iALIGN

ii INSERT

A

B

CUT LENGTH )(A) = A + ⁄ (9

CUT LENGTH (B) = B + ⁄ ()9

Repeat on the other side

iSQUEEZE

Repeat on the other side

INSTSCREEN |Rev | |3 C Feb 2020 10

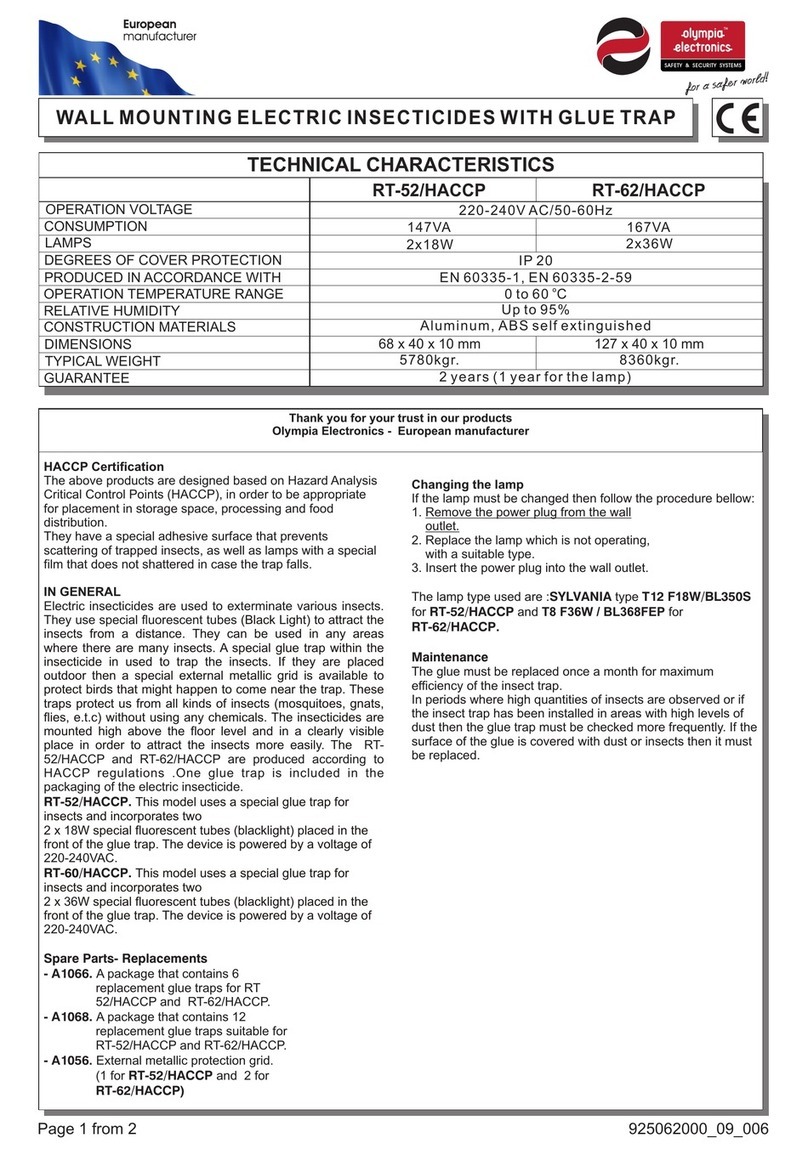

14. Commissioning

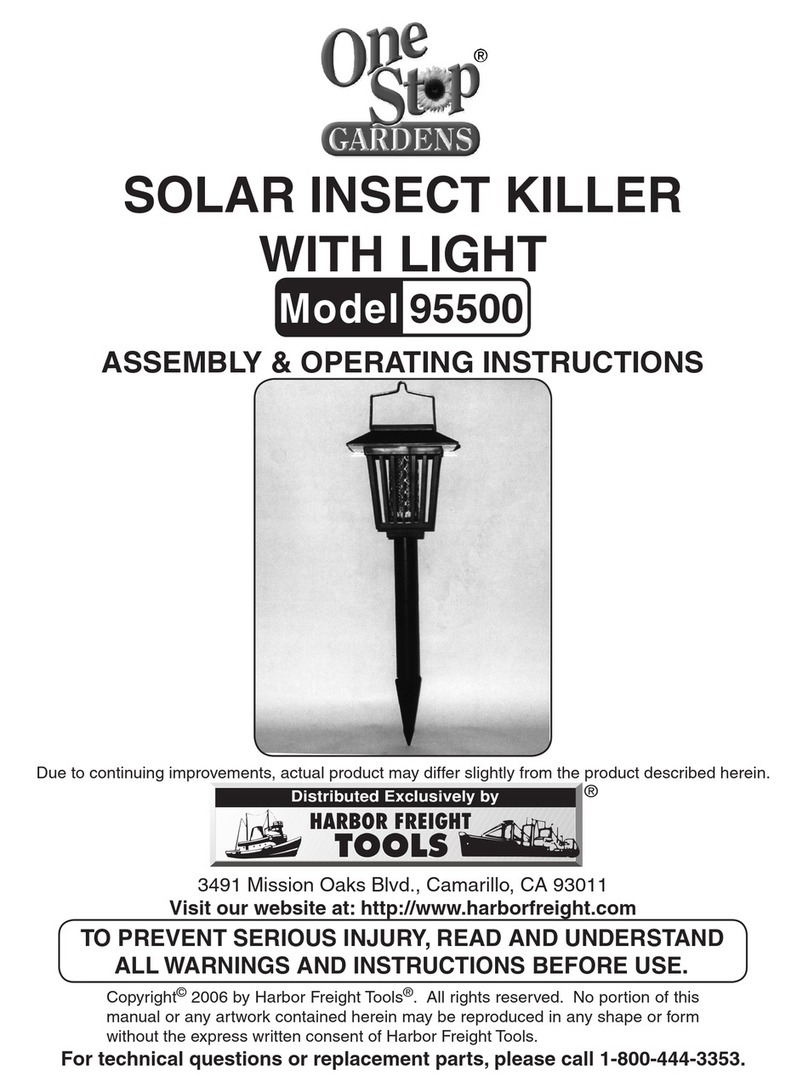

16. Fitting Handlebar Trim

1. Ensure Channel (RSC) is free from dirt and debris.

Ensure screen slides freely from side to side.2.

Ensure Screen meets at the Jamb or meeting Screen (double or corner applications) without any gaps.3.

(If not Refer to Step 1 Handle Adjustment)2 bar

Once Screen is operating correctly fit the remaining components (as shown below).4. ,

WS-HDPEX

HANDLEBAR

PLASTIC

EXTRUSION

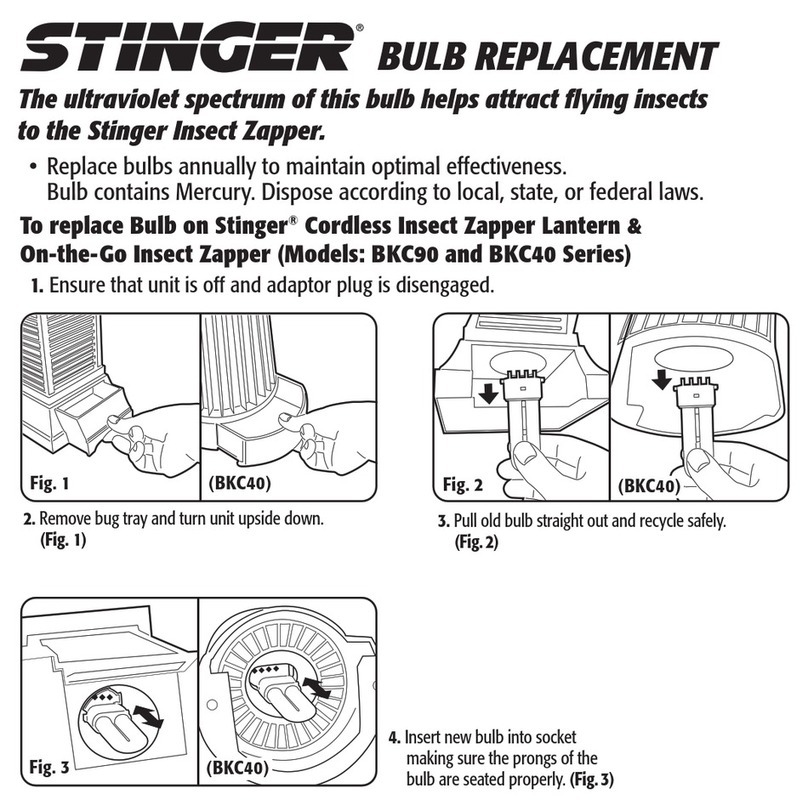

15. Fitting Channel Covers

ii SQUEEZE

iii SNAP

iv SLIDE UNDERNEATH HANDLEBAR

(approx )⁄ ()15

iLIFT HANDLEBAR

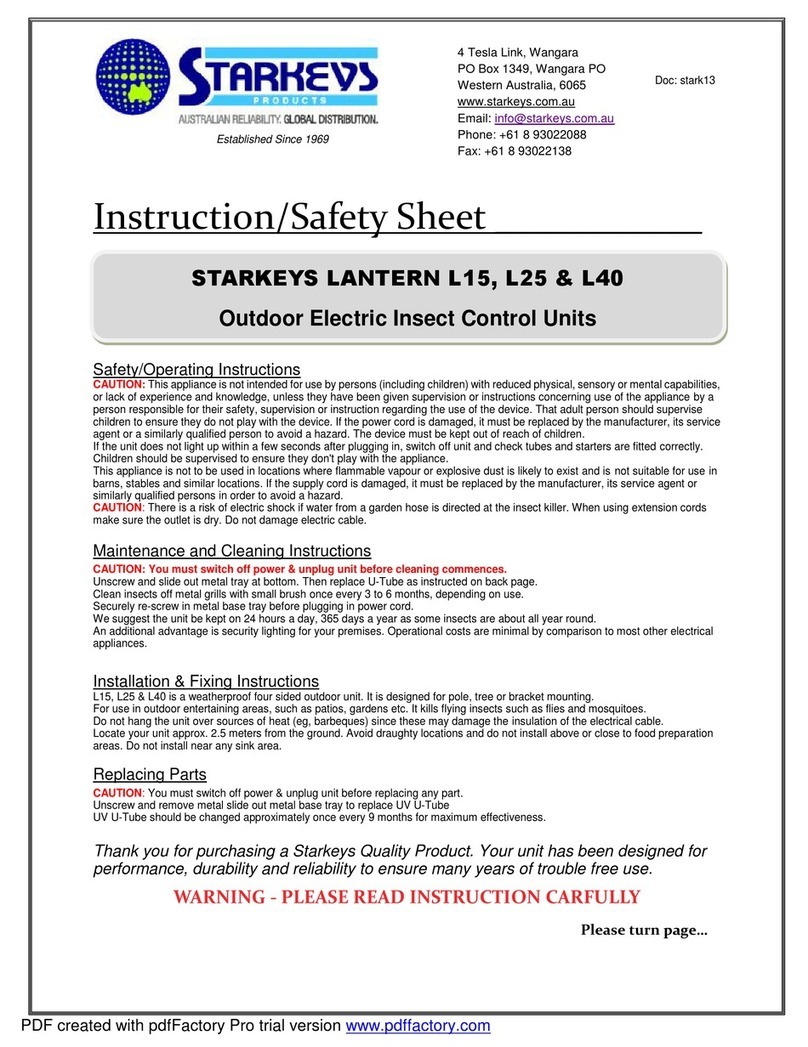

RSC

CHANNEL

RSJ

JAMB

MOUNTING

EXTRUSION

CORDS

Cords pass over

extruded cover

WS-COVEXP

CASSETTE

EXTRUDED

COVER

TRACK (RST or RSTT)

RSJ

JAMB

MOUNTING

EXTRUSION

RSC

CHANNEL

The screen is now installed

Multiple lengths of the cassette extruded maybe

fitted according to the width of the screen