7

REFERENCE INFORMATION

EMISSION-RELATED INSTALLATION INSTRUCTIONS

1

EMISSION-RELATED

INSTALLATION

INSTRUCTIONS

Failing to follow these instructio ns when

installing a certified engine in a vessel violates

federal l aw (40 CFR 1 068.105 (b )), s ubject to

fines or other penaltie s as described in the

Clean Air Act.

Maintenance, replacement, or rep air of the emis-

sion control de vices and systems ma y be per-

formed by any ma rine SI (sp ark ig nition) engine

repair establishment or individual.

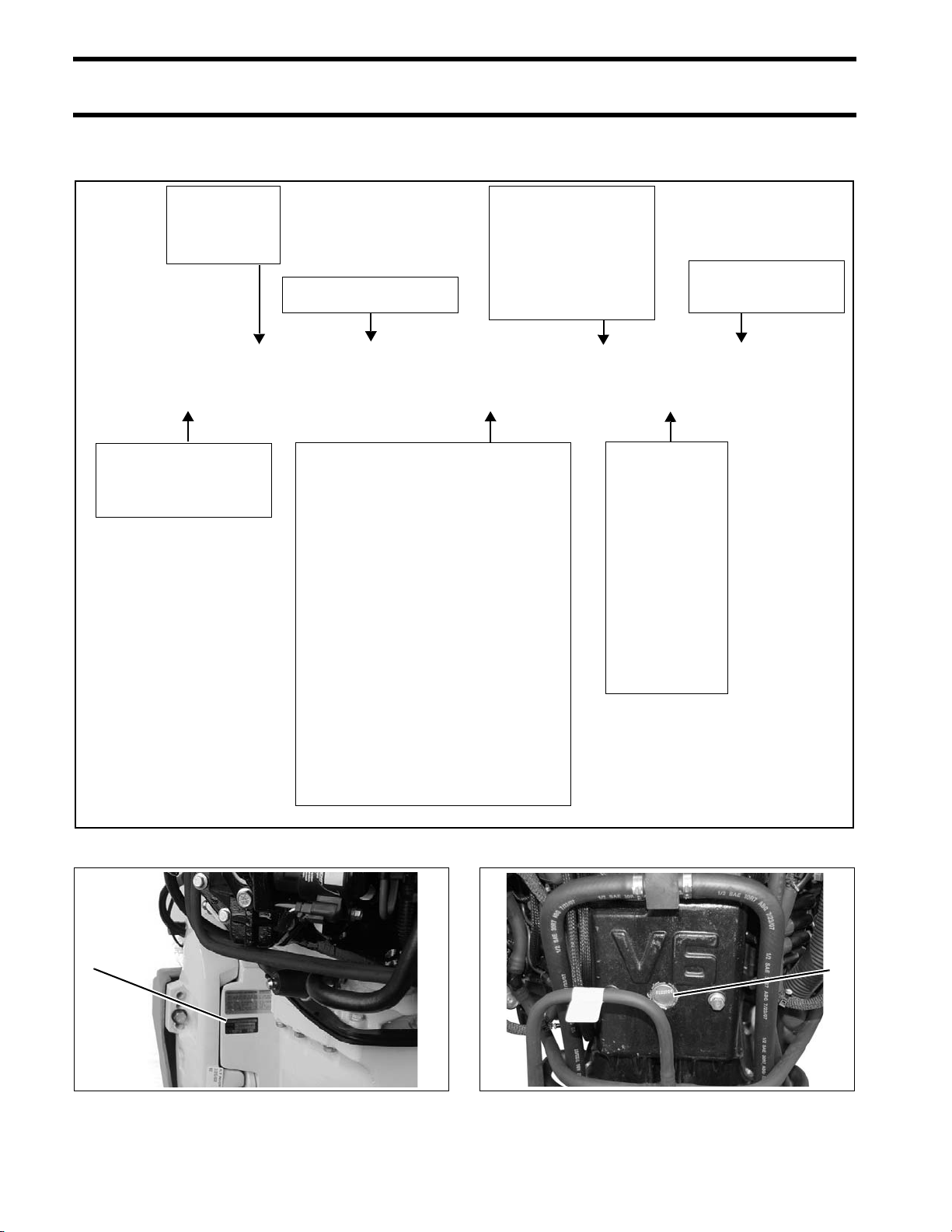

Manufacturer’s Responsibility

Beginning with 1 999 model year o utboards, man-

ufacturers o f ma rine outboards must de termine

the exha ust emissio n levels for each outbo ard

horsepower family and certif y the se o utboards

with the Unite d States of America Environmental

Protection Age ncy (EP A). An emissions control

information labe l, showing emission leve ls a nd

outboard specifications, mu st be placed o n each

outboard at the time of manufacture.

Dealer’s Responsibility

When pe rforming service on all 1 999 a nd more

recent Evinrude/Johnson outboards that carry an

emissions control information la bel, adjustments

must be kept with in pub lished factory specifica-

tions.

Replacement or repair of any emission rela ted

component must b e exe cuted in a manne r that

maintains emission levels within the prescrib ed

certification standards.

Dealers are not to mo dify the outbo ard in an y

manner that would alter the horsepower or allow

emission levels to excee d their predete rmined

factory specifications.

Exceptions include manu facturer’s prescrib ed

changes, such as altitude ad justments, for exa m-

ple.

Owner’s Responsibility

The owner/operator is required to have outboa rd

maintenance performed to maintain emission lev-

els within prescribed certification standards.

The owner/operator is not to, and should not allow

anyone to, modify the outboard in any manner

that wo uld a lter th e horsepower or a llow e mis-

sions levels to exceed their predetermined factory

specifications.

Tampering with the fuel system to change horse-

power or mo dify emission levels beyond fa ctory

settings or specifications will void the product war-

ranty.

EPA Emission Regulations

All new 19 99 and more recent Evinrude/Johnson

outboards are certified to the EPA as confo rming

to the requirements of the regulations for the con-

trol of air pollutio n from new watercraf t marine

spark ignition outboards. This certification is con-

tingent on certain adjustments being set to factory

standards. For this reason, the factory procedure

for servicing the product must be strictly followe d

and, whe never pra ctical, ret urned to the original

intent of the design. The responsibilities liste d

above are gen eral and in no way a comple te list-

ing of the r ules and reg ulations pertaining to th e

EPA re quirements on e xhaust emissions for

marine products. For more detailed information on

this subject, you may cont act th e fo llowing loca-

tions:

VIA U.S. POSTAL SERVICE:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

401 M St. NW

Washington, DC 20460

VIA EXPRESS or COURIER MAIL:

Office of Mobile Sources

Engine Programs and Compliance Division

Engine Compliance Programs Group (6403J)

501 3rd St. NW

Washington, DC 20001

EPA INTERNET WEB SITE:

www.epa.gov