CAUTION

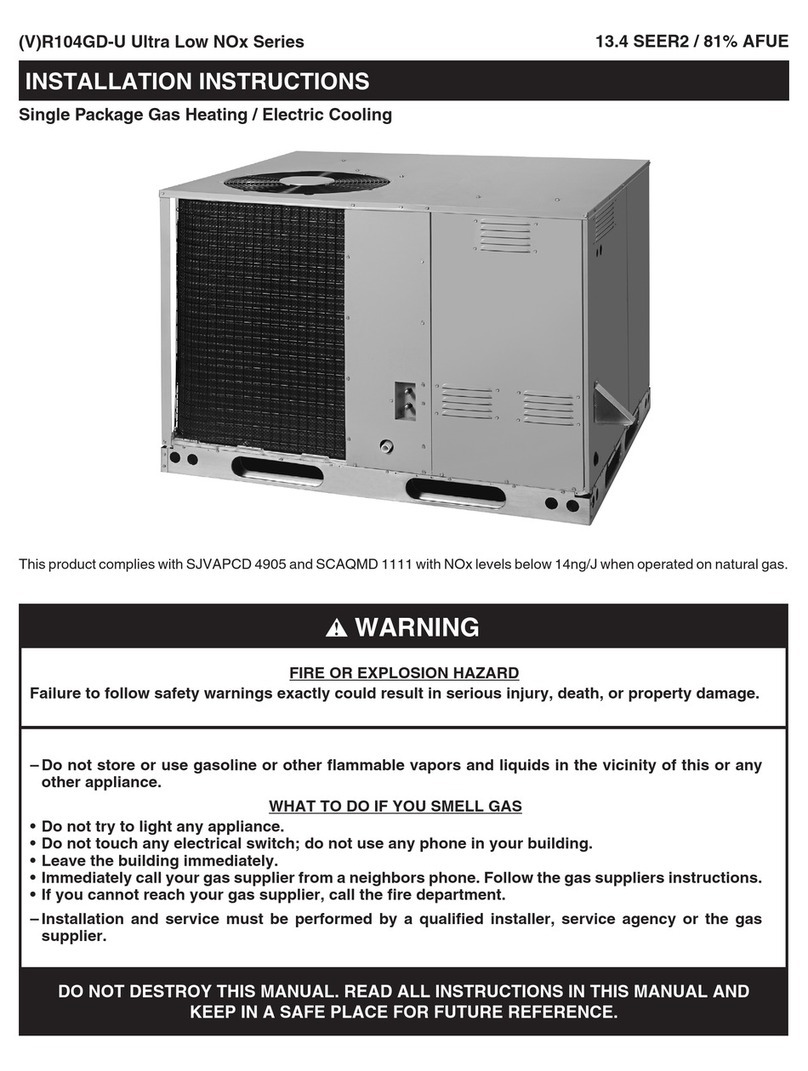

IMPORTANT –Read this manual before installation

2Warning

CAUTION

2

Always turn off electrical power and verify that the unit is

electrically safe before performing any maintenance on the unit.

This unit contains high-voltage electrical components.

This unit has moving parts. All repairs and maintenance should

be performed by a qualified technician to avoid serious injuries.

Always turn OFF electrical power and verify that the unit is

electrically safe before performing any maintenance on the

unit.

NO modifications shall be made to the unit under any

circumstances. WARRANTY will be immediately voided.

Do not use this device to EXHAUST steam, inflammable or

explosive gases.

Electrical connections shall be made by aQUALIFIED

electrician.

Airflows shall be as per the APPROVED SUBMITTAL in

order for the ventilation system to function properly and the

WARRANTY be honorred.

Installation shall be completed in CONFORMANCE with

LOCAL construction and safety codes.

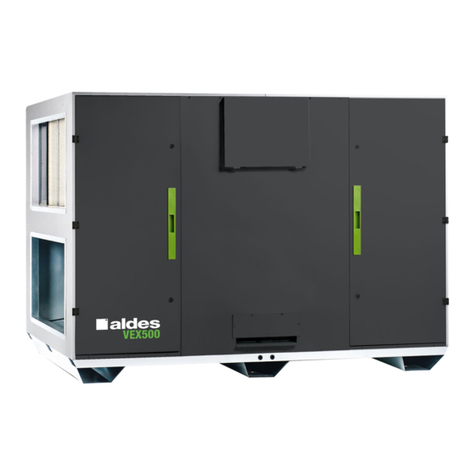

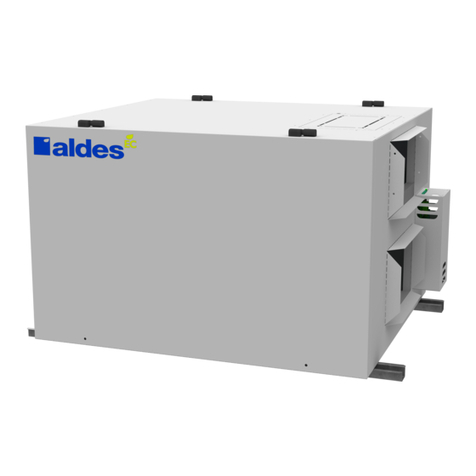

ALL drawings, photos and diagrams contained in this

document are for REFERENCE purposes only. Units may

differ.

ALDES reserves the RIGHT to MODIFY unit and its

components without prior warning.

Tel. CAN.: 1-800-262-0916 USA.:1-800-255-7749 www.aldes.com