The

2513

and

2516

are

intended

for

four main kinds of application -

General

vibration

measure-

ments.

Vibration measurements are

valuable in many branches

of

industry.

Some examples of applications are:

shock measurement in rolling mills, leak

detection in pipes,

and

pulsation mea-

surements

in

pneumatic

and

hydraulic

systems. Fields of use include power

generation, mining, motor vehicles,

ships,

and

railways.

Condition

monitoring.

It

is

well

known

that

most kinds

of

machinery

failures are preceded by a rise in vibra-

tion level. Regular measurement of ma-

chine vibration level can be used

to

de-

cide whether

the

machine requires

maintenance. This can form

the

basis of

a systematic

and

economical

technique

The

Types

2513

and

2516

are

com-

pact

battery-powered

instruments

easily held

and

operated

in

one hand.

The

2513

measures

in

SI

units,

and

the

2516

in

g's

and

in/s. A

document

folder designed

to

contain

both

the

Vibration

Meter

and

an

A4

note-pad

--

,..,

Adaptor

I

UA

0641

Accelerometer

Ilia

Type

4384

•

Magnet..,_

UA

0642

-

Ferromagnetic

Disc YO

0070

Plug

JP

0213

l

tO

.t

•

l(jar

......

Type

211•

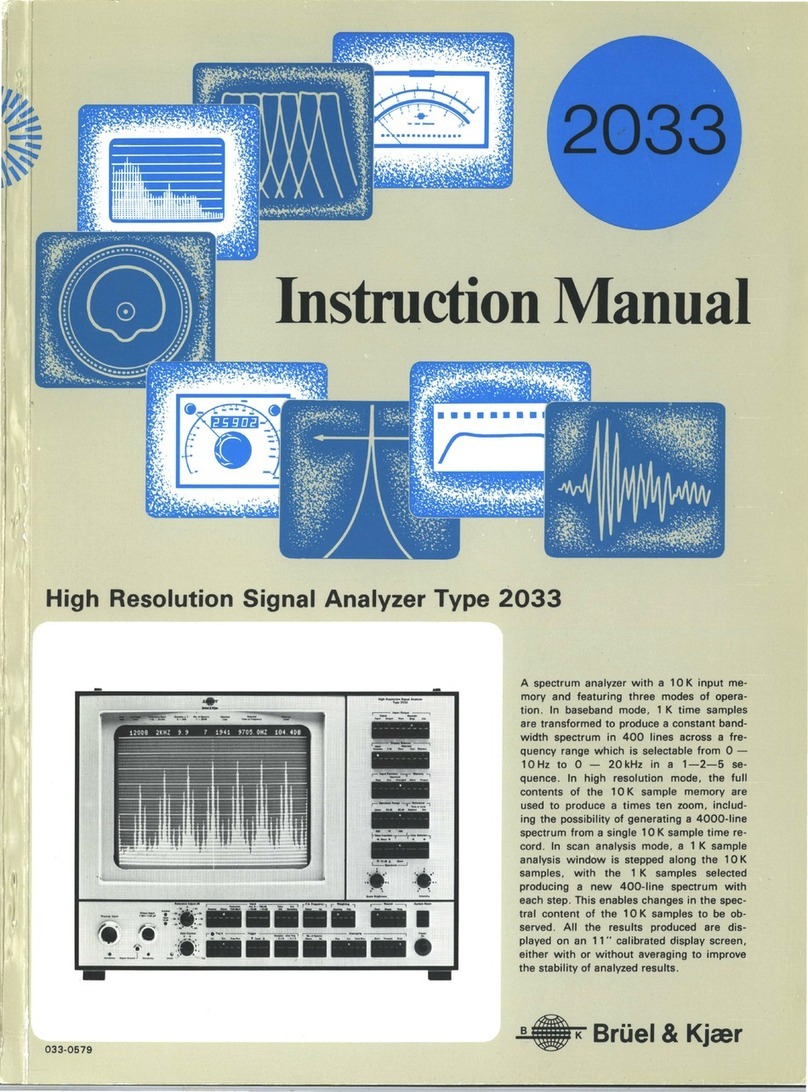

Fig.2.

The

interconnection arrangements

for the 2513

and

2516 (illustrated)

2

for scheduling maintenance.

It

is appli-

cable

to

a very wide range

of

industrial

plant, including machine-tools, steel,

board

and

paper

mills, chemical plants,

cement ovens, compressors, diesel en-

gines,

and

power stations.

Vibration

Severity

measure-

ments.

Vibration Severity is a

quantity

particularly useful in

the

evaluation of

the

running quality

of

rotating

and

re-

ciprocating machinery.

The

2513

and

2516 meet

the

requirements for

an

in-

strument

suitable for measuring Vibra-

tion Severity as laid down in ISO 2954

(1975). Vibration Severity criteria are

covered by ISO 2372, 2373

and

3945,

and corresponding national standards.

For quality-assurance personnel

and

technical

staff

engaged in buying or sell-

ing machinery,

the

2513

and

2516 pro-

vi~e ideal means of checking

that

the

for recording

measurements

taken

on

site is also

included

(Fig.l).

Each

Vi-

bration

Meter

is

supplied

with

a light-

weight Piezoelectric Accelerometer

Type

4384,

connected

to

the

instru-

ment

by a

sturdy

1,2 m coaxial cable

(see Fig.2).

Display

The

2513

and

2516

feature

a solid-

state

thermometer-type

display which

makes

them

especially easy

to

use

without

sacrificing accuracy.

It

con-

sists of a

column

of

41

red

light-emit-

ting

diodes (LEDs) covering a relative

amplitude

range of 1

to

100.

The

am-

plitudes

are

spaced

out

logarithmical-

ly,

thus

giving a

constant

accuracy

over

the

whole range.

The

LEDs, how-

ever,

are

equally spaced, so each suc-

cessive

LED

corresponds

to

an

ampli-

tude

11

%

greater

than

the

one below

it.

If

the

amplitude

measured

falls be-

tween

two

LEDs,

they

are

both

lit,

giving a resolution

of

6%.

The

display range

itself

can

be

switched

between

two

settings

differ-

ing

in

level by a factor

of

10, giving

an

overall

measurement

range

of

1000:1.

The

Leq

Concept

Anyone who has

tried

to

measure vibra-

tion with a conventional

instrument

will

have had

the

experience where

the

me-

ter

fluctuates so much

that

a kind of

visual average has

to

be

made of suc-

cessive readings.

It

is difficult

to

sustain

confidence in

the

validity ofsuch a mea-

surement,

and

in any case

the

"true"

level of such a fluctuating vibration

is

not

the

same

as

the

average reading.

What is needed is

an

indication of the

level which would have resulted in

the

same vibrational energy flow

at

the

measuring point, over a suitable period

of

time, as

the

fluctuating vibration

which actually occurred. This level is

widely known as

Leq

(for "Equivalent

Level").

vibration generated by a machine in op-

eration meets its contractual require-

ments. Because of

their

simplicity

of

op-

eration, only

the

briefest of introduc-

tions is needed before

the

user

starts

making accurate measurements with

the

2513 or 2516.

Hand-Arm

Vibration.

Of particu-

lar concern

to

manufacturers

and

users

of

portable power tools, and environ-

mental

health

authorities, are

the

ef-

fects of sustained exposure

to

vibration

transmitted

into

the

hands

and

arms of

their

operators.

The

2513

and

the

2516

incorporate

an

electronic weighting fil-

ter

to

permit measurements

to

.be made

of

the

overall level

of

exposure, in accor-

dance with

ISO/DP

5349 (Draft

1982-02-17) when used with a Charge

Attenuator available

to

order or a suit-

able alternative Accelerometer.

The

main

graduation

levels are

framed

in

"windows",

and

change

automatically

with

function setting. A

scale of decibel (dB)

graduations

is

provided in

addition

to

the

engineer-

ing-units scale.

The

60

s

Leq

facility

on

the

2513

and

2516

takes

the

vagueness

out

of

vibra-

tion

measurement

when

the

level is

fluctuating.

In

this

mode

of

operation,

the

display builds

up

an

indication

of

the

60s

Leq,

computed

by

mathemati-

cal

integration

from all

the

mean

square

levels occurring since

the

mea-

surement

started

(hence

the

name

"Integrating

Vibration

Meter").

At

the

end

of 60 s

the

measurement

is

termi-

nated

and

the

display

held

for a fur-

ther

60s.

After

that

the

instrument

is

automatically

switched off,

to

save

batteries.

The

operator

can

thus

write

down a single figure for

the

vibration

measurement,

with

complete confi-

dence

that

it

is a

repeatable

figure.

When

the

Leq

function is selected,

the

display simultaneously indicates

the

maximum

peak

value.

In

effect,

it

becomes two displays.

There

is no pos-

sibility of

ambiguity

because

the

max-

imum

peak

vibration

can

never be less

than

the

Leq

value (Fig.3).

Vel. &I I

-

SO

Reset

(Battl

f!'."'3-:

::--

30

•

On/Off

•

Fig.3.

The

display

of

the 2513, showing

Leq

and·Max. Peak indications simulta-

neously