Table of Contents

1 INTRODUCTION..............................................................................................................7

1.1 About the Probe...........................................................................................................7

1.1.1 Probe - Overview.................................................................................................7

1.1.2 VB20 an VB220...................................................................................................8

1.1.3 Probe - Functionality............................................................................................9

1.2 How to use this manual...............................................................................................10

2 PRINCIPLE OF OPERATION.........................................................................................11

3 SAFETY......................................................................................................................... 13

4 INSTALLATION AND INITIAL SETUP.............................................................................14

4.1 Quick Installation Gui e.............................................................................................14

4.2 The Enhance Chassis (EC)......................................................................................14

4.2.1 Dual Power Supply.............................................................................................15

4.2.2 Cooling System..................................................................................................15

4.3 The Enhance Chassis -48V DC version (ECDC).....................................................16

4.3.1 Dual Power Supply.............................................................................................16

4.3.2 Cooling System..................................................................................................17

4.3.3 ECDC Power Supply...........................................................................................17

4.4 Serial Number Location.............................................................................................18

4.5 Portable chassis (VB20).............................................................................................19

4.5.1 AC Power Supply ...............................................................................................19

4.5.2 Cooling System..................................................................................................19

4.5.3 Serial number location.........................................................................................19

4.5.4 Interfaces............................................................................................................ 19

4.6 The ACC/DCC Har ware (VB220).............................................................................20

4.6.1 Cooling System..................................................................................................20

4.6.2 ACC Power Supply.............................................................................................20

4.6.3 DCC Power Supply............................................................................................21

4.6.4 Serial Number Location......................................................................................21

4.7 The Har ware Mo ules an Connectors (VB220)......................................................22

4.7.1 The Probe Mo ule...............................................................................................22

4.7.2 The VB242 ASI Input Mo ule (VB220 option).....................................................23

4.7.3 The VB250 COFDM Demo ulator Mo ule (VB220 Option)................................24

4.7.4 The VB252 COFDM Dual Demo ulator Mo ule (VB220 Option)........................25

4.7.5 The VB260 QAM Demo ulator Mo ule(VB220 Option)......................................26

4.7.6 The VB262 Dual QAM/8VSB Demo ulator Mo ule (VB220 Option)..................27

4.7.7 The VB270 DVB-S/S2 Demo ulator Mo ule (VB220 Option).............................28

4.7.8 The VB272 ual DVB-S/S2 Demo ulator Mo ule (VB220 Option).....................29

4.7.9 The VB273 DVB-S/S2 Re un ancy switch (VB220 Option)................................30

4.8 Installing the Unit in a Rack (VB220).........................................................................34

4.8.1 Default Installation - Connectors at the Front of Rack........................................34

4.8.2 Optional Installation - Connectors at the Rear of Rack.......................................34

4.8.3 Optional Installation - Mi -Mounting...................................................................35

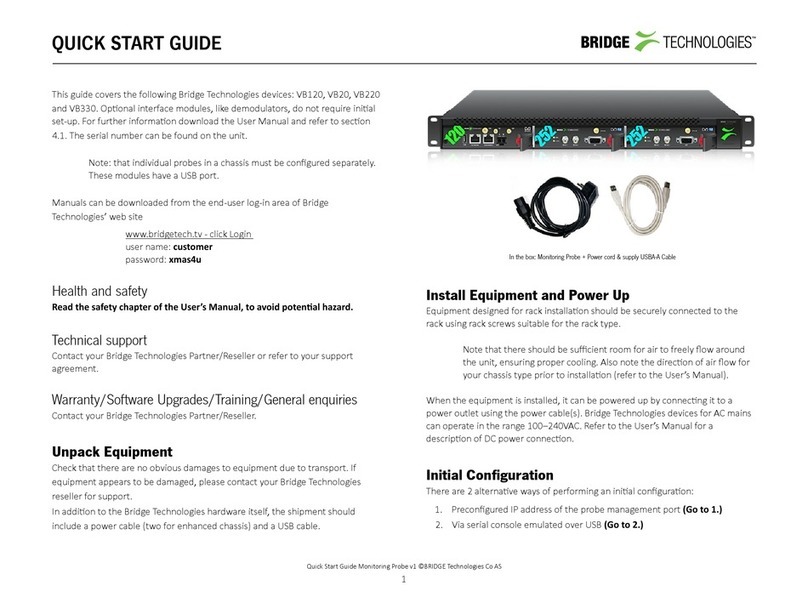

4.9 Powering up the Unit.................................................................................................35

4.10 Initial Configuration..................................................................................................36

4.10.1 Initial Configuration Using the Pre-Set IP-A ress...........................................36

4.10.2 Initial Configuration Via Serial Console Emulate Over USB...........................36

4.10.3 Verifying Correct Initial Setup of the Probe.......................................................40

4.10.4 Initial Setup Troubleshooting............................................................................41

5 QUICK SETUP GUIDE...................................................................................................42

5.1 Basic Setup: All Interfaces.........................................................................................42

5.2 Input Signal Definitions..............................................................................................42

5.2.1 ASI Input ...........................................................................................................42

5.2.2 Ethernet Input (IP Option Only)..........................................................................42

5.2.3 OTT Input (OTT Engine Option Only).................................................................43

5.2.4 Demo ulator Input(VB220).................................................................................43

5.3 Monitoring: All Interfaces............................................................................................44