4 Copyright 2013, Brooks Automation Inc Part Number 8040648, Revision A, 01/11/2013 ECO Number 63723 Brooks Automation www.brooks.com Printed in U.S.A 1

800-367-4887 USA

978-262-2400 International

Host RS-232 Connector

Table 1 provides information for connecting the Host computer to the On-Board IS Controller.

Table 1: Host RS-232 Connector Specifications

Parameter Value

Baud Rate 9.6 kbs

Data Bits 7

Parity Even

Number of Stop Bits 0

NOTE: The Host computer RS-232 cable must be fully shielded through to the outer shell. Use CTI-Cryogenics cable

8132157 or equivalent.

Startup

See the 8040647, On-Board IS Cryopump Operation Instructions, for details.

Status LEDs

Status LED III blinks when the On-Board IS Controller is operating, and indicates normal Intercomponent Network

communication.Status LED I and LED II remain off during normal operation.

Helium Mapping

A helium map is a collection of cryopumps and compressors that the On-Board IS Controller manages, so that the

system operates efficiently. The map controls when each cryopump uses a shared helium manifold and compressor for

each process tool. See the On-Board IS Cryopump System Operation Guide, CTI-Cryogenics part number 8040647,

for more information about helium maps.

To check the device (cryopumps and compressors) addresses in a helium map:

1. Make a physical inventory of the system, noting the address of each device.

2. Use the Remote keypad (part number 8187007K00, see Figure 3) to go to the On-Board IS Controller screen.

3. Choose Monitor and press Enter, choose Show Devices and then press Enter.

4. Ensure that all device addresses appear correctly.

If all device addresses match the physical inventory, continue to add or change a helium map. If the device addresses do not

match, check the cable connections and repeat from Step 2 through this step.

To change or add to a helium map:

1. Use the Remote keypad to go to the On-Board IS Controller screen.

2. Choose System Setup and press Enter, choose Helium and then press Enter, finally choose Helium Map X

(where Xis the number of the helium map you want to see) then press Enter. The Choose Map Pumps

screen appears.

3. Choose the addresses of cryopumps that match your inventory addresses, go to Accept Change, and then

press Enter.The Choose Compressors screen appears.

4. Choose the addresses of compressors that match your inventory addresses, go to Accept Change, and then

press Enter.The Verify Helium Map X screen appears.

5. Go to Accept Change and press Enter to set the helium map.

If you want to make changes to the helium map, press the back button as necessary and make the changes.

Product Information and Technical Support

Please

visit

the

Brooks

Automation

we

bsite at www.brooks.com or email to [email protected].On-Board®IS Controller (Pump Mount)

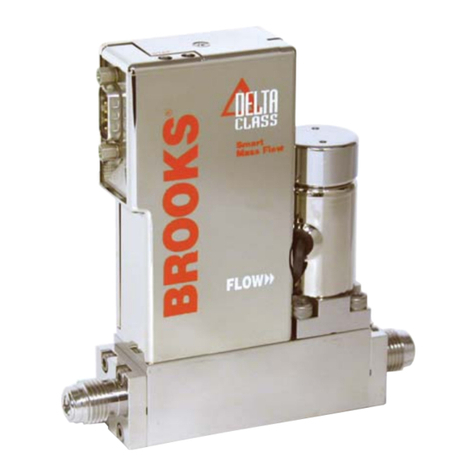

Quick Installation Guide

Part Number 8040648, Revision A, 01/11/2013

ECO Number 63723

On-Board IS Controller Specifications

Input Voltage and Power: 24 VDC +/- 10% (21.6 - 26.4) VDC - 18 watts

Ambient Temperature: 50º F - 100º F (10º C - 38º C)

Communication Interface: Host RS-232, Aux RS-232, Service RS-232 - 9 Pin D Connector

Communication Interface Baud Rate: 9600

On-Board IS Intercomponent Network Interface: RS-232, RS-485

On-Board IS Remote Interface: USB B Connector with RS-232 Protocol