7K116

There are three levels of hazard intensity that

appear with the safety alert symbol on safety

decals: DANGER, WARNING, and CAUTION.

The level of hazard intensity is determined by the

followingdefinitions:

DANGER - Immediate hazards which

WILL result in death or serious

personal injury.

WARNING - Hazards or unsafe practices

which COULD result in death or

serious personal injury.

CAUTION - Indicates potentially hazardous

situations, or directs attention to

unsafe practices which could

result in minor or moderate injury.

•Examinesafety decalsandbesureyou have

the correct safety decals for the machine.

•Order replacement decals through your

BRILLIONdealer.

•Keep these signs clean so they can be

observedreadily. Itisimportanttokeepthese

decals cleaned more frequently than the

machine. Wash with soap and water or

cleaning solution as required.

•Replace decals that become damaged or

lost. Also be sure that any new machine

components installed during repair include

decals which are assigned to them by the

manufacturer.

•When applying decals to the machine, be

sure to clean the surface to remove any dirt

or residue. Wherepossible, sign placement

should protect the sign from abrasion, damage,

or obstruction from mud, dirty oil, etc.

•Information and identification decals are

shown below. Safety decals for the

Overseeder and their locations on the

machine are pictured onthe following

twopages.

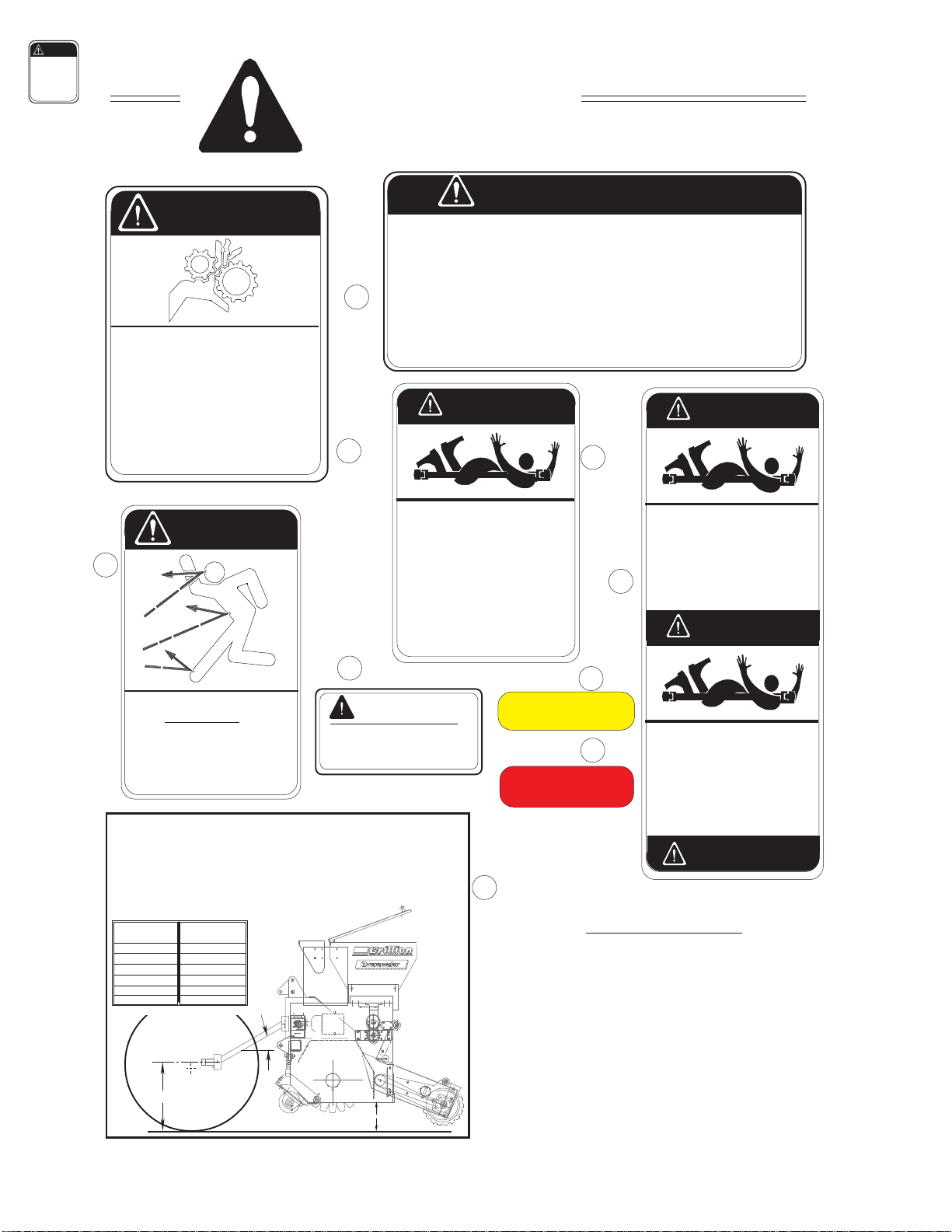

PLANTING RATES FOR SEED BOX

CALIBRATION OF SEED BOX

1. Rates arefor13-ToothDriver. Doubletheserates for26-ToothDriver.

2. Rates areintendedasa guide only. Variationin size andcleanlinesswill

affectrates. Checkacreage & Lbs.ofseedused for bestresults.

13-Tooth

Driver

(Usingthe26-toothSprocket

doublestheseedrateshown.)

Large Seed Box May Be Calibrated as Follows:

1. Raisemachine&lockin transport position.

2. Closetheseedboxonthesmallseedbox (if one ispresent.)

2. Placeatarpundermachineto collect seed.

3. Turnthe 37Toothsprocket clockwise as follows:

-82revolutionsfor6 Foot Seeder

-122revolutionsfor4Foot Seeder

4. Weighseedandmultiplyby10(20for

26-ToothDriver)

forapproximate

plantingrate

inlbs/acre.

7K218

37-Tooth

Driven

PoundsPer Acre Pounds Per 1000Sq. Ft.

123456 78 12 34 5 6 7 8

24 45 85 155 207 259 338 389

24 45 95 161 254 309 380 462 .52 1.03 1.94 3.55 4.76 5.95 7.76 8.92

.52 1.03 2.18 3.70 5.83 7.10 8.74 10.61

Indicator Setting

KENTUCKYBLUEGRASS

TALLFESCUE

*Willcracksome seeds at

thesesettings. Not

recommended: Lentils,

Sorgum.SidanGrass

12

10

11

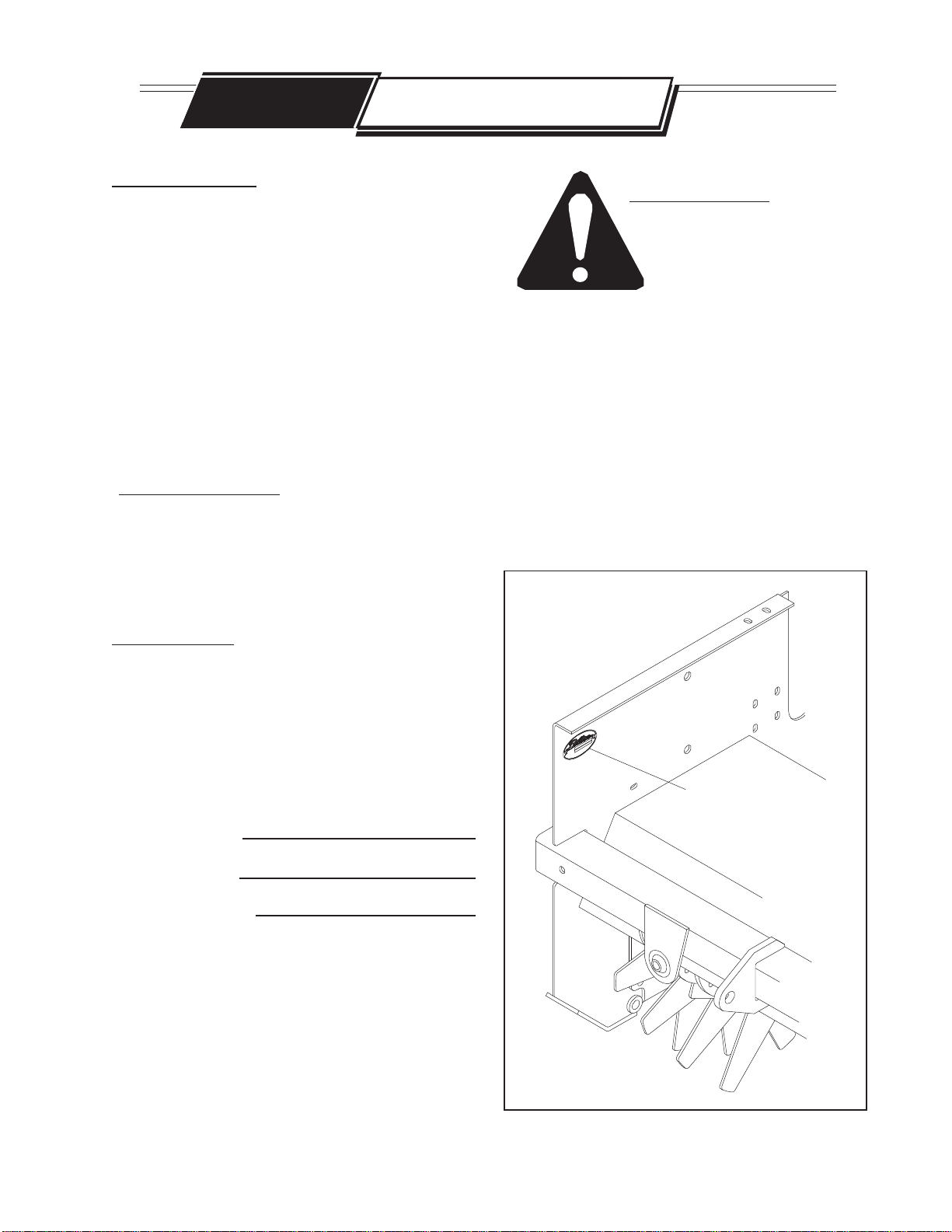

SAFETY DECALS

SAFETY DECALS

Page 5

INFORMATION & IDENTIFICATION DECALS

10. 7K218-SeedChart,Large Seedbox

[7K217 - Seed Chart, optional Small Seedbox]

11. 7K240-Decal,“BRILLION”

12. 6K402-Decal,“OVERSEEDER”

900rev601