CONTENTS

1.

INTRODUCTION

AND

SPECIFICATIONS

(Product

Data)

............................................................................. 1

2.

CONTROLS

................................................................

..

.............................................................................................. 3

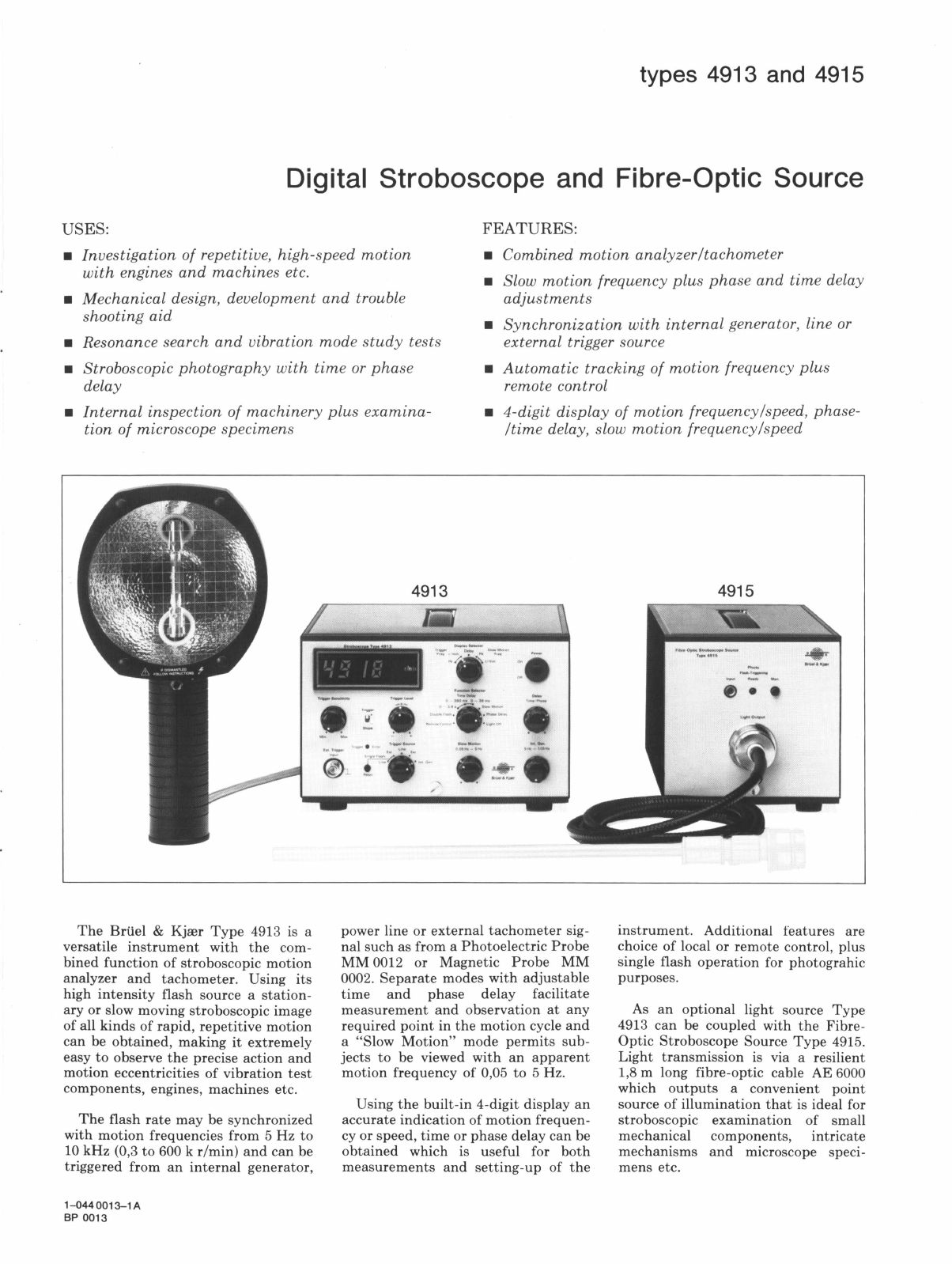

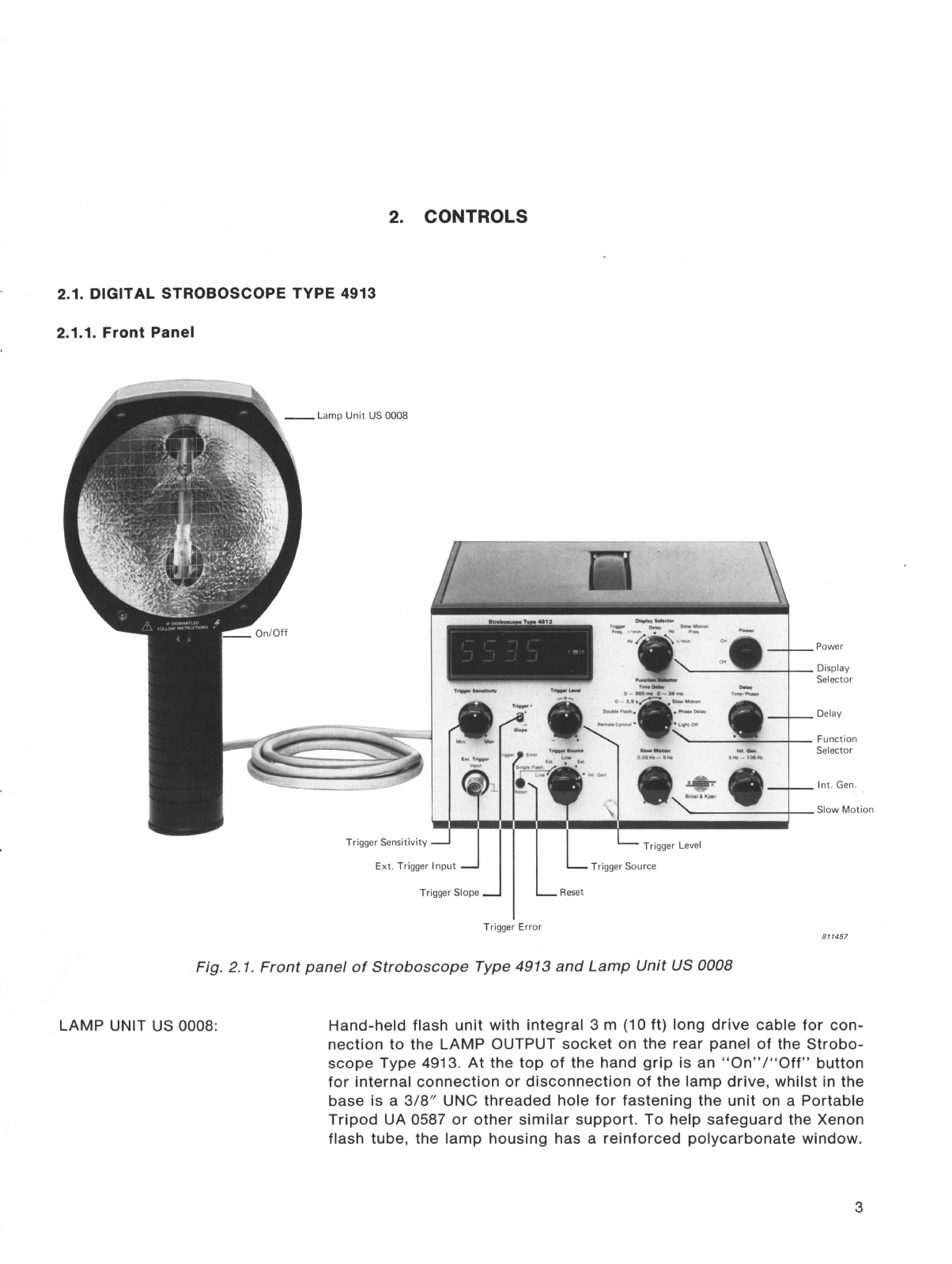

2.1. DIGITAL STROBOSCOPE TYPE 4913................................................................................ 3

Front Panel ......................................................................................

..

..................................... 3

Rear Panel ..............................................................................................................................6

2.2. FIBRE-OPTIC STROBOSCOPE SOURCE TYPE 4915

..

...........................

..

...................... 8

3.

OPERATION

WITH

HAND-HELD

LAMP

UNIT

US

0008.................................................................................. 9

3.1

. PRELIMINARY ........................................................................................................................9

Environment and Handling................................................................................................... 9

Mounting ................................................................................................................................. 9

Connection

of

Mains Supply ............................................................................................. 10

3.2. OPERATION AS A "FREE-RUNNING" STROBOSCOPE ..............................................

11

Determination

of

Motion

Frequency

or

Speed ...............................................................

11

Determination

of

Phase Delay

or

Lag.............................................................................. 13

Timing

of

Motion

Sequences and Events........................................................................ 14

Slow-Motion

Observation................................................................................................... 14

3.3. OPERATION FROM EXTERNAL TRIGGER SOURCE .................................................... 15

External Instruments ...........................................................................................................

15

Photoelectric Tachometer Probe

MM

0012 ..................................................................... 16

Magnetic Transducer

MM

0002 ......................................................................................... 17

3.4. USE WITH LINE TRIGGER SOURCE ...............................................................................

17

3.5. USE WITH DOUBLE FLASH IGNITION ............................................................................ 18

3.6. USE WITH SINGLE FLASH IGNITION .............................................................................. 18

Local and Remote Activation ............................................................................................ 18

Flash

Photography

............................................................................................................... 18

3.7. USE WITH AUXILIARY LIGHT SOURCE.......................................................................... 19

3.8. REMOTE CONTROL ...........................................................................................................

21

4.

OPERATION

WITH

FIBRE-OPTIC

SOURCE

TYPE

4915..............................................................................22

4.1. PRELIMINARY ......................................................................................................................

22

Environment and Handling.................................................................................................

22

Connections

and Mounting................................................................................................

22

Use and

Care

of

Fibre-Optic

Cable AE 6000 .................................................................

23

4.2. NORMAL SINGLE AND REPETITIVE FLASH OPERATION...........................................

24

4.3. SINGLE

"PHOTO"

FLASH OPERATION..........................................................................

24

Triggering .............................................................................................................................

24

Flash

Photography

...............................................................................................................

25