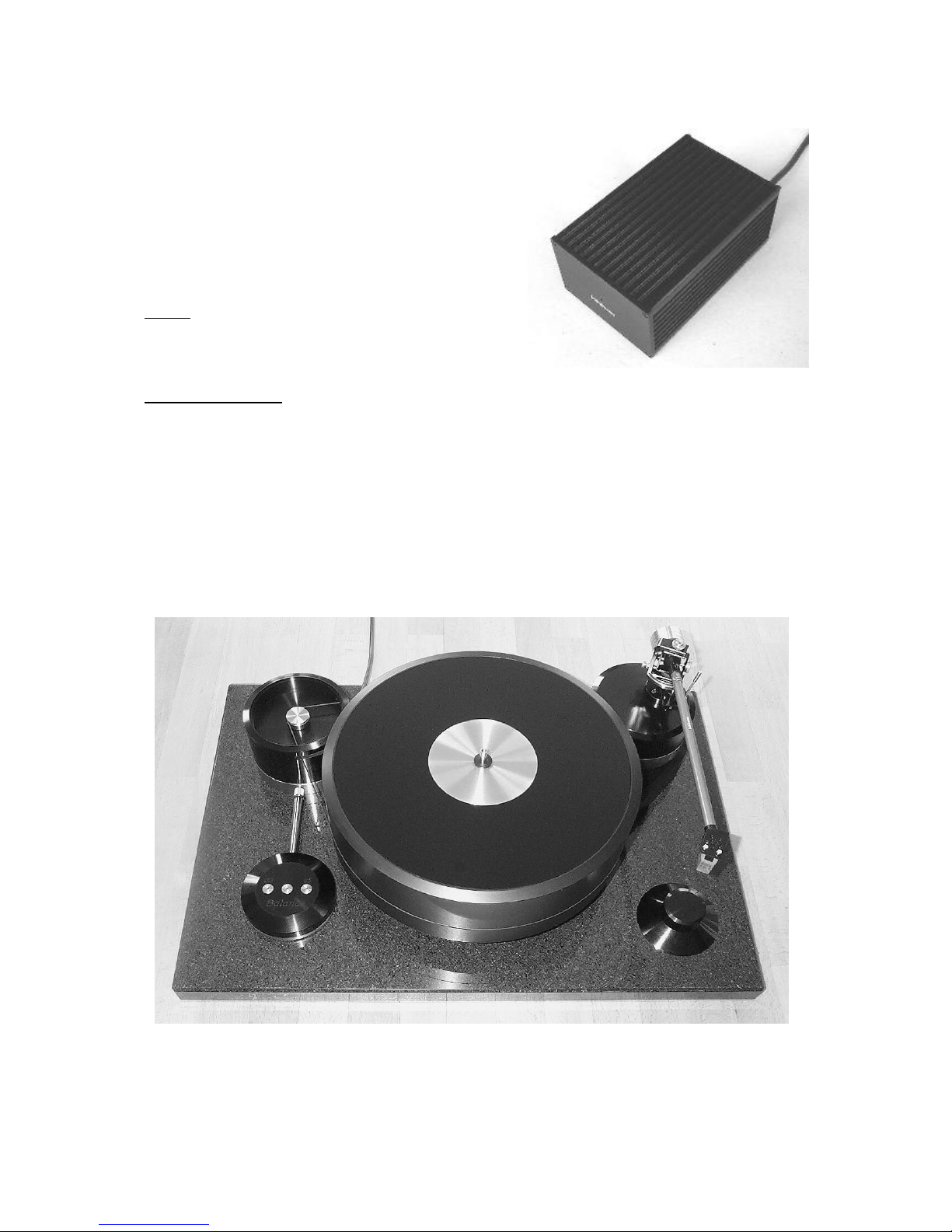

MOTOR :

The motor of the turntable is a separate device, independent from chassis and platter.

The motor can be connected via a three core line wire and a three pole plug with the

matching socket at the power supply. A cap srew on the plug prevents an unintended

unplugging during operation.

POWER SUPPLY :

The casing of the power supply consists of metal, it is completely closed.

The power supply features a three pole socket for the connection with the motor,

equipped with a cap screw ensuring impossible unintended removement of the plug.

Set up procedure for BALANCE turntable :

we recommend to use a ground base made from black granite stone (nero assoluto) of at

least 60 cm by 42 cm (centimeters), or 23.6 by 16.5 inch.

First, the plinth complete with tonearm base is placed on top of the ground base, the

bearing for the platter should be in the center of the base, with the tonearm base right

hand. The spikes are adjusted to just get in contact with the ground base surface

(screwdriver No. 3). The chassis should not lift from the ground.

The screw that fixes the tonearm base is unscrewed a little and the base is turned until

the effective length of the tonearm is correct. The tonearm should align with the right

edge of the ground base when rested in its armrest.

Next the psu for the heater of the bearing is connected at the back of the plinth, but not

yet switched on. Bearing and platter must have the same temperature when the platter is

layed on.

Therefore you hold the platter above the bearing, look through the center hole of the

platter and look for the axle of the turntable. Then lay down the platter carefully, only

the last two centimeters the platter will be exactly centered by the subplatter of the

bearing. Here the platter must be lowered exactly vertical to place it without getting

stuck.

Possibly the ground plate will get out of horizontal balance by the weight of the platter,

please control the balance on the platter surface again.

The motor is placed opposite the tonearmbase on the left hand side, the distance to the

platter should be about 1cm. Then the belt is tied around platter and motor pinion, the

motor is moved back or foreward to have the switch buttons freely accessible.

The motor is connected to the transistorized psu, or, if you have the tubed psu, directly

to it´s 3-pole socket. The transistor supply remains for the heater circuit of the bearing.