Brunata Optuna H UK-QB101575/29.05.2012

Installation Guide Pages 2/16

Brunata a/s · Vesterlundvej 14 · 2730 Herlev · tlf. +45 77 77 70 00 · fax +45 77 77 70 01 · brunat[email protected] · www.brunata.dk Table of contents:

1.0 INTRODUCTION............................................................................................................................................................. 3

1.1 GENERAL ..................................................................................................................................................................... 3

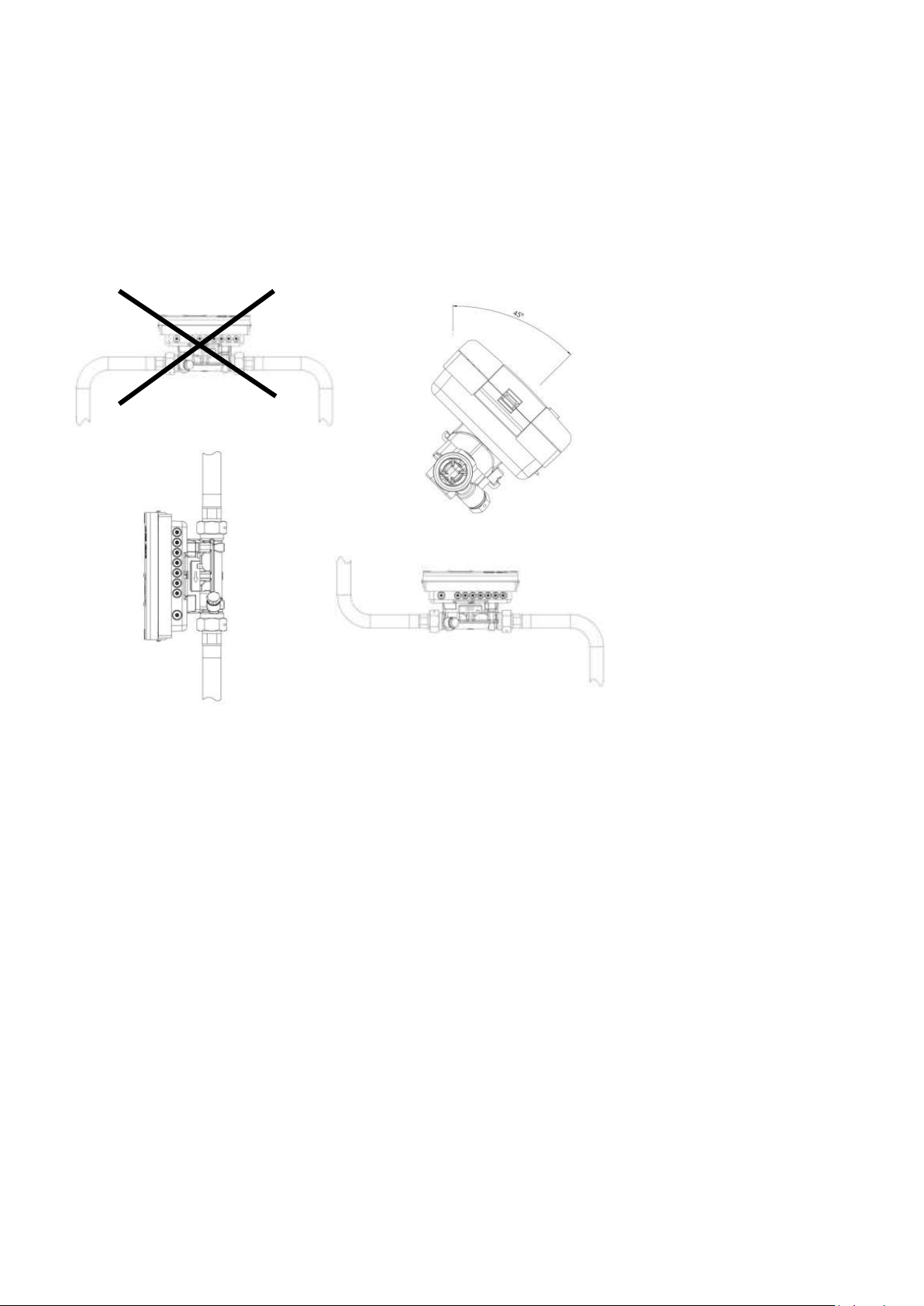

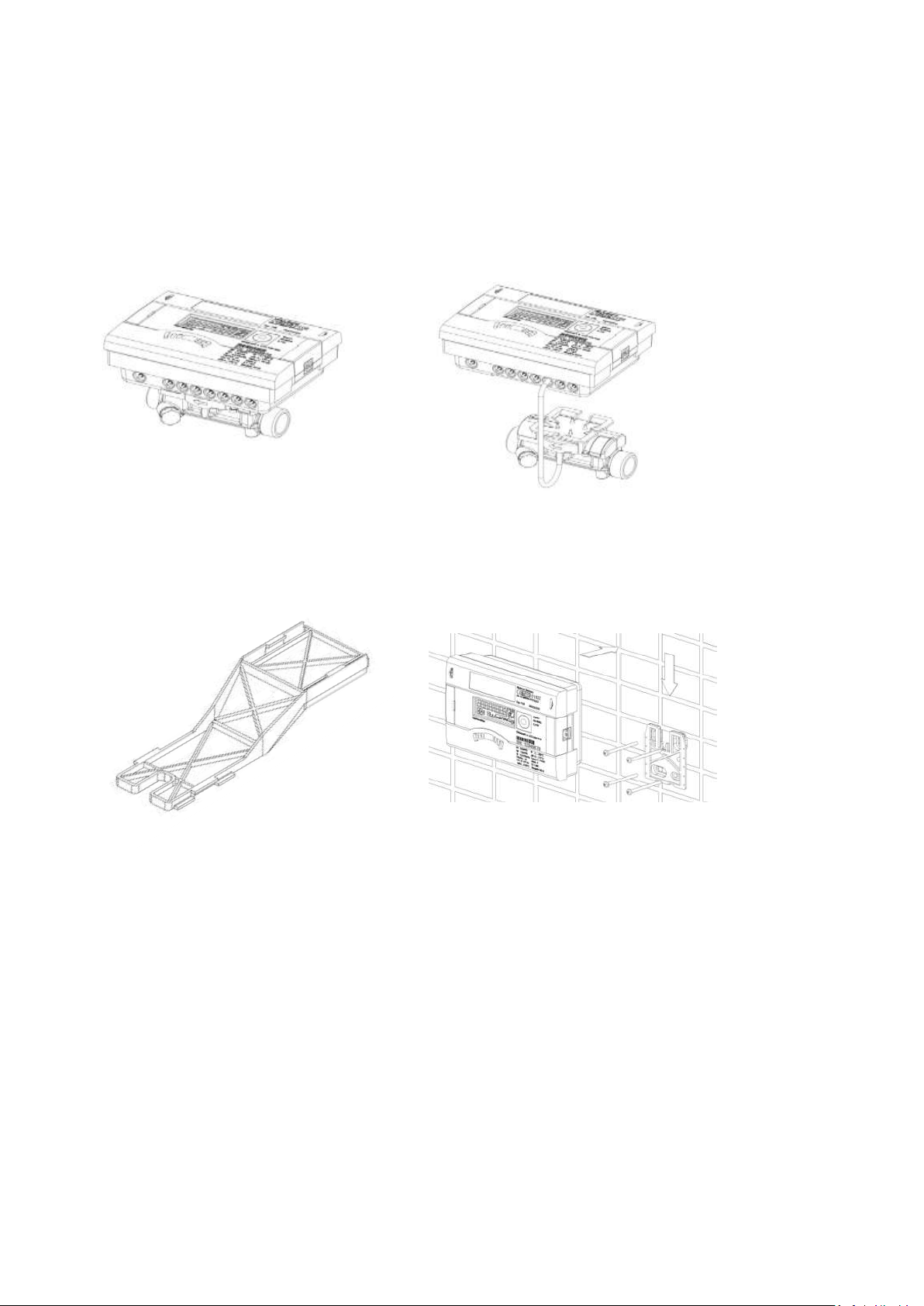

1.2 INSTALLATION OF ENERGY METER ..................................................................................................................................... 3

2.0 INSTALLATION OF TEMPERATURE SENSORS................................................................................................................. 6

3.0 POWER SUPPLY ............................................................................................................................................................. 7

3.1 BATTERY...................................................................................................................................................................... 7

3.2 MAINS UNIT................................................................................................................................................................. 7

4.0 EXTENSION MODULES .................................................................................................................................................. 7

4.1 INSTALLATION OF MODULES ............................................................................................................................................ 8

4.2 COMMUNICATION MODULES ........................................................................................................................................... 8

4.2.1 M-Bus ............................................................................................................................................................... 8

4.2.2 Communication over radio ............................................................................................................................... 9

4.2.3 RS-232 Communication module ....................................................................................................................... 9

4.2.4 RS-485 Communication module ....................................................................................................................... 9

4.3 PULSE INPUT FUNCTION MODULE ................................................................................................................................... 10

4.4 PULSE OUTPUT FUNCTION MODULE................................................................................................................................. 11

4.5 COMBINED FUNCTION MODULE...................................................................................................................................... 12

4.6 ANALOGUE OUTPUT FUNCTION MODULE.......................................................................................................................... 12

4.7 TEST OUTPUT ............................................................................................................................................................. 12

5.0 DISPLAY ....................................................................................................................................................................... 13

5.1 EXPLANATION OF SYMBOLS ........................................................................................................................................... 13

6.0 SIMPLE OPERATION .................................................................................................................................................... 14

6.1 OPERATION INSTRUCTIONS............................................................................................................................................ 14

7.0 ERROR CODES ............................................................................................................................................................. 15

8.0 DECLARATION OF CONFORMITY FOR DEVICES AFTER MID ........................................................................................ 16