Brave BRM500 Operation manual

Operation and Service Manual

BRM500

WARNING

Read and understand all instructions. Failure to follow all instructions

may result in serious injury or property damage.

• WARNING: Wear appropriate protective gear, this list includes, but is not limited to:

Safety glasses, A hard hat, Protective boots with slip resistant soles, Gloves, Hearing protection

• DANGER: Keep riders off and away from machine. Riders can be seriously injured or killed by

entanglement or by falling.

• WARNING: Keep guards in place and in working order. Never operate the product without the

guards in place.

• WARNING: While it is known that Diesel fuel combustion engines produce much lower

concentrations of carbon monoxide (CO) than gasoline engines, these emissions could

certainly generate lethal ambient concentrations given a sufcient amount of time, in an

enclosed space and under suitable environmental conditions. Operate only in an area with

good ventilation.

• WARNING: Check that all control levers/drives automatically go in the neutral position when

unattended, and shields are attached and functioning properly. Do not operate unless they are

functioning properly.

• WARNING: Be sure all drives are in neutral before starting the engine. Only start the engine

from the operator’s position.

• WARNING: Stop on level ground, lower implements, disengage the auxiliary hydraulics and

shut off the engine before leaving the operator’s position for any reason.

• DANGER: Do not smoke when refueling.

• WARNING: Before digging, have the area marked for underground utilities, and do not dig in

marked areas. Also, be aware of the location of objects and structures that may not be marked,

such as underground storage tanks, wells, and septic systems.

• WARNING: Locate the pinch point areas marked on the loader unit and attachments and keep

hands and feet away from these areas.

• WARNING: Never leave a running loader unit unattended. Always lower the loader arms, stop

the engine, and remove the key before leaving.

• WARNING: Do not exceed the rated operating capacity, as the loader may become unstable,

which may result in loss of control.

• WARNING: Do not carry a load with the arms raised. Always carry loads close to the ground.

• WARNING: Do not operate on slopes exceeding 15°. If the slope is greater than 5°, only go up

BRM500-000000

STOP!

ADD OIL TO ENGINE BEFORE USING: Enginne is shipped without oil. DO NOT start engine

without adding oil. INSPECT COMPONENTS: Closely inspect to mkae sure no components are

loose, missing or damaged.

2

BRAVE 800-350-8739 www.braveproducts.com

Brav

e

Product Registra�on Form

YOUR INFORMATION

Full Name:

Last

First

M.I.

Address:

Street Address

Apartment/Unit #

City

State

ZIP Code

Home Phone:

Alternate

Phone:

Email

PURCHASED FROM

Company:

Address:

Street Address

Apartment/Unit #

City

State

ZIP Code

MODEL INFORMATION

Purchase Date

Applica�on Type

□Homeowner

□Commercial

□Rental

Model (i.e. BRPT704H)

Serial # (i.e. )BRPT704HA123456

Signature

Register your product online at www.braveproducts.com

3

BRAVE 800-350-8739 www.braveproducts.com

English to Metric Conversions

1 gal/m = 3.7843 L/m

1 hp = .7457 kw

100 psi = 6.8964 bar

1 ft = .3048 m

1 in = 2.54 cm

1 lb = .4536 kg

(˚F – 32)

1.8 =˚C

20180730

WARNING: This product can expose you to chemicals including lead, which is

known to the State of California to cause cancer and birth defects or other repro-

ductive harm. For more information, go to www.P65Warning.ca.gov

ADVERTENCIA: Este producto puede exponerle a productos químicos incluso

el plomo, que es conocido al Estado de California causar cáncer y defectos de

nacimiento u otro daño reproductivo.

AVERTISSEMENT : Ce produit peut vous exposer aux produits chimiques en in-

cluant l’avance, qui est connue à l’État de Californie provoquer le cancer et les

anomalies congénitales ou d’autre mal reproducteur.

WARNING:

ADVERTENCIA:

AVERTISSEMENT: California Prop 65 Warning

Table of Contents

Specications .............................................................................................................1

Especicaciones ........................................................................................................2

Schedule, Maintenance.............................................................................................. 3

Mantenimiento de horarios........................................................................................4

Operation - Safety.......................................................................................................5

Machine Unpacking, General Safety.................................................................... 5

Electric Driven Intallation......................................................................................9

Machine Troubleshooting........................................................................................ 14

Desembalar la máquina, Seguridad General ......................................................... 16

Seguridad general ...............................................................................................17

Instalación de la máquina accionada eléctricamente ...................................... 20

localización de averías de la máquina............................................................... 27

Assembly, Final ........................................................................................................29

Assembly, Gun........................................................................................................30

Gun, Trigger .........................................................................................................31

Assembly, Final ......................................................................................................32

Assembly, Tank........................................................................................................33

Filter, Water - C04-00186..........................................................................................34

General Assembly ....................................................................................................35

Electrical Schematic............................................................................................ 36

Assembly, Pump......................................................................................................37

Water Pump...............................................................................................................38

Specications - N06-00201 ................................................................................ 38

Freezing conditions - Pump Oil Change...........................................................39

Pump Maintenance Record ..................................................................................... 40

Warranty - PÓLIZA DE GARANTÍA..........................................................................41

1

Specications

BRAVE 800-350-8739 www.braveproducts.com

Specications

Pump Motor

Motor P/N F02-00267

Motor Horsepower 1/2 HP

Motor Speed 1725 RPM

Motor Voltage 115v / 60 Hz 1PH

Motor Amps 115V (12.8 Amp)

PERFORMANCE

Discharge Volume

Up to 30 gal/hr / 114 L/hr

Pump Head Pressure

Up to 500 psi / 34.5 bar

GENERAL

Minimum Inlet Water Pressure over 65 psi may require water inlet regulator

10 psi / 0.68 bar

Weight

150 Lbs / 68Kg

Nozzle, Misting

p/n V12.0 80DB

Hose Assembly

1/4” x 50’ P/N K08-02150B46

Trigger Gun & Wand

Mist Gun – 36” p/n SM500-00158

ELECTRICAL

Machine Voltage

115v 60hz 1PH

Current

6 Amp

Switch, Toggle

p/n F04-00716

Power Cord set

115v – 15amp – 15’ long p/n F04-00171

2Specications

BRAVE 800-350-8739 www.braveproducts.com

FUNCIONAMIENTO

Volumen de Descarga

0.23 gal/hr / 0.87 L/hr

Presión de la cabeza de la bomba

200 psi / 14 bar

GENERAL

Presión mínima de agua de entrada más de 65 psi pueden requerir regulador de

entrada de agua

10 psi / 0.68 bar

Peso

150 Lbs / 68 Kg

Boquilla, nebulización

p/n V12.0 80DB

Ensamble de la Manguera

1/4” x 50’ P/N K08-02150B46

Pistola & Lanza

- Pistola p/n J06-00158-C

-Lanza– 36” p/n J06-00175

ELECTRICA

Voltaje de la máquina

115v 60hz 1PH

Actual

6 Amp

Cambiar, alternar

p/n F04-00716-1

Conjunto de cable de alimentación

p/n 3152-00344

Motor de la Bomba

Motor P/N F02-00267

Caballos de fuerza del motor 1.5 HP / 1.2 KW

Velocidad del Motor 1725 RPM

Voltaje del Motor 115v / 230v 60 Hz 1PH

Motor Amps 115V (12.8 Amp) / 230V 6.4( Amp)

Pump Oil Level

nivel de petróleo de la bomba

Especicaciones

3

Specications

BRAVE 800-350-8739 www.braveproducts.com

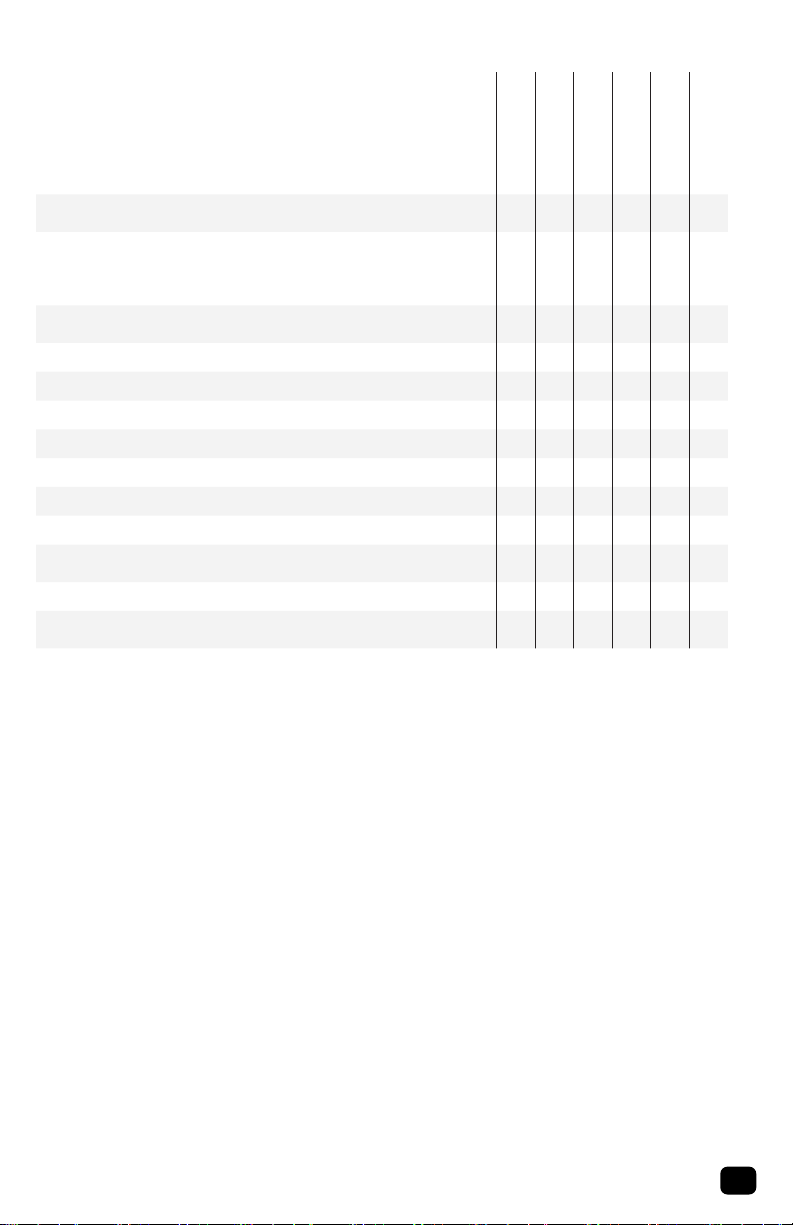

SANI-MISTER

daily

Each HR

1st 8 HRS

AFTER

1ST 50

EVERY 50

HRS

EVRERY

100 HRS

EVERY

500 HRS

YEARLY

Oil Bath Water Pump:

Oil Level- check and add as needed per PUMP

SERVICE insert ●

Oil Change- drain and rell

CAUTION: Used oil must be disposed into an

environmentally safe container and brought to an oil

recycling center

● ●

Oil Contamination- milky color indicates water

contamination – pump needs repair ●

Hoses:

Blistering, loose covering ●

Abrasion of cover exposing reinforcement ●

Cuts exposing reinforcement ●

Filter-Water:

Check lter for debris ●

Leaks:

Check for water and build up of scale at pipe

connections ●

Guards and Shields:

Check that all guards and shields are in place

and secure ● ●

Schedule, Maintenance

4Specications

BRAVE 800-350-8739 www.braveproducts.com

SANI-MISTER

daily

CADA HR

1st 8 HRS

DESPUES

DE1ST 50

CADA 50

HRS

CADA 100

HRS

CADA 500

HRS

ANUAL

Bomba de agua de baño de aceite::

Nivel de aceite: verique y agregue según sea

necesario según el SERVICIO DE BOMBA ●

Cambio de aceite: drenar y rellenar

PRECAUCIÓN: El aceite usado debe desecharse

en un contenedor seguro para el medio ambiente y

llevarse a un centro de reciclaje de aceite.

● ●

Contaminacion de Aceite- el color lechoso

indica la contaminación del agua - la bomba

necesita reparación

●

Magueras:

Bolas, Cubierta Suelta ●

Abrasión de la cubierta exponiendo refuerzo ●

Cortes que exponen el refuerzo ●

Filtro de Agua:

Revise el ltro por escombros ●

Fugas:

Verique el agua y la acumulación de

incrustaciones en las conexiones de la tubería. ●

Defensas y Placas:

Verique que todos las defensas y placas estén

en su lugar y seguros ● ●

Mantenimiento de horarios

5

Specications

BRAVE 800-350-8739 www.braveproducts.com

Machine Unpacking

All cleaners are carefully inspected and cartoned to protect against shipping damage. If there is

damage or missing parts, the transportation company agent should make a notation to that eect

on the bill. Refer to the parts list in this manual and advise what parts are missing or damaged. If

available, give the invoice number on all order bills. This procedure will enable needed parts to be

shipped quickly.

Thank you for choosing our product.

READ ALL Installation, Operation, and Maintenance instructions before operating the machine.

NOTE: Record model number and serial number and date of purchase.

IMPORTANT SAFETY INSTRUCTIONS

The safety alert symbol. This symbol is used to identify safety information about hazards that can

result in personal injury.

A signal word (DANGER, WARNING, or CAUTION) is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In addition, a hazard symbol may be used to represent

the type of hazard

This portion may be the most important in your manual. It is our desire at Steam Way International

that you have many years of satisfactory use, with no injuries to the operator, maintenance personnel,

customers or onlookers. If the operator uses good safety practices, the likelihood of injuries will be

minimal.

DANGER indicates a hazard which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, might

result in minor or moderate injury.

CAUTION, when used without the alert symbol, indicates a

situation that could result in damage to the

equipment

Read and understand this

“OPERATOR’S MANUAL” and “LABELS ON

THE MACHINE” before starting.

A - Explosion

B - Fire

C - Electric Shock

D - Toxic Fumes

E - Kickback

F - Hot Surface

G - Flying Objects

H - Slippery Surface

I - Fall

J - Fluid Injection

K - Moving Parts

L - Read Manual

Operation - Safety

Machine Unpacking, General Safety

6Specications

BRAVE 800-350-8739 www.braveproducts.com

GENERAL SAFETY

1. Before operating this machine, read and observe all safety, unpacking, and operating

instructions. Failure to comply with these instructions could create a hazardous situation.

2. The operator of this equipment should not operate this equipment when fatigued or under

inuence of alcohol or drugs.

3. The operator of this equipment should be thoroughly familiar with its operation and trained

in the job to be accomplished.

4. The operator of this equipment should wear protective face shields and other protective

clothing as required for safe operations. To reduce the risk of injury, keep children and

visitors away.

5. Dress properly. Do not wear loose clothing, gloves, neckties, or jewelry. They can

get caught and draw you into moving parts. Rubber gloves and nonskid footwear are

recommended when working outdoors. Also wear protective hair covering to contain long

hair.

6. Do not leave this machine unattended when it is operating.

7. All installations must conform to all applicable local codes. Contact your electrician,

plumber, utility company or seller for details.

8. Follow instructions on how to stop the machine and bleed pressures quickly. Be thoroughly

familiar with the controls.

9. Do not operate the machine if any mechanical failure is noted or suspected.

10. When starting a job, survey the area for possible hazards and correct before proceeding.

11. Keep all protective covers and shields in place. Replace all protective covers and shields

after adjustments are made to prevent accidental contact with hazardous parts.

12. If a water or fuel leak is found, DO NOT OPERATE THE MACHINE. Shut o and repair.

13. Inspect machine for damaged or worn components and repair or replace to avoid potential

hazards. Do not operate the machine if any mechanical failure is noted or suspected.

14. If chemicals are used in conjunction with this equipment, read and follow the product label

directions.

15. Always point the gun assembly in a safe direction away from people and do not direct

spray on the cleaner.

ELECTRIC MOTOR SAFETY

1. This machine must be electrically grounded. Failure to have the machine grounded may

result in the operator being electrically shocked and even death.

2. Fuses or circuit breakers should be compatible with machine requirements.

3. If an extension cord must be used to operate this machine, it should be as short as

possible. The extension cord must be properly sized and tted with a grounding type plug

and receptacle.

4. Do not plug–in or un–plug machine with wet hands.

5. Keep power cords and connections (connectors) out of water.

6. All wiring and electrical connections should comply with the National Electrical Code (NEC)

and with local codes and practices.

7. High voltage may be present within this machine. Servicing should only be performed by

properly trained personnel.

8. This product is provided with a ground fault circuit interrupter built into the power cord plug.

If replacement of the plug or cord is needed, use only identical replacement parts.

7

Specications

BRAVE 800-350-8739 www.braveproducts.com

MECHANICAL SAFETY

1. All guards, shields, and covers must be replaced after adjustments are made to prevent

accidental contact with hazardous parts.

2. Inspect machine for damaged or worn components and repair or replace to avoid potential

hazards. Do not operate the machine if any mechanical failure is noted or suspected. Drive

belts if so equipped must be inspected and tightened

3. Always use spray tip or steam impact nozzle specied in the machine specications.

SAVE THESE SAFETY INSTRUCTIONS

WARNING: RISK OF INJECTION OR SEVERE INJURY. KEEP CLEAR OF NOZZLE. DO

NOT DIRECT DISCHARGE STREAM AT PERSONS. THIS EQUIPMENT IS TO BE USED

ONLY BY TRAINED OPERATORS.

ADVERTENCIA: RIESGO DE INYECCIÓN O LESIONES GRAVES. MANTÉNGASE ALE-

JADO DE LA BOQUILLA. NO DIRIJA EL FLUJO DE DESCARGA HACIA PERSONAS. SOLO

OPERADORES ADECUADAMENTE CAPACITADOS DEBEN USAR ESTE

EQUIPO.

AVERTISSEMENT: RISQUE D’INJECTION OU DE GRAVES BLESSURES. RESTER À

L’ÉCART DE LA BUSE. NE PAS diriger la décharge FLUX DE PERSONNES. CET

ÉQUIPEMENT NE DOIT ÊTRE UTILISÉ QUE PAR UNE FORMATION

WARNING: Risk of eye injury. Spray can splash back or propel objects.

ADVERTENCIA: El agua rociada puede salpicar o propulsar objetos.

AVERTISSEMENT: Risque de blessure d’oeil. Le spray peut faire des éclaboussures en ar-

rière ou propulser des objets.

WARNING: Protect machine from freezing.

ADVERTENCIA: Proteja la máquina contra la congelación.

AVERTISSEMENT: Protéger la machine contre le gel..

8Specications

BRAVE 800-350-8739 www.braveproducts.com

WARNING: The high pressure stream of water that this equipment produces can cut through

skin and its underlying tissues, leading to serious injury and possible

amputation.

ADVERTENCIA: El chorro de agua a alta presión que este equipo produce, puede atravesar

la piel y los tejidos subcutáneos, provocando lesiones de gravedad que podrían dar lugar a

la amputación de un miembro.

La pistola rociadora contiene agua a alta presión incluso con el motor parado y el agua

desconectada, que puede causar la herida.

AVERTISSEMENT: Le ruisseau de haute pression d’eau que cet équipement produit

peut couper par la peau et ses tissus sous-tendants, en causant la blessure sérieuse et

l’amputation possible.

WARNING: Use of pressure washer can create puddles and slippery surfaces.

ADVERTENCIA: El uso de la hidrolavadora puede crear charcos y supercies

resbaladizas.

AVERTISSEMENT: L’utilisation de nettoyeur sous pression peut créer les mares et les

surfaces glissantes.

WARNING: Kickback from spray gun can cause you to fall.

ADVERTENCIA: El uso de la hidrolavadora puede crear charcos y supercies

resbaladizas.

AVERTISSEMENT: Rebondit de pistolet de pulvérisation peut vous causer d’automne.

9

Specications

BRAVE 800-350-8739 www.braveproducts.com

WARNING: Risk of electrocution. Contact with power source can cause electric shock or

burn.

ADVERTENCIA: Riesgo de electrocución. Contacto con la fuente de alimentación puede

causar la sacudida eléctrica o la quemadura.

AVERTISSEMENT: Risque d’électrocution. Contactez avec la source de pouvoir peut provo-

quer le décharge électrique ou brûler.

Electric Driven Intallation

INSTALLATION

Location

This machine should be installed by only qualied technicians. The machine should be set upon a

level surface where it will not be aected by strong winds, rain, snow, extreme heat, and freezing

temperatures. Install the machine considering locations for chemical pick-up, fuel connections,

electrical connections, water hook-up, venting, and maintenance.

Electrical Driven Installation

Electrical

Connect machine to an electrically grounded circuit that is fused or circuit-breaker-protected.

The circuit must match that which is specied in the ELECTRICAL section under MODEL

SPECIFICATION.

Extension Cord

The use of an extension cord that has undersize wire compared to the amp draw of your machine will

adversely limit the starting load carrying abilities of the motor and machine’s performance. Use only

extension cords that are intended for outdoor use. These extension cords are identied by a marking

“Acceptable for use with outdoor appliances; store indoors while not in use.” Use only extension

cords having an electrical rating not less than the rating of the product. Do not use damaged

extension cords. Use an extension cord in good repair free of frays or cracks in the outer covering.

Do not abuse extension cord and do not yank on any cord to disconnect. Keep cord away from heat

and sharp edges. Always disconnect the extension cord from the receptacle before disconnecting the

product from the extension cord.

10 Specications

BRAVE 800-350-8739 www.braveproducts.com

Copper Wire

Size Minimum

AWG

Machine

AMP Draw*

3 Conductor

Wires

Machine

AMP Draw*

2 Conductor

Wires

16 10 13

15 -- --

14 15 18

12 20 25

10 25 30

8 35 40

6 45 55

4 60 70

2 80 95

Based on Ambient Temperature of 86˚F (30˚C)

Based on no more than 100 feet

* Use AMP Draw indicated the same or higher than your machine output.

EXAMPLE: Machine AMP Draw 51, use 55 (2 Conductor): The thermostat type of cord

shall be C, PD, E, EO, EN, S, So, SRD, SJ, SJO, SV, SVO, SP.

The thermo set plastic types shall be ET, ETT, ETLB, ETP, ST, STO, SRDT, SJT, SJTO,

SVT, SVTO, and SPT.

Water Supply

This machine must have a water supply capable of ushing the machine after use. The water supply

must be at least 2 Gallon / 7.5 Liter to 5 gallon/ 18.9 Liter and a minimum water inlet pressure of 10

PSI/ 0.68 BAR.

Barrier

We recommend a barrier be installed between the machine and wash area to prevent moisture from

coming in direct contact with electrical controls, motors and transformers. This will increase the

machine’s life and lessen electrical problems.

Water Conditions

Local water conditions aect the pressure washer components adversely more than any other

element. In areas where troublesome conditions may exist with like equipment (such as water

heaters), we recommend the use of a water softener.

Freezing

This machine must be protected from freezing according to storage section of MACHINE

MAINTENANCE.

11

Specications

BRAVE 800-350-8739 www.braveproducts.com

CAUTION: Always use the factory supplied wash hose with your machine. Do not substitute other

hoses as a potential safety problem may develop.

CAUTION: If machine has been exposed to sub-freezing temperatures, it must be

thoroughly warmed to above freezing before operating. Failure to warm machine can

cause damage to the pump packings and other components.

¨ MAINTENANCE Refer to the MACHINE MAINTENANCE SCHEDULE for any maintenance

to be performed before operation of this machine.

¨ WATER SUPPLY: The water supply must be at least 2 Gallon / 7.5 Liter to 5 gallon/ 18.9 Liter

and a minimum water inlet pressure of 10 PSI/ 0.68 BAR.

♦ CHEMICAL TANK: Measure the amount of chemical and mix with water to ll the 5 gallon/

18.9 Liter gallon tank. Mix chemicals per the chemical manufacturer’s printed

directions. Follow all mixing, handling, application, and disposal instructions.

Wear gloves, boots, goggles, and protective clothing appropriate for the

chemical being used.

♦ CAUTION: RUNNING TANK EMPTY WITH PUMP RUNNING WILL DAMAGE

THE PUMP.

WARNING: Chemical Burn Hazard. Chemicals could cause burns resulting in death or seri-

ous injury, and/or property damage.

ADVERTENCIA: Riesgo de Quemadura Químico. Los productos químicos podrían causar

quemaduras que causan la herida de muerte o seria, y/o el daño a la propiedad.

AVERTISSEMENT: Le Produit chimique Brûle le Hasard. Les produits chimiques pourraient

provoquer brûle la conséquence dans la blessure mortelle ou sérieuse, et-ou le dommage

de propriété.

Chemicals

Mix chemicals per the chemical manufacturer’s printed directions. Follow all mixing,

handling, application, and disposal instructions. Wear gloves, boots, goggles, and

protective clothing appropriate for the chemical being used.

PRE-OPERATIONAL INSTRUCTIONS

PRE START-UP

1. The rst time the machine is operated, after repairs have been

made, or if the machine has set for a period of time (30 days or

more) follow the following procedures.

A. Flush the machine per instructions in MACHINE

MAINTENANCE.

B. Check position of water incoming ball valve.

12 Specications

BRAVE 800-350-8739 www.braveproducts.com

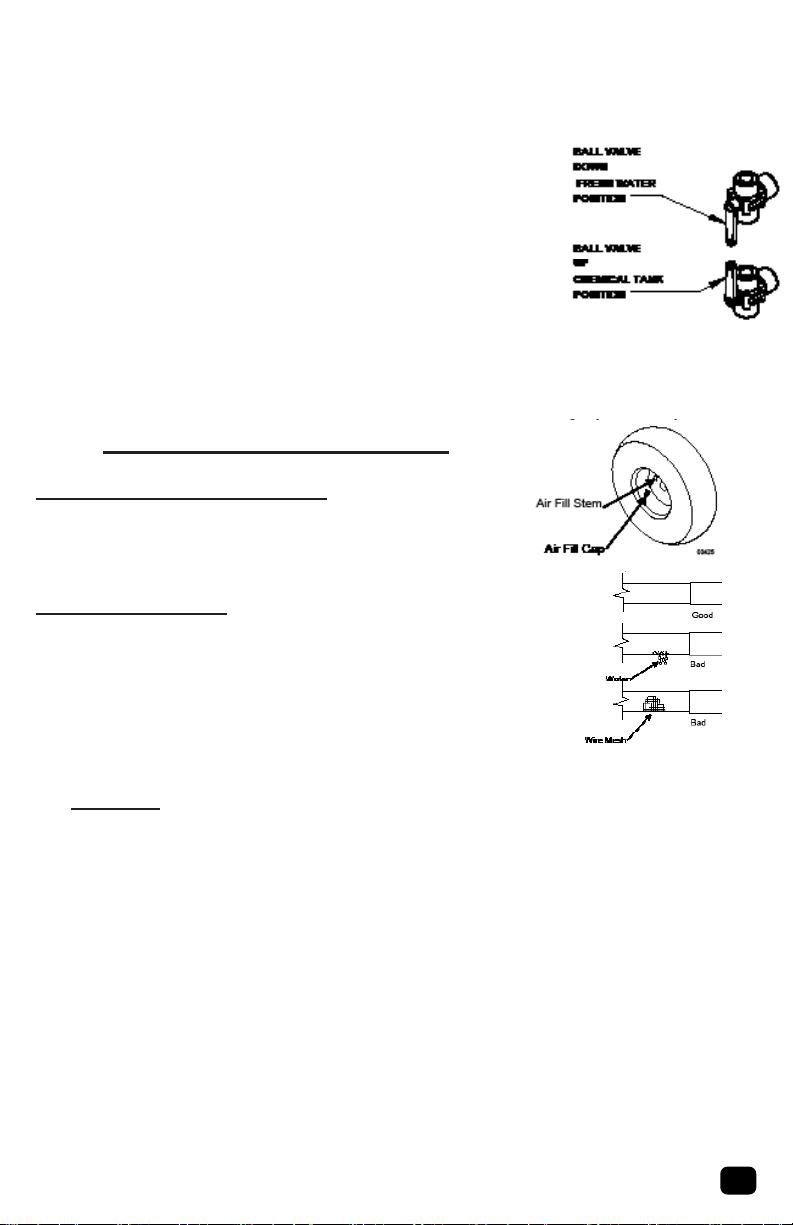

♦ CHEMICAL BALL VALVE: Check the position of the 3 way ball valve on the outlet of the

tank. Turn 3 way valve handle to the “up chemical tank position “opening the chemical tank.

♦ CHEMICAL: Mix chemical solution per chemical manufacturer instructions. Mix chemicals per

label instructions. Use necessary safety precautions.

♦ SPRAY TIP: Use the supplied nozzle to perform the job.

START-UP

1. Remove the nozzle.

2. Turn 3 way valve handle to the “up chemical tank position“ opening the chemical tank.

3. With the gun assembly in hand and trigger in “open” position ip the toggle switch to the

‘on’ position.

4. Open and close the trigger until there is steady ow from the wand to remove air in the line.

This will take 1 – 2 minutes.

5. Flip the toggle switch to the ‘o’ position.

6. Replace the nozzle.

7. For most eective sanitizing – disinfecting, keep nozzle from 8 to 24 inches away from the

cleaning surface.

NOTE: If you have not used all the chemical leave the ball valve handle to the “down fresh water”

position. This will shut o supply of the chemical to the pump and allow ushing of the system with

fresh water.

CAUTION: Do not operate the machine with empty chemical tank.

CAUTION: You need ush the pump after each use to prevent chemicals from damaging pump

components.

13

Specications

BRAVE 800-350-8739 www.braveproducts.com

Shut Down - machine need ushed after each

use

1. Flip the toggle switch to the ‘o’ position.

2. Remove the nozzle.

3. Turn 3 way valve handle to the “down fresh water” position

closing o the chemical tank.

4. Attach a garden hose to the 3-way valve.

5. Turn on the water.

6. Clear water should be owing from the wand.

7. Turn o water leaving it in “down fresh water” position.

8. Replace the nozzle.

9. Disconnect the garden hose and leave ball valve in “down fresh

water” position until you use the machine again.

10. If freezing conditions may exist, refer to STORAGE in

MACHINE MAINTENANCE

MACHINE MAINTENANCE

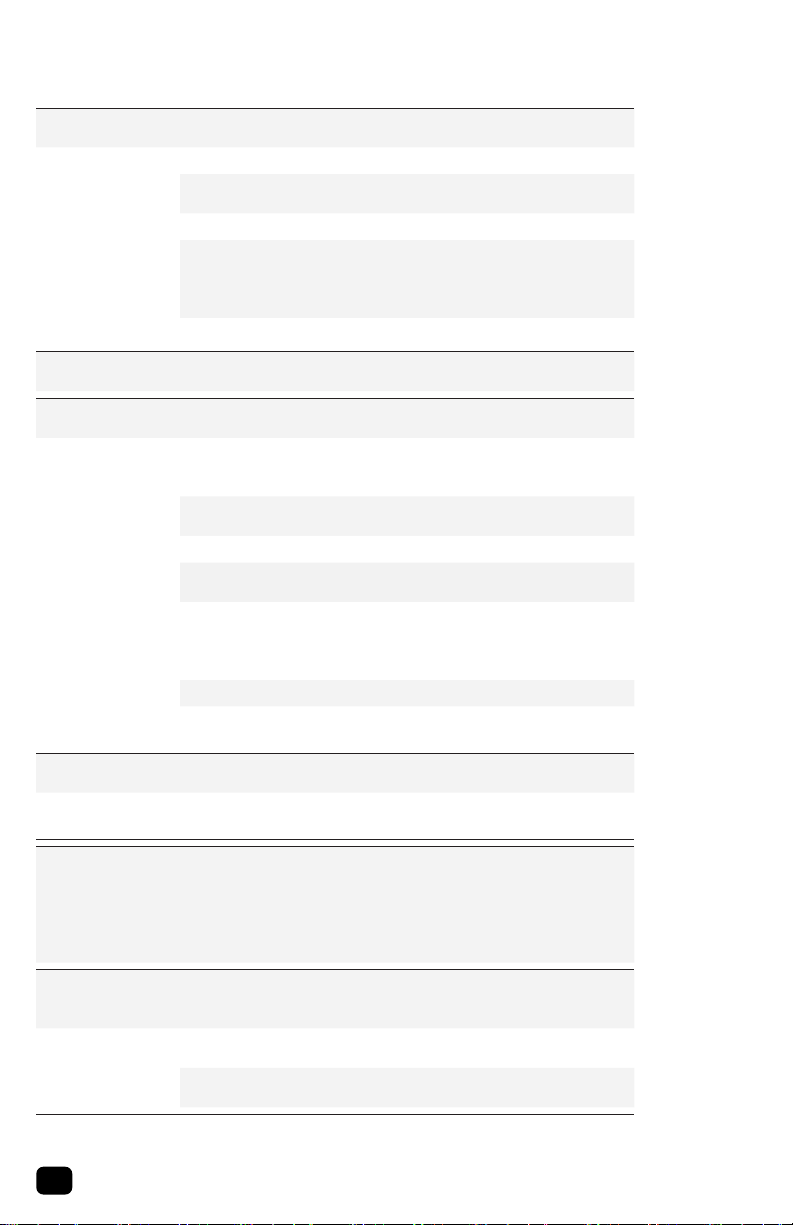

Checking the Tire Air Pressure

A.) Remove air ll cap

B.) Fill tire to 20psi (1.4bar)

C.) Replace air ll cap

Checking the Hoses

WARNING: Do not use a nger or skin to check for leaks. Escaping

uid under pressure has sucient force to penetrate the skin,

causing serious injury. Do not operate the pressure washer if the

hose is cracked, worn, or leaking.

A.) Check all hoses for leaks

B.) Check all hoses of worn areas

STORAGE

1. Turn 3 way valve handle to the “up chemical tank position “opening the chemical tank.

2. Drain the chemical from the tank.

3. To ush the tank, ll it with fresh water.

4. Remove the nozzle.

5. Turn 3 way valve handle to the “up chemical tank position “opening the chemical tank.

6. With the gun assembly in hand and trigger in “open” position ip the toggle switch to the ‘on’

position.

7. Open and close the trigger until there is steady ow from the wand to remove air in the line.

This will take 1 – 2 minutes.

8. Flip the toggle switch to the ‘o’ position.

9. Attach an air chuck to the air valve stem on the pump assembly. With the trigger gun in the

open position, apply air until a mixture of air and very little water is coming from the gun wand

10. Remove the air chuck.

11. Place machine in a dry place protected from weather condition.

14 Specications

BRAVE 800-350-8739 www.braveproducts.com

Machine Troubleshooting

Trouble Possible Cause Remedy

Poor cleaning

action

Hard water. Connect machine to water

softener.

Low pressure. See “low operating pressure.”

Little or no chemical being

drawn.

See “machine will not draw

chemical.”

Improper chemical. Obtain proper chemical.

Improper chemical mixture. Mix chemicals per the label.

Follow all mixing, handling,

application, and disposal

instructions.

Low discharge pressure. See “low operating pressure.”

Machine will not

draw chemical

No chemical solution. chemical tank ball valve not in

“up position”.

Low operating

pressure

Motor runs slow. See “Pump engine starts slow or

overheats and stops.”

Spray tip worn or wrong

size.

Replace with spray tip specied in

the GENERAL section of MODEL

SPECIFICATIONS.

Dirty or worn check valves

in water pump

See PUMP

TROUBLESHOOTING.

Air leak in inlet plumbing. Tighten all ttings.

Defective water pump. See PUMP

TROUBLESHOOTING.

Leaking discharge hose. If a water leak is found, DO NOT

OPERATE THE MACHINE.

Disconnect the power and replace

hose.

Defective unloader valve. Repair or replace unloader valve.

Chemical Tank ball valve

not fully open

Open inlet ball valve completely

in “up position”

Excessive,

unusual noise

Defective pump. See PUMP

TROUBLESHOOTING.

Defective motor. Call service technician or take

engine to repair/warranty station.

Excessive back

pressure

Spray tip built up with lime. Remove and clean, or replace

spray tip with tip specied in the

GENERAL section of MODEL

SPECIFICATIONS. Flush

machine per FLUSHING in

MACHINE MAINTENANCE.

Pump motor will

not start (motor

odes not hum)

No power. Use a dierent outlet, check

fuses in main disconnect switch.

Replace fuse if blown.

Defective motor ON/OFF

switch.

Call service technician.

Defective motor. Call service technician, or take

motor to Repair/Warranty station.

15

Specications

BRAVE 800-350-8739 www.braveproducts.com

Machine Troubleshooting Continued

Pump motor will

not start (motor

hums)

Pump frozen. Machine must be thoroughly

warmed to above freezing.

Defective motor. Call service technician or take

motor to Repair/Warranty station.

Defective water pump. See PUMP SERVICE.

Excessive back pressure. See “Excessive back pressure”

above.

Pump motor starts

slow or overheats

and stops

Low voltage See “Low voltage” below.

Excessive back pressure. See “Excessive back pressure”

above.

Defective motor. Call service technician, or take

motor to Repair/Warranty station.

Pump motor stops

and will not start

Motor starter “kicked out”

(if so equipped) or thermal

overload tripped.

Turn motor starter o to reset,

then turn on, or push thermal

overload reset button on motor.

Excessive back pressure. See “Excessive back pressure”

above.

Defective motor. Call service technician, or take

motor to Repair/Warranty station.

Low voltage Incoming voltage incorrect. Have a qualied technician

check the motor terminal voltage.

Correct voltage is in MODEL

SPECIFICATIONS.

Not large enough

extension cord.

Use an extension cord with

amperes of watts rating as high as

or higher than that or the MODEL

SPECIFICATIONS.

Too long extension cord. Shorten extension cord.

Machine shocks

operator

Machine improperly

grounded.

STOP operating machine. Call

service technician.

Outlet not grounded Have properly wired outlet

installed.

16 Specications

BRAVE 800-350-8739 www.braveproducts.com

Desembalar la máquina

Todas las lavadoras se revisan y embalan cuidadosamente en cajas de cartón para evitar que

se produzcan daños durante el transporte. Si existen daños o faltan piezas, el representante de la

empresa de transporte debe hacer una anotación al respecto en la nota de embarque. Consulte

la lista de piezas de este manual y notique si alguna de las piezas falta o está dañada. Si está

disponible, indique el número de factura en todas las notas de embarque de los pedidos. Este

procedimiento permitirá que las piezas necesarias se envíen rápidamente.

Gracias por elegir nuestro producto.

LEA TODAS las instrucciones de instalación, funcionamiento y mantenimiento antes de operar la

máquina.

NOTA: Registre el número de modelo, el número de serie y la fecha de compra.

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

El símbolo de alerta de seguridad. Este símbolo se usa para identicar información de seguridad

sobre peligros que pueden causar lesiones personales.

Una palabra de advertencia (PELIGRO, ADVERTENCIA O PRECAUCIÓN) se usa con el símbolo de

alerta para indicar la probabilidad y la gravedad potencial de la lesión. Además, un símbolo de peligro

se puede usar para representar el tipo de peligro.

Esta parte posiblemente es la más importante del manual. En Steam Way International deseamos

que utilice el producto de forma satisfactoria durante muchos años, sin que el operador, el personal

de mantenimiento, los clientes u otras personas sufran lesiones. La probabilidad de que ocurran

lesiones es mínima si el operador sigue las prácticas recomendadas de seguridad.

PELIGRO: Indica un peligro que, si no se evita, causará la

muerte o lesiones graves.

ADVERTENCIA: Indica un peligro que, si no se evita, podría causar la muerte o

lesiones graves.

PRECAUCIÓN: Indica un peligro que, si no se evita, podría causar lesiones

leves o moderadas.

PRECAUCIÓN: Cuando se usa sin el símbolo de alerta,

indica una situación que podría causar daños al equipo

Lea y comprenda este “MANUAL DEL OPERADOR” y las “ETIQUETAS DE

LA MÁQUINA” antes de comenzar.

Desembalar la máquina, Seguridad General

17

Specications

BRAVE 800-350-8739 www.braveproducts.com

Seguridad general

1. Antes de operar esta máquina, lea y siga todas las instrucciones de seguridad,

desembalaje y funcionamiento. No cumplir estas instrucciones puede causar una situación

peligrosa.

2. El operador de este equipo no debe usarlo cuando se encuentre fatigado ni tampoco bajo

la inuencia del alcohol o las drogas.

3. El operador de este equipo debe estar completamente familiarizado con su funcionamiento

y adecuadamente capacitado para realizar el trabajo.

4. El operador de este equipo debe usar caretas protectoras y ropa de protección según sea

necesario para operar el equipo de forma segura.

5. No deje esta máquina sola y sin vigilancia cuando esté funcionando.

6. Todas las instalaciones deben cumplir todos los códigos locales aplicables. Pregunte a su

electricista, plomero, empresa de servicios públicos o vendedor de servicios para obtener

información detallada al respecto.

7. Siga las instrucciones sobre cómo detener la máquina y purgar las presiones rápidamente.

Familiarícese completamente con los controles.

8. No opere la máquina si existe, o si sospecha que existe, cualquier falla mecánica.

9. Cuando comience un trabajo, revise la zona para descartar que existan peligros

potenciales y corrija cualquier problema antes de continuar.

10. Mantenga las tapas y cubiertas de protección colocadas. Vuelva a colocar todas las tapas

y cubiertas de protección después de realizar ajustes para evitar el contacto accidental con

partes peligrosas.

11. NO OPERE LA MÁQUINA si existe una fuga de agua o combustible. Apague y repare la

máquina.

12. Revise la máquina para descartar que existan componentes dañados o desgastados

y proceda a realizar las reparaciones o sustituciones necesarias para evitar peligros

potenciales. No opere la máquina si existe, o si sospecha que existe, cualquier falla

mecánica

13. Si este equipo se opera usando productos químicos, lea y siga las instrucciones de las

etiquetas de dichos productos.

14. Apunte siempre el conjunto de la pistola hacia una dirección segura lejos de cualquier

persona y no pulverice directamente sobre la lavadora.

Seguridad de la máquina accionada por motor

eléctrico

1. Esta máquina debe tener una conexión de puesta a tierra. No tener una conexión de

puesta a tierra puede causar que el operador sufra una descarga eléctrica e incluso la

muerte del operador.

2. Los fusibles o interruptores automáticos deben ser compatibles con las especicaciones de

la máquina.

3. Si es necesario usar una extensión eléctrica para operar la máquina, esta debe ser tan

corta como sea posible. La extensión eléctrica debe tener el tamaño correcto y debe

disponer de un tomacorriente y un enchufe con conexión a tierra.

4. No conecte ni desconecte la máquina con las manos húmedas.

5. Mantenga los cables de alimentación y las conexiones (conectores) fuera del agua.

6. Todo el cableado y las conexiones eléctricas deben cumplir el Código Eléctrico Nacional

(National Electrical Code, NEC) y los códigos y prácticas locales.

7. En el interior de esta máquina puede existir alta tensión. Únicamente personal

adecuadamente capacitado debe realizar tareas de mantenimiento o reparación.

Seguridad general

Table of contents

Other Brave Pressure Washer manuals