- Remove product residues and the cooling or heating media

- Rinse with cold or lukewarm water

- Allow a solution of the solvent to circulate through the system

- Rinse with clean hot water

- Rinse again with hot water with a decalcifier additive

- Rinse again with cold or lukewarm water

Inspection of cleaning

Cleaning is very important for the effectiveness of the plate heat exchanger. For this reason, the

cleaning of the plate heat exchanger must be checked, especially in the initial use period. People often

have little experience with the circulation time, temperatures and concentrations of the products that

are used.

Common causes of inadequate cleaning are:

- circulation volume too low

- cleaning period too short

- insufficient amount of chemicals for the deposits on the plates

- operating intervals twice as long

Loss of capacity

Internal leaks

External leaks

Loss of capacity

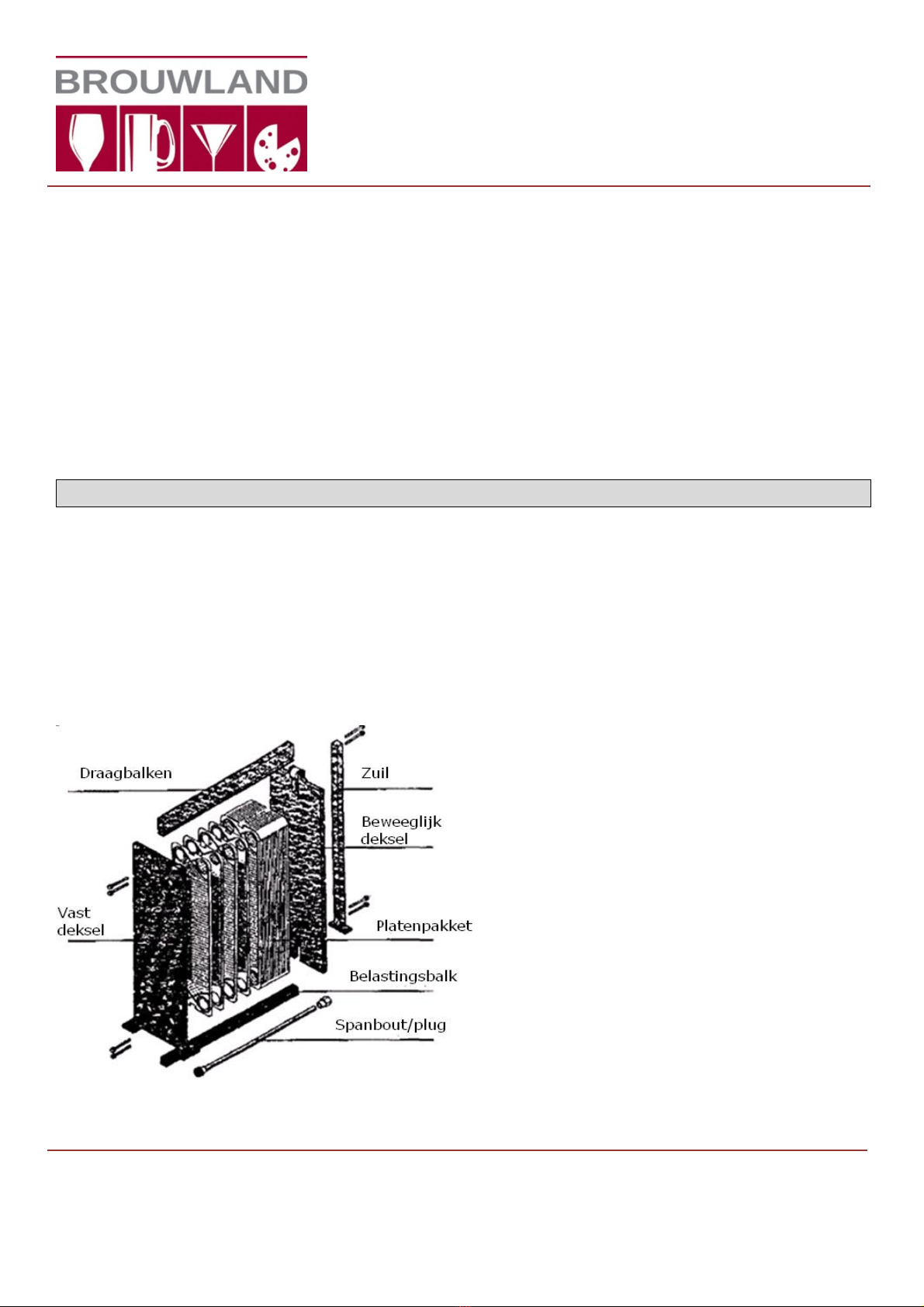

If the heat transfer capacity falls and/or the pressure drop rises, the plate heat exchanger must be

dismantled and the plates must be cleaned (see page 8). The plates must be clamped together

according to the values stated on the nameplate.

External leaks

- The plate heat exchanger may be operating at a higher pressure than the specified operating

pressure. Check the pressure. If it is too high, it must be reduced immediately to the operating

pressure stated on the nameplate.

- Adjust the clamping of the plate heat exchanger when it is no longer under pressure. Never exceed

the indicated minimum value when adjusting the clamping.

The fixed and moveable covers must always be parallel to each other after the plates have been

clamped together.

- Dismantle the plate heat exchanger for visual inspection. Check whether deposits have formed on the

plates, and check the plates for deformation. Check the gaskets. They must be elastic and not

deformed, and the sealing surfaces must be clean. Carefully clean all plates and gaskets –just one

grain of sand on a sealing surface can cause a leak.

- A plate stack that has been clamped to the minimum value after cleaning should be free from leaks.

If any leaks are present, the gaskets must be replaced.

- If there is a leak from the gasket drain holes, the sealing of the drain area is defective or the plate is

corroded in the drain area.

Internal leaks

If the media get mixed together, you should look for the cause in the holes of one or more plates. The

only way to eliminate the leak is to replace the plate or plates concerned.

Brouwland

Korspelsesteenweg 86 • B-3581 Beverlo, Belgium

Phone +32 (0)11 40 14 08 • Fax +32 (0)11 34 73 59

sales@brouwland.com • www.brouwland.com

Manual

057.110.x Wort Cooler Plate Heat Exchanger,

Stainless Steel