Operator’s manual

Rear disc mowers

KDT 180;KDT 220 S/W;KDT 260 S/W;

KDT 300;KDT 340

- 1 -

Contents page

1. IDENTIFYING THE MACHINE....................................................................................2

2. INTRODUCTION..............................................................................................................

2

3. PROPER USE....................................................................................................................

3

3.1. Technical data..................................................................................................................................4

3.2. Design and working principle..........................................................................................................5

3.3. Standard equipment and spare parts................................................................................................6

4. SAFETY ADVICE.............................................................................................................

8

4.1. Safety rules and regulations.............................................................................................................8

4.2. Transport……………......................................................................................................................9

4.2.1.Putting the mower onto another vehicle for transport..................................................................... 9

4.3. Working components….......……..................................................................................................10

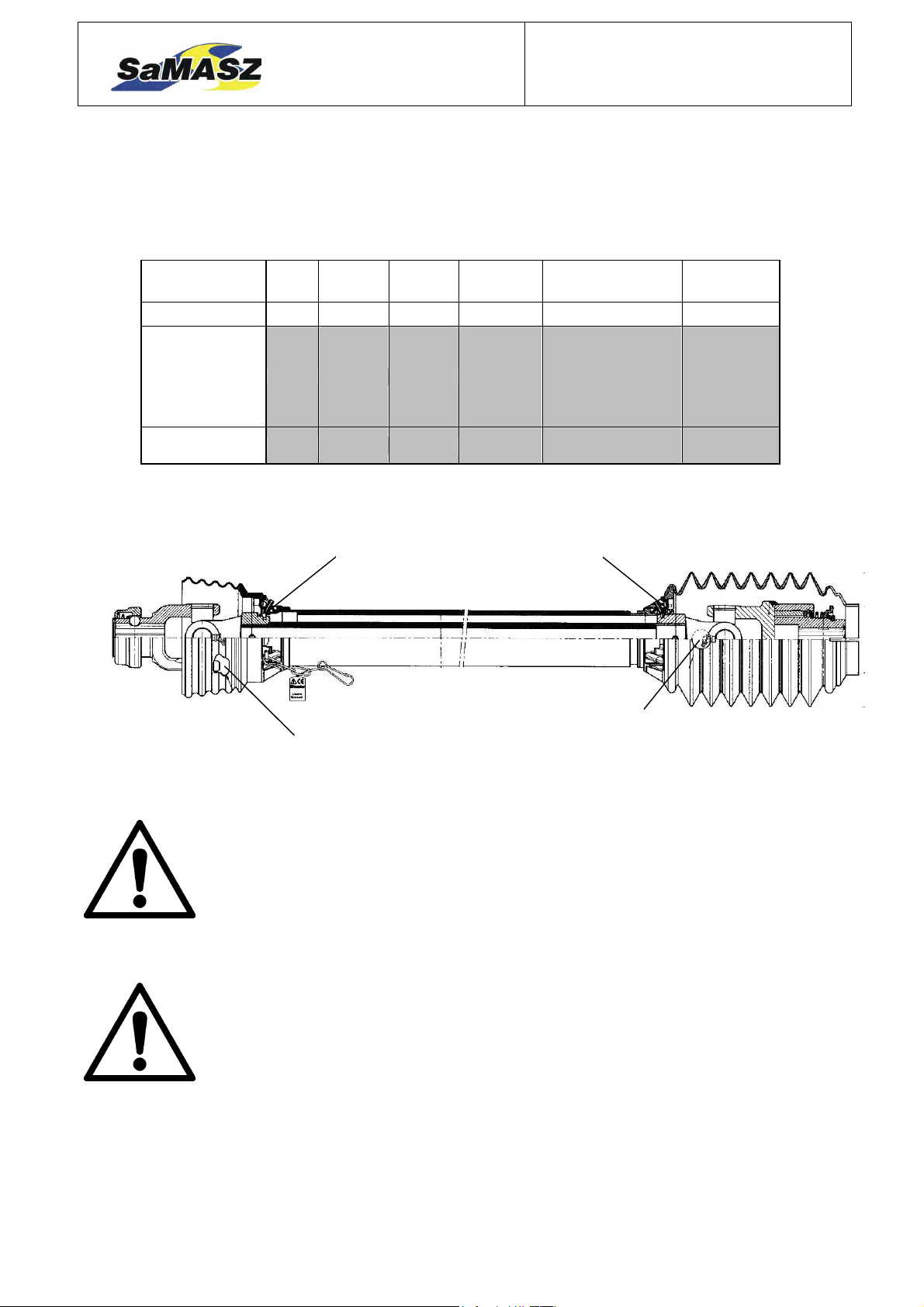

4.4. PTO shaft....................................................................................................................................... 10

4.5. Residual risk...................................................................................................................................10

4.6. Warning decals and their meaning.................................................................................................12

4.7. Design and operation of safety brekaway device.......................................................................... 17

5. OPERATION....................................................................................................................

17

5.1. Attaching the mower to the tractor................................................................................................17

5.2. Preparing the mower for transport.................................................................................................18

5.3. Preparing the mower for transport on public roads.......................................................................19

5.4. Mounting PTO shaft......................................................................................................................19

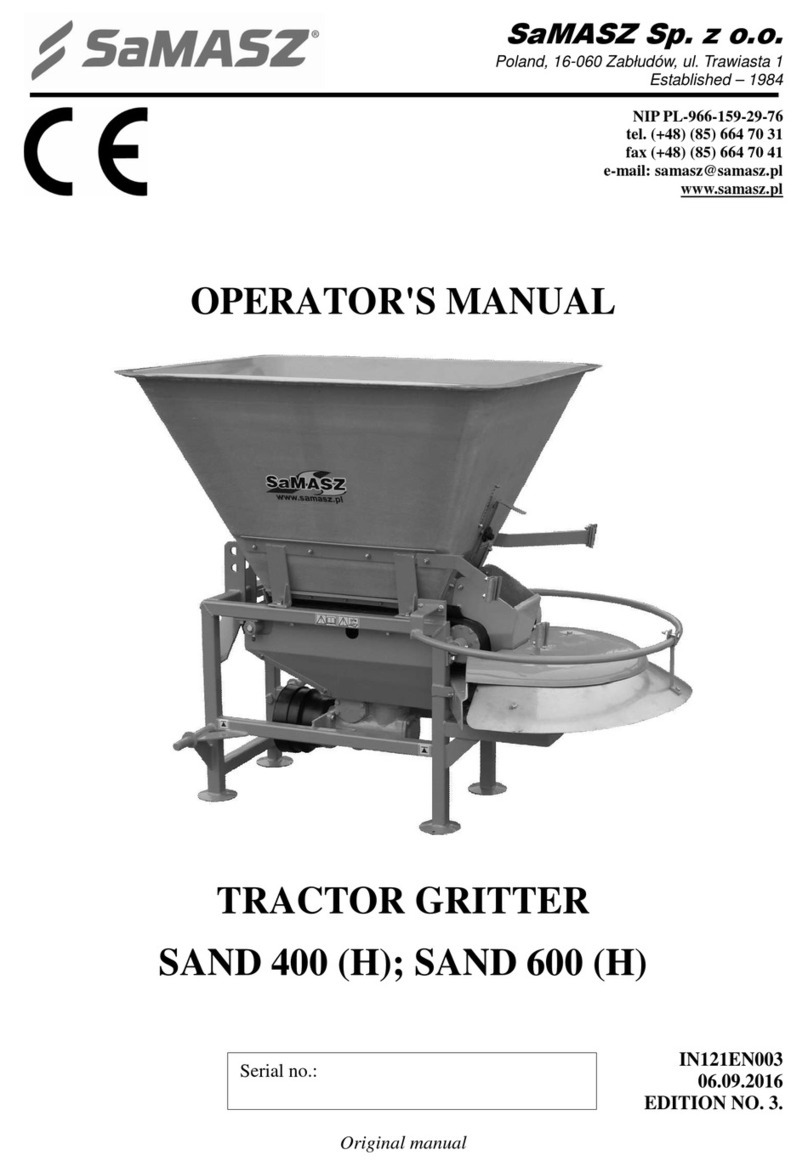

5.5. Switching from transport to working position...............................................................................20

5.6. Preparing the mower for work.......................................................................................................20

5.7. Operation (mowing)...................................................................................................................... 21

5.7.1.Essential information concerning mowing.................................................................................... 21

5.7.2.Taking turns over swaths............................................................................................................... 23

6. MOUNTING AND ADJUSTMENTS.............................................................................

23

6.1. Mounting and timing of the knives............................................................................................... 23

6.2. Replacing the knives......................................................................................................................23

6.3. Adjusting the cutterbar.................................................................................................................. 24

6.4. Adjusting the cutting height.......................................................................................................... 25

6.5. 3-point linkage support chain........................................................................................................25

6.6. Adjusting the space between tine conditioner's mask and its shaft...............................................26

6.7. Replacing the conditioner's tines................................................................................................... 26

6.8. Adjusting force of the pressure of roller conditioners...................................................................27

6.9. Maintenance and service................................................................................................................27

6.9.1.Checking the knives and knife holders..........................................................................................27

6.9.2.Checking the V-belts tension.........................................................................................................28

6.9.3.Checking the tension of tine conditioner's driving chain...............................................................28

6.9.4.Daily maintenance......................................................................................................................... 29

6.9.5.After-season maintenance..............................................................................................................29

7. LUBRICATION...............................................................................................................

29

7.1. Cutterbar........................................................................................................................................ 29

7.2. Intersecting axis gear..................................................................................................................... 30

7.3. Roller conditioner's gearbox..........................................................................................................30

7.4. Bearings and joints.........................................................................................................................31

8. DEFECTS AND THEIR REPAIRS…………………………………………………...

32

9. DISASSEMBLY AND WITHDRAWAL FROM USE.................................................

33

10. WARRANTY CARD...................................................................................................................33

11. WARRANTY TERMS.....................................................................................................

34