3

SAFETY

Your Jointmaker Pro is no different than any other

sharp tool—usecommonsense!

Although it may seem safe to take risks because

the saw blade is stationary—and the only motion is

provided by YOU —safety should never be taken

for granted.

Etched on the top of each sliding table is a graphic

element that is designed to remind you of the risk

to your fingers. It may seem obvious, but we

strongly recommend keeping your fingers out of

this zone, especially when the blade is tilted.

After you have spent an hour or two using the

Jointmaker Pro we hope you share your new found

ability with other members of your family—this tool

can be enjoyed by many who like making gallery

quality cuts in a noise free environment!

SAW RIGIDITY AND ERGONOMICS

Under all circumstances, the Jointmaker Pro needs

to be firmly anchored to a work surface or attached

to a stand. If the saw moves while cutting your

accuracy and enjoyment of the tool will be less than

optimal.

The front table height of the Jointmaker Pro should

be an inch or so below your belt line. At this height,

you will be able to make a full stroke without undue

stress on your back or arms. If possible we

recommend that the rear of the Jointmaker Pro be

approximately three inches higher than the front.

This incline shortens the stroke of your arms,

increases your ability to see your work and reduces

strain on your lower back during long work

sessions.

WORK HOLDING REQUIREMENTS

Traditionally when cutting wood with a hand saw

you clamp the material to be cut to a workbench or

hold your stock in a vise. With either method, the

stock should always be firmly anchored in order to

achieve optimal, and accurate, results.

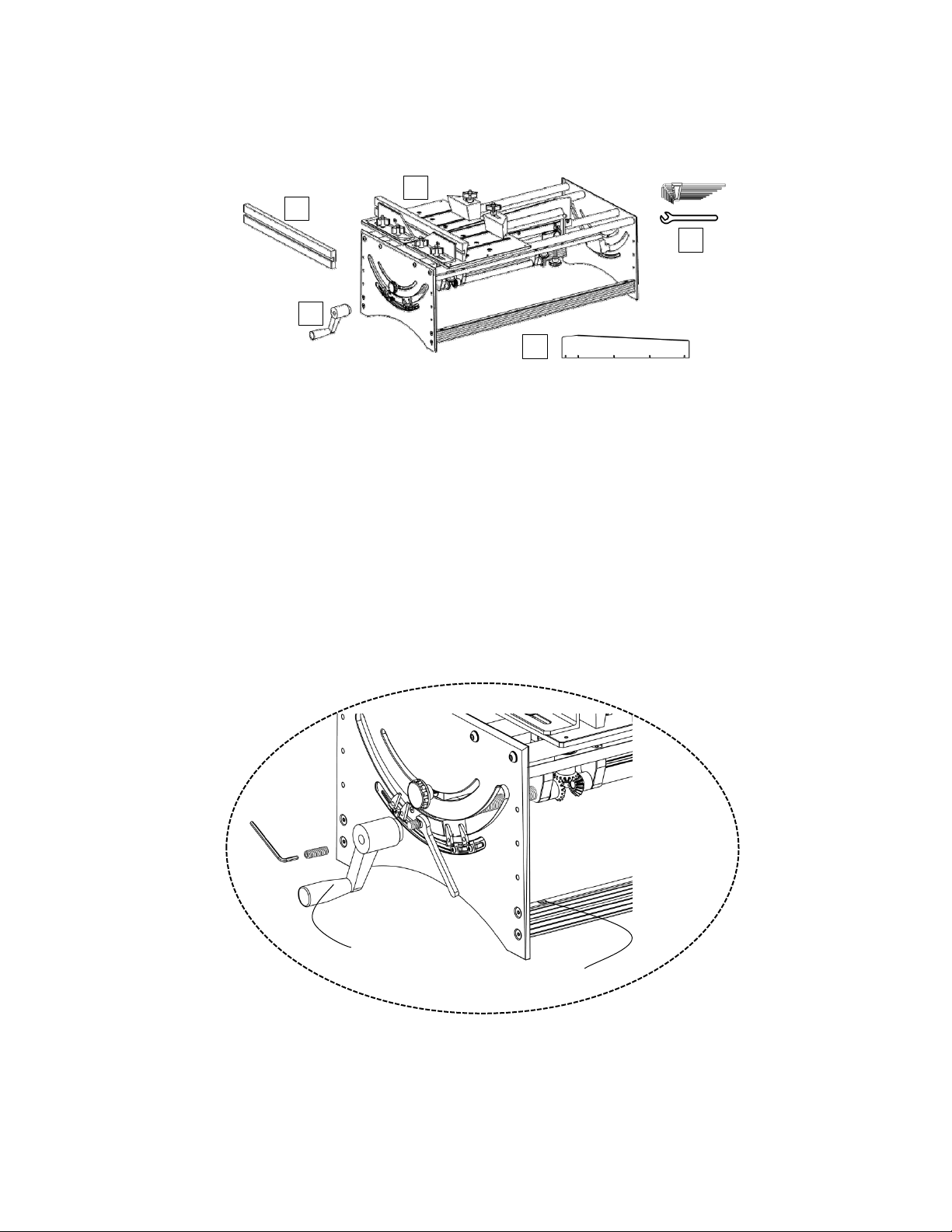

The same work holding requirements are true

when making most cuts with the Jointmaker Pro.

The sliding table is analogous to a workbench

surface and the angled trap clamps act as a vise.

These elements become particularly crucial with

the Jointmaker Pro because unlike any other hand

sawing experience, you are cutting from the bottom

up as opposed to top down. Without your stock

firmly anchored to the sliding tables, the negative

feed (the tendency of the wood to ride up over the

top of the blade) becomes difficult to manage with

hand strength alone. In almost all cases, we

strongly recommend that you utilize these work

holding aids for accuracy and blade longevity.

When using the blade in a tilted position, trap

clamping is mandatory.

SAW BLADES & DEPTH OF CUT

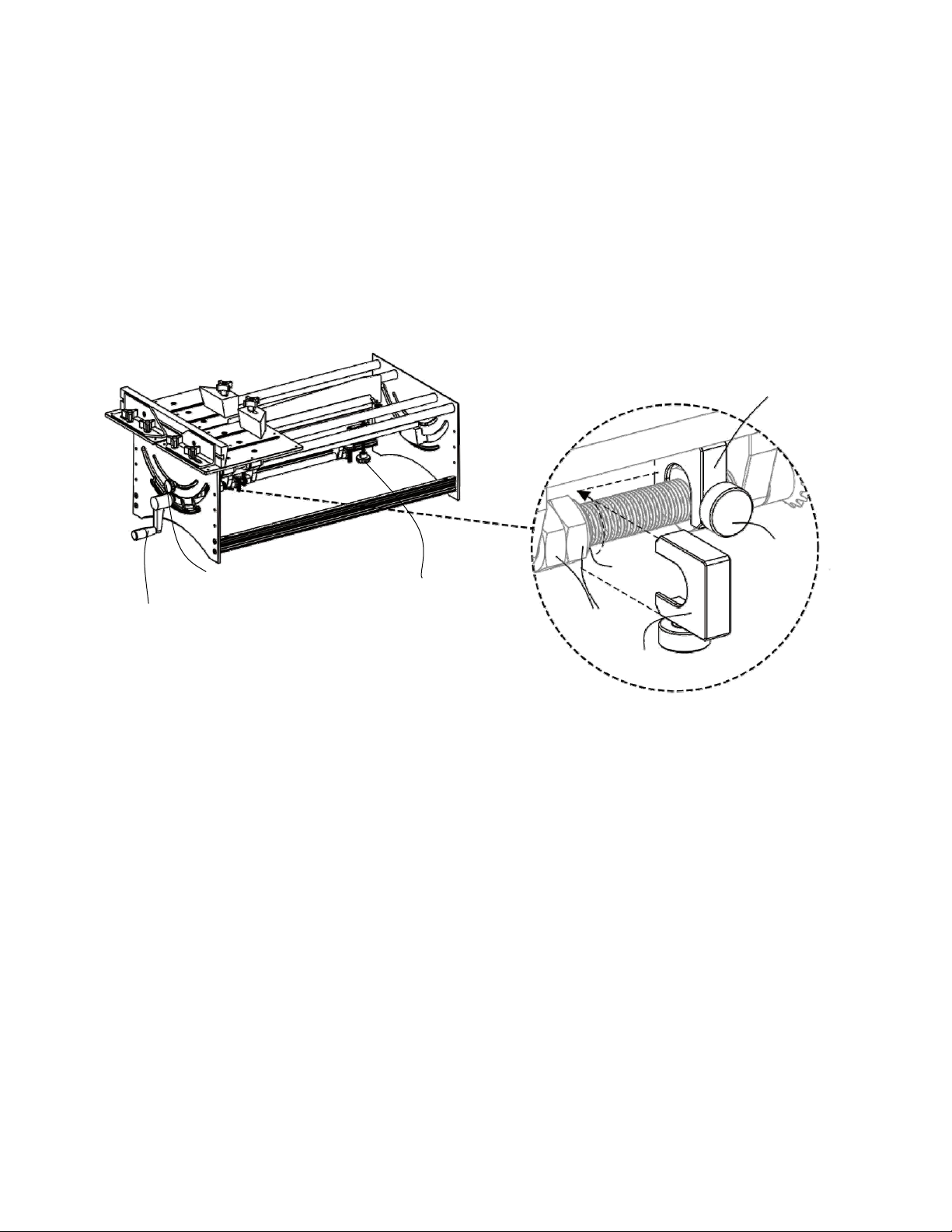

All of the saw blades currently designed for the

Jointmaker Pro contain between 350 and 460 teeth

over their length. Because the blade is inclined (the

front of the blade is lower than the back of the

blade) in relation to the table surfaces, each tooth

bears the exact same workload.

For example, a piece of walnut with a 1/2”x1/2”

cross-section can be cut in half with one stroke

using the standard crosscut blade. To correctly set

the blade for this cut, you would adjust the blade so

that the first couple of teeth are below table height,

and the last tooth of the saw blade is set with the

pitch adjustor to approximately 1/32 ’above the

stock of the wood. With the stock held firmly

against the fence, one stroke and the cut is

complete, smooth and accurate. See the Cutting

Guide page 6 for more details.

This example is possible because the standard

JMP crosscut blade has approximately 400 teeth.

Using the stock and set-up described above, each

tooth of the saw has a chip load of just over one

one-thousandth of an inch (.5/400 = 0.00125n). It is

the combination of the chip load, precise linear

movement and blade rigidity that makes

Jointmaker Pro cuts unparalleled in quality or

accuracy.