Bren-Tronics BTC-70844 Operation manual

850026 Rev B

OPERATION AND

SERVICE MANUAL

SOLDIER PORTABLE CHARGER

BTC-70844

USA Tel: (631) 499-5155 · Fax: (631) 499-5504

www.bren-tronics.com

WARNING

HIGH VOLTAGES ARE PRESENT IN THE

OPERATION OF THIS EQUIPMENT

Avoid contact with AC supply voltage connections during installation, operation or

maintenance of the battery charger.

CAUTION

ACID CONTAMINATES NICKEL-CADMIUM, LITHIUM-ION,

LITHIUM-POLYMER and NICKEL-METAL HYDRIDE BATTERIES

Every effort must be made to keep Nickel-Cadmium, Lithium-Ion, Lithium Polymer and

Nickel-Metal Hydride batteries as far away as possible from Lead-Acid batteries because

Lead-Acid batteries contain sulfuric acid. Do Not use the same tools and materials, such

as screwdrivers, wrenches, syringes, hydrometers, and gloves for both types of batteries.

Any trace of acid or acid fumes will permanently damage Nickel-Cadmium, Lithium-Ion,

Lithium Polymer and Nickel-Metal Hydride batteries on contact.

WARNING

NO SMOKING IS PERMITTED NEAR THE CHARGING STATION

Batteries can produce explosive gases during charging or discharge cycles. Never smoke

or allow open flames near the charging station.

TABLE OF CONTENTS

Para Pg Para Pg

CHAPTER 1 – INTRODUCTION

Scope............................................. 1-1 1-1

Technical Specifications ................ 1-2 1-2

Declaration of Conformity .............. 1-3 1-3

Accessories.................................... 1-4 1-4

Charge Cycle Description.............. 1-5 1-7

Sequential Charging Description ... 1-6 1-8

Upgrading Charger Software......... 1-7 1-9

CHAPTER 2 – OPERATING PROCEDURES

Panel Controls and Indicators........ 2-1 2-1

Preliminary Setup Procedures....... 2-2 2-3

Operating Procedures –

Charging Batteries.................... 2-3 2-4

Battery Revitalization and

Destorage ................................. 2-4 2-5

Battery Charger Cover Label ........ 2-5 2-7

Solid Red LED troubleshooting...... 2-6 2-8

Flashing Red LED troubleshooting 2-7 2-8

Operation in Extreme Environmental

Conditions................................. 2-8 2-9

Preparation for Movement.............. 2-9 2-9

Battery State-of-Charge Displays... 2-10 2-10

Battery Capacity Retention ............ 2-11 2-10

Battery Storage.............................. 2-12 2-11

CHAPTER 3 – MAINTENANCE INSTRUCTIONS

Introduction.................................... 3-1 3-1

Cleaning......................................... 3-2 3-1

Inspection....................................... 3-3 3-1

Basic Functional Test..................... 3-4 3-2

Simplified Operator

Troubleshooting Procedures..... 3-5 3-3

Warranty / repair Information ......... 3-6 3-5

Upgrade / Update Information........ 3-7 3-5

INTRODUCTION

1-1

CHAPTER 1

INTRODUCTION

1-1. SCOPE

The Soldier Portable Charger (P/N BTC-70844) is a CE –compliant, state-of-the-art,

high performance lightweight portable battery charger designed for field deployment or

shop usage. It provides fast reactivation of various rechargeable batteries. It is

capable of sequentially charging up to eight batteries completely unattended.

The Soldier Portable Charger is simple to use by design. Without any user

intervention, the Charger typically charges up to eight batteries, two at a time. Charge

times are substantially less for partially discharged batteries. The charge time for fully

depleted BB-2590/Us or BB-390B/U is less than 3 ½ hours. The charge time is

substantially less for partially discharged batteries. Charge times vary based on

battery type and the battery’s state of charge. The Charger automatically identifies the

specific battery type and provides the appropriate charge profile. Based on the

current operating environment, the Charger automatically customizes the charge

profile to provide the quickest charge in a safe manner. The charge status for each of

the batteries is conveyed to the user via easy-to-understand panel mounted LED

indicators (amber – CHARGE, green – READY and red – FAULT).

The Charger is universal by design. It can readily use either AC or DC input power –

whichever is most convenient for the user. The universal AC input fully allows 85-264

VAC and 47-440 Hz operation without any adjustment or user intervention.

Additionally, the DC input power permits a range of 20-33 VDC, standard on most

military vehicles.

The Charger is adaptive by design. It is microprocessor controlled and is presently

programmed to automatically charge over 50 different battery types as listed in the

Table 1. With the appropriate battery adapter, however, it can be readily

reprogrammed via RS232 software upgrade port in the field to charge a countless

number of additional battery types and chemistries including: Nickel Metal Hydride,

Nickel Cadmium, Lithium Ion, and Lithium Polymer. The Charger also provides a

Revitalization function for Nickel Cadmium batteries and a Destorage function for

Lithium Ion batteries.

The battery charger components are housed in a durable, non-conductive ABS

equipment case, as shown in Figure 1. The assembled unit is watertight when the

gasketed cover is securely latched and the pressure equalization valve on the front of

the case (near the carrying handle) is closed.

INTRODUCTION

1-2

1-2. TECHNICAL SPECIFICATIONS

Dimensions ...........................……... 580mm W x 375mm D x 230mm H

Weight (less adapters and cables)….…...12.5kg

(with adapters and cables)……… 15kg

Power Requirements

AC operation .....................……… Automatic selection: 85 to 264 VAC, single-

phase, 47 to 440 Hz, 375 VA max, with 1.95m

detachable three-wire power cord. (Power draw

125 V=3 A)

DC operation ................... ……… 20-33 VDC, 15A, with 1.55m DC cable

assembly. (Power draw 24 V=12.5 A)

Charging Output Voltage.......……… Automatically selected for each battery type

Duty Cycle.............................…….... Continuous

Protective Features…………………. Resettable circuit breakers for AC (7A) and DC

(20A) Power sources

Operating Temp. Range …………… -20˚C to 50˚C

Storage Temp. Range ..........………. -40˚C to 70˚C

Case Material........................………. ABS (Acrylonitrile Butadiene Styrene)

Case Color............................………. Olive Drab #34088 per Fed-Std-595B

Shipment...............................………. No restrictions

INTRODUCTION

1-3

1-3. Declaration of Conformity

Manufacturer’s Name: Bren-Tronics, Inc.

Manufacturer’s Address: 10 Brayton Court

Commack, New York 11725

U.S.A.

Declares the Product:

Product Name: Solder Portable Charger

Model Number: BTC-70844

Conforms to the following Product Specifications:

Safety:

IEC 60950-1

EMC:

EN 55022:1998 Class B Conducted Emissions, 150kHz to

30MHz

EN 55022:1998 Class B Radiated Emissions, 30MHz to 1GHz

EN 61000-3-2:1995 Harmonics

EN 61000-3-3:1995 Flicker

IEC 61000-4-2:1995 Electrostatic Discharge

IEC 61000-4-3:1997 Radiated Immunity

IEC 61000-4-4:1995 FFT/Burst, Power Leads

IEC 61000-4-5:1995 Surge Immunity

IEC 61000-4-6:1996 Conducted Immunity

IEC 61000-4-11:1994 Voltage Dips and Interrupts

Supplementary Information:

I Dennis Rosenberg declare that the above product complies with the

requirements of the Low Voltage Directive 73/23/EEC and the EMC Directive

89/336/EEC and carries the CE marking accordingly.

Dennis Rosenberg/Quality Engineer

INTRODUCTION

1-4

1-4. ACCESSORIES

Table 1 shows the various batteries and appropriate adapter plates the Charger can

charge as of the writing of this document.

Table 2 shows the various power cables and other accessories.

Table 1 - Supported Batteries and Adapters

ADAPTER ADAPTER NSN BATTERY TYPE BATTERY NSN

BTA-70360 6130-01-555-7818 BB-4600 NiCd 6140-13-113-0171

BTA-70394 5940-01-427-9247 BB-503A/U NiCd 6140-01-419-8193

BTA-70395 (1) 5940-01-427-9183 BB-326/U

BB-516A/U NiMH

NiCd 6140-01-533-7674

6140-01-419-8191

BTA-70396 5940-01-427-9278 BB-2847A/U

BB-2847/U Li Ion

Li Ion 6140-01-493-8092

6140-01-419-8194

BTA-70443 5940-01-467-8813 BB-2600/U

BB-2600A/U Li Ion

Li Ion 6140-01-467-5853

6140-01-490-4311

BTA-70492A 5940-01-513-5662 BT-70477

BT-70492

BT-70492A

NiMH

Li Ion

Li Ion

6140-14-513-5369

6140-01-523-9840

6140-01-523-9840

BTA-70557 5940-01-467-5852 BB-557/U NiCd 6140-01-071-5070

BTA-70574 5940-01-483-6772 ICOM SI NiCd ---

BTA-70581 --- CSEL Li Ion 6140-01-534-3856

BTA-70581A 5940-01-544-3476 CSEL Li Ion 6140-01-534-3856

BTA-70582 --- ALI 124

ALI 142/BA-682A

BA-682B

BA-684A

NiCd

Li Ion

Li Ion

Li Ion

---

6140-14-328-2258

6140-14-561-1542

6140-14-529-5971

BTA-70589 6130-01-564-8116 ALI 116

ALI 124

ALI 142/BA-682A

ALI 143/BA-687A

ALI 243

BA-684A

BA-685A

BA-682B

ALI 147

ALI 247

NiCd

NiCd

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

---

---

6140-14-328-2258

6140-14-530-0061

6140-14-553-4062

6140-14-529-5971

6140-14-529-5973

6140-14-561-1542

---

---

BTA-70589A --- ALI 142/BA-682A

ALI 143/BA-687A

ALI 243

BA-684A

BA-685A

BA-682B

ALI 147

ALI 247

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

6140-14-328-2258

6140-14-530-0061

6140-14-553-4062

6140-14-529-5971

6140-14-529-5973

6140-14-561-1542

---

---

BTA-70598 --- BT-70598 Li Ion ---

BTA-70715 5940-01-573-9693 BT-70593

BT-70715 Li Ion

Li Ion ---

---

BTA-70721 6130-01-573-4962 BT-70721 Li Ion ---

BTA-70732 --- BT-70732 Li Ion ---

BTA-70737 --- BT-70737 Li Ion ---

INTRODUCTION

1-5

BTA-70740 --- BT-70740 Li Ion ---

BTA-70763 6130-01-555-7821 BN-2250 NiCd 6140-13-116-5482

BTA-70774 5940-01-573-9679 Motorola –

NNTN7032A

NTN9816A

NTN9815A

Li Ion

NiCd

NiCd

---

---

---

---

BTA-70807 5940-01-493-6750 BB-2800/U Li Ion 6140-01-490-5372

BTA-70808 5940-01-493-6388 BB-2588/U

BB-388/U Li Ion

NiMH 6140-01-493-7623

6140-01-490-4313

BTA-70810 5940-01-493-6751 THALES – MBITR Li Ion ---

BTA-70811 5940-01-493-7622 AA CELLS NiMH ---

BTA-70812 5940-01-492-7238 BB-2557/U

BB-557/U Li Ion

NiCd 6140-01-490-5387

6140-01-071-5070

BTA-70817 --- D CELLS NiMH ---

BTA-70834 5940-01-501-3312 BB-2590/U

BT-70791A

BT-70791E

BB-390B/U

BB-590/U

BT-70876

SAFT – SAI-2590

Li Ion

Li Ion

Li Ion

NiMH

NiCd

Li Ion

Li Ion

6140-01-490-4316

---

---

6140-01-490-4317

6140-01-063-3918 -

--

---

BTA-70899 --- BB-2590/U

BB-390B/U

BT-70791A

BT-70791E

BT-70899A

BT-70876

Saft – SAI-2590

Ultralife – UBI-2590

Li Ion

NiMH

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

Li Ion

6140-01-490-4316

6140-01-490-4317 -

--

---

---

---

---

---

BTA-70858 --- DRT 4453/4411 Li Ion ---

BTA-70406-3 --- BA-386 NiCd ---

BTA-70851 (1) --- Racal 931 NiCd ---

BTA-70852 --- PTR-349 NiCd ---

BTA-70853 --- Loral – RT1606 NiCd ---

BTA-70872 --- BB-NM10 NiCd ---

BTA-70868 --- LI-145

LI-80 Li Ion

Li Ion ---

---

BTA-70706-1 --- BB-2598 Li Ion ---

BTA-70406 --- BB-586 NiCd 6140-01-084-1460

BTA-70661 --- BT-70661 Li Ion ---

BTA-70685 --- ALKABAT NiCd ---

NOTES:

1) The Adapter BTA-70480/3 is not compatible with this charger.

2) This list was complete at the date of publication. Additional adapters may be available, but

may require updated software.

INTRODUCTION

1-6

Table 2 - Power Cables and Other Accessories

DESCRIPTION ORDER NUMBER PART NUMBER NSN

IEC AC POWER CORD US 591609 ---- ----

IEC AC POWER CORD EU 590233-3 ---- ----

IEC AC POWER CORD UK 590233-UK ---- ----

DC POWER CABLE BTA-70844-24 ---- ----

DC HUMMER CABLE BTA-70835 J-6362A/U 5940-01-501-6714

DC SPLITTER CABLE BTA-70816 CX-13560/G 5995-01-505-7883

BB-390/2590 SELF DISCHARGER BTF-70791 SDD2 6130-01-490-4310

Figure 1-4.1 DC ADAPTER CABLE

Figure 1-4.2 DC HUMMER CABLE

Figure 1-4.3 DC SPLITTER CABLE

For use with the DC Hummer cable

Figure 1-4.4 BB-390 /2590 SELF DISCHARGER

INTRODUCTION

1-7

1-5. CHARGE CYCLE DESCRIPTION

Each of the battery types that are capable of being charged by the Charger is

connected to the charger via their respective battery adapter (plate or cable). Each

adapter can charge two batteries simultaneously. The appropriate battery adapter is

installed on the control panel and serves as the electrical interface between the

batteries being charged and the charger circuits. The battery charger control circuits

constantly monitor the following battery conditions during the charge cycle, as

appropriate, to ensure that the battery is properly being charged:

a. Temperature (T)

b. Voltage (V)

c. Current (I)

d. Time (t)

e. Voltage change (ΔV)

f. Temperature rate of change (ΔT/Δt)

The charger operation during a typical charge sequence is automatic and the battery

charge status is displayed to the user by the panel LED indicators as follows:

a. Detection - The charger tries to detect a battery in an adapter. The CHARGE

LED (amber) blinks slowly during this process.

b. Pre-charge – The charger brings the battery voltage up to a safe level before

the rapid charge process begins. This step may take several minutes for a very

discharged battery. The CHARGE LED (amber) blinks rapidly during this

process.

c. Fast Charge – A timed fast charge cycle brings the battery to approximately

90% of full charge capacity. The CHARGE LED (amber) is lit solid during this

process.

d. Ready – The fast charge cycle is complete. The Battery may be removed and

used at this time. The READY LED (green) is lit steadily at this time.

e. Trickle / Top-off – When fast charge is complete, the charger will top off of the

battery to 100%. Each battery is charged for five minutes at a time. For Lithium

Ion and Lithium Polymer batteries the top-off cycle will stop after the battery is

100% charged. For all other types, the Trickle / Top-off cycle is repeated

indefinitely to keep the battery at 100% charge. Leaving the battery on the

charger will not harm the battery. The battery may be removed and used at this

time. The READY LED (green) blinks during this process.

The Battery may be removed and used at anytime during the charge cycle without

damage to the charger or battery. The state-of-charge indicator (SOC) will display the

battery condition. NOTE

After removing a battery from the charger, wait for the

corresponding battery status LED’s to turn off before installing a

new battery.

INTRODUCTION

1-8

1.6. SEQUENTIAL CHARGING CYCLE DESCRIPTION

The Charger is a dual-channel sequential charger. It automatically charges up to eight

batteries. The charge time depends on the battery type and state-of-charge.

Two independent charging channels, designated A and B, can charge one battery at a

time. Upon charge completion of the first battery, each channel sequentially charges

up to three additional batteries that are waiting in queue. Sequencing to the other

three Ports is performed completely automatic and requires no intervention by the

user. While the four batteries charged by the A channel are located at either the rear

or left side of each adapter Port (depending on the adapter type), the four batteries

charged by the B channel are located at either the front or right side of each adapter

Port. This is readily seen in Figure 1.6-1.

Figure 1.6-1 – Charger Typical Configuration

During the sequencing process, the channel spends only as much time as is

necessary to charge each battery to greater than 90% capacity. A partially charged

battery will charge quicker than a totally discharged battery. It then sequences, in

numerical order (Port 1 – Port 2 – Port 3 – Port 4 – Port 1 – Port 2, etc.), to the next

battery in queue. As the channel sequences through the four Ports and comes to a

INTRODUCTION

1-9

battery that has already been charged, it will attempt to Trickle or Top-off that battery

(if necessary) for approximately 5 minutes (10 minutes for dual section batteries like

the BB-390, BB-2590, BB-557, and BB-2557) and then continue onto the next Port.

This means batteries added later may charge first, depending ontheir position on the

charger. If certain batteries must be charged first, then this must be taken in to

account. When the charger moves to a position it will charge or top off the battery at

that position, as necessary. This allows batteries to be added or removed at anytime.

The charger automatically keeps track of the current state of each Port.

1.7 UPGRADING CHARGER SOFTWARE

The software in the charger is readily field upgradeable. By loading new software into

the charger, it is possible to alter its operation and add or change the charging profiles

for the batteries. Loading new software into the charge is accomplished via the use of

a standard RS232 interface of a personal computer (PC) running Windows 95™ or

higher. Utilizing special software running on the PC in conjunction with the boot

program resident within the charger, a two-way communication link is established and

the revised operational parameters and battery charge profiles can be loaded into the

charger. Specific instructions for upgrading the Charger software is provided with the

software upgrades.

OPERATION

2-1

CHAPTER 2

OPERATING PROCEDURES

2-1. CONTROLS AND INDICATORS

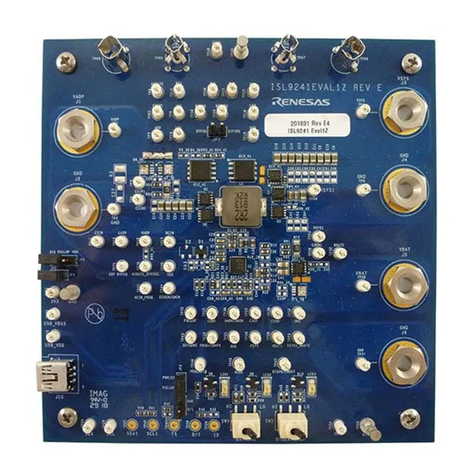

Battery charger panel components are described below and shown in Figure 2-1.

Item Function

AC ON/OFF power switch......Turns battery charger AC supply on or off.

AC CKT BREAKER................Turns power to the charger off in an overload condition.

Remove the overload condition and push to reset.

LOW VEH POWER LED........The Low Vehicle power indicator lights when external DC

power is too low to charge batteries. The charger will

stop charging batteries.

TEMP FAULT LED.................The Temperature Fault indicator lights when charger

temperature is too high (50°C) or too low (-20°C). The

charger will stop charging batteries.

DC ON/OFF power switch......Turns battery charger DC supply on or off. If both AC and

DC power are connected and both power switches are

on, then DC Power will be used by the charger.

DC CKT BREAKER................Turns power to the charger off in an overload condition.

Remove the overload condition and push to reset.

CHARGE LED........................The Amber LED lights steady while the associated

battery is being fast-charged. A slow blinking indication

means the charger is trying to find a battery at the select

position. A fast blinking indication means the charger is

precondition the battery before charging it.

READY LED...........................The Green LED indicates the associated battery is fully

charged and ready to be removed for use. Steady light

means the battery has completed fast charge. A blinking

indication means the battery is being topped off.

FAULT LED............................If the Red LED lights steady the associated battery, or

adapter plate, is defective or will not accept charge. A

blinking indication means the battery’s temperature

sensor or communication connection is not making

contact with the adapter.

AC INPUT Connector.............Input connection for AC cable assembly. (Provided)

DC INPUT Connector.............Input connection for DC cable assembly. (Optional)

Battery Adapter Port...............Provides interface connection for battery adapters.

RECONDITION Switch…….…Activates NiCad revitalization or Li-Ion destorage function

with battery in POS 1.

RECONDITION LED………….Lights amber during revitalization / destorage process.

OPERATION

2-2

Figure 2-1 – Charger Front Panel Components

OPERATION

2-3

2-2. PRELIMINARY SETUP PROCEDURES

Step 1. Place the unit on the work surface. Unscrew the pressure equalization valve

(near the carrying handle) in a counterclockwise direction about two full turns.

Unfasten latches and open cover.

Step 2. Set AC and DC power ON-OFF switches, to OFF position.

Step 3. The Cover may be removed by removing both hinge pins with pliers.

Step 4. For AC operation: Connect AC power cord from AC INPUT connector to

power source and set AC power ON-OFF switch to ON position. Observe

that POWER ON LED lights, fan operates, and all LED status indicators blink

in order (amber, green, then red) briefly when power is first applied.

Step 5. For DC operation: Connect DC cable from 24 VOLT DC INPUT connector to

DC power source (via NATO slave receptacle found in most military vehicles)

and set DC power ON-OFF switch ON position. Observe that POWER ON

LED lights, fan operates, and all LED status indicators blink in order (amber,

green, then red) briefly when power is first applied. Note that if both AC and

DC power are connected that DC power will be used if the DC power switch is

on.

Step 6. Observe that only the POWER ON LED is lit.

Step 7. Install appropriate battery adapter(s) on panel for battery types to be charged.

Install the Adapter(s) by placing the back of the adapter into the rear retainer

and rotating the adapter down until the front retainer clicks over it. Note the

alignment of the pins. The connector can only plug in one way. Do not force

it. Be sure that battery adapter and connector are fully seated. For Cable

type Adapters Line up the pins to the connector. 18 Pin Connectors will plug

in toward the right side on the charger. Again do not force the connector. All

battery adapters are interchangeable, only the battery connections are

different. The adapters may be mixed. It is not necessary to use only one

type of adapter at a time.

Step 8. Observe, after a short delay, the amber CHARGE LED’s blink for several

seconds at each installed adapter. This shows battery charger circuits are

initialized to the selected battery adapter and are ready to accept a battery (or

batteries) for charging. If all of the Indicators for a channel light at the same

time, the Adapter could not be recognized or the adapter is damaged. Insure

it is seated correctly. Verify that the charger software revision supports the

adapter.

OPERATION

2-4

2-3. OPERATING PROCEDURES – CHARGING BATTERIES

Step 1. With the appropriate battery adapter installed, insert the first battery to be

charged in the Port-1 Channel-A battery location. Insure the battery is fully

seated into the adapter. Observe that CHARGE LED (amber) for the

corresponding location is lit or blinking rapidly. The CHARGE LED for the B

battery location will continue to blink if it is searching for a battery on that

channel. If the FAULT LED (red) is lit, the battery or adapter may be

defective. Check by removing battery and adapter. Then reinstall adapter

and battery. If the FAULT LED again lights, go to the Trouble Shooting

section of this Guide.

Step 2. Install the next battery into the Port-1 Channel-B battery location.

Step 3. Install the rest of the batteries. The indicators for these batteries will not light

until the charger has finished the batteries in the preceding Port locations.

Step 4. After fast charging is complete, the CHARGE LED extinguishes and the

READY LED is lit. After the charger cycles through the batteries, it will top-

off batteries that have completed fast charge. The battery is slow-charged to

full capacity, as indicated by the blinking READY LED (green). The battery is

charged for five minutes at a time (10 minutes for dual section batteries) then

the charger will move on to the next battery. For Lithium type batteries, the

cycle will stop after the battery is 100% charged. For other types the cycle is

repeated indefinitely to keep the battery at 100% charge. As long as the

READY LED is lit (blinking or solid) the battery may be removed and returned

to service and another battery may be installed for charging.

NOTE

BB-390A/U and BB-390B/U batteries include two independent 12-volt

sections. A relay "clicking" may be heard from the battery adapter when

battery sections are switched. Other types of adapters may also contain

relays and click intermittently during normal operation.

NOTE

Battery charger power may be left ON while batteries and/or adapters are

removed or replaced. Batteries maybe left on the charger for long periods

oftime without damaging the batteries or charger. This is true whether the

charger is on or off.

CAUTION

To avoid damage to the adapter or SPC front panel connectors, always

remove the adapter by grasping the front section finger-grips firmly with

one hand while moving the front retainer back with the other. Lift the front

of the adapter straight up from the panel. DO NOT attempt to remove the

adapter by pulling upward from the rear.

OPERATION

2-5

2-4. BATTERY REVITALIZATION AND DESTORAGE

The procedures outlined below describe the means of invoking the Revitalization and

Destorage functions of the Charger as well as the sequence of operations the charger

will execute to perform the commanded tasks. NiCad and NiMh Batteries are always

Revitalized. Li-Ion batteries are always destored. The charger will decide what to do

based on the battery’s chemistry.

a. NiCad Revitalization

Revitalization exists only on Position 1 and is available for both the A and B channels of

the Charger. Due to the increased power dissipation from discharging the batteries, this

function will not operate above 40º C. The following procedure is used to invoke the

Revitalization process:

1. Plug the Adapter into POS 1.

2. Power up the Charger.

3. Once the Adapter is recognized (the BAT LED’s blink Amber in Position 1), press

the RECONDITION SW pushbutton for the A or B channel; the RECON LED will

light Amber for the corresponding channel.

4. Plug the battery into the activated channel.

5. Revitalization will commence upon recognition of the battery.

Autonomously, the Charger will perform the following revitalization sequence:

1. Check the thermistor; if the temperature is above 40º C it will not proceed.

2. Discharge the battery without a capacity measurement.

3. Fully charge the battery.

4. Discharge the battery and calculate the capacity.

5. Fully charge the battery.

6. If the capacity in step 4 is greater than or equal to 80% of the battery

specification, the BAT LED turns Green, the RECON LED remains lit and

process is complete.

7. If the capacity in step 4 is less than 80%, repeat step 4 and 5 a second time. If

after the second cycle the capacity is less than 70% of the battery specification,

the BAT LED turns Red, the RECON LED remains lit and the process is

complete.

b. Li-Ion Destorage

Destorage exists only on Position 1 and is available for both the A and B channels of

the Charger. Due to the increased power dissipation from discharging the batteries, this

function will not operate above 40º C. The following procedure is used to invoke the

Destorage process:

1. Plug the Adapter into POS 1.

2. Power up the Charger.

OPERATION

2-6

3. Once the Adapter is recognized (the BAT LED’s blink Amber in Position 1), press

the RECONDITION SW pushbutton for the A or B channel; the RECON LED will

light Amber for the corresponding channel.

4. Plug the battery into the activated channel.

5. Destorage will commence upon recognition of the battery.

Autonomously, the Charger will perform the following Destorage sequence:

1. Check the thermistor; if the temperature is above 40º C it will not proceed.

2. Fully discharge the battery.

3. Fully charge the battery.

4. Discharge 55% of the specified capacity from the battery.

5. The BAT LED turns Green, the RECON LED remains lit and process is complete.

OPERATION

2-7

2-5. BATTERY CHARGER COVER LABEL

Shown below are the instructions contained on the "SHORT FORM - OPERATING PROCEDURE" label, attached inside

the Charger cover.

LED INDICATIONS FOR EACH BATTERY

S = STEADY, F = FLASHING, RF = RAPID FLASHING

YELLOW GREEN RED RECON MEANING REMARKS

F F F Charger start up. All lights blink by color when charger is turned ON.

Power on, no adapter. Adapter(s) must be installed.

F Power on, adapter present, no battery present. Install battery(s) on to adapter.

RF Battery identification and prequalification. Battery identification and prequalification is in progress - wait.

S Battery is fast charging.

F Battery is being topped off. Battery is ready to use. Remove it when ready.

S Battery charging complete. Battery is ready to use. Remove it when ready.

S or F S or F F Charging or identification contacts damaged or dirty. Clean battery contacts. Check adapter pins. Clean, repair or

replace as necessary.

S Faulty battery. Remove battery and replace a the same positon for one

additional charge cycle. See “Red LED Troubleshooting” in

user manual.

S Recondition / Destore Enabled. Cycle will begin when charger get to the battery.

S S Recondition / Destore cycle in progress

S Recondition / Destore cycle complete. Recondition / Destore cycle complete. Remove it when ready.

S S S Recondition / Destore has failed. Battery may be defective.

F Temperature > 104° F / 40°C recondition not allowed. Reduce Ambient temperature and restart recondition cycle.

S S S Damaged or Unknown adapter. Replace Adapter.

If a Software update is required visit web site for details.

OPERATION

2-8

2-6. SOLID RED LED TROUBLE SHOOTING

1. Remove battery and inspect all contacts. Clean if nessasary. Then, reinstall at

same location for another charge cycle. Note battery and adapter location for

laterreview.

2. If charge indications go "red" again at the same location remove battery and do

the following:

a. If the battery was in storage see para 2-14.

b. Check battery: older than 3 yrs? Maybe ready for disposal. Discharge &

recharge, IF RED AGAIN?

c. Check warranty instructions on battery. If not covered or no instructions,

dispose of.

d. Note success/failure of future battery charges at this location. More

"RED" lights? Change adapter.

2-7. FLASHING RED LED TROUBLE SHOOTING

1. This condition is telling you that some of the battery contacts are not connecting

to the charger.

a. For BB-390 thermal contacts not making contact with the charger.

b. For BB-2800, BB-2600 and other batteries the communication pin(s) are

not making contact with the charger.

2. To minimize this issue before you first start using the charger: Ensure….

a. The contacts are clean on the battery.

b. The adapter contact pins are in place and retain their spring action: Check

by pushing down the pins and releasing.

3. You can still charge Batteries with thermal / communication pins missing or

damaged, it will just take longer, and may not fully charge in one cycle.

4. If the flashing "red" condition continues after this check, mark location of

condition and battery affected.

a. You can pull batteries and clean thermal contacts on the battery.

b. Check adapters again. Mark for future review, if a continuing problem at

this location: change adapter.

OPERATION

2-9

2-8. OPERATION IN EXTREME ENVIRONMENTAL CONDITIONS

Observe these precautions when the Charger is operated in areas where severe

climatic conditions may exist:

a. Operation in Arctic Climates. The battery charger is designed to function in

temperature extremes as low as -4°F (-20°C.). The following precautions should be

observed:(1) Handle equipment carefully. The plastic components may become more

brittle.

(2) Keep equipment clean and dry.

(3) Prevent ice from forming on the Charger and batteries. Ice formations

may prevent proper electrical connections. Melting ice may cause water

to enter the charger.

b. Operation in Desert Climates. The Charger is designed to operate in

temperature extremes as high as 122°F (50°C) and the dryness associated with a

desert environment. Sand and dust accumulation on and in the charger may cause

poor electrical connections and reduce the cooling effectiveness of the charger. Follow

proper cleaning and maintenance guidelines to assure proper operation. When not in

use, be sure that cover is fully latched and pressure relief valve is fully closed (in a

clockwise direction).

c. Operation in Salt Spray. Keep equipment clean and dry at all times and

immediately wipe salt spray from exposed surfaces, cables and connectors. When not

in use, be sure that cover is fully latched and pressure relief valve is fully closed (in a

clockwise direction).

NOTE

Battery charge acceptancevarieswith ambienttemperatureconditions. At

temperatureslower than 32°F (0°C)orhigher than 104°F (40°C)itmaybe

necessary to initiate two complete charging cycles to secure a fully

charged battery.

2-9. PREPARATION FOR MOVEMENT

a. Set both AC and DC POWER switches to OFF.

b. Remove any installed batteries.

c. Disconnect and coil AC power cable.

d. Remove the DC Power cable and pack separately.

e. Replace Charger cover if it was removed by reinstalling the hinge pins.

f. Close cover and secure with latches.

g. Close pressure equalization valve on front of unit by turning fully clockwise.

Table of contents

Other Bren-Tronics Batteries Charger manuals

Popular Batteries Charger manuals by other brands

Bebob

Bebob VS4-RL user manual

VOLTCRAFT

VOLTCRAFT UFC-8 operating instructions

Ericsson GE

Ericsson GE 19B801507P1 Maintenance manual

Hamlet

Hamlet XPWNB100PDU user manual

Global Technology

Global Technology Six-bay Multi-chemistry Charger Operation manual

Mammooth

Mammooth M.DC.T.CH.20.40.2.4 instruction manual