7

1. STARTING UP

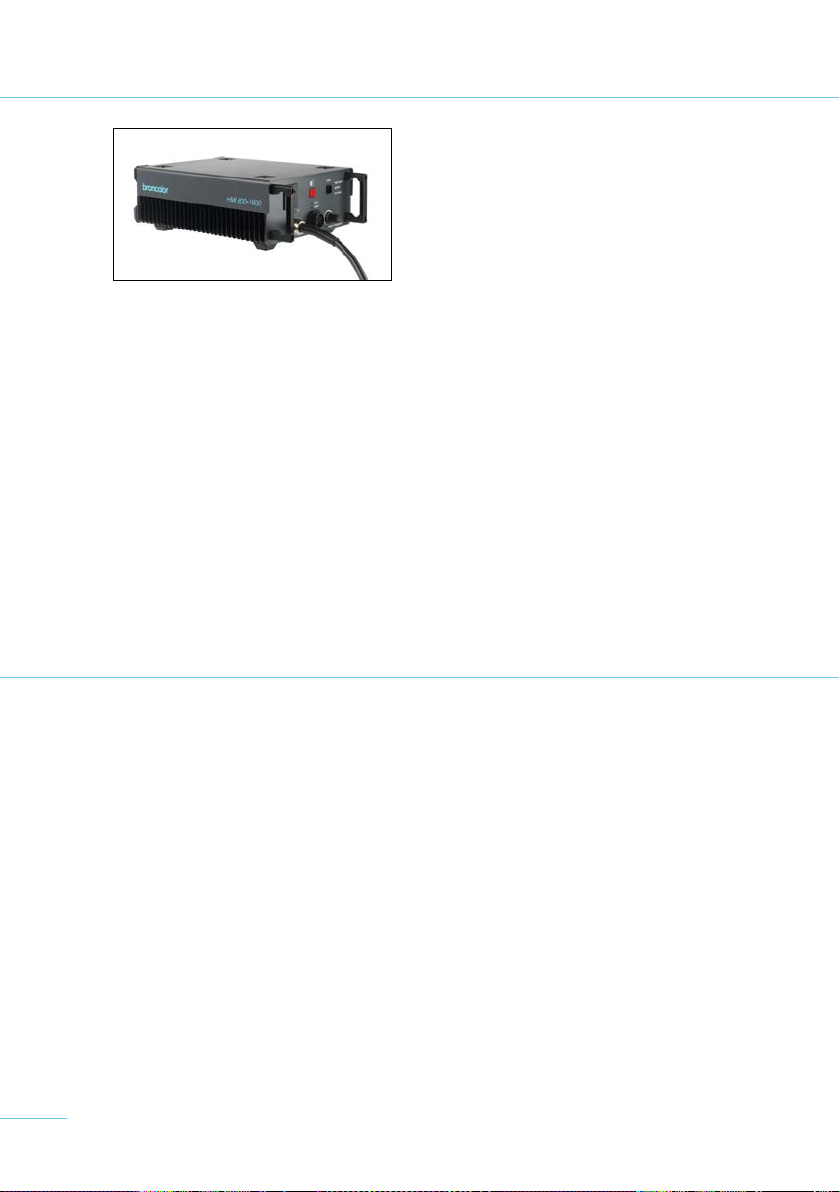

The ballast unit HMI 800.1600 is a flicker-free electronic ballast units which are made for mains

voltages from 90 V to 265 V. They adjust automatically to the mains (AC-line) voltage applied.

The unit is suitable for operation with hot-restrike (HR) lamps. This means that the lamp may be

switched on again at any time while hot, making waiting time unnecessary. For safety reasons,

the high ignition voltages required for this purpose call for a faultless earth conductor. For this

reason the unit must only be connected to a power supply with an earthed mains plug. Correct

functioning of the earth conductor is indicated by the control lamp (3).

Step 1

Fit a compatible bulb to the lamp (see Section 2: Fitting or changing a bulb) and a reflector, an

adapter for a Softbox or Para (see Section 3: Mounting and removing reflectors and adapters). The

lamp is equipped with an integral safety switch (17), and can only be operated when a reflector or

an adapter is mounted. When it is used with an adapter, the focusing wheel (11) must be turned

to the “Bare Bulb” position (bulb as far forwards as it will go) so that the safety switch is actuated

and the bulb can be fired.

Step 2

Connect the lamp to the ballast unit, and the ballast unit to the earthed mains supply. Switch on

the main switch (2) and check whether the earth control LED (3) illuminates. If this is not the case,

for safety reasons disconnect the ballast unit immediately from the mains and check the earth

conductor.

Step 3

Operate switch (9) on the lamp and press button (4) on the ballast unit. The bulb fires and starts

operating. By operating the switch (9) on the lamp or on the ballast unit (4), the light can be

switched off again.

The ballast unit has an automatic warming-up circuit, which heats the bulb quickly to its operating

temperature. Except in an emergency avoid switching off the unit during the warming-up phase,

because this shortens the life of the bulb. The optimum colour temperature is reached after about

one minute.

Should the bulb fail to trigger, the ballast unit will switch off the ignition sequence after 2 seconds,

and button (4) on the ballast unit blinks (see Section 7). To make another attempt to start, press

the button (4) on the ballast unit or (9) on the lamp. To protect the igniter circuit, this is blocked

for 30 seconds after about ten attempts at ignition. Afterwards further ignition attempts are pos-

sible. Take care that the ventilation slots are not obstructed on either the ballast unit or the lamp.

Step 4

The output regulator (8) on the ballast unit can be used to set the desired light output (setting

range 50 % –100 %). When setting the output, it is important to remember that, depending on the

bulb used, the colour temperature can change slightly with the output. When the bulb is switched

on, the output is automatically set to the maximum so that the bulb heats up as quickly as pos-

sible. The duration of this depends on the bulb temperature when it is switched on, and is likely

to be between 5 and 60 seconds. At the end of this period, the unit adjusts automatically to the

setting of regulator (8).