Self–Regulating Heating Cable

Installation & Maintenance

Instruction Manual

SAVE THESE INSTRUCTIONS!

Additional copies of this manual are available upon request.

You must read and understand this manual before installing, operating, or

servicing this product. Failure to understand these instructions could result

in an accident causing serious injury or death.

Keep these instructions for future reference.

Language Page

English ................................................................................................................................................................................................................................. 1

Spanish (Español) ............................................................................................................................................................................................................... 33

French (Français) ................................................................................................................................................................................................................ 65

German (Deutsch) .............................................................................................................................................................................................................. 97

Italian (Italiano) .................................................................................................................................................................................................................. 129

English

Self Regulating Heating Cable

© BriskHeat® Corporation. All rights reserved.

2

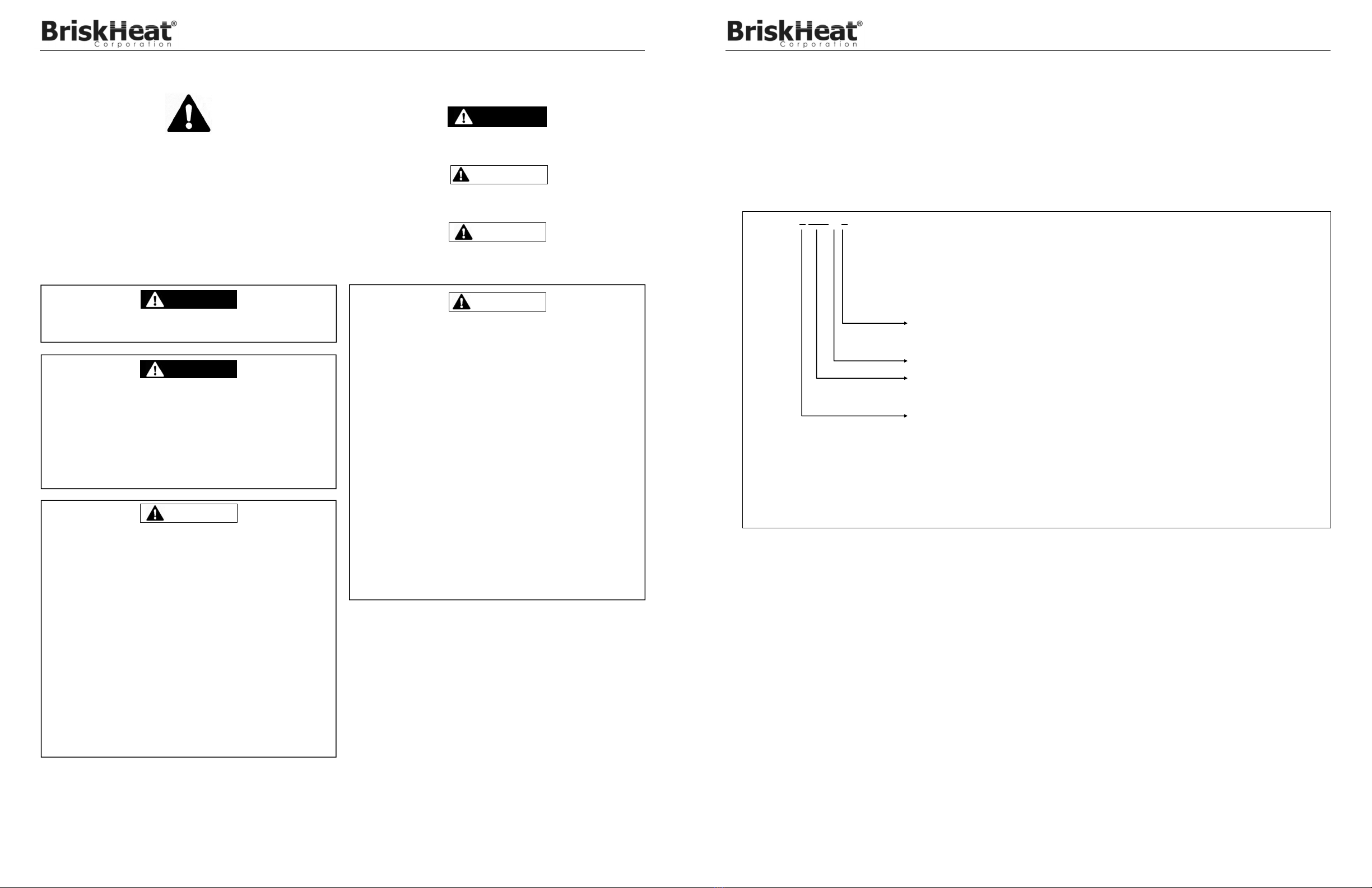

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ........................................................................................................................................................................... 3

PART INTENDED USE ...................................................................................................................................................................................................... 4

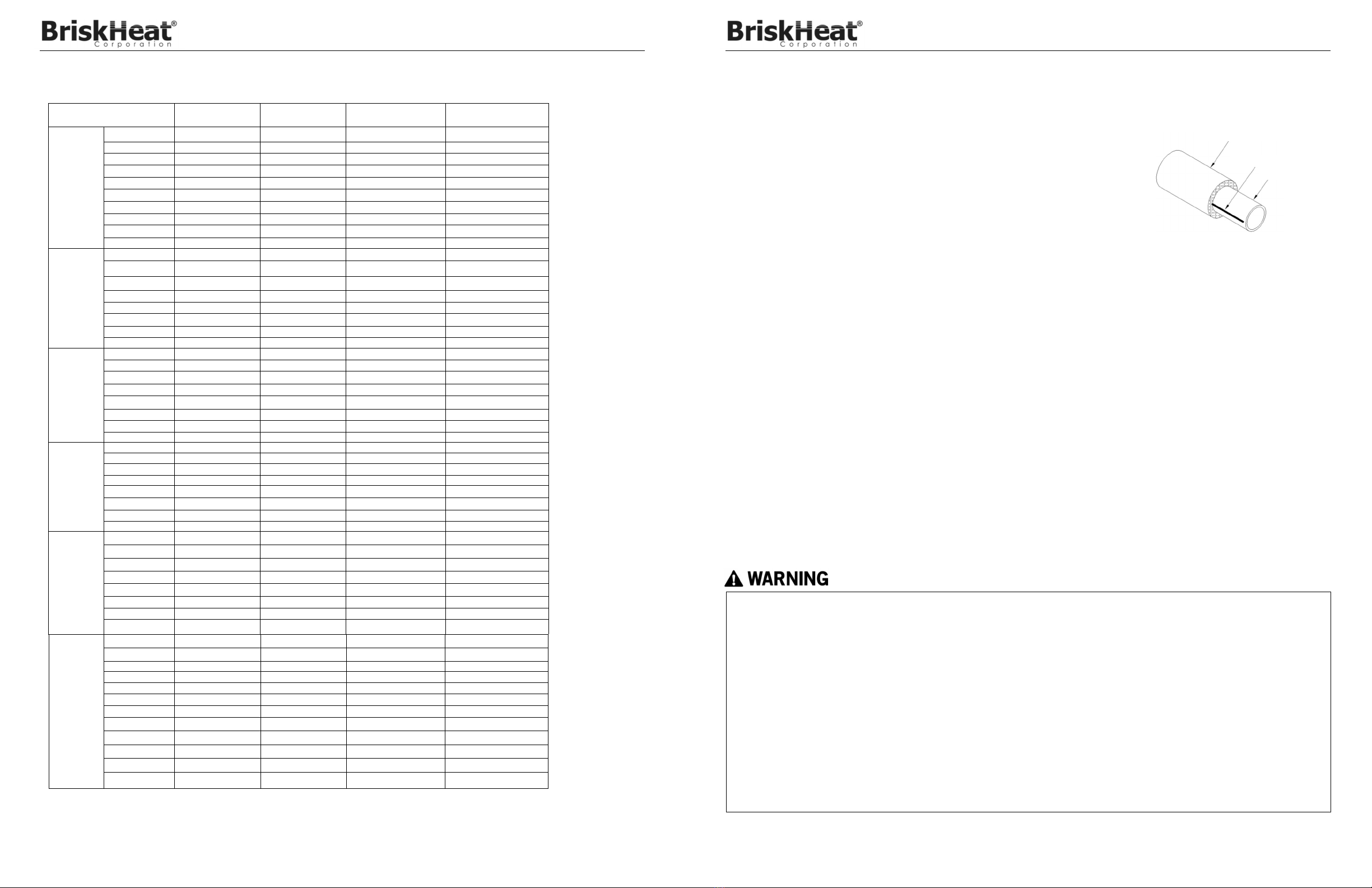

PART NUMBER MATRIX .................................................................................................................................................................................................. 4

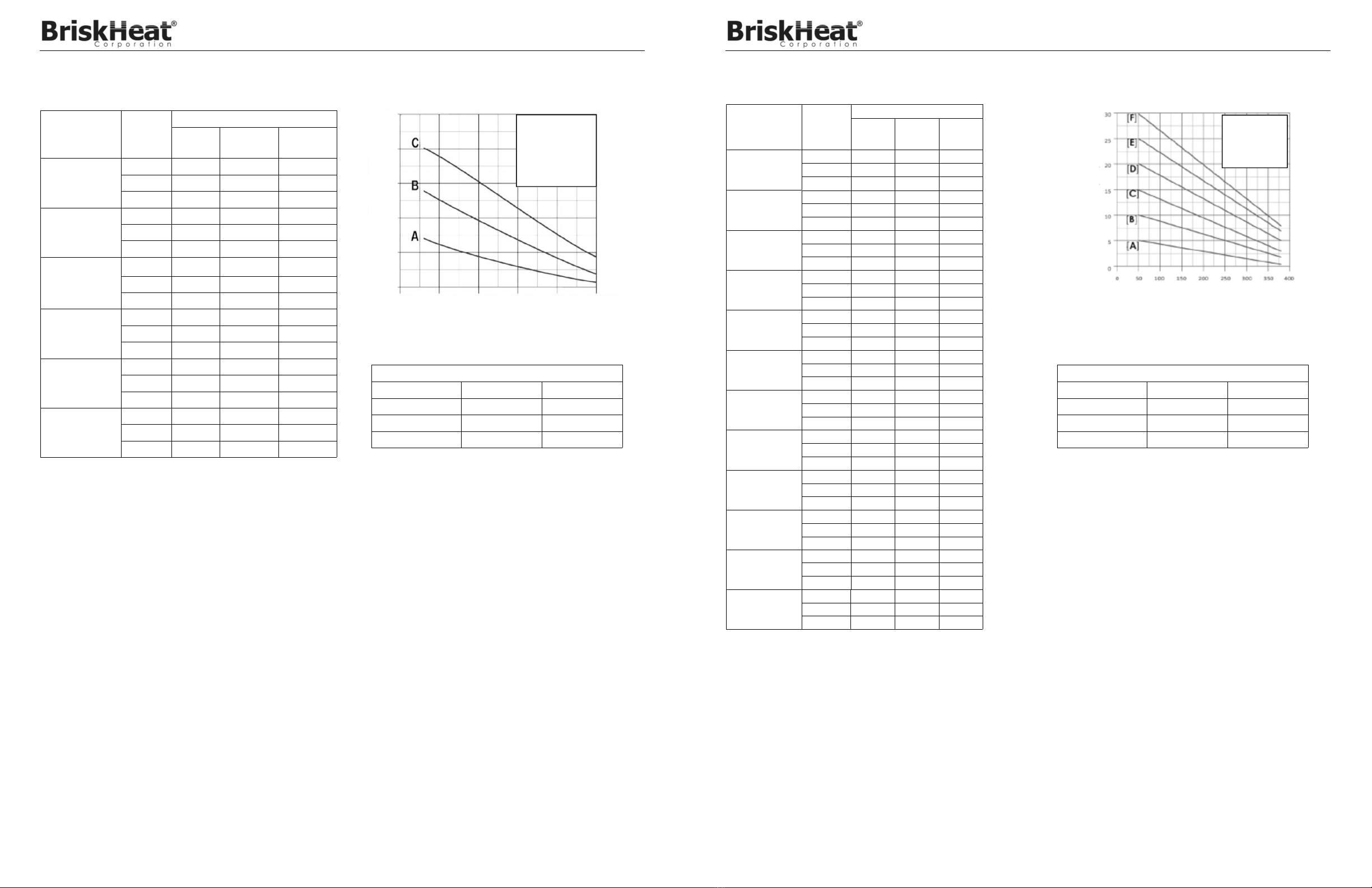

TECHNICAL PARAMETERS ............................................................................................................................................................................................. 5

GENERAL INFORMATION ................................................................................................................................................................................................ 6

How Heating Systems Work ......................................................................................................................................................................................... 6

PRODUCT SELECTION .................................................................................................................................................................................................... 6

RECEIPT & STORAGE ..................................................................................................................................................................................................... 6

Receipt .......................................................................................................................................................................................................................... 6

Storage .......................................................................................................................................................................................................................... 6

INSTALLATION ................................................................................................................................................................................................................. 6

Scheduling .................................................................................................................................................................................................................... 7

Pre-Installation Check ................................................................................................................................................................................................... 7

Heater Handling ............................................................................................................................................................................................................ 7

Heating Cable Location ................................................................................................................................................................................................. 7

Straight Tracing ............................................................................................................................................................................................................. 7

Spiraling ........................................................................................................................................................................................................................ 8

Attachment .................................................................................................................................................................................................................... 8

Cutting the Heating Cable ............................................................................................................................................................................................. 8

Installation Details ......................................................................................................................................................................................................... 8

SYSTEM COMPONENTS ............................................................................................................................................................................................... 11

System Component Compatibility .............................................................................................................................................................................. 12

SLCBL Connection / Termination Kits ....................................................................................................................................................................... 13

SLCBL, SLMCBL, SLHCBL Connection / Termination Kits ....................................................................................................................................... 14

FM APPROVED SLCAB connection / termination kit ................................................................................................................................................. 15

FM APPROVED SLMCAB connection / termination kit .............................................................................................................................................. 15

CSA APPROVED SLCAB AND SLMCAB connection / termination kit ....................................................................................................................... 16

THERMAL INSULATION ................................................................................................................................................................................................. 17

Pre-Installation Checks ............................................................................................................................................................................................... 17

Installation ................................................................................................................................................................................................................... 17

Marking ....................................................................................................................................................................................................................... 17

THERMOSTATS & SENSORS ........................................................................................................................................................................................ 17

ELECTRICAL REQUIREMENTS ..................................................................................................................................................................................... 17

Voltage Rating............................................................................................................................................................................................................. 17

Electrical Loading ........................................................................................................................................................................................................ 18

Ground Fault Protection .............................................................................................................................................................................................. 24

Waterproofing .............................................................................................................................................................................................................. 24

TESTING ......................................................................................................................................................................................................................... 24

Recommendations ...................................................................................................................................................................................................... 24

Procedure .................................................................................................................................................................................................................... 24

START-UP ....................................................................................................................................................................................................................... 27

Heat-up Time .............................................................................................................................................................................................................. 27

Diversity Factor ........................................................................................................................................................................................................... 27

OPERATION & MAINTENANCE ..................................................................................................................................................................................... 27

System Design, Installation & Documentation ............................................................................................................................................................ 27

Preventive Maintenance.............................................................................................................................................................................................. 27

Visual Inspections ....................................................................................................................................................................................................... 27

Frequency ................................................................................................................................................................................................................... 27

Personnel Training ...................................................................................................................................................................................................... 27

Maintenance ................................................................................................................................................................................................................ 27

Piping Repairs ............................................................................................................................................................................................................. 27

DAMAGED PRODUCTS .................................................................................................................................................................................................. 28

TROUBLESHOOTING GUIDE ........................................................................................................................................................................................ 28

WARRANTY INFORMATION .......................................................................................................................................................................................... 32