If the battery voltage is low, a battery symbol

will be displayed on the screen and soon

afterwards, the wrench will turn off. Replace

with a new set of batteries.

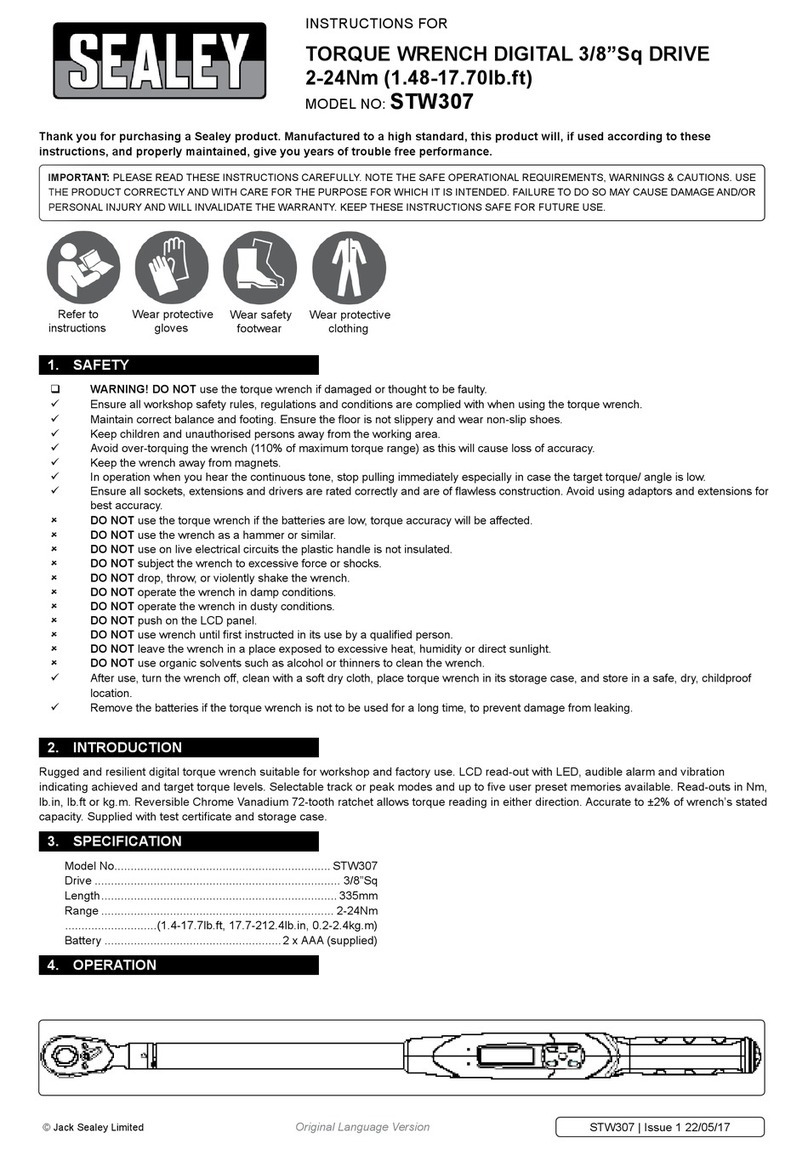

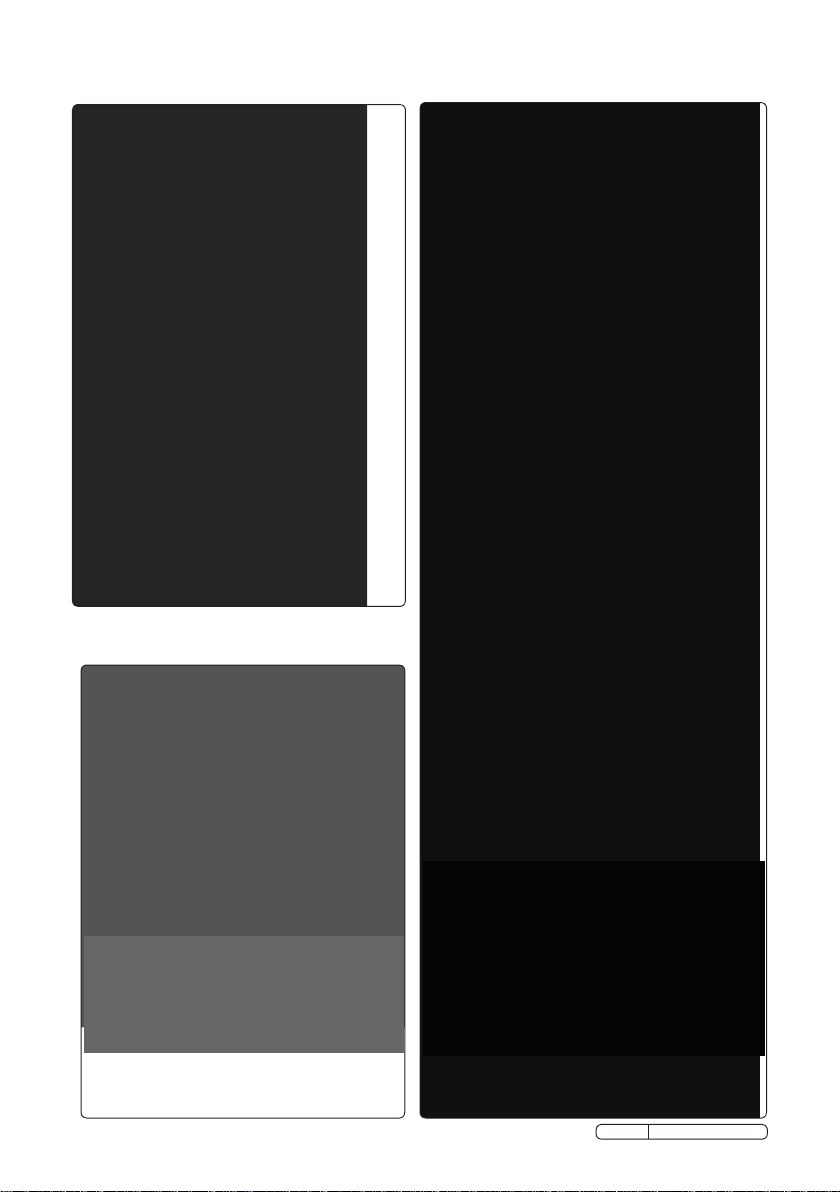

OPERATIONAL OVERVIEW:

Follow the schematics to use the wrench

correctly.

3.2. Track Mode: the torque is preset in the set-up

menu. As the wrench applies a turning force, the

read-out will show a continually increasing torque

figure. When 80% of the preset value is

reached, the buzzer sounds intermittently and the

green LEDs flash. When the force reaches

99.5% of the preset value, the buzzer sounds

continually and the red LEDs are fully lit. If the

force applied goes over the stated maximum

capacity, the LCD display will flash.

NOTE: there is no mechanical ‘click’ when the

wrench reaches the preset torque. As the turning

force on the wrench is released the digital

readout rolls back down to zero.

3.3. Peak Hold Mode: the torque is preset in the

set-up menu as in Track Mode, use the wrench

exactly the same, except that when the force is

released, the display stays at the maximum

torque that has been applied. This value can

then be stored if required (50 memory spaces).

As the ratchet is reversible, the wrench can be

used on reverse thread fixings and can also be

used to show the amount of torque required to

undo a nut or bolt.

3.4. Power On. Place the wrench on a horizontal

level surface and press the ‘C’ button. The

wrench will power-on and auto zero re-set.

If the wrench is not used for two minutes, it will

switch off automatically. Press the ‘C’ button to

power-on the wrench again.

If ‘Er0’ appears on the screen during this

process, the wrench has been used at more

than 110% of it’s maximum torque capacity and

this may have caused loss of accuracy and/or

the wrench may have been damaged.

3.5. Reset in use. To reset the wrench to zero before

taking the next reading, press the ‘C’ button.

When using Angle Mode, the wrench must

be placed on a horizontal surface to re-set it, if

it isn’t, a series of four zeros will display in the

top half of the LCD screen, Place wrench on a

horizontal surface and press ‘C’ again to re-set.

In Torque Mode, do not apply any external

forces to the ratchet head whilst re-setting.

3.6. Full reset. If the wrench appears to malfunction,

or ‘Er5’ appears on the screen, remove the

battery compartment cover, replace it and press

the ‘C’ button to re-set the wrench.

3.7. Memory full. If all 50 memories are used, ‘full’

will appear on the display. It will then be

necessary to clear the memory in set up mode.

Selecting Pre-set No.

STW305 ISSUE No:1 - 09/06/10

Original Language Version