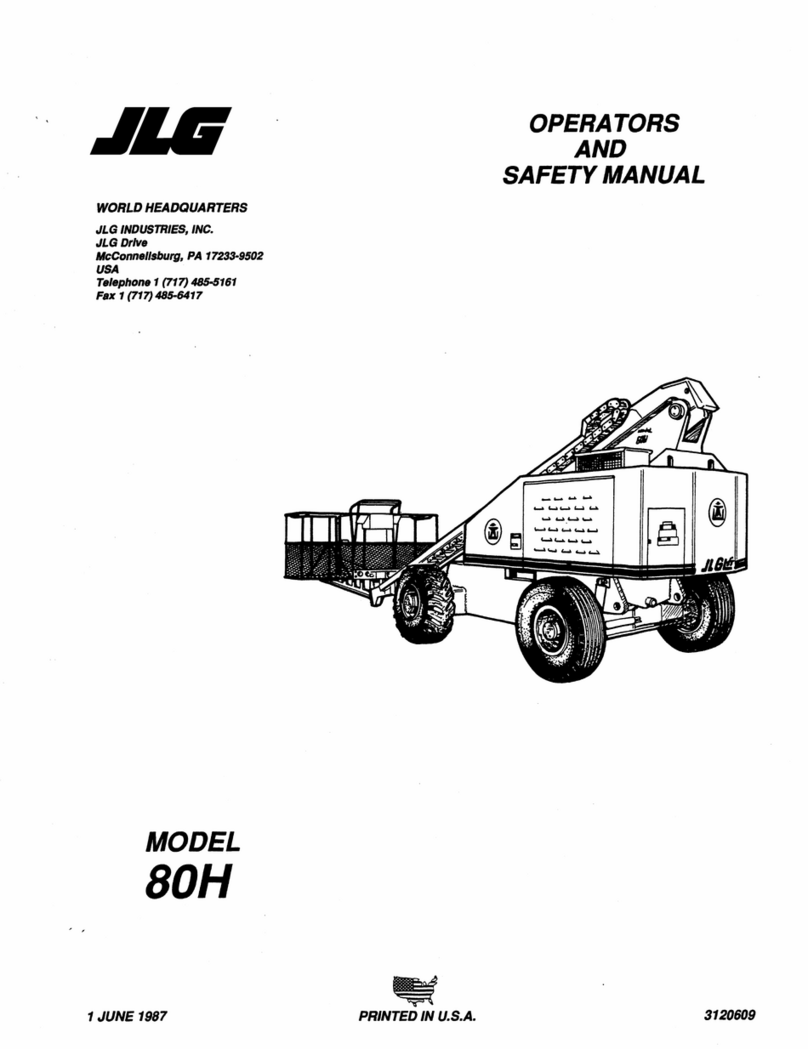

JLG

JLG 80H Operator's and safety manual