Contents

CHAPTER 1

Introduction.......................................................................................................................................... 1

1.1 About this Manual...................................................................................................................................... 1

1.2 Introduction................................................................................................................................................ 1

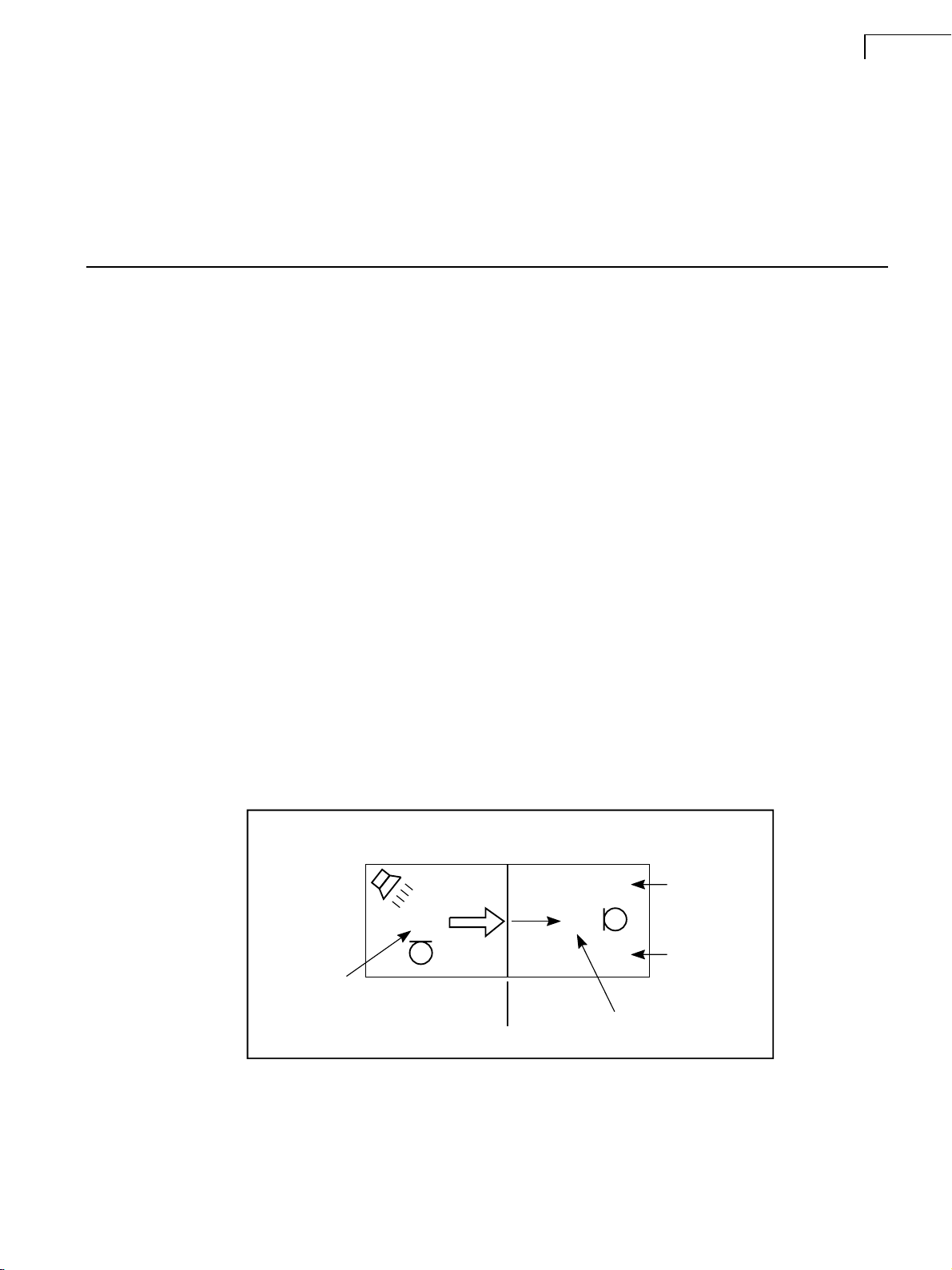

Measuring Sound Insulation ...................................................................................................................... 1

Measuring Impact Sound Insulation .......................................................................................................... 2

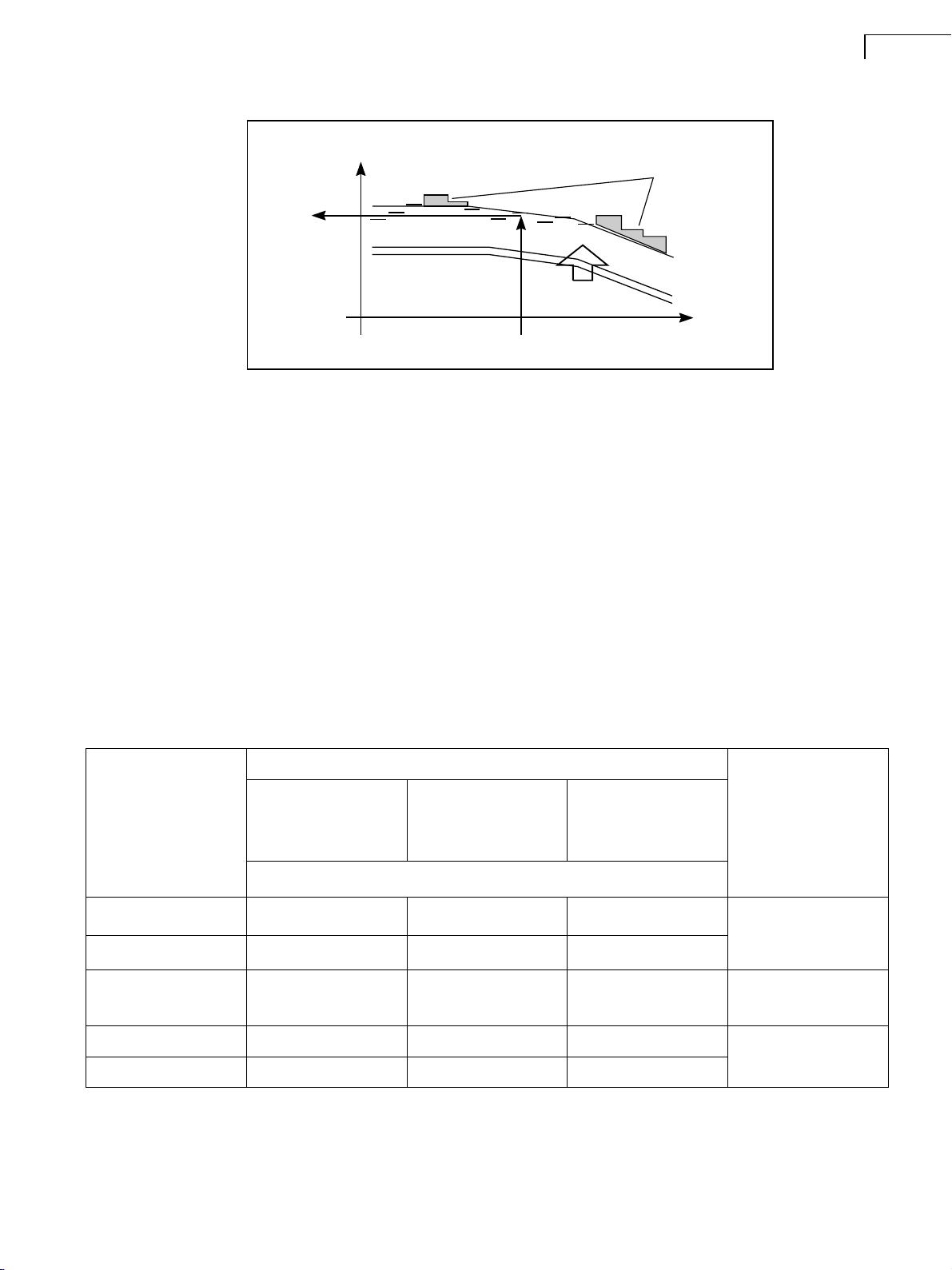

Weighting................................................................................................................................................... 2

1.3 How Much is Too Much? ........................................................................................................................... 3

1.4 Construction of Tapping Machine Type 3207............................................................................................ 4

CHAPTER 2

A Complete Measurement System..................................................................................................... 5

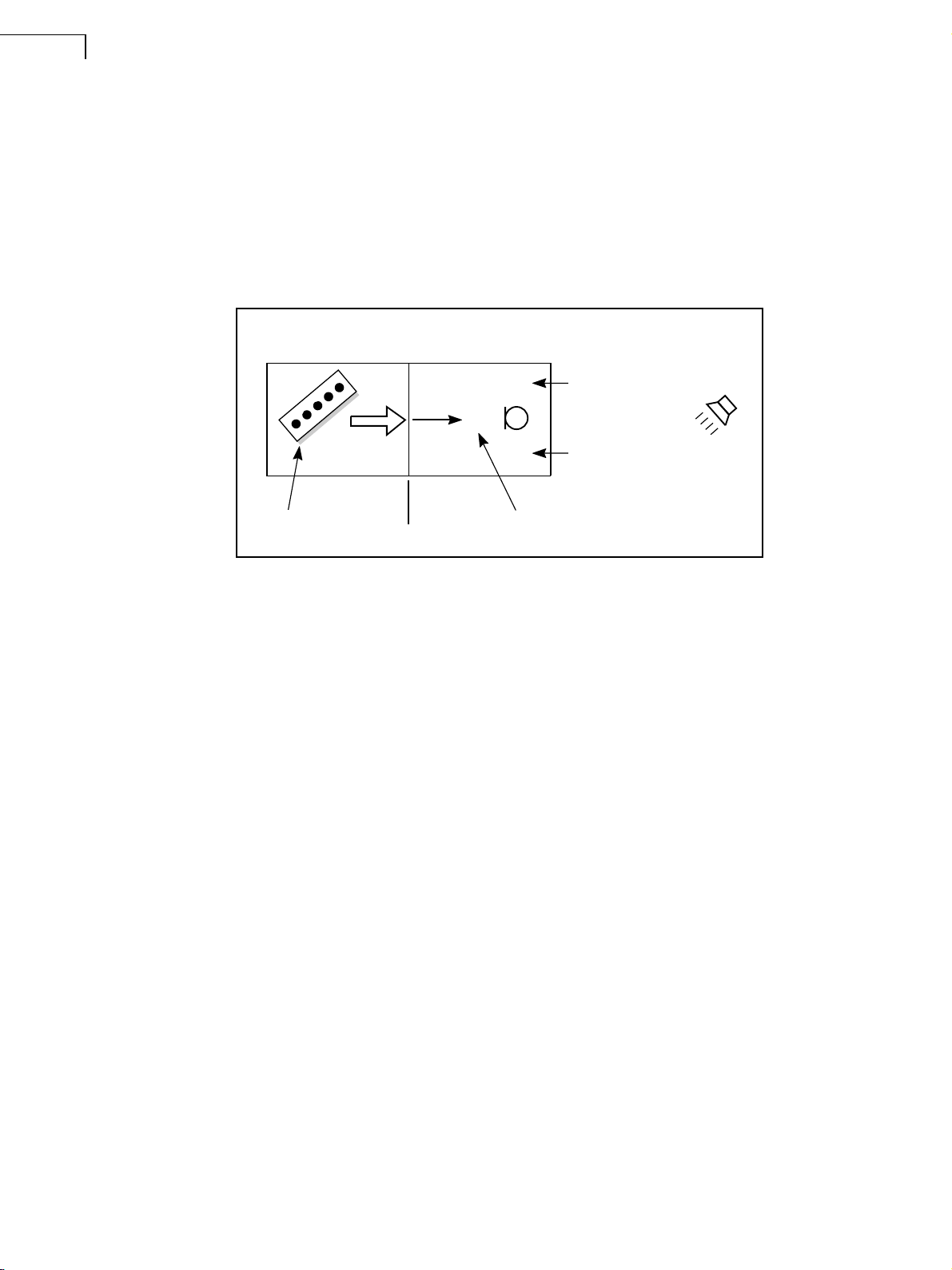

2.1 A Complete Measurement System for Architectural and Building Acoustics ............................................ 5

2.2 Use of 2260-D/BZ-7204............................................................................................................................. 6

Measurement............................................................................................................................................. 6

Data Bookkeeping ..................................................................................................................................... 6

Positions and Average............................................................................................................................... 7

Reuse of Information ................................................................................................................................. 8

Built-in Generator ...................................................................................................................................... 8

Calculations ............................................................................................................................................... 8

Printing ...................................................................................................................................................... 9

Data Transfer to a PC................................................................................................................................ 9

2.3 Assessment and Reporting ....................................................................................................................... 9

Qualifier Type 7830 ................................................................................................................................... 9

Data Transfer............................................................................................................................................. 9

Qualifier Calculations................................................................................................................................. 9

Flexible Reverberation Averaging ........................................................................................................... 10

Documentation ........................................................................................................................................ 10

Building Acoustics Standards and Measured Parameters ...................................................................... 10

CHAPTER 3

User Guide for the Tapping Machine ............................................................................................... 13

3.1 Before Use............................................................................................................................................... 13

3.2 Initial Start-up .......................................................................................................................................... 15

3.3 Measuring................................................................................................................................................ 16

3.4 After Measuring ....................................................................................................................................... 16

3.5 Hints and Tips.......................................................................................................................................... 17

CHAPTER 4

Options and Accessories.................................................................................................................. 19

4.1 Remote Control Operation....................................................................................................................... 19

General.................................................................................................................................................... 19

Wireless Remote Control Kit UA-1476 .................................................................................................... 19

Using Remote Control Kit UA-1476......................................................................................................... 20

Remote Operation via Cable AQ-0633.................................................................................................... 21

Remote Control using Third Party Remote Control Systems .................................................................. 22

4.2 Battery Option.......................................................................................................................................... 23

General.................................................................................................................................................... 23

Installing Battery Kit UA-1477.................................................................................................................. 23

Battery Operation .................................................................................................................................... 25