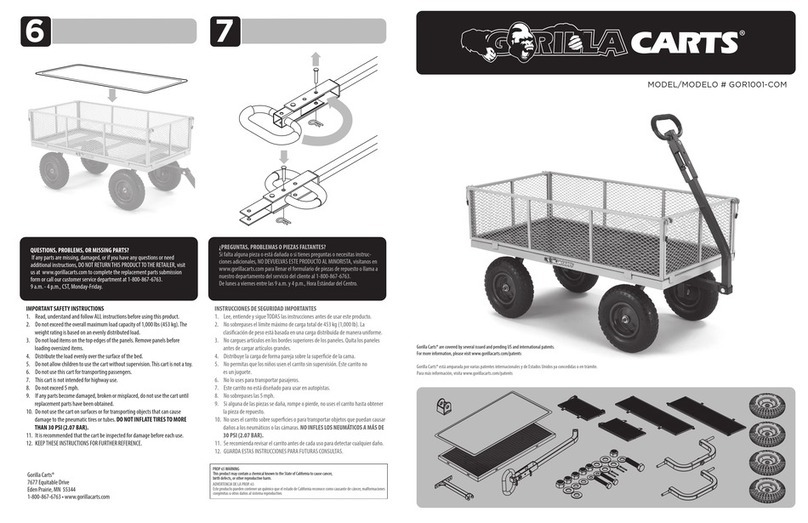

brent Corner Auger 1080 Installation and maintenance instructions

PART NO. 280900

OPERATOR’S MANUAL

PARTS CATALOG

MODELS

1080 & 880

Corner Auger

TM

GRAIN CART

Model 1080 Beginning With Serial Number B20920100

Model 880 Beginning With Serial Number B20910100

2

Introduction

WARNING! CALIFORNIA PROPOSITION 65 WARNING: THIS MACHINE MAY CONTAIN MINERAL

OILS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, AND

OTHER REPRODUCTIVE HARM.

INTRODUCTION

NOTE: The information, specifications, and illustrations in the manual are on the basis of

information available at the time it was written. Due to continuing improvements in the de-

sign and manufacture of Brent products, all specifications and information contained herein

are subject to change without notice. Obtain the complete and most current information

before starting any job.

Foreword

This symbol identifies important safety messages. When you see it, read the message

that follows and be alert to the possibility of personal injury.

Remember, safety instructions stated in this manual are for your protection. Read them carefully

and follow them closely when working around or using this machine.

Read and study this manual completely before attempting to operate this implement. Take this

manual to the field for handy reference when operating, adjusting or servicing your machine.

When referenced, “Right-Hand” (RH) and “Left-Hand” (LH) side of the machine are

determined by standing behind the machine and facing in the direction of travel.

Revised 011906-7

3

Introduction

Product Identification

When ordering parts or when requesting further information or assistance, always give the fol-

lowing information:

- Machine name

- Model number

- Serial number

Please fill out and retain this portion for your records. The serial number decal is located at

the left front corner of your grain cart.

Purchase date Model Serial no.’s

Dealer City

Dealer Contact Phone

Revised 041608-15

Wheel bolts tightened (recheck after initial

use)

Tire pressures checked

Hardware tightened

Machine lubricated

Safety and operating procedures reviewed

Field adjustment information reviewed

Lubrication procedures reviewed

Warranty information reviewed

Hydraulic hoses properly routed/fittings tight

PRE-OPERATION CHECKLIST

4

Introduction

TABLE OF CONTENTS

SECTION I - SAFETY

GENERAL HAZARD INFORMATION .................1-2

SAFETY DECALS...............................................1-3

FOLLOW SAFETY INSTRUCTIONS..................1-4

OPERATING.......................................................1-4

TRANSPORTING................................................1-5

SERVICING/MAINTENANCE..............................1-5

DRIVELINE SAFETY..........................................1-6

PREPARING FOR EMERGENCIES...................1-7

WEARING PROTECTIVE EQUIPMENT.............1-7

SECTION II - OPERATION

PREPARING TRACTOR..................................... 2-2

PREPARING CART

INSPECTION ............................................... 2-2

LUBRICATION ............................................. 2-2

HITCHING TO TRACTOR

DRAWBAR CONNECTION.......................... 2-3

HITCH SETTINGS....................................... 2-3

JACK............................................................ 2-3

TRANSPORT CHAIN CONNECTION.......... 2-3

HYDRAULIC CONNECTIONS..................... 2-4

ELECTRICAL CONNECTIONS.................... 2-5

LIGHT MODULE.......................................... 2-5

LAMP BRACKET......................................... 2-5

TOWING............................................................. 2-6

AUGER OPERATION

COUPLING PTO DRIVE SHAFT................. 2-6

CHAINS ....................................................... 2-7

SHEAR BOLT/FRICTION CLUTCHES ........ 2-7

PTO-DRIVEN AUGER ................................. 2-8

SCALE (OPTIONAL) .......................................... 2-9

HYDRAULIC DRIVE (OPTIONAL).................... 2-15

TARP (OPTIONAL) (PRIOR TO SERIAL #B24060100).. 2-16

TARP (OPTIONAL) (SERIAL #B24060100 & UP)........ 2-17

OPTIONAL TRACK

OPERATING PROCEDURES.................... 2-18

DAILY OPERATING CHECKLIST.............. 2-18

TRACK ALIGNMENT................................. 2-19

WHEEL ALIGNMENT................................. 2-21

SECTION III - MAINTENANCE

LUBRICATION

CART ........................................................3-2

TRACK OPTION...........................................3-3

TRACK SYSTEM MAINTENANCE......................3-4

TRACK TENSION.........................................3-4

CHECKING TRACK TENSION..............3-4

ADJUSTING TRACK TENSION.............3-4

TRACK ALIGNMENT...........................................3-5

CHECKING TRACK ALIGNMENT................3-5

ADJUSTING TRACK ALIGNMENT...............3-6

IDLER WHEEL REPLACEMENT.........................3-7

MID-ROLLER REMOVAL.....................................3-8

IDLER WHEEL HUB ASSEMBLY........................3-9

MID-ROLLER ASSEMBLY.................................3-10

MID-ROLLER INSTALLATION...........................3-10

TRACK HUB BEARING SETTING ..................3-12

IDLER HUB ................................................3-12

MID-ROLLER HUB.....................................3-12

HITCH SETTINGS

HEIGHT ADJUSTMENTS ...........................3-13

HITCH BUSHINGS.....................................3-13

WHEEL NUT TORQUE .....................................3-14

TIRE PRESSURE & WARRANTY.....................3-14

AUGER DRIVE LINE

BEARINGS..................................................3-15

GEAR BOX.................................................3-15

SEASONAL STORAGE .....................................3-15

PAGE

AUGER SYSTEM

LOWER AUGER.........................................3-16

UPPER AUGER..........................................3-17

REMOVAL OF AUGER LINER..........................3-18

ASSEMBLY OF TUBE LINER...........................3-18

VERIFY PTO SHAFT LENGTH.........................3-19

PTO SHAFT & CLUTCH...................................3-22

PTO QUICK DISCONNECT..............................3-25

PTO CLUTCH ..................................................3-26

SCALE TROUBLE SHOOTING.........................3-27

SCALE CALIBRATION & SET-UP.....................3-28

TARP TROUBLE SHOOTING ...........................3-31

INSPECTION & MAINTENTANCE..............3-31

TRACK TROUBLE SHOOTING.........................3-31

ELECTRICAL SYSTEM SCHEMATIC ...............3-32

HYDRAULIC SYSTEM SCHEMATIC.................3-33

TORQUE CHART

HARDWARE ...............................................3-34

HYDRAULIC FITTINGS..............................3-35

WHEEL TORQUE REQUIREMENTS .........3-35

Revised 041608-15

5

Introduction

SECTION IV - SET-UP

BASIC CART SET-UP

FOLDING SIDE EXTENSION SET-UP........4-2

LADDER ...................................................... 4-2

LAMP SET-UP............................................. 4-2

DIRECTIONAL SPOUT INSTALLATION...... 4-3

ADJUSTABLE AXLE (OPTIONAL)............... 4-4

TIRE PRESSURE........................................ 4-4

DRIVELINE STORAGE................................ 4-4

SCALE KIT INSTALLATION

HITCH ASSEMBLY...................................... 4-5

JUNCTION BOX.......................................... 4-5

LOAD CELL INSTALLATION....................... 4-5

INDICATOR MOUNTING............................. 4-6

ELECTRICAL CONNECTION...................... 4-6

LOAD CELL CONNECTION........................ 4-7

TARP INSTALLATION (PRIOR TO SERIAL #B24060100)

END CAPS & BOWS .................................. 4-8

RIDGE STRAP, TARP, TUBES.................... 4-9

ROLL TUBE SPOOLS............................... 4-10

ROLL TUBE CABLES & RATCHETS .......4-11

HAND CRANK........................................... 4-13

CABLE TENSION...................................... 4-13

TARP INSTALLATION (SERIAL #B24060100 & UP)

END CAPS & BOWS ................................ 4-14

RIDGE STRAP, TARP, TUBES.................. 4-15

HAND CRANK........................................... 4-17

CABLE TENSION...................................... 4-18

HYDRAULIC DRIVE INSTALLATION............... 4-19

TABLE OF CONTENTS

SECTION V - PARTS

FINAL ASSEMBLY...............................................5-2

HITCH..................................................................5-4

AXLE - RIGID 880/1080 ....................................5-5

AXLE - ADJUSTABLE 880/1080.........................5-6

AXLE MOUNTING...............................................5-7

HUB - SINGLE WHEELS....................................5-8

HUB - DUAL WHEELS........................................5-9

WHEELS & TIRES ............................................5-10

DECALS.............................................................5-11

SIDE BOARDS - 880........................................5-12

SIDE BOARDS - 1080......................................5-13

ELECTRICAL.....................................................5-14

DRIVE COMPONENTS .....................................5-17

AUGER..............................................................5-18

FOLD INDICATOR.............................................5-20

CLEANOUT DOOR............................................5-21

FLOW DOOR SEALS........................................5-22

AUGER CYLINDER...........................................5-23

HYDRAULICS....................................................5-24

DIRECTIONAL SPOUT......................................5-26

PTO ASSEMBLY...........................................5-28/29

PTO CLUTCH...............................................5-30/31

45OGEAR BOX.................................................5-32

DRIVE LINE U-JOINT ASSEMBLY ...................5-33

SCALE UNIT - 880/1080 (OPTIONAL).............5-34

TARP - 880/1080 (OPTIONAL)

PRIOR TO SERIAL #B24060100...............5-36

SERIAL #B24060100 & UP.......................5-38

HYDRAULIC DRIVE (OPTIONAL).................... 5-40

TRACK ASSEMBLY & AXLE (OPT)................. 5-41

TRACK ROLLER FRAME ............................... 5-42

TRACK MID-ROLLER ASSY ........................... 5-43

TRACK HUB & SPINDLE ............................... 5-44

VIDEO SYSTEM OPTION................................ 5-45

6

Introduction

ACCIDENTS

CAN BE PREVENTED

WITH YOUR HELP!

No accident-prevention program can be successful without the whole-hearted cooperation of the

person who is directly responsible for the operation of the equipment.

A large number of accidents can be prevented only by the operator anticipating the result be-

fore the accident is caused and doing something about it. No power-driven equipment, whether it be

transportation or processing, whether it be on the highway, in the harvest field, or in the industrial plant,

can be safer than the person who is at the controls. If accidents are to be prevented--and they can be

prevented--it will be done by the operators who accept the full measure of their responsibility.

It is true that the designer, the manufacturer, and the safety engineer can help; and they will

help, but their combined efforts can be wiped out by a single careless act of the operator.

It is said that, "the best kind of a safety device is a careful operator." We, at Unverferth Mfg.

Co., Inc. ask that you be that kind of operator.

SAFETY PRECAUTIONS

Read this manual carefully before operating.

Never enter the grain cart while the auger is running.

Make sure PTO guard is kept in place.

Never allow anyone on the unit while moving through the field.

Be careful when moving unit near electrical lines with discharge auger up.

Never tow a loaded unit more than 8 m.p.h. or on a road.

Never exceed the maximum recommended hitch pin size which allows for uneven terrain.

Make use of night-time lighting provided on your new cart.

Use caution when unloading on the go, while moving through gullies, wash-

outs, and uneven terrain.

Always check behind you before backing up.

Counter-weight your tractor front end.

Be careful on steep slopes. A loaded grain cart is hard to stop.

Do not fold or unfold auger while moving.

When auger is not in use, be sure to fold to the rest position.

Never unhook a grain cart while it is being loaded.

Turn the tractor power off and remove the key from the ignition before servicing the attached

implement.

Tow only an empty cart on-road and have a rated transport chain attached.

Revised 060807-12

1-1

Safety

SECTION I

SAFETY

GENERAL HAZARD INFORMATION ............. 1-2

SAFETY DECALS ..........................................1-3

SAFETY.......................................................... 1-4

FOLLOW SAFETY INSTRUCTIONS......... 1-4

OPERATING.............................................. 1-4

TRANSPORTING....................................... 1-5

SERVICING/MAINTENANCE.....................1-5

DRIVELINE SAFETY.................................1-6

PREPARING FOR EMERGENCIES.......... 1-7

WEARING PROTECTIVE EQUIPMENT....1-7

Revised 061207-12

1-2

Safety

REMEMBER:

THINK SAFETY

A CAREFUL OPERATOR IS THE

BEST INSURANCE AGAINST AN

ACCIDENT!

GENERAL HAZARD INFORMATION

Most accidents involving product operation, maintenance and repair are caused by failure to observe

basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazard-

ous situations before an accident occurs. A person must be alert to potential hazards. This person

should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, maintenance or repair of this machine can be

dangerous and could result in injury or death. Do not operate or perform

any maintenance or repair on this machine until you have read and

understood all applicable safety, operation, maintenance, or repair

information.

NOTE! This SAFETY ALERT SYMBOL is found throughout this manual. Signal words are used

to alert users of potential hazards and the severity of these hazards.

SIGNAL WORDS:

DANGER:

INDICATESANEXTREMELYHAZARDOUSSITUATIONORAC-

TION THAT WILL RESULT IN SERIOUS INJURY OR DEATH.

WARNING: INDICATES A HAZARDOUS SITUATION OR ACTION THAT

COULD RESULT IN SERIOUS INJURY OR DEATH.

CAUTION: INDICATESAN UNSAFE SITUATION ORACTION THAT MAY

RESULT IN PERSONAL INJURY.

IMPORTANT: Is used for instructions on operating, adjusting, or servicing a

machine.

This symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Revised 060807-12

1-3

Safety

251927

Revised 060807-12

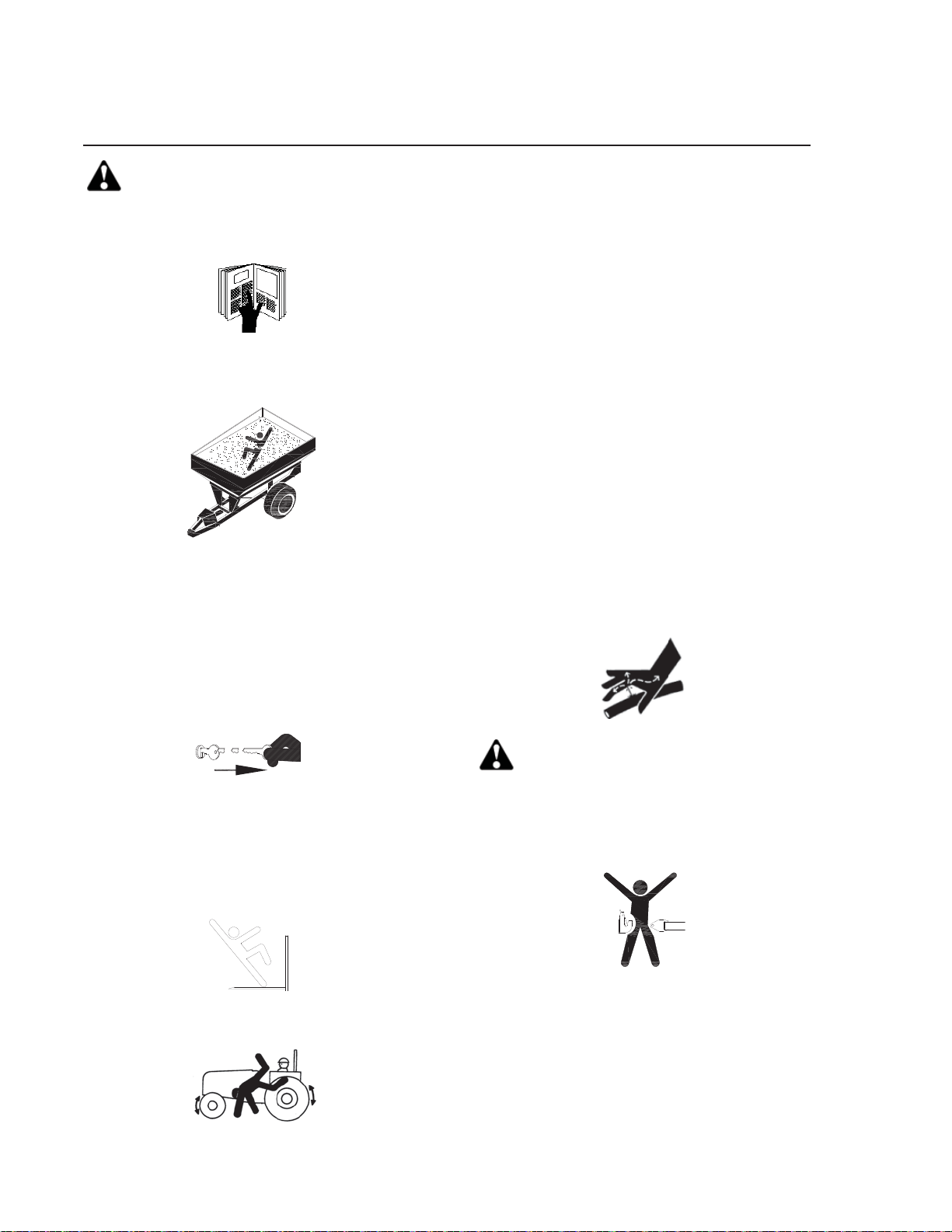

SAFETY DECALS

WARNING

Replace lost, damaged, painted, or unreadable decals immediately. If parts that have de-

cals are replaced, also make sure to install new decals. These decals inform and remind

the operator with operational information and safety messages.

1-4

Safety

OPERATING

Do not stand between the cart and tractor when

hitching. Always engage parking brake and stop

engine before inserting hitch pin.

SAFETY

FOLLOW SAFETY

INSTRUCTIONS

Read and understand this operator's manual and

the tractor operator's manual before operating.

Do not wear loose fitting clothes, as they may

catch in moving parts.

Do not allow anyone to ride on the equipment.

Make sure everyone is clear before operating

machine or tractor.

Never play in or on the grain. Flowing grain

traps and suffocates victim in seconds.

Never attempt to operate implement unless you

are in driver’s seat.

Escaping fluid under pressure can penetrate the

skin causing serious injury. Relieve pressure

before disconnecting hydraulic lines or servicing

hydraulic system. See tractor operator's manual

for procedure to relieve pressure.

Use a piece of cardboard or wood to detect

leaks of hydraulic fluid under pressure. Correct

hydraulic leaks immediately.

Do not bend or strike high-pressure lines. Do

not install bent or damaged tubes or hoses.

Repair all oil leaks. Leaks can cause fires,

personal injury, and environmental damage.

Route hoses and lines carefully to prevent pre-

mature failure due to kinking and rubbing against

other parts. Make sure that all clamps, guards

and shields are installed correctly.

IF INJURED BY ESCAPING HYDRAULIC OIL,

SEE A DOCTOR AT ONCE, SERIOUS IN-

FECTION OR REACTION CAN DEVELOP IF

PROPER TREATMENT IS NOT ADMINISTERED

IMMEDIATELY.

Secure drawbar pin with safety lock and lock

tractor drawbar in fixed position.

All machinery should be operated only by trained

and authorized personnel.

To prevent machine damage, use only attach-

ments approved by the manufacturer.

Always shut tractor engine and hydraulic power

unit engine off and remove the keys from igni-

tion before servicing implements.

1-5

Safety

SAFETY

Be sure the tires are inflated to the recom-

mended pressure.

Always make certain everyone and everything

is clear of the machine before beginning op-

eration.

DO NOT allow ANYONE to enter or climb on

the Grain Cart during operation. If entry is

necessary, be sure P.T.O. is disengaged, chute

door is closed, tractor engine is off, the igni-

tion key removed and tractor brakes are locked

before entry.

TRANSPORTING

Comply with state and local laws governing

highway safety when moving machinery on

public roadways.

Use accessory lighting or warning lights when

transporting at night to adequately warn opera-

tors of other vehicles.

Regulate speed to road conditions. Maximum

speed should never exceed 20 m.p.h.

Make sure that SMV emblem, reflectors, and

lights are visible to approaching traffic.

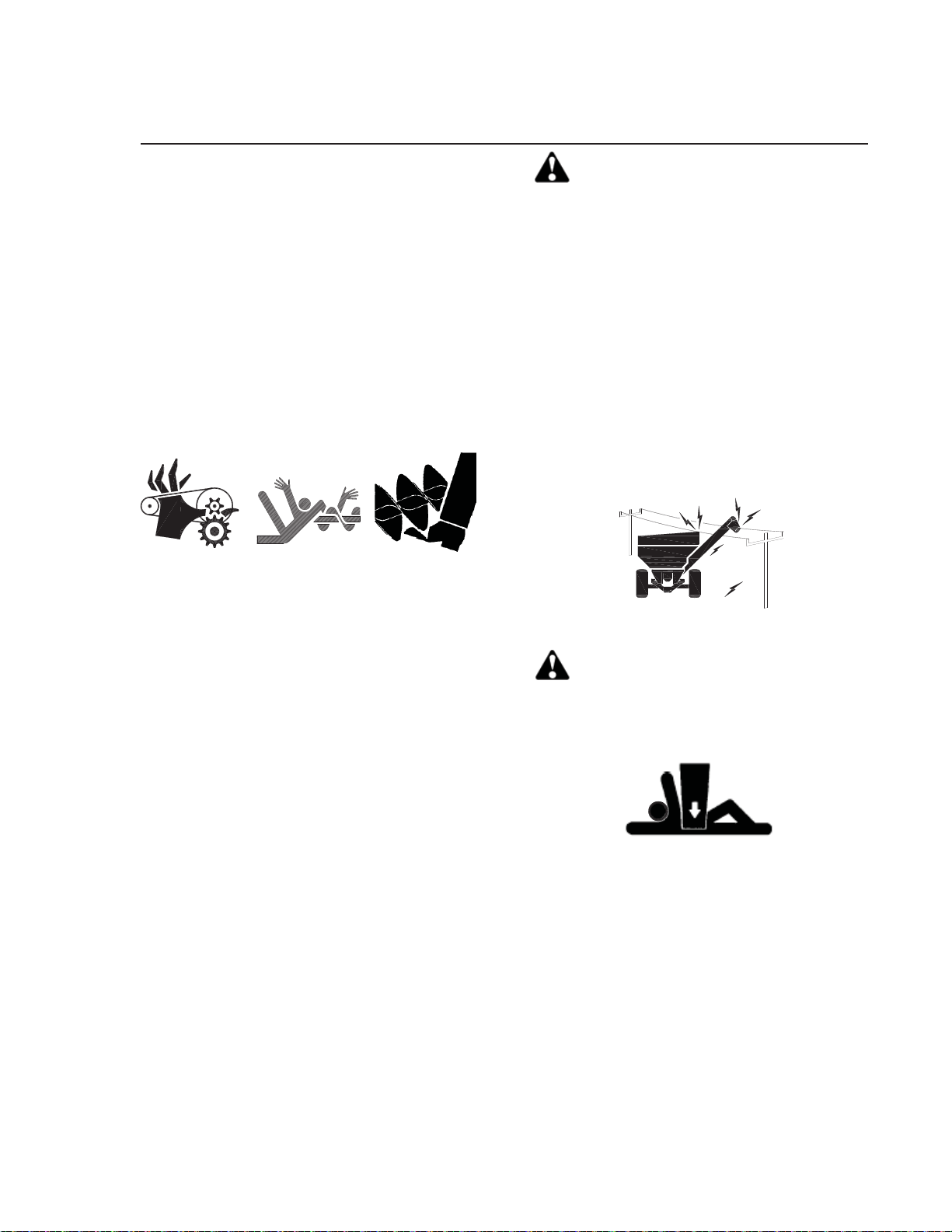

Avoid contact with overhead utility lines. Electri-

cal shock can cause serious injury or death.

SERVICING/

MAINTENANCE

To avoid possible injury, lower the implement

to the ground before servicing.

Properly ballast the tractor before operating.

(See tractor operator’s manual.)

Regulate speed to field conditions, maintain

complete control at all times.

Use extreme care when operating close to

ditches, fences, or on hillsides.

Do not dismount from a moving tractor.

Check box for any debris or excess grain be-

fore each use.

Be sure that all safety shields are in place and

securely latched.

Do not work under an unsupported implement.

Use blocks or jackstands with a load rating equal

to or greater than the weight of the implement

for adequate support.

Do not grease or oil the equipment while in

operation.

Work in a clean and dry environment.

Before attempting any repairs you are unfamiliar

with, consult your local dealer.

When working around the cart, be careful not

to be cut by sharp edges.

1-6

Safety

DRIVELINE SAFETY

Do not allow children near equipment that is

running or engaged.

Keep all guards and shields in good condition

and properly installed at all times.

Avoid personal attire such as loose fitting cloth-

ing, shoestrings, drawstrings, pants cuffs, long

hair, etc. that can be come entangled in a

rotating driveline.

Do not exceed 1000 rpm PTO speed.

Disengage the PTO, stop the tractor engine, and

remove key from ignition before making inspec-

tions, or performing maintenance and repairs.

Inspect the driveline, quick disconnect, overload

shear-bolt limiter or clutch, and shielding often.

Repair immediately. Use replacement parts and

attaching hardware equivalent to the original

equipment. Do not alter the original design of

the driveline.

Avoid excessively long hardware or exposed

and protruding parts which can snag and cause

entanglement.

Lubricate the driveline as recommended in the

MAINTENANCE section.

Keep hoses, wiring, ropes, etc. from dangling

too close to the driveline.

Install driveline and shields according to rec-

ommended lengths and attaching methods with

recommended hardware. The driveline shield

should rotate independently a full rotation and

telescope freely. The retaining chain must be

secured to the implement safety shield.

Attach offset drawbar hitch end in the down

position and use a recommended hitch pin with

a low head so that no interference occurs with

driveline during operation on uneven or terraced

terrain.

Be careful not to hit the driveline with tractor

tires when turning.

Due to variances in tractor drawbar design and

operating position, it is critical that proper

extended and collapsed lengths of the tele-

scoping PTO shaft be verified before first

operation. If the extended length of the PTO

shaft is not sufficient, it may become uncoupled

in operation and cause serious injury or death

from contact with uncontrolled flailing of PTO

shaft assembly components. Refer to the MAIN-

TENANCE section of this manual for detailed

instructions.

254917

1-7

Safety

PREPARING FOR

EMERGENCIES

Keep a first aid kit and fire extinguisher nearby.

Keep emergency numbers for fire, rescue, and

poison control personnel near the phone.

WEARING PROTECTIVE

EQUIPMENT

Wear clothing and personal protective equipment

appropriate for the job.

Wear steel-toed shoes when operating.

Wear hearing protection when exposed to loud

noises.

Do not wear additional hearing impairing devices

such as radio headphones, etc.

1-8

NOTES

2-1

Operation

SECTION II

OPERATION

PAGE

PREPARING TRACTOR...........................2-2

PREPARING CART

INSPECTION.......................................2-2

LUBRICATION.....................................2-2

HITCHING TO TRACTOR

DRAWBAR CONNECTION..................2-3

HITCH SETTINGS...............................2-3

JACK USAGE......................................2-3

TRANSPORT CHAIN CONNECTION..2-3

HYDRAULIC CONNECTIONS ............2-4

ELECTRICAL CONNECTIONS............2-5

OPTIONAL LIGHT MODULE...............2-5

LAMP BRACKET ADJUSTMENT........2-5

TOWING...................................................2-6

AUGER OPERATION

COUPLING PTO DRIVE SHAFT ........2-6

CHAINS...............................................2-7

SHEAR BOLT/FRICTION CLUTCHES 2-7

PTO-DRIVEN AUGER.........................2-8

SCALE......................................................2-9

HYDRAULICALLY DRIVEN AUGER.......2-15

TARPS

PRIOR TO SERIAL #B24060100......2-16

SERIAL #B24060100 & UP...............2-17

OPTIONAL TRACK

OPERATING PROCEDURES............2-18

DAILY OPERATING CHECKLIST......2-18

TRACK ALIGNMENT.........................2-19

WHEEL ALIGNMENT ........................2-21

REVISED 041608-15

2-2

Operation

Soft Start™ System: Check for wear or

damage. Lubricate as recommended. Do not

over lubricate.

Hydraulic System: Check all hoses and cyl-

inders for signs of leakage. Hoses should not

be kinked, twisted or rubbing against sharp

edges. Re-route or repair hoses as neces-

sary. Refer to SAFETY section for additional

information on safe repair and inspection of

hydraulic components.

Tires/Wheels: Check tire pressures and

maintain at recommended values listed

in the MAINTENANCE section of this

manual. Maintain 400 ft.-lbs. torque val-

ue for the 3/4" wheel lug nuts and 500

ft.-lbs. for the 7/8" dual-wheel bolts.

IMPORTANT: INSTALLING WHEELS WITH-

OUT THE PROPER INSET COULD RESULT

IN HUB OR SPINDLE FAILURE. THIS WILL

CAUSE SUBSTANTIAL DAMAGE TO CART.

IMPORTANT: FREQUENTLY CHECK THE

TORQUE OF ALL WHEEL LUG NUTS, PAR-

TICULARLY DURING THE INITIAL TRANS-

PORT AND OPERATION OF THIS CART. IF

A LUG BOLT OR STUD BECOMES LOOSE,

THIS MAY RESULT IN THE LOSS OF A

WHEEL.

For questions regarding new tire warranty,

please contact your local original equipment

tire dealer. Used tires carry no warranty.

Tire manufacturers' phone numbers and web

sites are listed on page 3-3 for your con-

venience.

LUBRICATION

Lubricate the cart as outlined in the MAIN-

TENANCE section of this manual.

PREPARING TRACTOR

Before operating cart, read the tractor oper-

ator's manual and gain an understanding of

its safe methods of operation.

Check the tractor brakes and warning lights.

Make sure they are in proper working or-

der.

Check the tractor hydraulic oil reservoir and

add oil if needed.

Verify that the tractor is adequately ballasted

for drawbar operation at the anticipated draft

load.

If possible, adjust the tractor drawbar verti-

cally so the topside of the drawbar is ap-

proximately 17-22 inches from the ground.

Ensure that the drawbar is locked in the

center position.

On tractors equipped with a 3-point hitch,

raise and secure the linkage to prevent in-

terference with the cart tongue and hydraulic

hoses during turning.

PREPARING CART

Perform the service checks as outlined below.

Repair or replace any damaged or worn parts

before operating.

Hardware:

Check for loose bolts and nuts, and

tighten as needed. Check again after the first

half-day of operation.

Pivot Pins: Check that all pins are in place

and in good condition. Replace any worn,

damaged or missing pins.

Auger: Inspect auger for damage and

wear.

Hitch: Check hitch wear plates for damage

and wear. Be aware of the size of hitch

adapter bushing that is being used. Select

correct size for the hitch pin/draw bar you

are using.

REVISED 020107-11

2-3

Operation

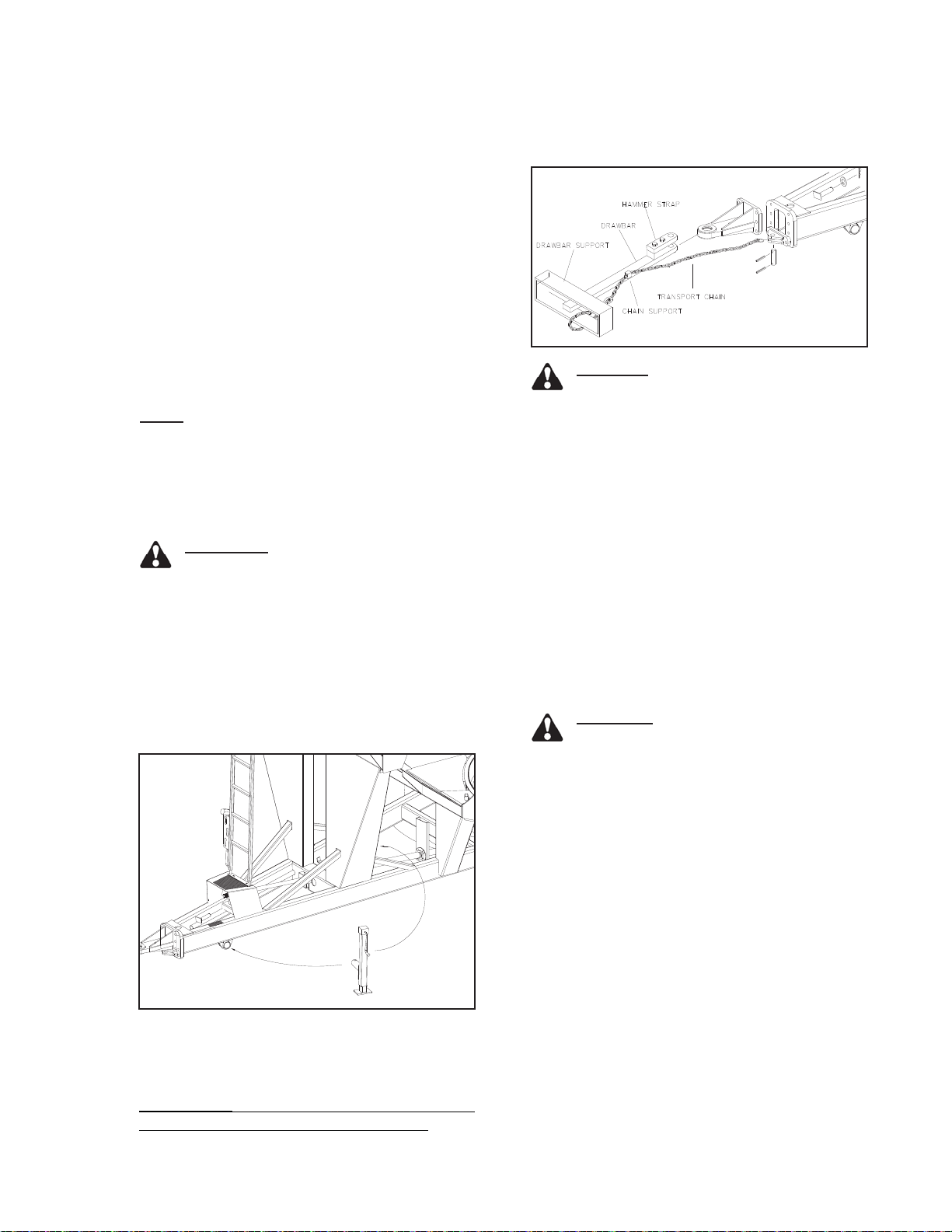

CAUTION! ALWAYS USE TRANSPORT

CHAIN WHEN TRANSPORTING IMPLE-

MENTS. FAILURE TO USE A TRANSPORT

CHAIN COULD CAUSE PERSONAL INJURY

IF CART BECOMES DISENGAGED.

Always use intermediate chain support when

connecting grain cart directly to a tractor. DO

NOT use the intermediate chain support as

the chain attaching point. Fig. 6 shows how

the transport chain must be installed between

tractor and grain cart.

Transport chain should have a minimum rat-

ing equal to the gross weight of implement

and all attachments. Use only ASAE approved

chains. Allow no more slack in chain than

necessary to permit turning.

CAUTION! REPLACE TRANSPORT

CHAIN IF ANY LINK OR END FITTING

IS BROKEN, STRETCHED, OR DAMAGED.

DO NOT WELD TRANSPORT CHAIN.

HITCHING TO TRACTOR

DRAWBAR CONNECTION

This cart is intended to be hitched to a trac-

tor drawbar. Do not attempt to hitch to any

other location on the tractor other than the

drawbar.

The cart is equipped standard with a single

tang hitch. A hitch pin between 1-1/2" or 2"

diameter must only be used with a clevis-

type tractor drawbar. An optional hammer

strap is available if your tractor has a single

tang drawbar.

NOTE: The use of a smaller diameter hitch pin

will result in additional clearance between the

hitch and pin. This additional clearance may

cause accelerated pin wear, tractor and cart

hitch wear, along with more pronounced jolting

from the cart during transport operation.

WARNING! DO NOT STAND BE-

TWEEN THE CART AND TRACTOR

WHEN HITCHING. ALWAYS ENGAGE PARK-

ING BRAKE AND STOP ENGINE BEFORE

INSERTING HITCH PIN.

After inserting drawbar pin, secure drawbar

pin with a locking device to help prevent

uncoupling during use.

Use jack to support an empty grain cart,

never a loaded grain cart.....always have a

loaded grain cart hooked to tractor.

IMPORTANT: Mount jack in storage location

indicated after cart is hitched to tractor.

JACK USAGE

TRANSPORT CHAIN

CONNECTION

253913

252919

REVISED 020107-11

Fig. 1

Fig. 2

2-4

Operation

HYDRAULIC CONNECTIONS

IMPORTANT: When coupling hydraulic hoses

to ports on tractor, be sure that coupler ends

are clean of dust, dirt and debris. Failure to do

so could contaminate hydraulic system result-

ing in excessive wear and possible failure.

Clean hydraulic hose couplers before connect-

ing to tractor. For convenience it is recom-

mended to connect the flow door circuit hoses

to tractor implement coupler #1, auger spout

circuit hoses to coupler #2, and attach auger

fold circuit to coupler #3.

This unit is equipped with color bands at-

tached to the hydraulic hoses. This will help

in identifying the hose function and correct

hook up.

Green Raise Auger

Lower Auger

Red Flow Door Open

Flow Door Close

Yellow Spout In

Spout Out

After initial set-up or replacement of any hy-

draulic component on the cart, air must be

removed from the cart hydraulic system. See

Purge Procedure.

Route hoses away from areas that may

cause abrasion or kinking of hoses during

operation.

Before disconnecting hoses from the tractor,

relieve pressure from the lines. See tractor

operator's manual for proper procedures.

Shut-off engine and apply parking brake be-

fore disconnecting hoses. Install couplers into

storage slots provided.

Fig. 3

2-5

Operation

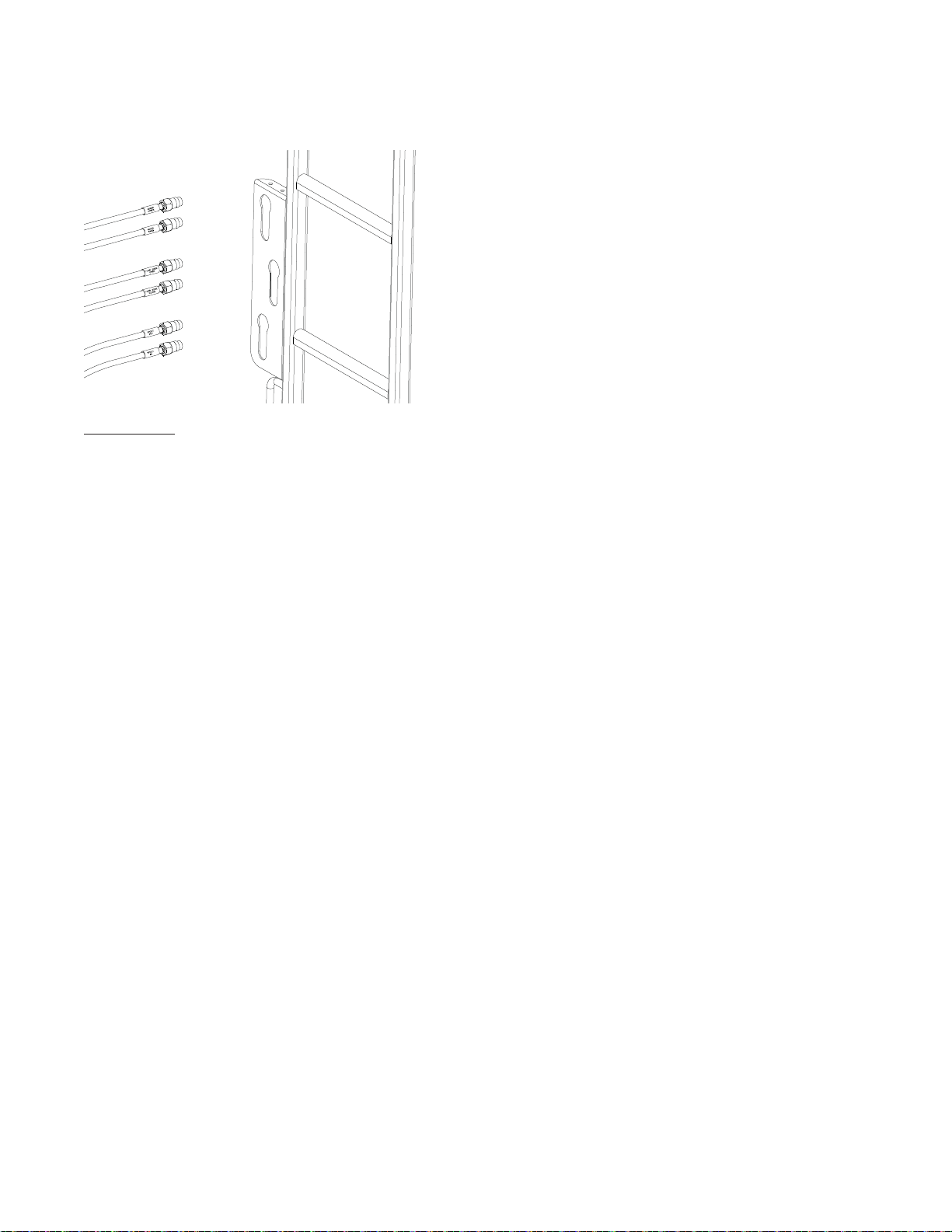

LAMP BRACKET ADJUSTMENT

The lamp bracket width is adjustable. Ensure

that the brackets are adjusted such that the

reflectors are no more than 16" from outer

edge of the tires.

ELECTRICAL CONNECTIONS

WARNING! DO NOT ATTEMPT TO

INSTALL, ATTACH OR REPAIR ANY

ELECTRICAL APPLICATIONS ON THE CART

IF WORK AREA IS WET. ALLOW AREA TO

DRY BEFORE ANY WORK IS DONE. ELEC-

TRICAL SHOCK OR ELECTROCUTION MAY

RESULT IF WORK AREA IS NOT DRY.

This cart is equipped with a seven-pin SAE

connector plug which will connect with the

receptacle found on most newer tractors. If

your tractor does not have this type of re-

ceptacle, an SAE J-560 seven-point socket

can be purchased from your Unverferth dealer

(Part number 92824).

The wiring schematic for this cart, shown in

the maintenance section, complies with ANSI/

ASAE Standard S279.11/SAEJ137. Although

most newer tractors conform to this standard,

many older tractors can have a slightly differ-

ent electrical function than standard. Because

of this, always verify correct electrical function

before using this cart.

OPTIONAL LIGHT MODULE

In some areas, the lights may be required to

flash in the specific pattern described in ASAE

S279.10. In these areas, use the Enhanced

Turn Signal Kit (251095). See your dealer for

more information.

254920

220978

220912

REVISED 013107-11

Fig. 4 Fig. 6

Fig. 5

2-6

Operation

TOWING

This cart is not equipped with brakes. Ensure

that the towing vehicle has adequate weight

and braking capacity to tow this implement.

As a guideline, the towing vehicle should

be sized such that the cart does not weigh

over 1.5 times the towing vehicle weight.

Never tow a loaded grain cart over public

roads.

Do not exceed 10 mph during off-highway

travel. Do not exceed 8 mph when cart is

fully loaded.

Secure drawbar pin with a locking device

and lock tractor drawbar in centered position.

Connect the PTO driveshaft to the tractor.

Secure transport chain to tractor chain sup-

port before towing.

CAUTION! THE STANDARD TRANS-

PORT CHAIN PROVIDED IS FOR THE

BASIC CART WHEN TOWED EMPTY FOR

ROAD TRAVEL.

It is probable that this cart is taller, wider

and longer than the towing tractor. Become

aware of and avoid all obstacles and hazards

in the travel path of the equipment, such as

power lines, ditches, etc.

Always have auger folded back into storage

position when auger is not in use.

To prevent damage during turning when using

non-PTO equipped towing vehicles, store the

PTO driveshaft in the brackets provided on

the inside right frame rail.

AUGER OPERATION

WARNING! NEVER ENTER CART

WITH AUGER OR TRACTOR RUN-

NING. SERIOUS OR DEATH CAN OCCUR

DUE TO ENTANGLEMENT WITH ROTATING

COMPONENTS. ALWAYS STOP ENGINE

AND REMOVE KEY BEFORE ENTERING

CART.

DANGER! THE GRAIN CART IS NOT

INSULATED. KEEP AWAY FROM

ALL ELECTRICAL LINES AND DEVICES.

ELECTROCUTION CAN OCCUR WITHOUT

DIRECT CONTACT.

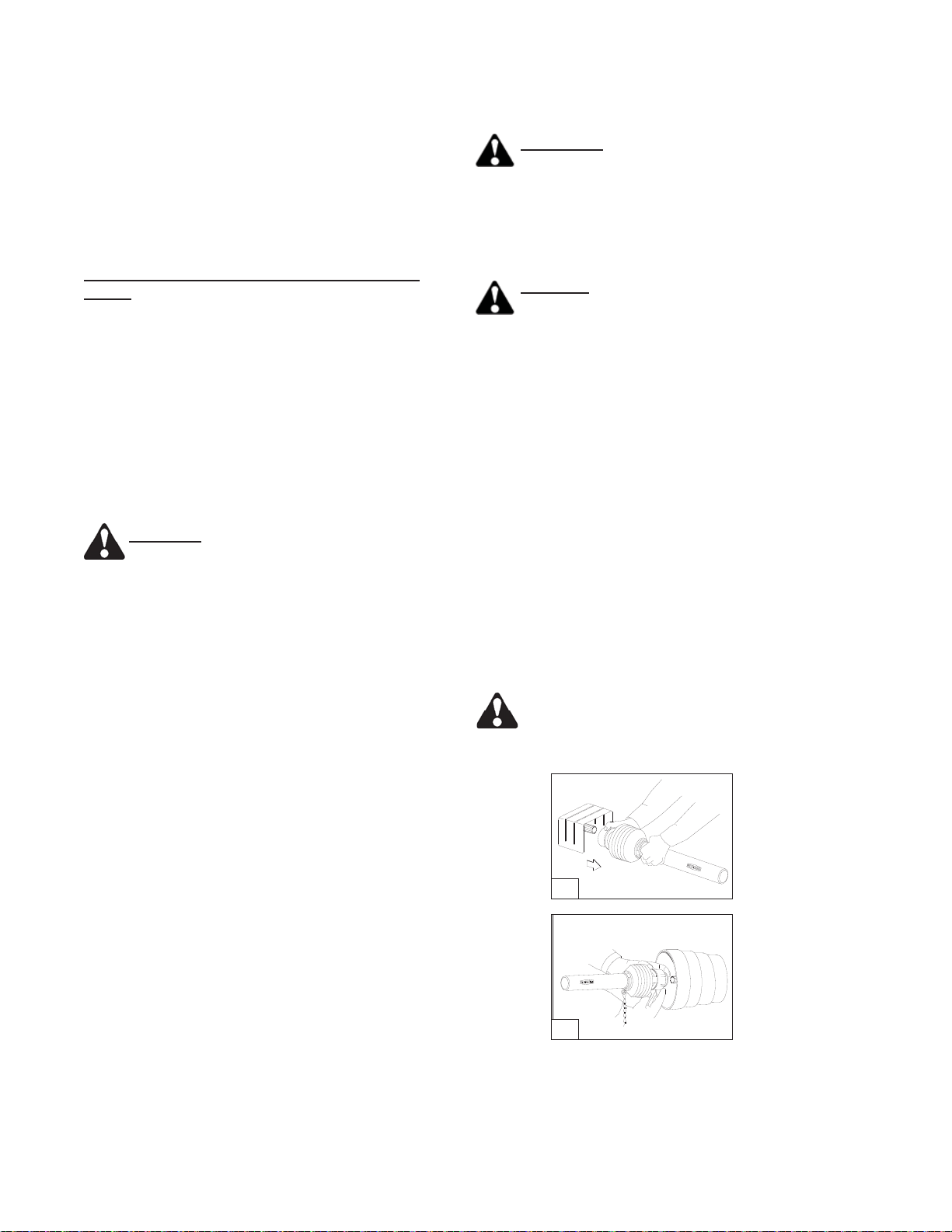

COUPLING THE PTO DRIVE SHAFT

(FIGS. E1 - E2)

Clean and grease the PTO and implement input

connection (IIC)

AS-Lock

1. Pull locking collar and simultaneously push

PTO drive shaft onto PTO shaft until the

locking device engages.

Push-Pull Lock

2. Pull locking collar and simultaneously push

PTO drive shaft onto PTO shaft until the

locking device engages.

Check to insure all the locks are securely

engaged before starting work with the

PTO driveshaft.

E1

E2 250968E

This manual suits for next models

1

Table of contents