8 | Page Rev4.1

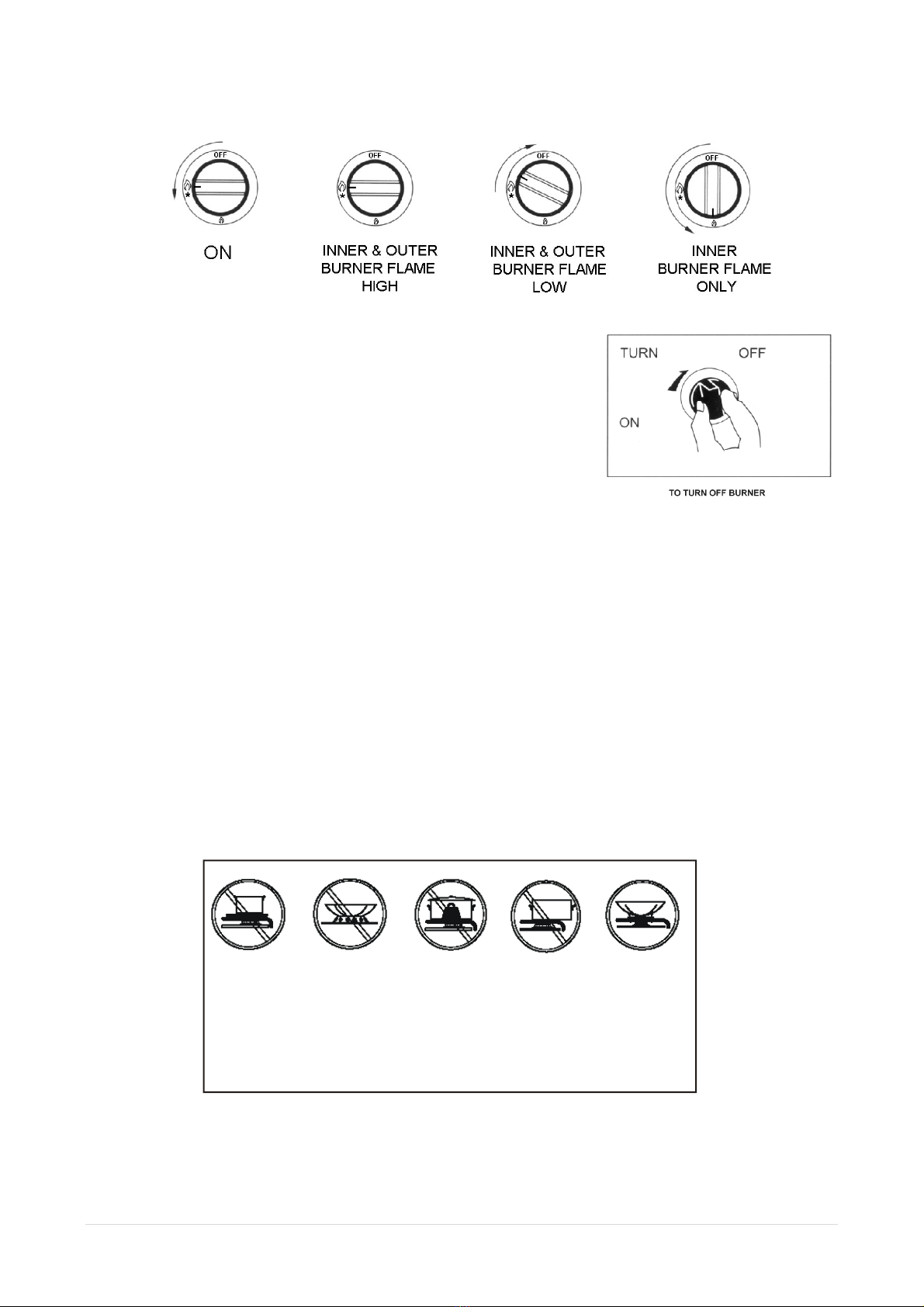

DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE.

MAINTENANCE.

DO NOT MODIFY THIS APPLIANCE.

Keep the appliance clean regularly by wiping with a damp cloth.

Before checking and maintaining the appliance, make sure the main gas valve is turned off.

Make sure the burner head(s) is/are clean before using the appliance. Use a steel wire brush to

clean the burner if it is heavily clogged. If the burner is heavily clogged, do not use the unit.

Contact Bromic Pty Ltd or an authorized agent for assistance to carry out service and

maintenance. Do not attempt to remove the burner unit(s) yourself.

Check the gas hoses regularly for wear or leaks. If any wear or leaks are presents, please

contact Bromic for replacement.

Do not touch the burner, trivet, tray etc. immediately after use or when in use. This could burn

your hand.

Clean the trivet and tray after each use. Always wipe off spills, do not leave spills to dry on the

surface of the trivet, tray or burner.

Wash the burner head and burner cap with a moist and soaped sponge or cloth. Do not put

them in cold water immediately after use as thermal shocks could cause cracking.

Always clean off any liquid as soon as it is spilt. This will prevent food remains from sticking to

the hob surface and you will save yourself any unnecessary effort. Do not leave acidic liquids (e.g.

lemon juice, vinegar, etc.) on the hob.

Due to the high temperatures endured, the wok burner and the stainless steel zones (grease drip

tray, burner outline, etc.) can change colour. This is normal. After each use, clean these areas with

a product that is suitable for stainless steel.

SERVICE INSTRUCTIONS FOR AUTHORISED PERSON such as LICENSED GAS FITTER OR

PLUMBER. DO NOT MODIFY THIS APPLAINCE.

Access to components under the hob. Ensure the appliance is cool before attempting any

service and the gas supply is turned off or disconnected.

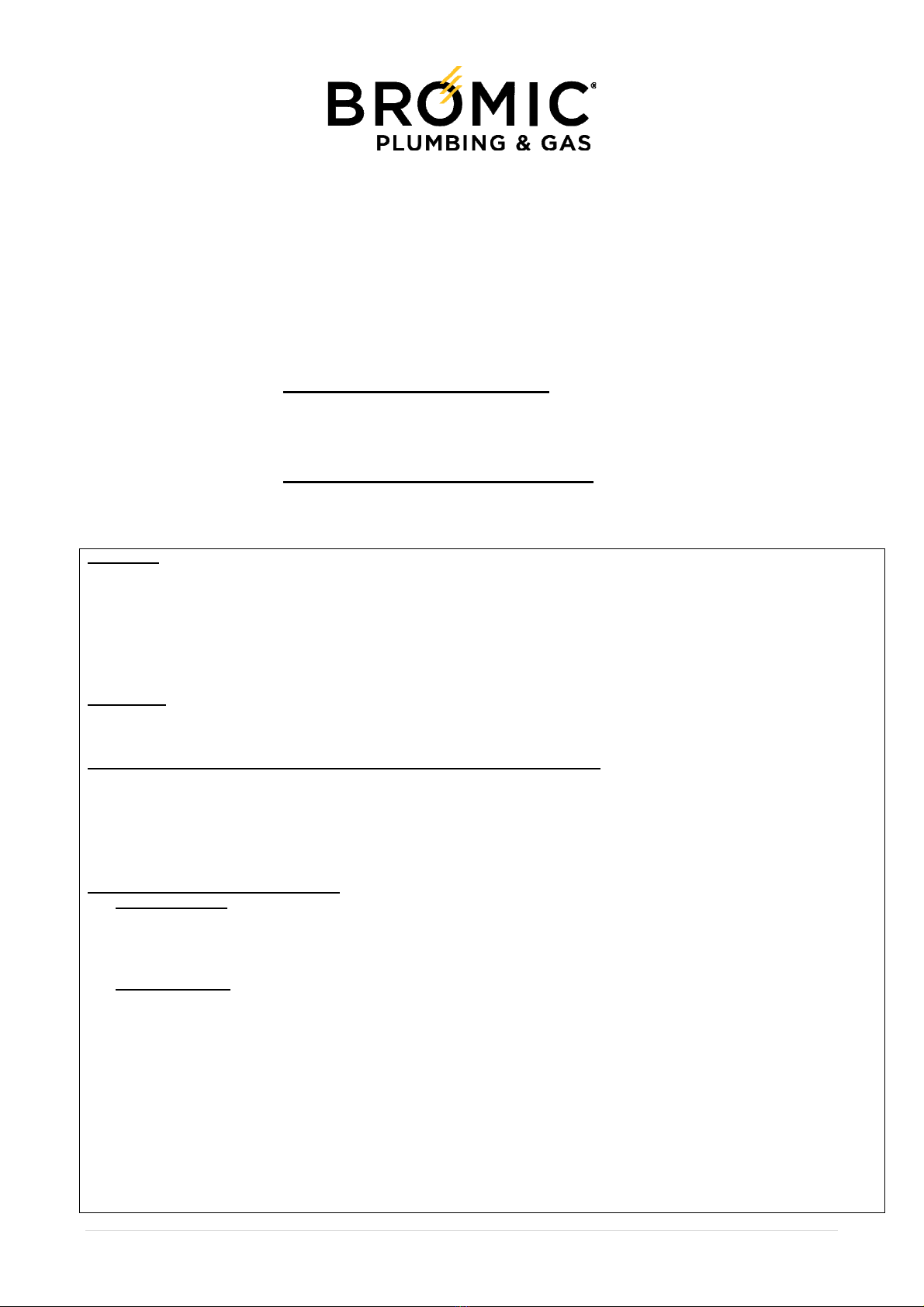

Disconnect regulator or hose from gas supply. Remove trivet/s, spillage bowls/s and burner

caps. Invert the appliance. The gas connection with regulator (NG) or hose (LP), gas manifold,

burner/s, gas valve/s, thermocouple/s and spark electrode/s are exposed for removal.

To remove the regulator (NG) or hose (LP) disconnect from gas inlet fitting. Replace in reverse

order.

To remove the burner – remove the spring clip retaining the underside of the burner head to

the burner mounting bracket. Drop the burner through the hole vacated by the spillage bowl.

The burner body and primary aeration shutters are accessible to cleaning or adjustment.

Replace in reverse order.

To remove the gas valve inclusive of outer/inner and pilot injector and electrode / electrode

bracket – remove the manifold (2 screws) connecting to the underside of the gas valve.

Remove the control knob and remove the disc (2 screws) securing the gas valve to the front

control fascia. The gas valve, injectors and electrode are accessible for replacement. The

injector outer and inner burner supply, are secured into the gas valve via 9.0mm hex flat. To

access the pilot injector remove the 2 screws securing the electrode bracket to the gas valve.

The pilot injector is secured to the gas valve via 6.0mm hex flat. To replace the electrode

disconnect the HT silicon lead and remove the 2 screws securing the electrode bracket to the

gas valve. Replace in reverse order.