Technical Manual

FT420 –Iss 2.4

6

Figure33 FT420 System Configuration Options............................................................................................63

Figure34 Supervised Relay Outputs.............................................................................................................64

Figure 35 Dry contact relay outputs...............................................................................................................65

Figure36 Alertcom Tone ConfigurableOutputs............................................................................................65

Figure37 ZoneConfiguration Options...........................................................................................................67

Figure 38 Power Supply Trimpot Location....................................................................................................70

Figure39 FT420 withAll Options...................................................................................................................76

Figure40 FT420 withGas KitInterface.........................................................................................................77

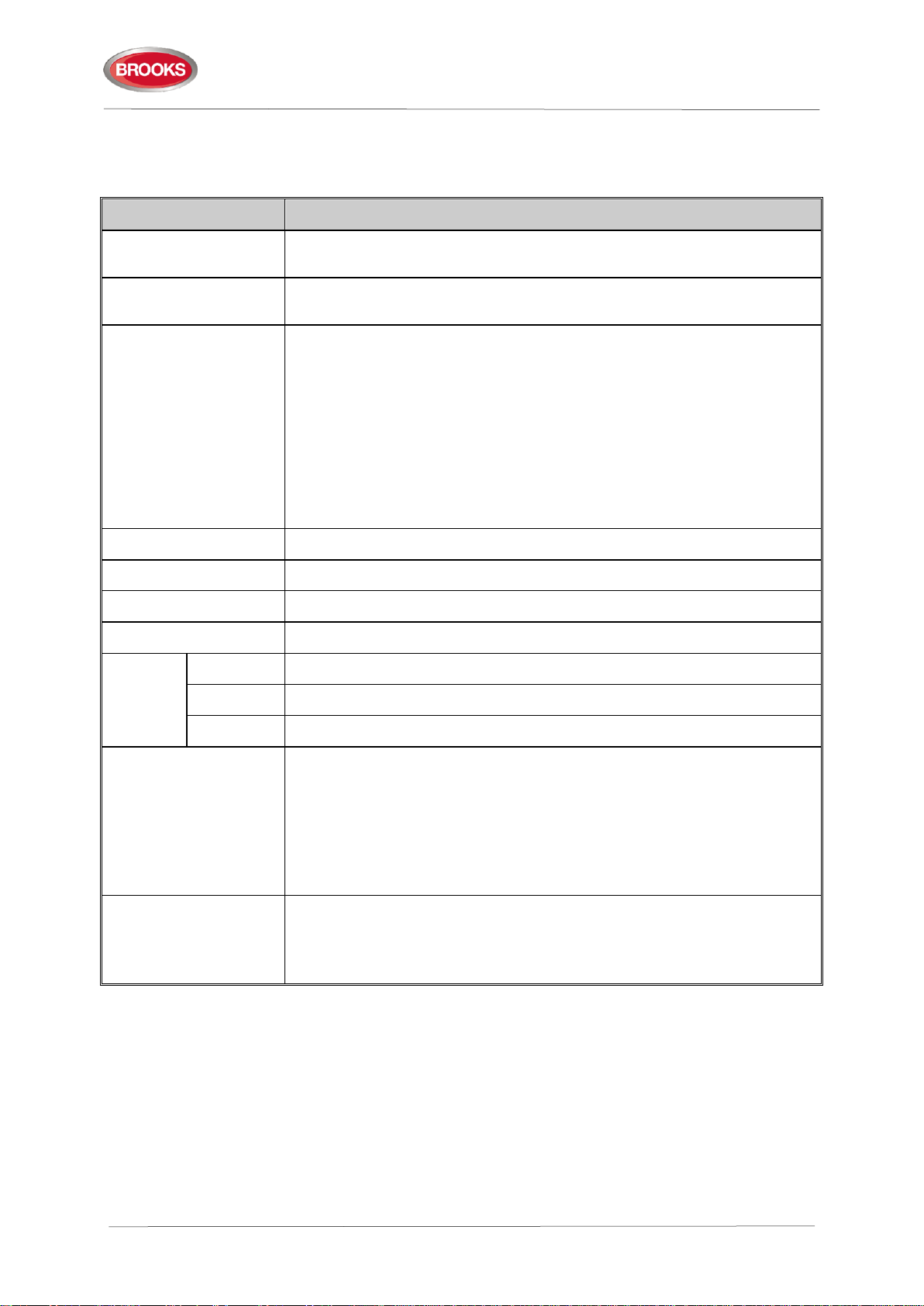

TABLELIST

Table 1 General Specifications......................................................................................................................10

Table 2 System Module Summary.................................................................................................................12

Table 3 Modules and Features......................................................................................................................13

Table 4 Expansion Limitation.........................................................................................................................15

Table 5 Main Control Board JumperSettings................................................................................................17

Table 6Main Control Board Connections......................................................................................................18

Table 7 Main Display Driver Board Jumper Settings.....................................................................................20

Table 8 Main Display Driver Board Connections...........................................................................................21

Table 9 BatteryCharger CurrentLimiting Connection...................................................................................22

Table 10Battery Capacity / Max Charging Current.......................................................................................22

Table 11ZoneExpansion Board Jumper Settings........................................................................................23

Table 12ZoneExpansion Board Connections..............................................................................................24

Table 13RelayExpansion BoardJumperSettings.......................................................................................25

Table 14RelayExpansion BoardConnections.............................................................................................26

Table 15SupervisedOutput Expansion BoardJumper Settings...................................................................27

Table 16SupervisedOutput Expansion BoardConnections.........................................................................28

Table 17OWS Plug-inModule Connections.................................................................................................29

Table 18 Generic Display Driver Board Jumper Settings...............................................................................30

Table 19 Generic Display Driver Board Connectors......................................................................................30

Table 20 OWS Front Display Board Connections..........................................................................................31

Table 21Fuse Specifications.........................................................................................................................32

Table 22LEDIndicating Patterns..................................................................................................................35

Table 23Fault LEDIndications......................................................................................................................35

Table 24 Buzzer Indicating Patterns..............................................................................................................36

Table 25OWS Tone andVoice Messages ...................................................................................................36

Table 26CIESignalling Patterns...................................................................................................................37

Table 27End of Line Resistor Specifications.................................................................................................39

Table 28ZoneInput Circuit Specifications.....................................................................................................40

Table 29CompatibleActuating Devices........................................................................................................40

Table 30Control OutputSpecifications..........................................................................................................41

Table 31Connection of theAudioAmplifier 60W, 120W and 250W .............................................................48

Table 32OWS Audio VolumeAdjustment.....................................................................................................48

Table 33GasFront Status LEDIndication and flash Pattern.........................................................................51

Table 34 Mains Power Supply Requirement .................................................................................................54

Table 35Power SupplyMonitoring Characteristics.......................................................................................54

Table 36Current Consumption of Function Modules....................................................................................55

Table 37Current Consumption of Typical CIEConfigurations ......................................................................56

Table 38 Battery calculation example............................................................................................................56

Table 39Cable Resistance of the Reference Cables....................................................................................58

Table 40 CableTypes for Different Connections...........................................................................................59

Table 41 CIE I/O Logic Numbers...................................................................................................................62

Table 42ConfigurableAlertcom Tones.........................................................................................................66

Table 43Pre-commissioningResistance Measurement Record...................................................................71

Table 44Pre-CommissioningBattery Voltage Measurement Record...........................................................73

Table 45Power ONAC/DC Power Supply Calibration Record.....................................................................73

Table 46 CIE General Record.......................................................................................................................74

Table 47 CIE Expansion Board Record.........................................................................................................74

Table 48CIEMaintenance Record................................................................................................................75