Attention is drawn to the requirements of the

Health and Safety at Work Act 1974 which applies

to the U K. Similarly in other countries the machine

should always be operated to conform with the

appropriate regu lations.

is

rI.

All machines in the Bridgeport range, together with their accessories are designed and produced to ensure safety to the

operator as far as is reasonably practicable.

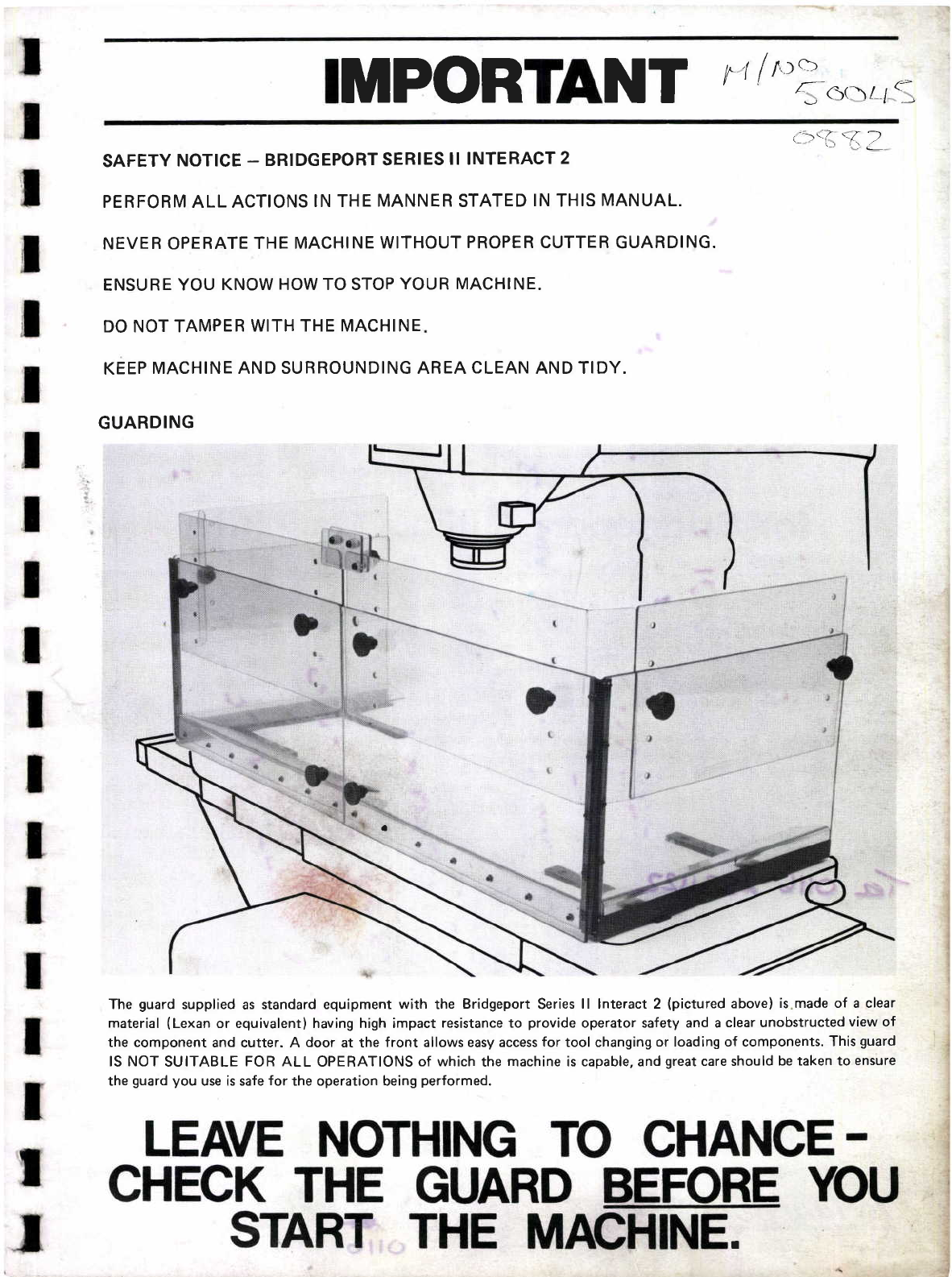

Every machine and where appropriate, the attachments, are

provided with a cutter guard which will satisfy statutory

requirements for a large number of applications. However,

as the machine and attachments are designed for general

engineering applications the guard supplied will not cover

every possible requirement for effective guarding of the

cutter. Under no circumstances should any machine from

the Bridgeport range of machines be used without the

correct safety guard for the operation to be performed. As

we have no control over the end use of our machines, it is

the user's responsibility to ensure that the machine is

properly used and guarded for every operation.

i

t

i

I

i

I

i

I

I

i

(.- otlt 253t(22-.

, Bridgeport Machines Division of Textron Limited,

P.O. Box 22, Forest Road,

Leicester LE5 0FJ, England

Telephone: ( 531122; Telex: 34598

ollb