© 2007-2008 Broseley Fires Ltd

This will help to keep the chimney hot and working efficiently.

Check that all the seals of the appliance are in good order and that the connections to the chimney are also

sound.

12.0 MAINTENANCE - CLEANING THE APPLIANCE

Take great care choosing the products you use to clean your appliance. A major amount of cleaning can be

carried out using hot soapy water and a soft cloth. Using the wrong products will cause damage to its

surfaces. Never use bleach or chlorine based products, caustic cleaners, paint solvents, biological powders,

coarse abrasives or salt.

Never mix different products as they may cause a chemical reaction with each other and cause harm to

either you or the appliance.

13.0 RECOMMENDED CLEANING PRODUCTS

For the more stubborn stains, a mildly abrasive cleaner should be used, such as ‘Astonish’.

This is safe to use on enamel surfaces. Do not use Astonish on the chrome components.

For any further information, please contact your Dealer!

13A DAILY CARE

To keep the surfaces of your appliance bright and clean, a daily wipe over with a lint free cloth, soaked in hot

water and a little soap is all that is needed.

To buff the cleaned surfaces, a soft, dry, lint free cloth should be used.

In order to keep your appliance in tip top condition, it is necessary to wipe up any spills or condensation

streaks as soon as is safe to do so. (i.e. when the unit is cold)

This will prevent the mark burning onto the appliance and becoming a much tougher stain to remove at a later

date, or causing a permanent mark. Try not to use excessive amounts of water when cleaning the appliance.

13B CLEANING THE OUTSIDE OF THE APPLIANCE:

The appliance has three main surface finishes; These should be cleaned when the appliance is cool.

The cooking surface is cast iron and can be cleaned with a lint free damp cloth. Do not leave this surface wet

as it will go rusty.

The side panels of the stove are Italian Majolica tiles that are completely hand-made.

The majolica tiles may show micro crackles, speckles, and shadings. These characteristics certify their

precious origin.

For the cleaning of the majolica tiles, we suggest you use a soft, dry cloth; do not use detergent or liquid,

the latter might soak in and make the crackles more visible.

The doors of the appliance are solid cast iron and painted with heat proof paint. These can also be cleaned

with a lint free damp cloth and then wiped over with a dry cloth. Should re-painting be necessary, contact

your local supplier for a can of paint.

13C ASH REMOVAL:

Not only does the appliance need to have the ash removed from the ash pan and fire chamber, but also from

around the outside of the oven. Because of the way in which the appliance works; by sending hot smoke and

gasses around the oven before exiting up the chimney; there will inevitably be soot deposits on these

components.

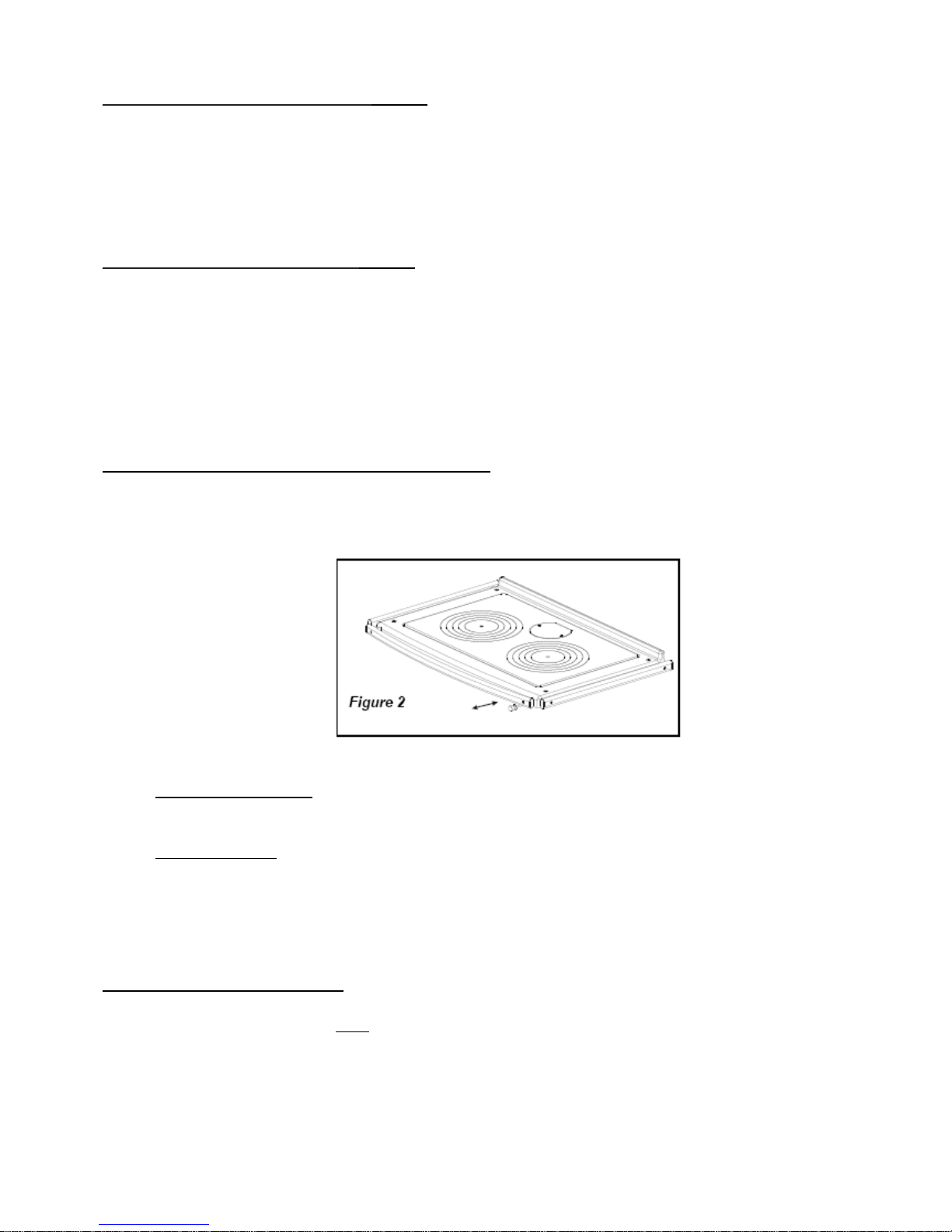

To clean these out, it is necessary to remove the hob rings and then the hob ring surround. It is only held in

position by its weight and care should be taken when lifting because of this.

Once removed, you will have access to the area above the fire box and the top of the oven.

To get access to the area down the right hand side of the oven, remove the rectangular plate to the right of

the hob ring surround. This also just lifts out.

To gain access under the oven, you can remove the access plate (located behind the oven door). This is easily

done by removing the two screws at the front edge of the plate. This plate has been sealed in position using

a heat proof silicone sealant. This may need to be reinstated if the old seal leaks when the plate is replaced.