Hanyoung TPR-2N User manual

110 V a.c, 220 V a.c, 380 V a.c, 480 V a.c

50 , 60 (common)

50 A, 70 A

Resistance load / inductive load (Select by conversion switch)

Resistance load / inductive load (Select by internal parameter)

4 - 20 mA d.c

1 - 5 V a.c, 0 - 10 V a.c, 0 - 5 V d.c (FND)

ON/OFF

External volume (10 k

Phase control, Cycle control, ON/OFF control (switch selection)

Phase control, Cycle control, ON/OFF control (parameter selection)

SOFT START / DOWN

Above 95 % of input voltage (when applying max current input)

50 A(Natural cooling), 70 A (Forced cooling)

Indicate the output by LED

Indicate the voltage and state by 7 segments

Min. 100 (500 V d.c Mega standard)

0 ~ 100 %

2000 V a.c at 50/60 for 1 minute

Noise by noise simulator ( 2 )

0 ~ 50 (with no freezing), 30 ~ 85 % R.H.

-25 ~ 70

Approximately 2 kg

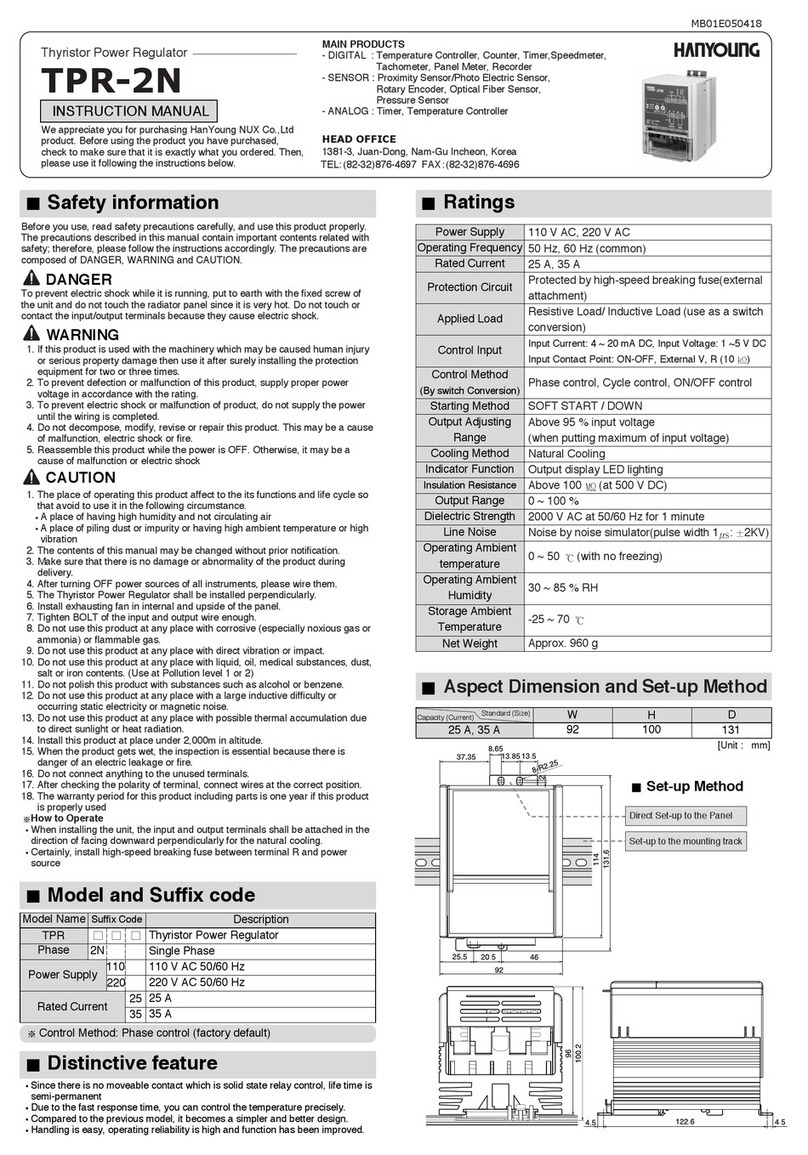

Dimension and Set-up Method

Before you use, read safety precautions carefully, and use this product properly.

The precautions described in this manual contain important contents related with

safety; therefore, please follow the instructions accordingly. The precautions are

composed of DANGER, WARNING and CAUTION.

To prevent electric shock while it is running, put to earth with the fixed screw of

the unit and do not touch the radiator panel since it is very hot. Do not touch or

contact the input/output terminals because they cause electric shock.

1. If this product is used with the machinery which may be caused human injury

or serious property damage then use it after surely installing the protection

equipment for two or three times.

2. To prevent defection or malfunction of this product, supply proper power

voltage in accordance with the rating.

3. To prevent electric shock or malfunction of product, do not supply the power

until the wiring is completed.

4. Do not decompose, modify, revise or repair this product. This may be a cause

of malfunction, electric shock or fire.

5. Reassemble this product while the power is OFF. Otherwise, it may be a

cause of malfunction or electric shock

1. The place of operating this product affect to the its functions and life cycle so

that avoid to use it in the following circumstance.

A place of having high humidity and not circulating air

A place of piling dust or impurity or having high ambient temperature or high

vibration

2. The contents of this manual may be changed without prior notification.

3. Make sure that there is no damage or abnormality of the product during

delivery.

4. After turning OFF power sources of all instruments, please wire them.

5. The Thyristor Power Regulator shall be installed perpendicularly.

6. Install exhausting fan in internal and upside of the panel.

7. Tighten BOLT of the input and output wire enough.

8. Do not use this product at any place with corrosive (especially noxious gas or

ammonia) or flammable gas.

9. Do not use this product at any place with direct vibration or impact.

10. Do not use this product at any place with liquid, oil, medical substances, dust,

salt or iron contents. (Use at Pollution level 1 or 2)

11. Do not polish this product with substances such as alcohol or benzene.

12. Do not use this product at any place with a large inductive difficulty or

occurring static electricity or magnetic noise.

13. Do not use this product at any place with possible thermal accumulation due

to direct sunlight or heat radiation.

14. Install this product at place under 2,000m in altitude.

15. When the product gets wet, the inspection is essential because there is

danger of an electric leakage or fire.

16. Do not connect anything to the unused terminals.

17. After checking the polarity of terminal, connect wires at the correct position.

18. The warranty period for this product including parts is one year if this product

is properly used

Safety information

WARNING

CAUTION

DANGER

Power Supply

Operating Frequency

Rated Current

Starting method

Output adjusting range

Cooling method

Insulation Resistance

Output adjusting range

Dielectric Strength

Line noise

Operating ambient

temperature/humidity

Storage temperature

Weight

Ratings

1381-3, Juan-Dong, Nam-Gu Incheon, Korea

TEL:(82-32)876-4697 FAX:(82-32)876-4696

Model and Suffix code

Power regulator (regular type)

Power regulator (FND indication type)

Single phase ABS COVER

110 V a.c 50/60

220 V a.c 50/60

330 V a.c 50/60

440 V a.c 50/60

50 A

70 A

None

Communication function (RS485/422)

Model

Suffix Code

Information

TPR

TPRF 2N

110

220

330

440 50

70 N

1

Type

Phase

Power Supply

Rated Current

Option (Only applicable to

FND indication type)

Capacity H

WD

50 A, 70 A

Standard 194.7115.2 131

MB0103E090120

HEAD

OFFICE

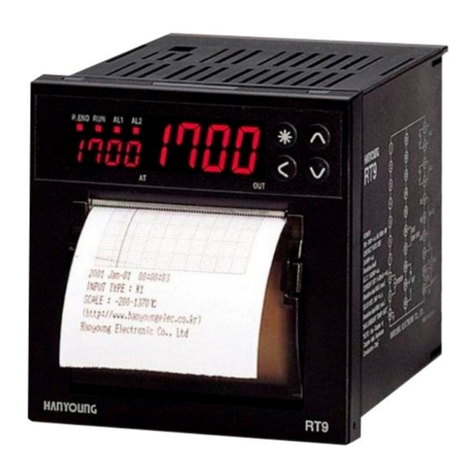

Thyristor Power Regulator

TPR-2N (50/ 70A)

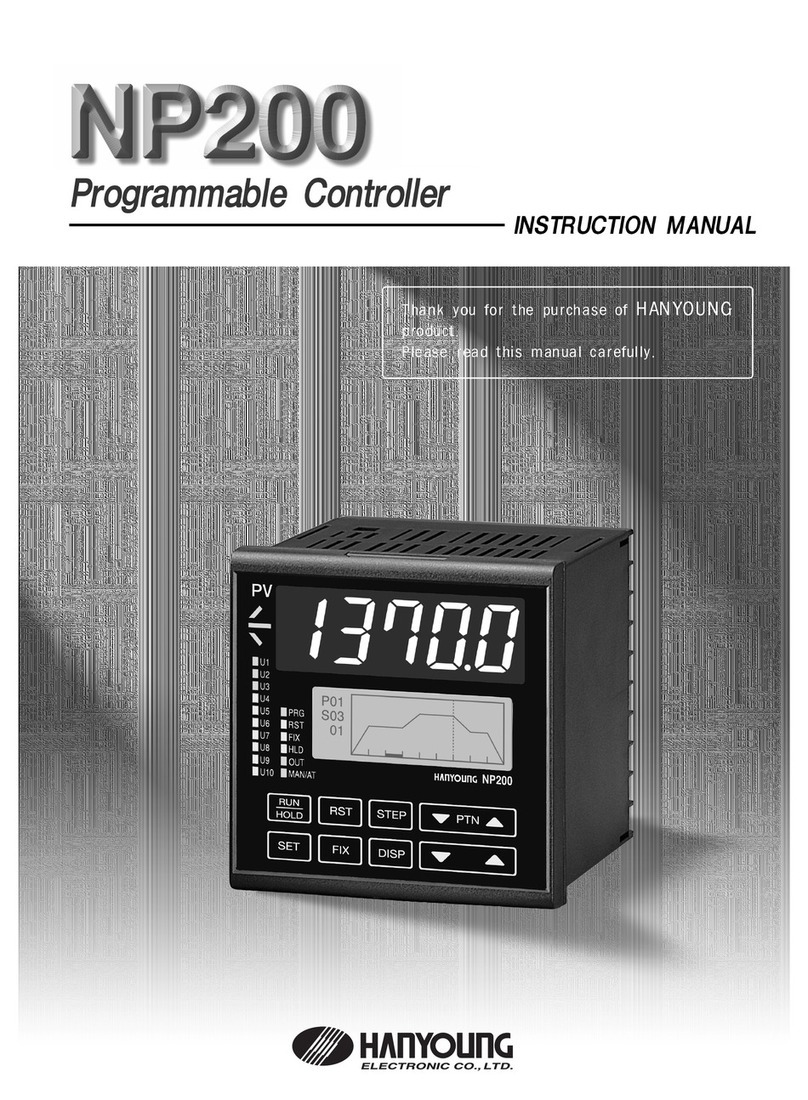

Thank you for purchasing HANYOUNG NUX Co.,Ltd. product.

Please check whether the product you purchased is the exactly

same as you ordered. Before using this product, please read

instruction manual carefully.

INSTRUCTION MANUAL

Rated Load

Control

method

Indicating

method

Control

input

Regular type

FND type

Regular type

FND type

Regular type

FND type

Current input

Voltage input

Contact input

External V.R

Connection Diagram Name of each parts

Regular type

Terminal arrangement (regular type / FND type) Regular type

Function explanation

FND type

Input signal terminal connection diagram

(Regular type / FND type)

4 - 20 mA d.c (Regular type / FND type)

1- 5 V d.c / 0 -10 V d.c (Regular type / FND type)

ON/OFF terminal connection diagram (Regular type / FND type)

REMOTE input terminal connection diagram (regular type / FND type)

DIP S/W explanation

Volume explanation

0 - 10 V regular type : Make to order

Please refer to the function explanation of FND TYPE for FND indicating screen

Set internal jump to 1- 5 V with regular type when doing ON / OFF (Initial mode)

S/W

NO.

1

2

3

4

5

Explanation

ON OFF

ON OFF

RESISTOR

PHASE

LOCAL( Use InsideVR)

4 - 20

Inductance

CYCLE

REMOTE (Use external VR)

1 - 5 V (ON/OFF), 0 - 10 V

REMOTE (External VR ONLY)

PW.Max : Change output value within

0 ~ 100 %

O.C: Set over current alarm value

SOFT/ START: Set soft start time

LED explanation

SOFT-START

Overheat alarm (O.T)

Over current alarm (O.C)

Load disconnection alarm (LL)

Display state of output quantity (FIRE)

Function description

Output voltage limitation (PW. Max.)

Cycle control (ZERO CLOSING CONTROL : DIP S/W2 : OFF)

Phase control (PHASE DIP S/W2 : ON)

ON/OFF control (Contact control DIP S/W4 : OFF)

Symbol

RUN

SOFT

O.T

O.C

LL

FIRE

Lighted when power supplied

Lighted when soft start operated

Lighted when heat sink overheated

Lighted when over current occurred

Lighted when load disconnection detected

Lighted when output become ON

RUN / STOP

With regular type, all functions temporarily stop and RUN LAMP is lighted

With FND type, all functions temporarily stop and it is in communication standby state.

When using induction load and etc within capacitive load, turning ON the power switch will

supply maximum electric power to the load and this may destroy power device and damage

the load. This function prevents above malfunction to happen by making load voltage to

increase gradually.

Set time : 0 ~ 50 Second

Initial value : 0 Second

Soft-Start will not operate if soft-start volume is set as the minimum.

It does not operate within the cycle control

It is unnecessary within the ON / OFF control mode

Cycle Control method is a method of making a loaded power as proportionally

repeated ON/OFF cycle by a signal of input control in a fixed cycle. The

proportionally repeated ON/OFF cycle makes the power applied to the load be

regularly. This method is better than Phase Control since this control method

makes the loaded power be ON/OFF at the zero point of AC when it is ON/OFF so

that there is almost no noise occurrence and it is better for the linearity compared

to the Phase Control.

In Cycle Control, SOFT START function is not operating.

AC power source has 50/60 frequency and 1/2 cycle of 60 frequency appears

a value of 0 ~180 degree in about 8.33 . Phase Control is a method that after

inputting 1/2 cycle into AC power source, it proportionally generates power

between 0 ~ 180 degree in 8.33 according to the control signal. Also, this

method can be fully adjusted according to the wave form of AC so that AC motors

and other variety of electronic devices are controlled easily.

ON/OFF Control is automatically set by the wiring terminal. (Refer to the wiring

diagram of the input signal terminal.) Not by receiving the input voltage and input

current, this method controls the output voltage by receiving contact point signal

of relay and others.

Inductance input (DIP S/W1 : OFF)

This is a mode that is used when load contains a lot of inductance components such as

coil. Max output value is limited to 50 %.

Operation Example]

Indicate LED

FI : Proportional lighting depending on an amount of output

PR : ON when phase angle resistance load selected

PL : ON when phase angle induced load selected

CR : ON when CYCLE control selected

SF : ON when SOFT START is set

AL : ON when OC, OT alarm operated

OC : ON when yield the over current output

AO : ON when automatically operated

If temperature of heat sink goes over 90 degree Celsius, then it will be lighted and alarm

output will become ON.

Setting range: 0 ~ 90

Initial value: Set maximum value

When value goes over the set value, then over current LED will be lighted immediately.

Also, staying in this condition for more than 0.5 second will output the alarm.

Setting range: 0 ~ max used current value

Initial value: Set maximum value

Only possible to use with phase control. Irms standard 1 digit err less than 3 A

Load disconnection detection: When output value is more than the set value and if the

load current is less than 1A, alarm will be. Only applicable in phase control.

Setting range: 0 ~ 100 %

Initial value: 100 %

This is a function that limits output voltage when using input signal (Ma,V) or external

volume (10 k ). 0 % of output will be yield if volume is set to the min, 50 % of output will be

yield if volume is set to middle of the min and max. And 100 % of output will be yield if volume is

set to the max.

Initial setting is max.

It is unnecessary within ON / OFF control mode.

LED will be lighted when output become ON and it will be lighted proportionally depending

on output quantity.

Information

FND type

Option (communication)

Just like MODE Fg-2, it enters into correction mode and save the data (please refer to

2.PARAMETER EDIT MODE)

SEL : Pressing this key more than 2 sec will enter into the manual mode and, adjust an

amount of output by UP / DOWN key (ignore input signal)

Pressing key for more than 2 sec will save the data and will return to the auto- mode.

RESET: During operation, system will be temporarily stopped when alarm is operated.

RESET key restores the system

OC OFFSET: Adjust when current indicating value is not accurate. (Initial VR = middle)

Only possible to use in the phase control Irms standard Less than 1 digit err 3 A

impossible to measure/compensate

RS232C / RS485 communication PARAMETER and PROTOCOL

DATA FORMAT(ASC CODE)

SET transmit and SLAVE response from HOST COMPUTER: 14 BYTE FORMAT

STX - ID - ‘S’ - lists - sign - DATA(10^3) - DTA(10^2) - DATA(10^1)

---1-----3-----1------1--------1-----------1----------------------1--------------------1---------

DTA(10^0) - BCC - ETX

----------1--------------2-------1----

STX - ID - ‘R’ - lists - BCC - ETX

--1-----3-----1-------1-------2--------1--

1. ID (Instrument number)

‘ 0 ’ ~ ‘9’ ASC

CODE 3- Byte (0 ~ 255)

2. SET / READ

‘S’ :

set ( C , E , H , M , N , P , R , S , s , L , V , W , X , Y , Z )

‘R’ : read ( A , C , E , F , I , M , N , O , P , S , s , T , t , L , V , W X , Y , Z )

3. List

‘A’ :

Alarm type (R)0 : NO ERR, 1 : OC, 2 : OT, 4 : LL

‘C’ :

Input mode (R/S)

0 : 4 - 20 1 - 5 V, 3 : 0 - 10, 4 : VOL 5 : onoff, 6 : 4 - 20

7 : 1 - 5 V , 8 : 0 - 5 V, 9 : 0 - 10 V 10 : onoff

0 - 5 : The output limit by slope setting

6 - 10 : The output limit by external volume

E: Elevation (R/S) -100 ~ +100 %

F: Operation frequency 60 or 50

H: STOP setting 1

I: Input value % (R) 0 ~ 100 %

L: Load type 0 : Resistance load 1 : Induction load

M: Operation mode 0 : Phase angle control 1 : Cycle control

N: Communication instrument number

O: Output value %

P: Power set value

R: Run

S: Soft start time 0 ~ 50 Sec

s: Soft up/down time 0 ~ 12 Sec

T: Operation mode ---> 0 : Run 1 : STOP

sign = ‘ ’ : MINUS, ‘+’ : PLUS

DATA = ‘0’ ~ ‘9’

Explanation

OFF : UNLOCK , Loc1 : ALL LOCK, Loc2 : LOCK all modes except manual mode

Just like Fig-2, among 4 - 20 , 1- 5 V, 0 - 5 V, 0 - 10 V, external VR (VOL) and ON/OFF input, only one of

them gets to selected. And input selection with POINT always yield output / limit in external VR.

PA-R: phase angle control resistance load MOT: phase angle control induction load CYC1: cycle control time

proportion (100 period fixed method) CYC2: cycle control (period proportion-high speed response)

When input SIGNAL is greater than GRDF, output always become GRDF set value.

Amount of output = compensate amount of ELEF / 50 x input SIGNAL output.

Time of input SIGNAL and the amount of output become same (Start to count right after power ON)

Time of when amount of input changed become same as output during operation.

OC set value < current amount of output, then alarm operates

OC set value < OT indicating value, then alarm operates

When yielding output more than the set value and if current is less than 1 A, then ALARM LED will be lighted (With phase angle control)

Output limit / Input limit, OLIM: Yield the output as input SIGNAL is dissolved from output limit GRDF set value

Set the standard display state when turning ON the power

ID : 0 ~ 255

24 ~ 1 Mbps

Err - OC = Over current, Err - T = heat sink over heated, Err - LL = load disconnection

Initial value

Information

Lock function

Input setting

Operation mode setting

Output limit setting(0 ~ 100%)

Output OFFSET compensation

-100 ~ GRDF %

SOFT START (0 ~ 250 s)

SOFT up / down(0 ~ 25 s)

Over current alarm setting

Heat sink over heat alarm setting

Load disconnection alarm

Output limit / input limit

Display mode setting

Communication instrument number setting

Communication speed setting

Error Massage

Parameter symbol

LOCK Mode

1 SEL

OPRT

GRDF

ELEF

SST

SUD

OC

OT

LL

LIMIT

DISP

ID

BOUD

The others

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

OFF

4 - 20

PA - R

100

0

30

5

0

0

0

OLIM

INP

0

96

Other Hanyoung Controllers manuals