Brother LX-200 User manual

SERVICE MANUAL

MODEL: LX-200/LX-900/LX-910D

REVISED EDITION May, 2000

Unauthorized copying of all or part of the contents of this manual is prohibited.

The contents of this manual may change without notice.

INTRODUCTION

This Service Manual describes the Cool Laminator LX-200/900/910D specifications, operating

principles of the mechanisms, disassembly and reassembly procedures, and maintenance and

troubleshooting procedures.

This Service Manual is intended for use by trained technicians. It is not intended for use by the

user.

The manual is divided into the following chapters.

Chapter 1. Specifications

Chapter 2. Mechanism

Chapter 3. Disassembly Procedures

Chapter 4. Reassembly Procedures

Chapter 5. Electronic Controllers

Chapter 6. Maintenance

Chapter 7. Troubleshooting

Appendix Main PCB Circuit Diagram

Chapter 1.

SPECIFICATIONS

1-i

CONTENTS

Chapter 1. SPECIFICATIONS

1.1 Mechanical Specifications.................................................................................................1-1

1.1.1 Appearance...........................................................................................................1-1

1.1.2 Operating Panel ....................................................................................................1-1

1.1.3 Indicators...............................................................................................................1-2

1.2 Electrical Specifications ....................................................................................................1-2

1.2.1 Power Supply........................................................................................................1-2

1-

1

1.1 Mechanical Specifications

1.1.1 Appearance

[1] External dimensions (W x D x H) 357 mm x 293 mm x 195 mm

[2] Mass Approx. 4.6 kg (main unit only)

357 mm

293 mm

195 mm

Fig. 1.1-1Appearance

1.1.2 Operating Panel

[1] Number of Keys 5(Power switch, Cut key, Feed key,

Start/Stop button, Cutting mode selector)

[2] Key Arrangement

Power switch

Cut key (Horizontal)

Feed key

Start/Stop button

Cutting mode selector

Fig. 1.1-2Key Arrangement

1-

2

1.1.3 Indicators

[1] Positions Start/Stop button LED indicators (red, green, orange)

1.2 Electrical Specifications

1.2.1 Power Supply

[1] Power supply Commercial power supply (locally available power supply).

Converted to DC by the AC adaptor.

Chapter 2.

MECHANISMS

i

CONTENTS

Chapter 2. MECHANISMS

2.1 Mechanical Operating Principles......................................................................................2-1

2.1.1 Description of Mechanisms (Border Mode)..........................................................2-1

2.1.2 Feed and Compression Mechanisms...................................................................2-2

2.1.3 Cutter Mechanism (Border Mode)........................................................................2-4

2.1.4 Paper Size Detector Mechanism..........................................................................2-6

2.1.5 Trimming Mechanism...........................................................................................2-8

2-

1

2.1 Mechanical Operating Principles

2.1.1 Description of Mechanisms (Border Mode)

1. When a document is inserted into the paper loading gate, the paper feed rollers feed

it to the driving roller.

2. As the document passes between the paper feed rollers, the paper size detector

determines its size (length and width).

3. When the document passes between the film cartridges it is sandwiched between

the upper and lower films in the compression-feed area, where the films and

document are compressed between the driving roller and sub-roller.

4. The compressed document and film is fed to the cutting area, where it is cut to the

document size detected by the paper size detector with borders added. It is then

transported to the next stage.

5. The laminated document is fed out of the eject gate by the paper eject rollers.

Paper loading gate Paper feed sub-roller Roll film (upper)

Film cartridge

Sub-roller

Y-cutter blade

X-cutter unit

Paper eject roller

Eject gate

Paper eject sub-roller

Ejecting area

Cutting area

Driving roller

Compression-feed area

Roll film (lower)

Paper width detector

Paper feed roller

Paper loading area

Paper length

detector

Fig. 2.1-1Description of Mechanisms

2-

2

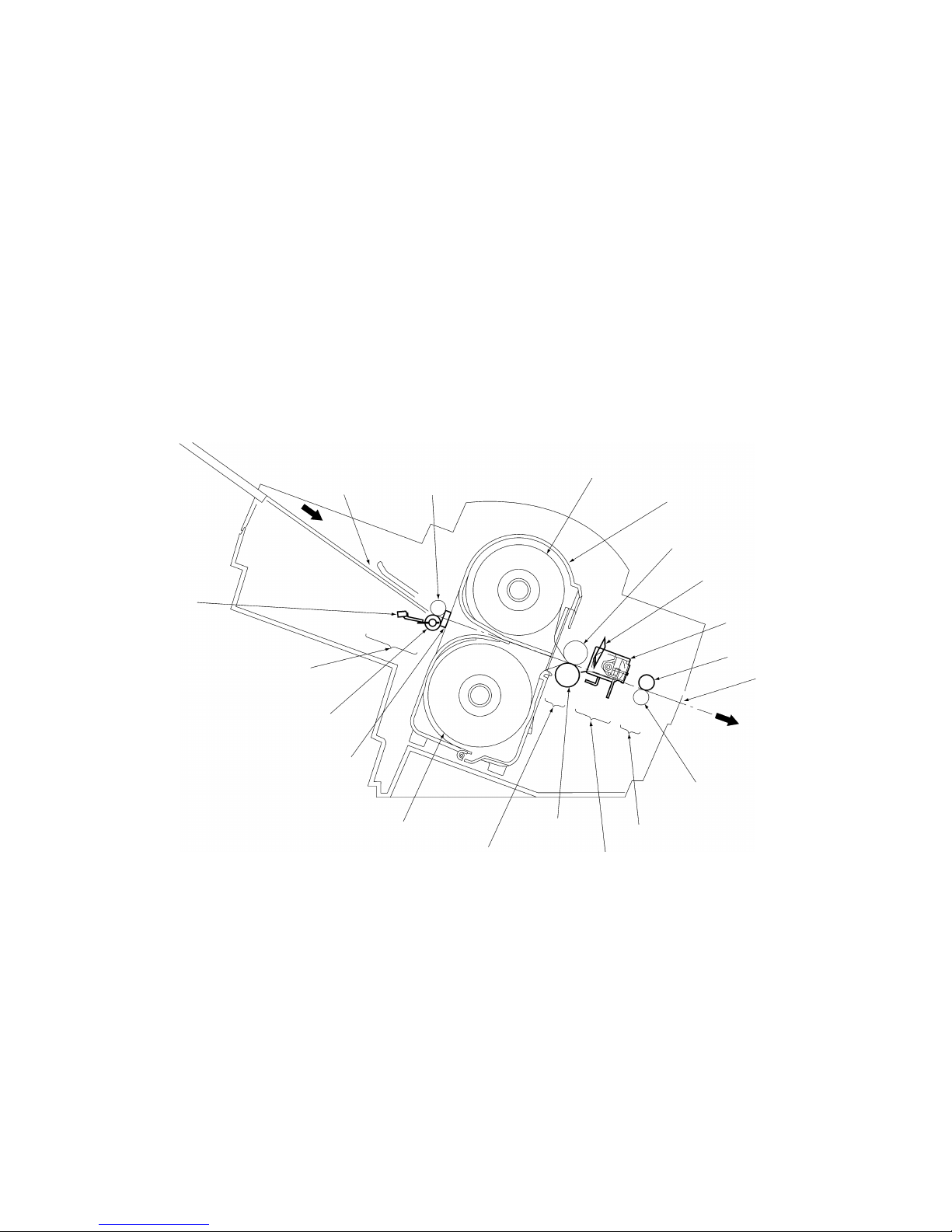

2.1.2 Feed and Compression Mechanisms

The feed and compression mechanism controls the motor drive to feed the document

into the film cartridge, compression-feed the films, and eject the laminated document.

When no compression-feed is applied while feeding a document into the film cartridge

or ejecting a laminated document, the LF motor rotates clockwise and the motor drive is

transmitted via gears to the paper feed roller and paper eject roller.

At this time, the planet gear (A) is free from the drive gear (A), such that the drive is not

transmitted to the driving roller.

During compression-feeding of the films, LF motor rotates counterclockwise to move the

planet gear (A) against the drive gear (A), such that the drive from the LF motor is

transmitted to the driving roller.

Also, planet gear (B) moves against the drive gear (B) and planet gear (C) moves

against the drive gear (C), such that the LF motor drive continues to be transmitted to

the paper feed roller and paper eject roller, without changing the direction of roller

rotation.

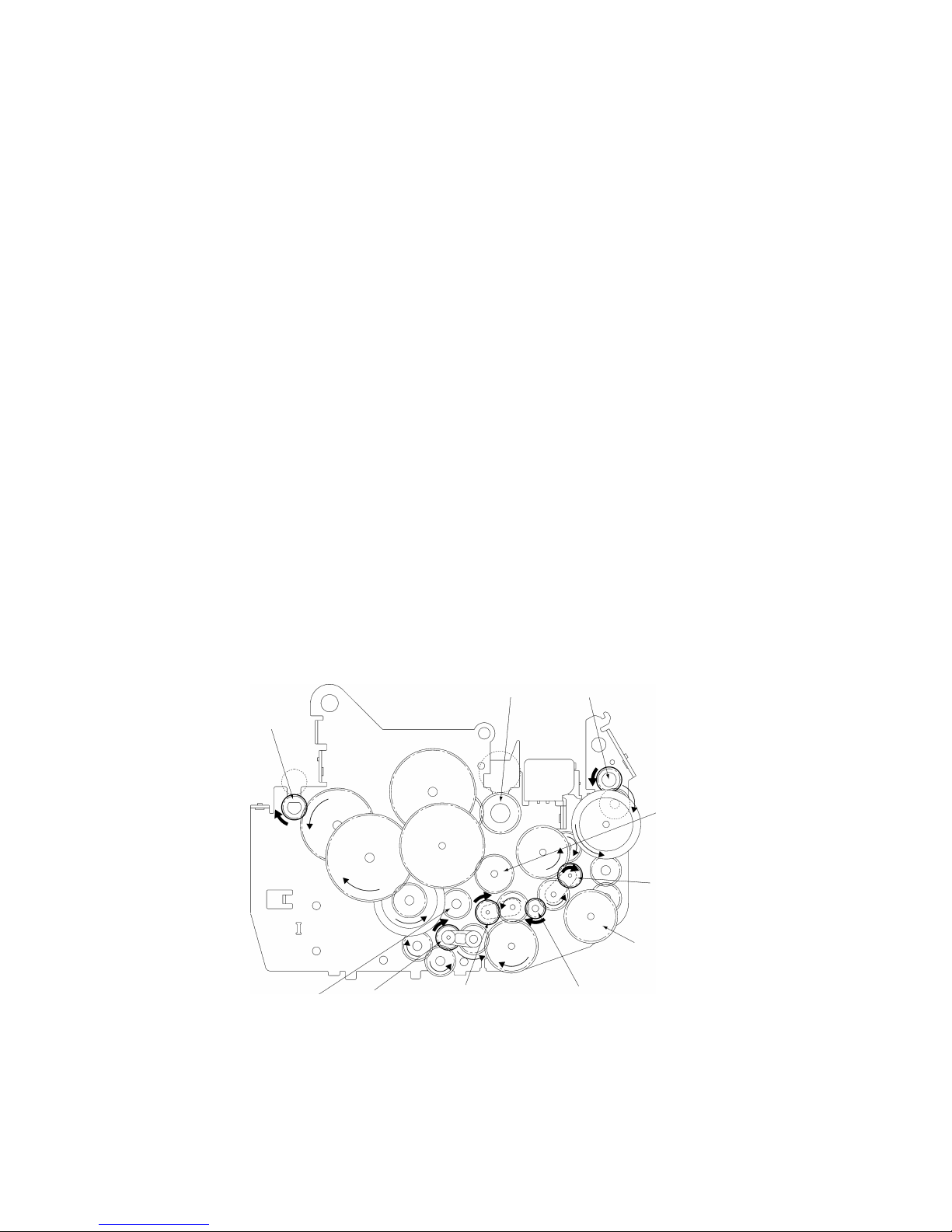

•Operation when Feeding Document into the Film Cartridge or when Ejecting a

Laminated Document

1. When the LF motor rotates clockwise (as indicated by the arrow in the diagram),

the drive is transmitted via a series of gears to drive the paper feed roller and

paper eject roller in the directions indicated by the arrows. At this time, planet

gear (A) is free, such that no drive is transmitted to drive gear (A) and the driving

roller does not rotate.

2. The document is fed into the film cartridge when the paper feed roller rotates in

the direction indicated by the arrow.

3. The laminated document is ejected from the eject gate when the paper eject

roller rotates in the direction indicated by the arrow.

Paper feed roller

Drive gear (A)

Planet gear (C)

Drive gear (C)

LF motor gearPlanet gear (A)

Planet gear (B)

Drive gear (B)

Driving roller Paper eject roller

Fig. 2.1-2Operation when Feeding Document into the Film Cartridge or when Ejecting a Laminated Document

2-

3

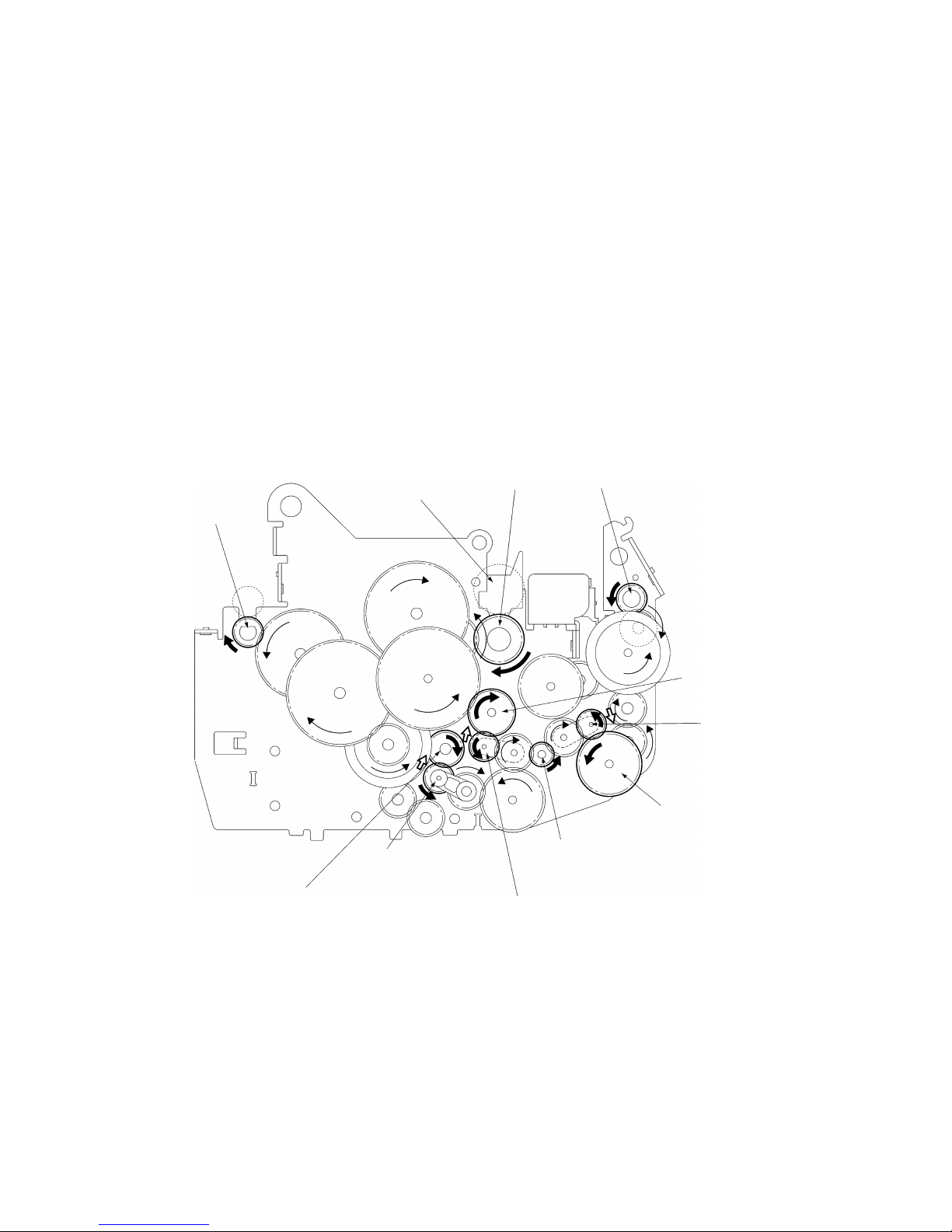

•Operation During Film Compression-Feed

1. When the leading edge of the document enters the compression-feed area, LF

motor starts to rotate counterclockwise, as indicated by the arrow.

2. Planet gear (A), which had been free, moves to engage with drive gear (A). The

drive from the LF motor is then transmitted to the various gears, as shown in the

diagram, and the driving roller rotates as indicated by the arrow. Also, planet

gear (B) moves against the drive gear (B) and planet gear (C) moves against the

drive gear (C), such that the LF motor drive continues to be transmitted to the

paper feed roller and paper eject roller, without changing the direction of roller

rotation.

3. The rotation of the driving roller is transmitted to the sub-roller. These rollers

feed the films and press them against the document. At this time, the rotations

of the paper feed roller and paper eject roller continue uninterrupted.

4. When the trailing edge of the document leaves the compression-feed area and

the X-cutters finish cutting the film, the LF motor reverses to rotate

counterclockwise. Planet gear (A) again becomes free such that the driving

roller rotation stops and feeding of the films also stops.

Paper feed roller

Sub-roller Driving roller Paper eject roller

Drive gear (A)

Drive gear (C)

Planet gear (C)

LF motor gear

Planet gear (A)

Planet gear (B)

Drive gear (B)

Fig. 2.1-3Operation During Film Compression-Feed

2-

4

2.1.3 Cutter Mechanism (Border Mode)

The cutter mechanism cuts the laminated document to the size of the document plus an

added border. Both edges of the films are cut to suit the width of the document and the

leading edge and trailing edge are cut according to the document length.

•Y-Cutter Vertical Drive Operation

1. The TC motor rotates clockwise from its reference position to drive the cam

clockwise via a series of gears. The cam rotates the Y-diversion lever clockwise

about its pivot. (All rotations indicated by arrows. )

When the Y-diversion lever reaches its maximum displacement position with the

cam at approximately its 180°‹ rotated position, rotation of the TC motor pauses.

2. When the Y-diversion lever reaches its maximum displacement position, its

movement lowers the two Y-cutter blades from the standby position to the

cutting position, where they start cutting the edges of the laminated film.

3. When the Y-axis cutters reach the trailing edge cutting position, the TC motor

starts rotating again and stops when it reaches its reference position. This

rotation returns the cam and Y-diversion lever to their original positions and the

cutters move to their standby positions.

Y-cutter blade

Pivot

Standby position

Cutting

position

Planet gear

Film

Film surface

TC motor

Idle gear 1

Idle gear 2

Idle gear 3

Cam (hatched area)

Y-diversion lever

TC motor gear

Fig. 2.1-4Y-Cutter Vertical Drive Operation

2-

5

•Cutting Leading and Trailing Edges (X-cutter Mechanism)

1. All the rollers which feed the document stop when the cut position at the leading

edge of the document reaches the cutting position of the rotary cutter and fixed-

blade cutter.

2. The DC motor rotates to drive the carriage in the X-cutter assembly via the spiral

mechanism (not illustrated).

3. As the carriage makes a reciprocal movement, the rotary cutter attached to the

carriage moves against the fixed cutter to cut the compressed leading edge of

the document.

4. The rotation of the rollers which feed the document restarts when the cutting of

the leading edge is complete. Then, when the cut position at the trailing edge of

the document reaches the cutting position of the rotary cutter and fixed-blade

cutter, the feed rollers stop again.

5. The document trailing edge is cut in the same way as the leading edge, by a

reciprocal movement of the rotary cutter attached to the carriage.

6. The rotation of the rollers restarts to feed the laminated document from the eject

gate after the cutting of the trailing edge is complete.

Rotary cutter Document

Sub-roller

Driving roller

DC motor

Paper eject sub-roller

Paper eject roller

X-cutter

Frame

Section A-A’

DC motor FrameRotary cutter

Carriage

Paper eject roller

Paper eject sub-roller

Fixed cutter

Driving roller

Sub-roller

Document

Fig. 2.1-5Cutting Leading and Trailing Edges (X-cutter Mechanism)

2-

6

2.1.4 Paper Size Detector Mechanism

•Paper Length Detection

1. When the leading edge of the document passes between the paper feed rollers,

it rotates the paper sensor crank about the pivot to turn on the paper sensor

which detects the document leading edge.

2. When the trailing edge of the document passes out of the paper feed rollers, the

paper sensor crank reverts to its original position to turn off the paper sensor to

detect the document trailing edge.

Document feed surface

Paper feed sub-roller

Paper feed roller

Pivot

Paper sensor crank

Paper sensor

ON

OFF

Fig. 2.1-6Paper Length Detection

2-

7

•Paper Width Detection

1. The Y-cutter arm L (sensor unit) moves in the direction of the arrow. When the

PL detect lever touches the document, it rotates about the pivot to switch off the

photosensor.

2. When the photosensor turns off, the Y-cutter arm L movement stops and this

position is detected as the document width.

Y-cutter arm L

Sensor unit

Document

Pivot

Part of the PL detect lever that touches the document.

PL detect lever

Photosensor

* Photosensor ON status

* Photosensor OFF status

Fig. 2.1-7Paper Width Detection

2-

8

2.1.5 Trimming Mechanism

1. When a corner of the laminated document is inserted over the T-cutter plate, the

sensor lever operates a leaf switch that detects the document.

2. When the document is detected, the motor gear of TC motor rotates in the direction

of the arrow (counterclockwise) from its reference position to drive the T-cam gear in

the direction indicated by the arrow (clockwise) via a series of gears.

3. Rotation of the T-cam gear forces the T-cam roller to make a vertical movement,

such that T-lever1 moves vertically, rotating around its pivot.

4. As T-lever 1 moves vertically, the T-cutter mounted on the end of T-lever 1 moves

up and down, trimming the corner of the laminated document into a rounded radius.

T-sensor lever Leaf switch

Laminated

document

Pivot

T-cutter Planet gear

Idle gear 2

Idle gear 3

T-lever 1

T-cam roller

T-cam gearIdle gear 1TC motor Motor gear

T-cutter plate

Fig. 2.1-8Trimming Mechanism

Chapter 3.

DISASSEMBLY PROCEDURES

i

CONTENTS

Chapter 3. DISASSEMBLY PROCEDURES

3.1 Safety Precautions ............................................................................................................3-1

3.2 Removing the Film Cartridge............................................................................................3-1

3.3 Covers...............................................................................................................................3-2

3.3.1 Removing the Trimmer Upper Cover...................................................................3-2

3.3.2 Removing the Top Cover......................................................................................3-3

3.3.3 Removing the Sub-tray.........................................................................................3-4

3.3.4 Removing the Paper Tray and Paper Guide.........................................................3-4

3.3.5 Removing the Body Cover B.................................................................................3-5

3.3.6 Removing the Front Cover....................................................................................3-7

3.3.7 Removing the Cover Switch Assy ........................................................................3-8

3.3.8 Removing the Dial Switch Holder Assy B.............................................................3-9

3.3.9 Disassembling the Dial Switch Holder Assy B ...................................................3-10

3.4 Chassis............................................................................................................................3-12

3.4.1 Removing the Harness Connectors....................................................................3-12

3.4.2 Removing the PE Sensor Unit............................................................................3-12

3.4.3 Removing the Chassis Unit ................................................................................3-13

3.5 PCBs................................................................................................................................3-15

3.5.1 Removing the Main PCB Assy............................................................................3-15

3.5.2 Removing the Jack PCB Assy............................................................................3-15

3.5.3 Removing the Switch PCB Assy.........................................................................3-16

3.6 T-Chassis ........................................................................................................................3-17

3.6.1 Removing the T-Chassis Unit.............................................................................3-17

3.6.2 Disassembling the T-Chassis Unit......................................................................3-18

3.7 Y-CA Chassis..................................................................................................................3-19

3.7.1 Removing the Y-CA Chassis Assy .....................................................................3-19

3.7.2 Disassembling the Y-CA Chassis Assy..............................................................3-20

3.7.3 Removing the Roller Holder Assy.......................................................................3-21

3.7.4 Disassembling the Roller Holder Assy ...............................................................3-22

3.8 Sensor Frame and Y-cutter Arm L..................................................................................3-23

3.8.1 Removing the Sensor Frame..............................................................................3-23

3.8.2 Removing the Y-cutter Arm L .............................................................................3-23

3.8.3 Disassembling the Sensor Frame ......................................................................3-24

3.8.4 Disassembling the Y-cutter Arm L......................................................................3-25

3.9 Paper Feed Roller...........................................................................................................3-26

3.9.1 Removing the Paper Feed Sub-roller Assy........................................................3-26

3.9.2 Removing the Paper Feed Roller Assy...............................................................3-27

ii

3.10 Paper Eject Roller ...........................................................................................................3-28

3.10.1 Removing the Y-D Shaft.....................................................................................3-28

3.10.2 Removing the Paper Eject Sub-roller Unit..........................................................3-29

3.10.3 Removing the Paper Eject Roller Unit................................................................3-29

3.11 Y-diversion Lever ............................................................................................................3-30

3.11.1 Removing the Y-diversion Lever Assy................................................................3-30

3.11.2 Disassembling the Y-diversion Lever Assy ........................................................3-31

3.12 X-cutter............................................................................................................................3-32

3.12.1 Removing the X-cutter Unit.................................................................................3-32

3.12.2 Disassembling the Tape Sensor Unit .................................................................3-32

3.13 Driving Roller...................................................................................................................3-33

3.13.1 Removing the Driving Roller...............................................................................3-33

3.14 Left Side of the Chassis ..................................................................................................3-33

3.14.1 Removing the Gears...........................................................................................3-33

3.14.2 Disassembling the Left Side of the Chassis.......................................................3-35

3.15Right Side of the Chassis................................................................................................3-36

3.15.1 Disassembling the Right Side of the Chassis.....................................................3-36

3.16 Lower Chassis.................................................................................................................3-37

3.16.1 Removing the Left and Right Sides of the Chassis............................................3-37

3.16.2 Removing the Cassette Holder...........................................................................3-38

3.16.3 Removing the Encoder (ENC) Sensor PCB.......................................................3-38

3.16.4 Removing the Cassette Detect Switch...............................................................3-39

This manual suits for next models

2

Table of contents

Other Brother Laminator manuals