BST regi star 20 User manual

Assembly manual

Product line register

regi_star 20

969780505002

© BST eltromat International GmbH 2014

Heidsieker Heide 53

D-33739 Bielefeld

German

register

TO

regi_star_MA_T_en

Rev. 1.2.1 - 08/2014

1General Assembly Instructions ________________________________ 1

1.1 Structure of the Assembl Manual _______________________ 1

1.2 General Instructions ___________________________________ 1

1.3 Qualified Personnel____________________________________ 2

1.4 Designation___________________________________________ 2

1.5 General Conditions ____________________________________ 2

1.6 Structure of the safet instructions ______________________ 3

1.6.1 Warning of danger to persons _______________________ 3

1.6.2 Warning of damage to assets _______________________ 4

1.6.3 Other information _________________________________ 4

1.7 Liabilit ______________________________________________ 5

1.8 Warrant and guarantee ________________________________ 5

2System overview and safety instructions for register control systems 6

2.1 Components of a Register Control S stem_________________ 6

2.2 Safet Instructions ____________________________________ 7

3Register ontrol Assembly ____________________________________ 9

3.1 Traverse Bar Assembl _________________________________ 9

3.2 Register Sensor Assembl _____________________________ 13

3.3 Measuring Camera Assembl ___________________________ 13

3.4 Shaft Encoder Assembl _______________________________ 13

3.5 Control Unit Assembl ________________________________ 15

3.6 Mounting Plate Assembl ______________________________ 17

3.7 Assembl of the drives for linear roller positioning (Option) _ 18

3.8 La ing and connecting cables __________________________ 19

4Remote service and other network functions____________________ 22

4.1 Integration of the BST eltromat

router (INSYS MoRoS Modem) _________________________ 22

4.2 Direct network integration of an BST eltromat s stem _____ 23

Table of ontents

register

regi_star_MA_Kap_1_en

Rev. 1.2.1 - 08/2014

1

1 General Assembly Instructions

1.1 Structure of the Assembly Manual

The present assembl manual is subdivided into four chapters:

•hapter 1: This chapter contains general advice and requirements

regarding the assembl of BST eltromat s stems. Moreover, the

structure of safet instructions will be explained.

•hapter 2: This chapter gives an overview of the s stem components.

Moreover, this chapter lists all safet instructions, which indicate

possible dangers.

•hapter 3: This chapter describes the assembl process. In addition,

the chapter contains cross-references to other assembl instructions

of other manufacturers, whose products are part of the described

BST eltromat s stem.

•hapter 4: This chapter describes the integration of the BST eltromat

s stem into a network (required for remote service and other network

functions).

1.2 General Instructions

The present assembl manual describes the operating routines for the

safe and proper installation and commissioning / start-up of the s stem.

For this purpose, adhere to the step-b -step operating sequence.

• Reading this assembl manual attentivel is indispensable for effec-

tive and fault free assembl of this s stem.

• Ensure that this assembl manual is available to all persons assem-

bling this s stem. Observe all relevant information and instructions.

• Ensure that this assembl manual is alwa s complete and in a

perfectl legible condition.

• Onl operate the s stem when in a perfect condition.This s stem is

designed as a unit to be fitted to a complete machine line. Do not

start up this machine within CENELEC member states until the

complete machine is approved to meet the EC machine directives.

register

regi_star_MA_Kap_1_en

Rev. 1.2.1 - 08/2014

2

1.3 Qualified Personnel

Onl allow qualified personnel to install and service the s stem. For the

purpose of this documentation these are persons who:

• are familiar with the general safet regulations (in particular with the

accident prevention regulations),

• are trained for installation and commissioning of mechanical and

electrical components,

• have familiarised themselves with this assembl manual

• If the s stem is applied in explosive areas, please make sure that

this person has also

1.4 Designation

•The contents on the t pe plate clearl identifies the s stem.

• Refer to the enclosed EC Conformit Declaration for the CE s mbol

of identification.

1.5 General onditions

•Onl operate the s stem in accordance with the intended use stated

in the documentation. Expressl agree an exceptions with BST

eltromat.

• Perfect and safe operation of the s stem requires the correct trans-

port, erection and installation as well as careful operation and correct

maintenance and repair.

• Installation, commissioning / start-up and operation are onl permis-

sible in closed production facilities.

•Onl use original BST eltromat spare parts. Onl this will ensure that

function safet is maintained.

• Unauthorised modifications (mechanical / electrical) are expressivel

forbidden. The warrant will automaticall become null and void if

the s stem is modified in an wa .

S stem manufacturer: BST eltromat International GmbH

Heidsieker Heide 53

D-33739 Leopoldshöhe

Service: Tel.: +49 - 52 08 - 987 - 680

Fax: +49 - 52 08 - 987 - 349

E-Mail: [email protected]

register

regi_star_MA_Kap_1_en

Rev. 1.2.1 - 08/2014

3

• For installation, commissioning / start-up and operation of this s stem

adhere to the current valid safet and accident prevention regulations.

• Electrical components ma onl be assembled in de-energized con-

dition.

• Motors must be assembled in accordance with the assembl method

(flange / foot assembl ) the motor manufacturer stipulates / provides

in his own assembl manual.

• All components of the incomplete s stem must be assembled so that

the do not affect the free moving space of the staff and of other

machine components.

• The incomplete machine ma not be started before all mounted parts,

in particular all covers, safet elements (e.g. emergenc stops etc.)

and safet sensors have been assembled and an operational check

has been carried out.

1.6 Structure of the safety instructions

The safet instructions in this assembl manual are of a uniform structure

in accordance with the following examples.

Signal word! Information text

• The pictograph indicates the t pe of danger.

• The signal word indicates the severit of the danger.

• The information text describes the individual danger and provides

instructions on how to avoid danger.

1.6.1 Warning of danger to persons

Pictographs

Warning of a dangerous point

Warning of dangerous electrical voltage

Warning: danger of entanglement

register

regi_star_MA_Kap_1_en

Rev. 1.2.1 - 08/2014

4

Signal words

DANGER! Warns of imminent danger. Consequences of non-observance: death or

serious injur .

WARNING! Warns of a possibl ver dangerous situation. Possible consequences of

non-observance: death or serious injur .

AUTION! Warns of a possibl dangerous situation. Possible consequences of non-

observance: Slight, minor injuries.

1.6.2 Warning of damage to assets

Pictograph

Signal word

STOP! Warns of possible damage to assets. Possible consequences of non-

observance: Damage to the plant or its surroundings.

1.6.3 Other information

Pictographs

Warning of possible damage to assets.

STOP

Additional information, instructions and tips.

Cross reference to further and / or related chapters with details of the

chapter number and chapter heading.

register

regi_star_MA_Kap_1_en

Rev. 1.2.1 - 08/2014

5

1.7 Liability

The supplied documentation was created with utmost care. Deviations,

however, ma occur due to the continuous development of the described

products. If errors are detected in the documentation or in the event of

update according to the technical progress, we reserve the right for

modifications at an time and without prior announcement. No claims

can be made for modification or correction on products alread delivered.

Furthermore, the General Sales and Deliver terms of BST eltromat appl .

1.8 Warranty and guarantee

The General Sales and Deliver terms of BST eltromat as well as the

terms of the individual order appl .

register

6

regi_star_MA_Kap_2_en

Rev. 1.2.1 - 08/2014

2 System overview and safety instructions for register control systems

Review This chapter gives an overview about the register control components.

Moreover, this chapter contains a summar off all safet instructions

and which need to be observed for register control assembl works.

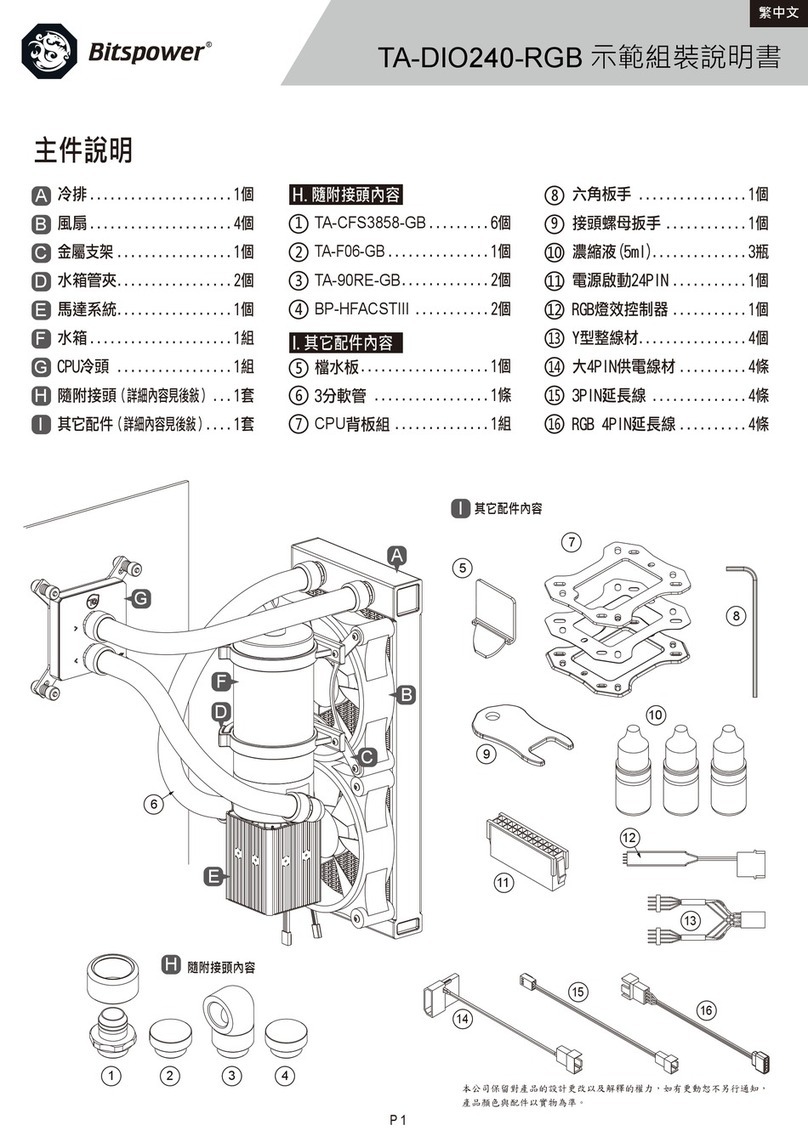

2.1 omponents of a Register ontrol System

A register control s stem consists of the following components:

• control unit,

• register sensor (fibre optic/measuring on the traverse bar and elec-

tronics in the housing),

• traverse bar,

• shaft encoder,

• drive for the positioning of linear rollers (optional)

If the register control s stem is used in an explosive area, different

terminal boxes for connecting the cables will be delivered as well. It is

possible to have the components delivered on a mounting plate instead

of a control unit. The following image shows an example of the different

assembl / installation locations of a web monitoring s stem. The

displa ed printing press is a general example and must in no case

conform to our model.

Fig. 2.1

register

regi_star_MA_Kap_2_en

Rev. 1.2.1 - 08/2014

7

2.2 Safety Instructions

The following safet instructions must be observed for the assembl of

the register controller:

WARNING! Guarantee securit at the components assembl location

before starting the assembl works. During the entire assembl works,

the printing press must be full stopped and secured against restart.

Possible consequences of non-observance can be death or serious injur .

WARNING! Elecrical voltage! Guarantee securit at the connection

points b means of de-energizing the circuits and secure them against

recharge of voltage! Death or serious injur can be consequences of non-

observance.

AUTION! Attention: Do not expose the cables to mechanical forces

(e.g. pulling, folding, crushing, stretching or twisting)!

AUTION! The servo motors of the length and side register ma

unexpectedl change running direction and velocit . You ma onl

operate the register controller if safet -relevant blockings of the motor

command have been realised through machine control.

AUTION! In order to avoid accidents or damages, a second person is

needed to transport and to assemble the traverse bar.

AUTION! Danger of crushing! When transporting the traverse bars,

make sure that the sled for lateral adjustment has been fixed with the

release handle. Injur can be consequence of non-observance.

AUTION! Never transport the control unit b means of pure muscle

strength. Use onl appropriate means of transport such as fork trucks,

elevating trucks and truck cranes. Back damages and other injuries can

be consequence of non-observance.

STOP! In order to avoid damages on the s stem, never cover the control

units ventilators and fences!

STOP! Be careful when transporting and assembling the shaft encoder.

Protect the shaft encoder against impacts and do not put weight on the

encoder shaft to avoid damages. Consider the maximum offsets in order

to avoid a damage on the shaft encoder coupling.

When choosing the assembl location, consider the respective compo-

nents machine categor !

register

regi_star_MA_Kap_2_en

Rev. 1.2.1 - 08/2014

8

The following safet instructions must be observed in case of using a

motorized traverse bar:

WARNING! Danger of explosion! The traverse bar is used in zone 1.

Occasionall an explosive atmosphere ma occur which can be ignited

b electrical or mechanical energ . To prevent such an ignition, adhere

to the following instructions:

• Observe the supplied documentation for the motor, the coupling and

the limit switch.

• Connect a potential compensation unit with a diameter of at least

4mm² to the traverse bar (see drawings on pages 1 and 2).

• For traverse bar with sensor rail: Remove the protective film from the

sensor rail prior to commissioning/start-up!

• The traverse bar must not have contact to the printed web when the

machine is running. This must be considered when choosing the

assembl area.

The following safet instructions must be observed in case of using the

optional drives for linear roller positioning:

AUTION! Danger of entanglement! Protect the coupling area between

the servo motor and the angle gear of the linear roller with an adequate

protection device (e.g. cover) permanentl . Possible consequences of

non-observance can be serious injur .

AUTION! Danger of crushing! Pinch points can occur between the

linear roller (being driven b BST eltromat) and other machine compo-

nents (e. g. guide rollers, bars, dr ers, etc.). Consider the motor-driven

adjustment of the linear roller in the risk assessment of the complete

machine. In addition ou have to integrate the servo control into the

safet s stem of the complete machine (e.g. emergenc stop). Otherwise

death or serious injur can be consequences during operation.

AUTION! The register motors can unexpectedl change running direc-

tion and velocit during operation. Consider the possibilit of uncontrol-

led movement in the risk assessment of the complete machine.

AUTION! Danger of burning! The surfaces of the drive motors can reach

a temperature of 140° C during operation. Therefore equip the motors

with a protection against contact. Otherwise burnings can be the

consequence. Also refer to the manufacturer documentation of the drive

motors on this topic.

STOP! Use a limit switch with forced opening for the end position

detection of the linear roller to prevent the destruction of the gearing,

the coupling or the linear roller. Otherwise injuries caused b falling

objects can occur in addition to the damage of propert .

register

9

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

3 Register ontrol Assembly

Review This chapter describes the assembl of all register control components.

All requirements the assembl / installation location needs to fulfill will

be cited. Moreover, important safet instructions will be given and, if

necessar , the operating steps will be described in particular.

3.1 Traverse Bar Assembly

The traverse bar serves to assemble the sensing head/measuring camera

and is set across the web on the machine stand. B means of a sled,

the register sensor can be slid over the entire traverse bars width. There

are different t pes of traverse bars, which distinguish mainl in the

following characteristics

• T pe of sensor holder

• T pe of cable la ing (optical fibre holder or drag chain)

• T pe of lateral adjustment (manuall adjustable or motorised)

• T pe of background mirror (none, partial mirror or mirror across the

entire traverse bar width)

The following illustration shows examples of two manually adjustable

traverse bars:

• Traverse bar without background mirror (left)

• Traverse bar with background mirror (right).

In addition, the required space for the respective traverse bar t pe is

indicated in the illustration.

Fig. 3.1

The following illustration shows examples of two motorised traverse bars:

• Traverse bar withour background mirror (left).

• Traverse bar with background mirror (right).

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

10

In addition, the required space for the respective traverse bar t pe is

indicated in the illustration.

Fig. 3.2

All relevant information on our register controllers traverse bar

t pe can be found in the customer documentation under MECHANICAL

DRAWINGS.

Assembly Methods There are three different methods to assemble the traverse bar. There

is a special end piece on the traverse bar which depends on the assembl

method.

Winding: There must be M10 tap holes at the traverse bars front face.

The traverse bar is fixed with an M10 screw. For assembl , a suitable

drill-hole must be made on the machine stand.

Round shank: For assembl , a compatible counter piece must be present

on the machine stand.

Flattened round shank: For assembl , a compatible fork piece must be

present on the machine stand.

Safety Instructions

WARNING! Guarantee securit at the traverse bar assembl location

before starting the assembl works. During the entire assembl works,

the printing press must be full stopped and secured against restart.

Possible consequences of non-observance can be death or serious injur .

ATTENTION! In order to avoid accidents or damages, a second person

is needed to transport or to assemble the traverse bar.

ATTENTION! Danger of crushing! When transporting the traverse bars,

make sure that the sled for lateral adjustment has been fixed with the

release handle. Injur can be consequence of non-observance.

When choosing the assembl location, consider the machine categories

of the register sensor and of the traverse bar (if applicable)! Further

information on this issue can be found in the register sensors operating

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

11

manual and in the assembl instructions of the traverse bar. If ou are

using a motorized traverse bar: Do not use the supplied terminal box in

explosive areas!

The following safet instructions are onl relevant for the motorized

variants of the traverse bar:

WARNING! Danger of explosion! The traverse bar is used in zone 1.

Occasionall an explosive atmosphere ma occur which can be ignited

b electrical or mechanical energ . To prevent such an ignition, adhere

to the following instructions:

• Observe the supplied documentation for the motor, the coupling and

the limit switch.

• Connect a potential compensation unit with a diameter of at least

4mm² to the traverse bar (see drawings on pages 1 and 2).

• For traverse bar with sensor rail: Remove the protective film from the

sensor rail prior to commissioning/start-up!

• The traverse bar must not have contact to the printed web when the

machine is running. This must be considered when choosing the

assembl area.

Integrate the traverse controls into the EMERGENCY STOP function of

the machine in order to be able to switch off the power suppl of the

traverse bar adjustment b means of the EMERGENCY STOP!

Fig. 3.3

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

12

Assembly Location At the assembl location, it must be provided that

• the side walls of the machine stand have a sufficient load-bearing

capacit . The required load-bearing capacit is calculated as follows

(a is the length of the traverse bar):

a [mm] * 0,008 + 1 [kg] (manuall adjustable traverse bar)

a [mm] * 0,001 + 5 [kg] (motorised traverse bar)

• there is enough space for assembl (see Fig. 3.1 and Fig. 3.2),

• the traverse bar can be assembled parallel to the web and orthogonal

to the side walls,

• the traverse bar does not vibrate when the machine is running,

• a spacing of 9 mm between register sensor and web is possible at

each traverse bar position,

• the electrical connections of the register sensor are well-accessible

and

• the web is guided straight and without web flapping.

Please note that the background panel of a traverse bar with rear mirror

is movable:

Fig. 3.4

A traverse bar with background panel must be assembled so that the

background panel in position A touches the web.

Assembly Carr out the following operating steps in order to assemble the traverse

bar:

ff • Fit the traverse bar into the assembl location and fix the traverse

bar provisoril with screw clamps.

• Adjust the traverse bar precisel . Take the above-mentionned requi-

rements into account.

• Mark the drillings required for the desired assembl method.

• Dismantle the traverse bar.

Carr out the required drillings and install the needed assembl counter

pieces.

• Fit the traverse bar into the assembl location and plug the end pieces

of the traverse bar into the respective assembl counter pieces.

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

13

• Adjust the traverse bar precisel . Take the above-mentionned requi-

rements into account.

• Screw / arret the assembl counter pieces to fix the traverse bar!

For further advice on mounting the terminal box and on the traverse bars

operation conditions, please see the provided documentation.

Repeat this procedure for all traverse bars.

3.2 Register Sensor Assembly

For a detailed register sensor assembl see register sensor

manual chapter ASSEMBLY and COMMISSIONING.

3.3 Measuring amera Assembly

For a detailed measuring camera assembl see register measu-

ring cmaera manual chapter ASSEMBLY and COMMISSIONING.

3.4 Shaft Encoder Assembly

The shaft encoder is mounted on the print unit to s nchronize the register

control with the web. There is a shaft encoder model which ma onl be

used in non-explosive areas and another one which ma be used in zone 1.

Safety Instructions

WARNING! Guarantee securit at the shaft encoder assembl location

(if necessar , terminal boxes assembl location, too) before starting the

works. During the entire assembl works, the printing press must be full

stopped and secured against restart. Possible consequences of non-

observance can be death or serious injur .

STOP! Be careful when transporting and assembling the shaft encoder.

Protect the digitizer against impacts and don’t put weight on the encoder

shaft to avoid damages.

STOP! Mount the shaft encoder onl directl on the shaft. Do not mount

an machine elements like drives and gear belts between shaft encoder

and shaft to avoid damages on the shaft encoder.

For shaft encoder application in explosive areas:

The shaft encoder falls in machine categor 2G and ma onl be used

in zone 1, zone 2 and in non-explosive areas.

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

14

Assembly Instructions •Mount the shaft encoder, depending on the t pe of drive, on the main

drives or on the counter pression c linders shaft.

• The shaft encoder must be mounted in a transmission ratio corres-

ponding to the application (e.g. 1:1).

• The shaft encoder must be mounted so that no slip can occur.

Assembly Conduct the following steps in order to mount the shaft encoder:

• Mount the shaft encoder flange (A, not included in the eltromat scope

of deliver ) on the machine side.

• Plug the shaft encoder coupling (B) on the c linders shaft end (or

on the deviation rolls end) and tighten it.

• Plug the shaft encoders shaft ( ) in the shaft encoder coupling.

• Adjust the shaft encoder axiall aligned and tighten it on the shaft

encoder flange.

STOP! Consider the maximum offsets in order to avoid a damage on

the shaft encoder coupling:

• radial: max. arbour offset 0.2 mm

• axial: max. arbour offset 1 mm

• angle offset: max. 2°

• Tighten the shaft encoder coupling on the shaft encoder shaft.

• For further advice on mounting the shaft encoder and the coupling,

please see the provided documentation.

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

15

If ou use the shaft encoder in an explosive area, ou have to install a

terminal box, to which the shaft encoders cables are connected.

The terminal box falls in the machine categor 3G and ma onl be used

in zone 2 and in non-explosive areas.

• Loosen the screws and remove the cover of the terminal box.

• Fix the terminal box with 2x M4 screws.

• Fix the protective earth conductor of the terminal box terminal on

the machine stand.

After cable connection:

• Close the cover of the terminal box b means of the four screws.

For further advice on mounting the terminal box, please see the provided

documentation.

3.5 ontrol Unit Assembly

The control unit contains the register control hardware and provides the

opportunit of operatig the register control s stem b means of a touch

screen and a ke pad. There are different t pes of control units. The

following image shows a common t pe of control unit with climate

control.

All relevant information on our register control s stems control

unit t pe can be found in the customer documentation under MECHA-

NICAL DRAWINGS.

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

16

Fig. 3.5

ATTENTION! Never transport the control unit b means of pure muscle

strength. Use onl appropriate means of transport such as fork trucks,

elevating trucks and truck cranes. Back damages and other injuries can

be consequence of non-observance.

The control unit ma onl be used in non-explosive areas.

Assembly Location The assembl location has to fulfill the following requirements:

• The dust or humidit load should be as small as possible.

• The surrounding temperature ma not exceed 40°C. Otherwise, a

housing with climate control must be used.

• The control unit ma not be exposed to vibrations when the s stem

is running.

• The floor of the assembl location should be flat and solid and should

have an appropriate load capacit .

Assembly Advice In addition, ou should consider the following points for the control unit

assembl :

• Consider the length of the provided cables.

• Make sure that each door of the control unit is accessible.

• Place the control unit ergonomicall for the user.

• Make sure that the control unit is dul grounded.

STOP! In order to avoid damages on the s stem, never cover the control

units ventilators and fences!

If the provided cables are longer than required, store the non-laid cable

sections, if possible, in the control units cable box.

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

17

For further information on the control unit, please see the provided

documentation.

3.6 Mounting Plate Assembly

It is possible to purchase the register control hardware without control

unit. In this case, the mere construction groups are delivered on

mounting plates. The can be mounted into an existing console or into

a tall cupboard. The la out and the number of these mounting plates

depend on the customer’s needs. The following image shows exemplaril

the sectioning into energ suppl module, main control panel and output

module

Fig. 3.6

All relevant information on our register control s stems moun-

ting plates can be found in the customer documentation under MECHA-

NICAL DRAWINGS.

Assembly Location Please consider the following when choosing the assembl location:

• The dust or humidit load should be as small as possible.

• The surrounding temperature ma not exceed 40°C.

• There must be enough space for electrical connections.

• Consider the cable length.

Make sure that there is enough cooling air.

Assembly Carr out the following steps to assemble the mounting plates:

ff • Mark the drill-holes on the back wall of the console or the tall cupboard

(see the mechanical drawings for boring measures)

• Drill the holes and cut the correspondent windings.

• Tighten the mounting plates on the back wall.

register

regi_star_MA_Kap_3_en

Rev. 1.2.1 - 08/2014

18

3.7 Assembly of the drives for linear roller positioning (Option)

As an option the register control can be delivered with drives for

adjustment of the register via linear roller positioning. These drives

consist of servo controls (mounted in cabinets) and servo motors. The

servo motors are connected with the customer-supplied linear roller via

a coupling (if necessar included in deliver ). The following figure shows

an example of a servo motor.

Fig. 3.7

Safety instructions

The cabinets and the motors for linear roller positioning ma onl be

used in non-explosive areas.

WARNING! Ensure securit at the assembl location of the servo motor

before starting the works. During the entire assembl works, the printing

press must be full stopped and secured against restart. Possible

consequences of non-observance can be death or serious injur .

AUTION! Danger of entanglement! Protect the coupling area between

the servo motor and the angle gear of the linear roller with an adequate

protection device (e.g. cover) permanentl . Possible consequences of

non-observance can be serious injur .

AUTION! Danger of crushing! Pinch points can occur between the

linear roller (being driven b BST eltromat) and other machine compo-

nents (e. g. guide rollers, bars, dr ers, etc.). Consider the motor-driven

adjustment of the linear roller in the risk assessment of the complete

machine. In addition ou have to integrate the servo control into the

safet s stem of the complete machine (e.g. emergenc stop). Otherwise

death or serious injur can be consequences during operation.

AUTION! The register motors can unexpectedl change running direc-

tion and velocit during operation. Consider the possibilit of uncontrol-

led movement in the risk assessment of the complete machine.

STOP! Use a limit switch with forced opening for the end position

detection of the linear roller to prevent the destruction of the gearing,

the coupling or the linear roller. Otherwise injuries caused b falling

objects can occur in addition to the damage of propert .

Table of contents

Other BST Computer Hardware manuals