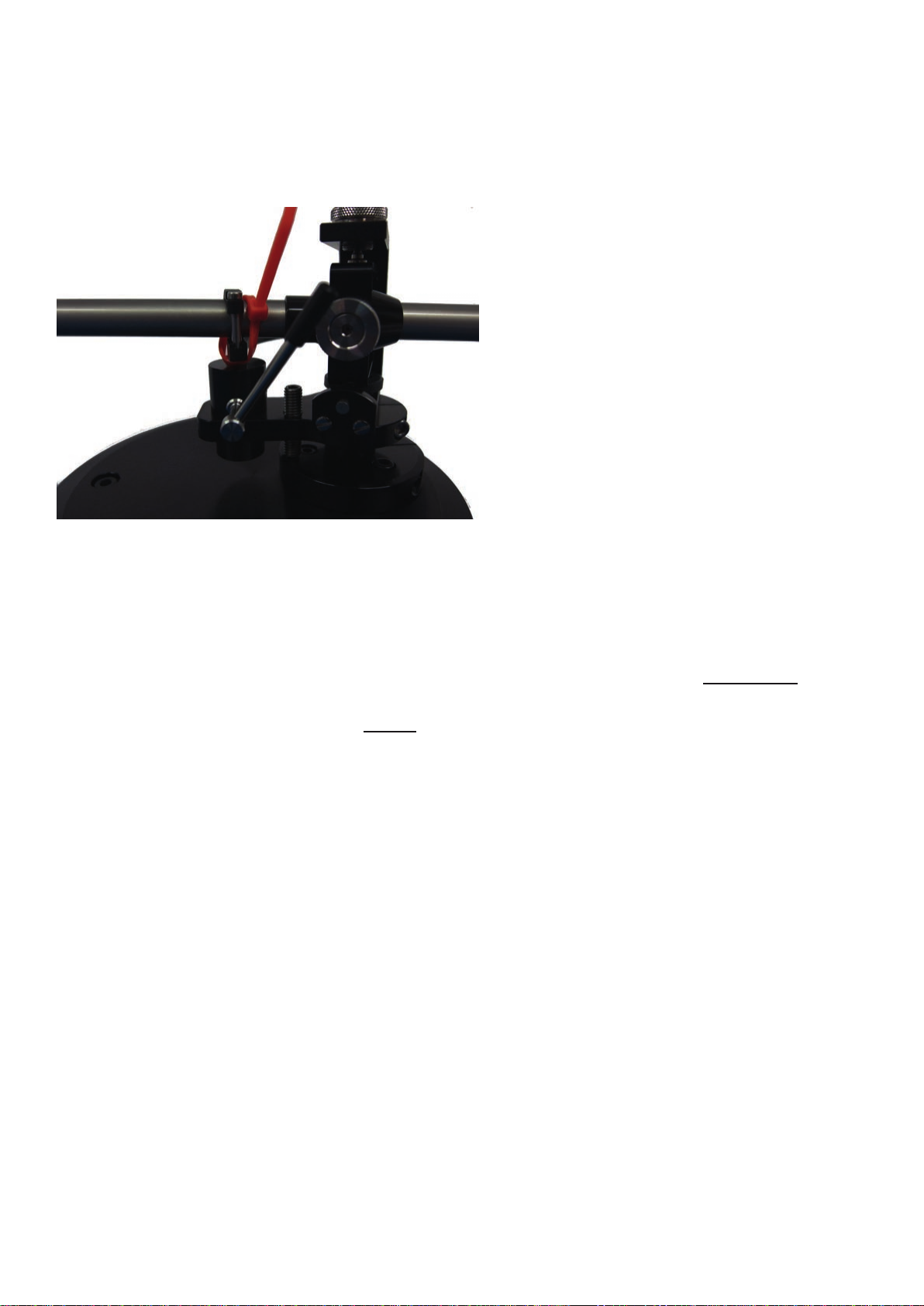

5. GENERAL INFORMATION FOR BRINKMANN BELT DRIVE TURNTABLES

Brinkmann Sinus Motor

For over two decades Brinkman Turntables employed the

highly-regarded German manufacturer Papst to supply Tape

Capstan motors for use in our belt drive turntables. Techni-

cally and musically we had good results with this motor in

Helmut Brinkmann’s extensive research and development

program, which resulted in the development of our bespo-

ke, direct drive motor for the Oasis and Bardo turntables

and how to apply this knowledge to reduce cogging in a

motor. The next logical step was to apply this knowledge

to the design of a new motor for the belt drive turntables.

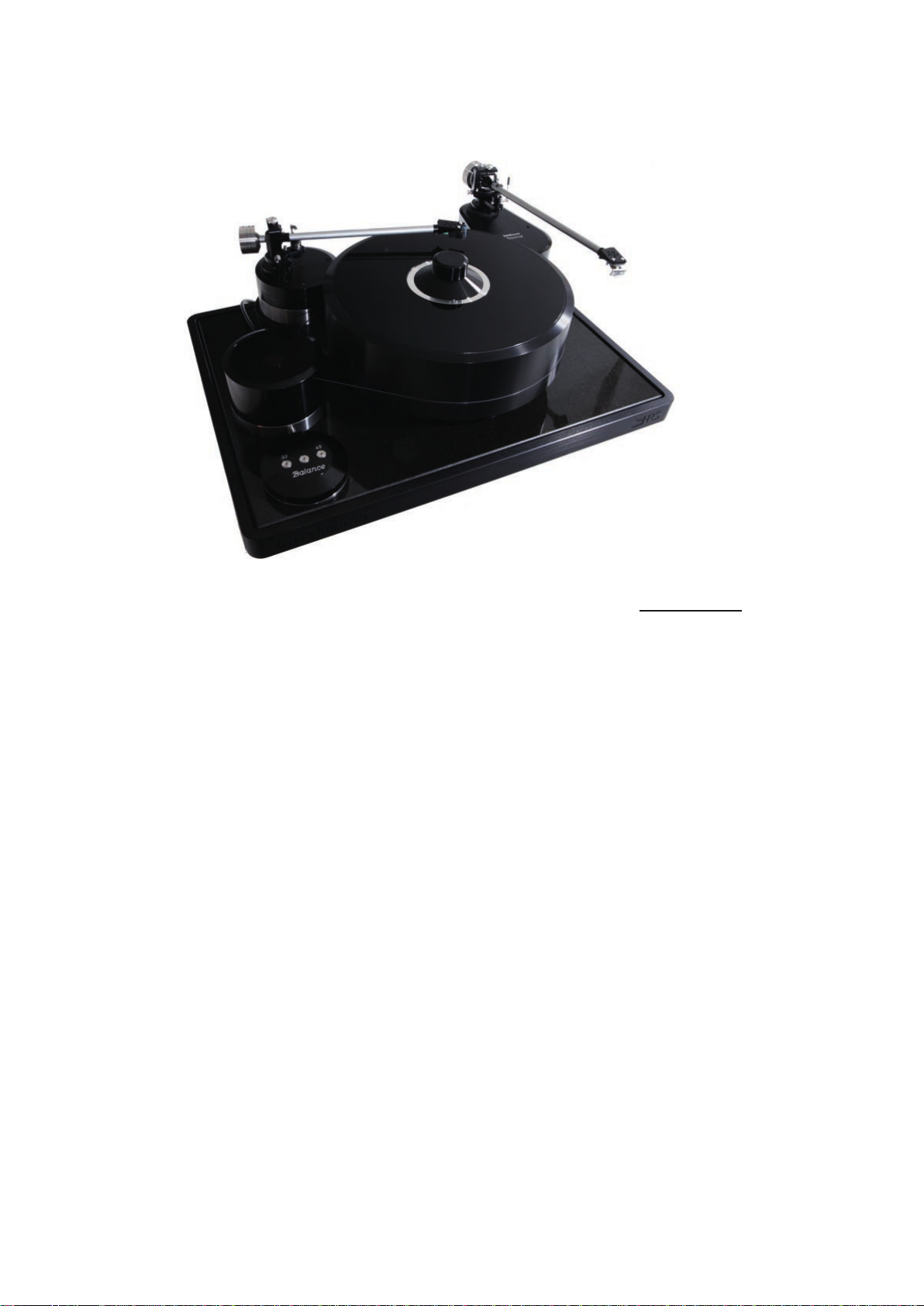

Compared to the Papst, Brinkmann’s new Sinus

circuitry—as opposed to the commonly used two-phase design used by Pabst and others--enab-

-

supply, which also enhances Brinkmann direct drive motors.

-

-

-

from the moment of turn-on.

8