6

Step 5: Electrical ConnectionsStep 5: Electrical Connections

Step 5: Electrical ConnectionsStep 5: Electrical Connections

Step 5: Electrical Connections

After the flow controller has been installed in the system it is ready for

operation.

Controller: You must provide a setpoint/command signal to the controller.

The controller will read the setpoint signal and will automatically adjust the

valve to the appropriate position to achieve the desired flow and will provide

a flow signal proportional to the full scale flow of the device as indicated on

the device label.

Step 6: OperationStep 6: Operation

Step 6: OperationStep 6: Operation

Step 6: Operation

5

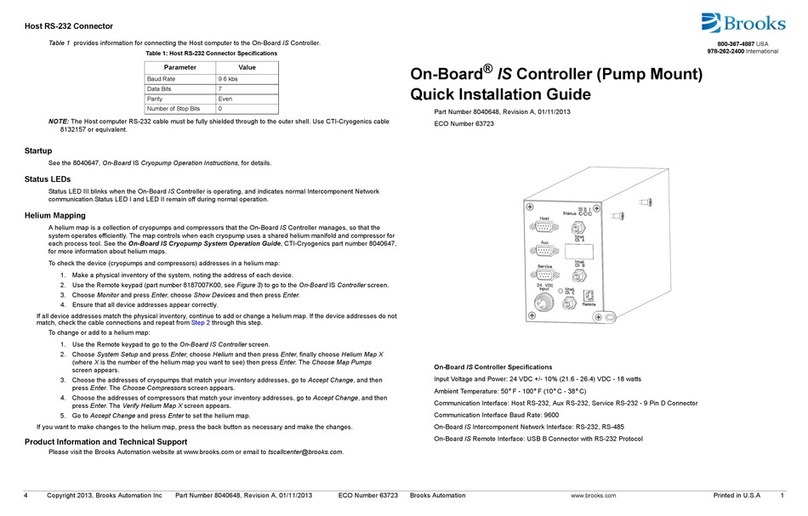

To insure proper operation, the Model 585xEMH must be connected per Figure 5.

As a minimum, the following connections must be made:

Voltage I/O VersionVoltage I/O Version

Voltage I/O VersionVoltage I/O Version

Voltage I/O Version

• Chassis Ground (Pin 14)

• Signal Common (Pin 10)

• Signal Output (Pin 2)

• +15 Vdc Supply (Pin 5)

• -15 Vdc Supply (Pin 6)

Each device is factory adjusted to provide a flow signal of zero volts (±10 mVdc)

at zero flow. The adjustment is made in our calibration laboratory which is

temperature controlled to the temperature specified at the time of order. After

initial installation and warm-up in the gas system, the zero flow indication may

be other than the factory setting. This is primarily caused by changes in

temperature between our calibration laboratory and the final installation. The

zero flow reading can also be affected, to a small degree, by changes in line

pressure and mounting attitude.

To check zero, always mount the controller in its final configuration and apply

power to the instrument and any associated heaters for 60 minutes to reach a

stable thermal condition prior to applying flow. Flow the process fluid into the

instrument and allow sufficient time for the sensor to reach normal operating

temperature.

Note: Before zeroing the instrument, zero pressure differential MUST be

established across the device. If there is pressure across the instrument during the

zero process, any detected flow through the sensor will be misinterpreted as the

zero flow reading. This will result in calibration inaccuracy during normal

operation.

Close the shutoff valve downstream of this instrument to eliminate any pressure

differential across the instrument. Once zero differential pressure is established

and verified, check the flow output signal using a suitable voltmeter. If it differs

from the factory setting, adjust it by removing the lower pot hole plug (refer to

Figure 4) which is located closest to the 7-pin circular connector on the remote

electronics module. Adjust the zero potentiometer until the desired output signal

is within +/- 10 mV of zero on the output of the device.

15 Pin D-Connector15 Pin D-Connector

15 Pin D-Connector15 Pin D-Connector

15 Pin D-Connector

The remote electronics box can be mounted in any position that is convenient and within reach of the high temperature cable. The temperature limit of the

electronics is 0-50°C (32°F -122°F).

Connect the remote electronics box with the controller utilizing the 15-pin D sub connector on the end of the cable which is wired to the remote electronics box.

Step 4: Remote Electronics BoxStep 4: Remote Electronics Box

Step 4: Remote Electronics BoxStep 4: Remote Electronics Box

Step 4: Remote Electronics Box

Receipt of EquipmenReceipt of Equipmen

Receipt of EquipmenReceipt of Equipmen

Receipt of Equipmentt

tt

t

If the packing case is damaged, the local carrier should be notified at once

regarding their liability. Carefully remove the equipment from the packing

case and inspect for damage or missing parts. If damaged, please contact

Brooks Instrument at one of the locations listed on the back of this Quick

Start Guide.

Return ShipmenReturn Shipmen

Return ShipmenReturn Shipmen

Return Shipmentt

tt

t

Please note that prior to returning any instrument to the factory Brooks

Instrument requires the completion of Form RPR003-1, a Brooks Instrument

Decontamination Statement, as well as a Materials Safety Data Sheet (MSDS)

for fluid(s) used in the instrument. Copies of these forms can be found

online at

BrBr

BrBr

BrooksInstrumenooksInstrumen

ooksInstrumenooksInstrumen

ooksInstrument/Returns.comt/Returns.com

t/Returns.comt/Returns.com

t/Returns.com along with complete details on

how to process your return shipment or you can contact your nearest Brooks

location for the necessary forms and instruction.

EquipmenEquipmen

EquipmenEquipmen

Equipment Receipt and Return Prt Receipt and Return Pr

t Receipt and Return Prt Receipt and Return Pr

t Receipt and Return Procedurocedur

ocedurocedur

ocedureses

eses

es

4

Pin Function

1 Command Common

2 0-5 Volt, Signal Output

3 Not Used

4 Not Used

5 +15 Vdc Supply

6 -15 Vdc Supply

7 Valve Voltage Out

8 Command Input

9 Supply Voltage Common

10 0-5 Volt Signal Common

11 +5 Vdc Reference Output

12 Valve Override

13 Not Used

14 Chassis Ground

15 Not Used

5