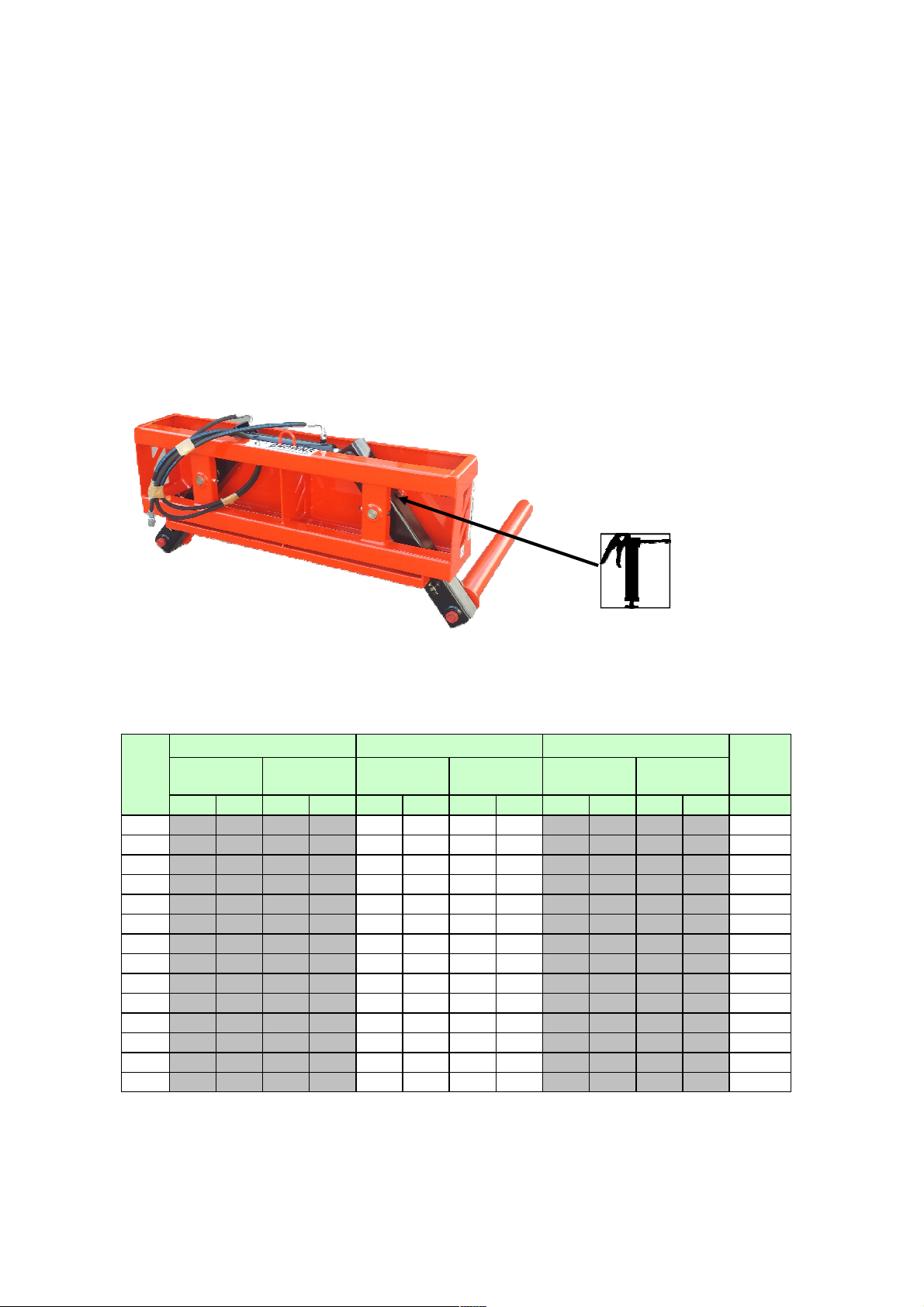

1.0 Introduction

Congratulations on your purchase of a new Browns machine. In order to correctly

use the machine please carefully read this manual. The manual has been written to

provide operating and maintenance procedures and related safety information which

will allow you to use and maintain this machine in a correct and safe manner.

This operators manual should be regarded as part of the machine. You must en-

sure that you and anyone else who is operating, maintaining or working with the ma-

chine be familiar with the operating and maintenance procedures and related safety

information contained in this manual.

Owners must give operating instructions to operators or employees before allowing

them to operate this machine. It is the operators responsibility to read and under-

stand all safety and operating instructions in this manual. Remember all accidents

can be avoided.

A person who has not read and understood all operating and safety instructions is

not qualified to operate the machine. An untrained operator exposes themselves

and bystanders to possible serious injury or death.

Caution

This symbol indicates important safety messages in this manual. When you

see this symbol, be alert to the possibility of injury to yourself or others, and

carefully read the message that follows.

The most important safety device on the machine is a

safe operator

1.1 General Information

The illustrations and data used in this manual were current at the time of printing,

but due to possible engineering or production changes, this product may vary slight-

ly in detail. Browns reserves the right to redesign or change components as may be

necessary without notification to anyone.

No liability can be accepted for inaccuracies or omissions in this manual, although

every possible care has been taken to make it as complete and accurate as possi-

ble.

Throughout this manual, references may be made to,

LEFT-HAND SIDE -the side which is on the left only when an observer is

facing in the normal forward direction of travel of the machine, i.e. the operator

looking forward from rear of machine.

RIGHT-HAND SIDE -the side which is on the right only when an observer is

facing in the normal forward direction of travel of the machine.

COMPETENT PERSON -for any task means a person who has acquired

through training, qualifications or experience, or a combination of them, the

knowledge and skills to carry out that task.

2