©2015 HYSTER COMPANY

TABLE OF CONTENTS

Series Code / Model Designation Reference Table ................................................................................................ 1

General .....................................................................................................................................................................1

Description ...............................................................................................................................................................2

Remove and Install ..................................................................................................................................................3

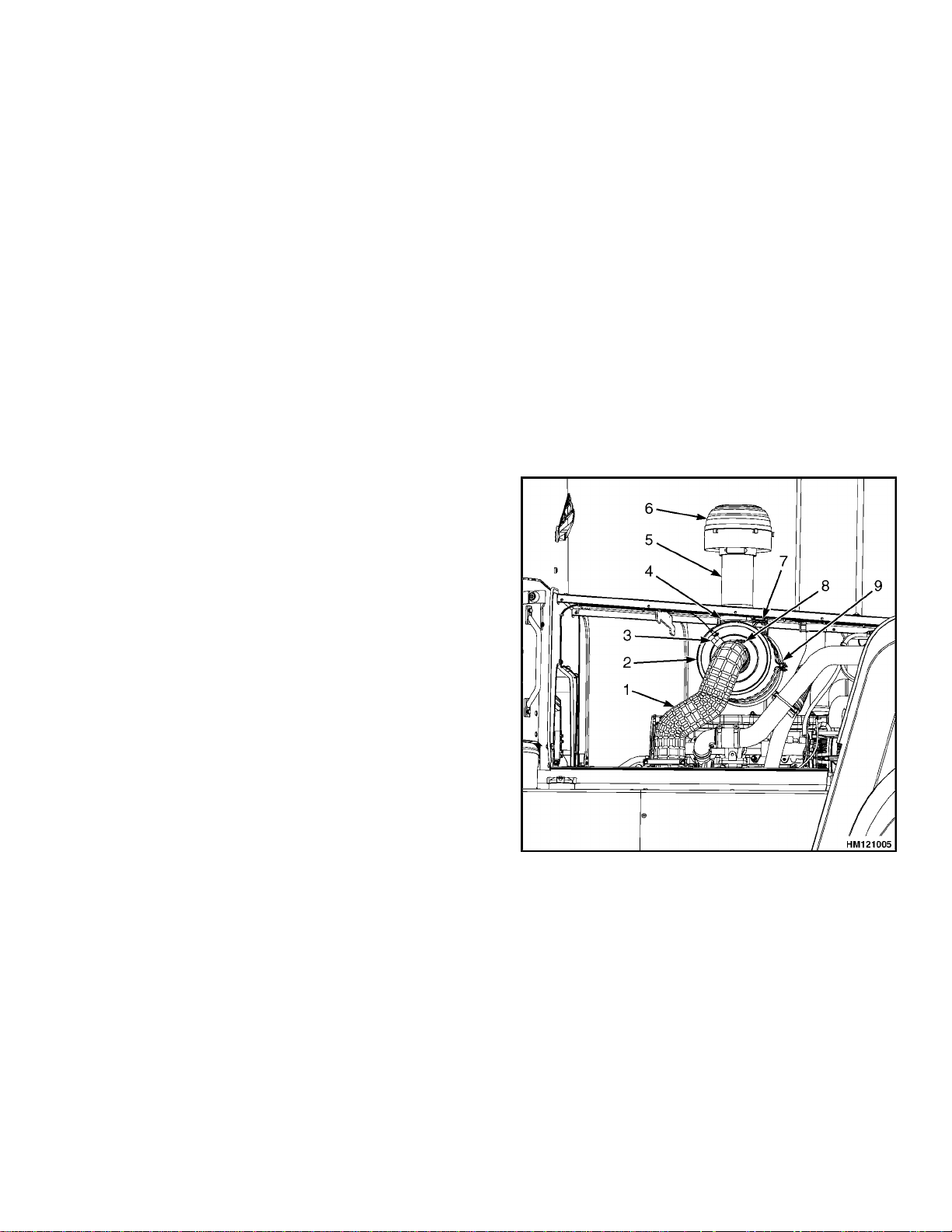

Air Filter Assembly (Tier 3/Stage IIIA) .............................................................................................................3

Remove ............................................................................................................................................................3

Install ..............................................................................................................................................................3

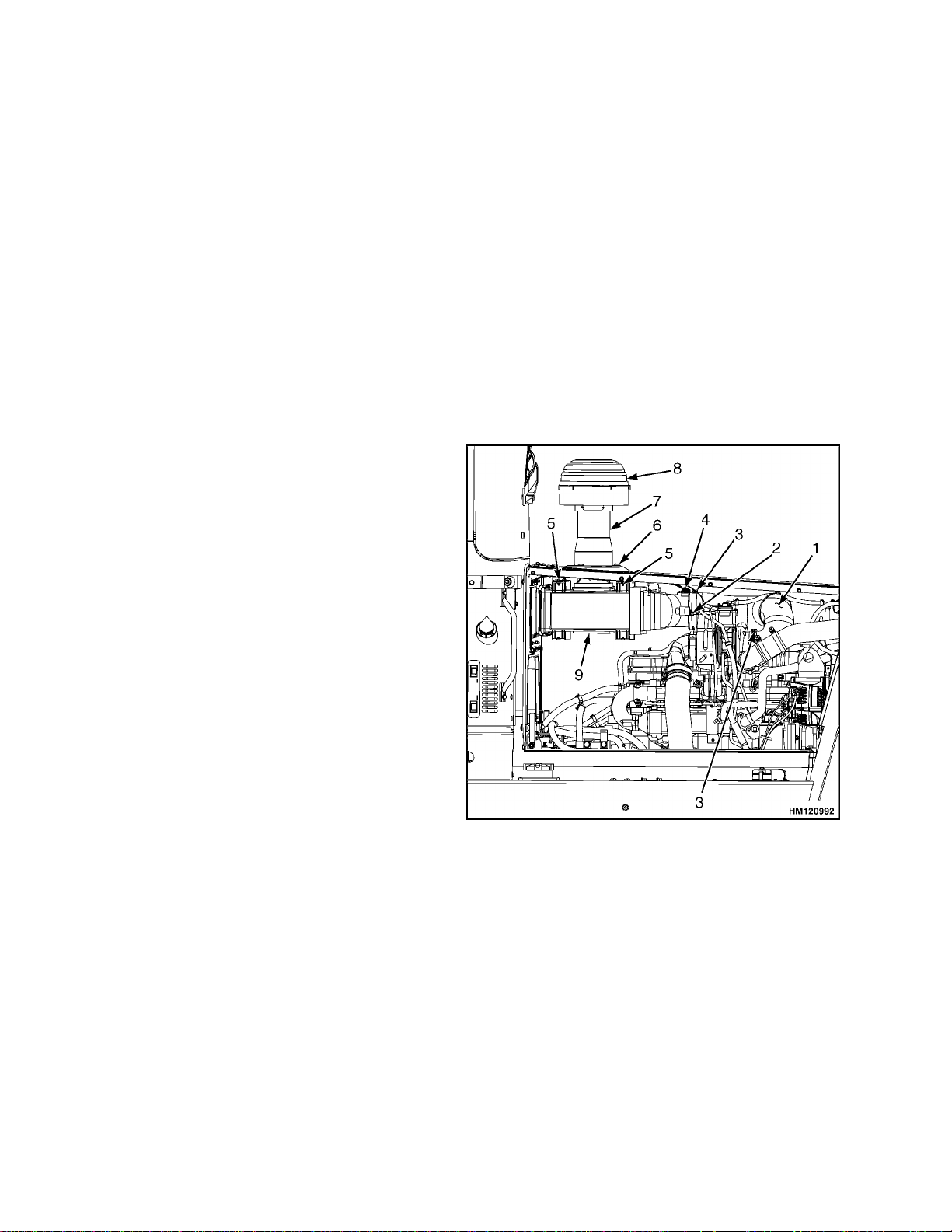

Air Filter Assembly (Tier 4F/Stage IV) ..............................................................................................................4

Remove ............................................................................................................................................................4

Install ..............................................................................................................................................................4

Exhaust System (Tier 3/Stage IIIA) ...................................................................................................................5

Remove ............................................................................................................................................................5

Install ..............................................................................................................................................................5

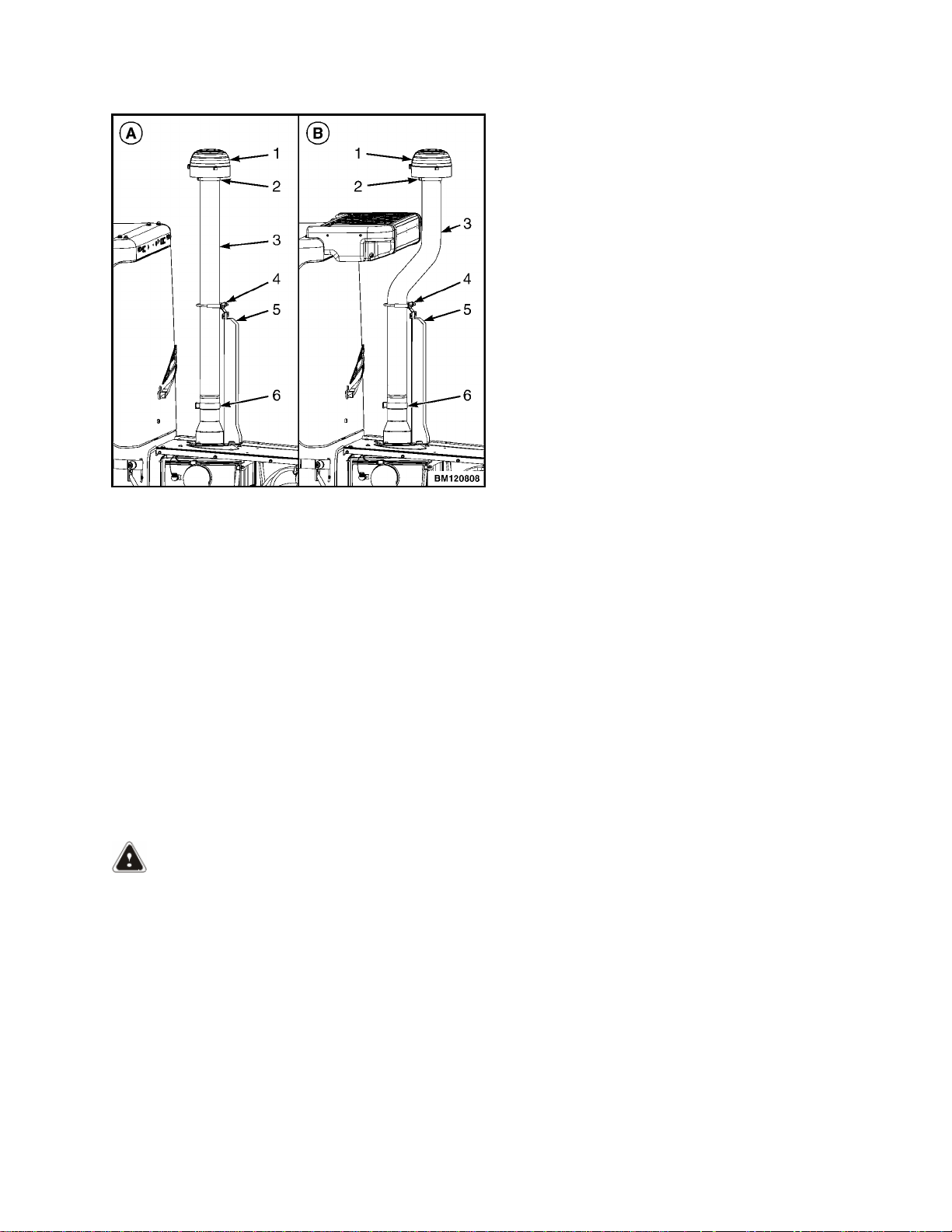

Exhaust System (Tier 4F/Stage IV) ...................................................................................................................6

Exhaust Pipes High Mount ............................................................................................................................6

Remove ........................................................................................................................................................6

Install ..........................................................................................................................................................6

Exhaust Pipes and Diffuser Low Mount ....................................................................................................... 8

Remove ........................................................................................................................................................8

Install ..........................................................................................................................................................8

Engine After Treatment (EAS) System (Tier4F\Stage IV) ..............................................................................8

Preparation .....................................................................................................................................................8

Remove ............................................................................................................................................................9

Install ............................................................................................................................................................10

Exhaust Seal Rings .......................................................................................................................................10

Selective Catalytic Reducer (SCR) ...............................................................................................................11

Remove ......................................................................................................................................................11

Install ........................................................................................................................................................11

Decomposition Reactor Tube (DRT) ............................................................................................................ 12

Remove ......................................................................................................................................................12

Install ........................................................................................................................................................12

Diesel Oxidation Catalyst (DOC) .................................................................................................................12

Remove ......................................................................................................................................................12

Install ........................................................................................................................................................12

Hood Assembly ..................................................................................................................................................12

Remove ..........................................................................................................................................................12

Install ............................................................................................................................................................14

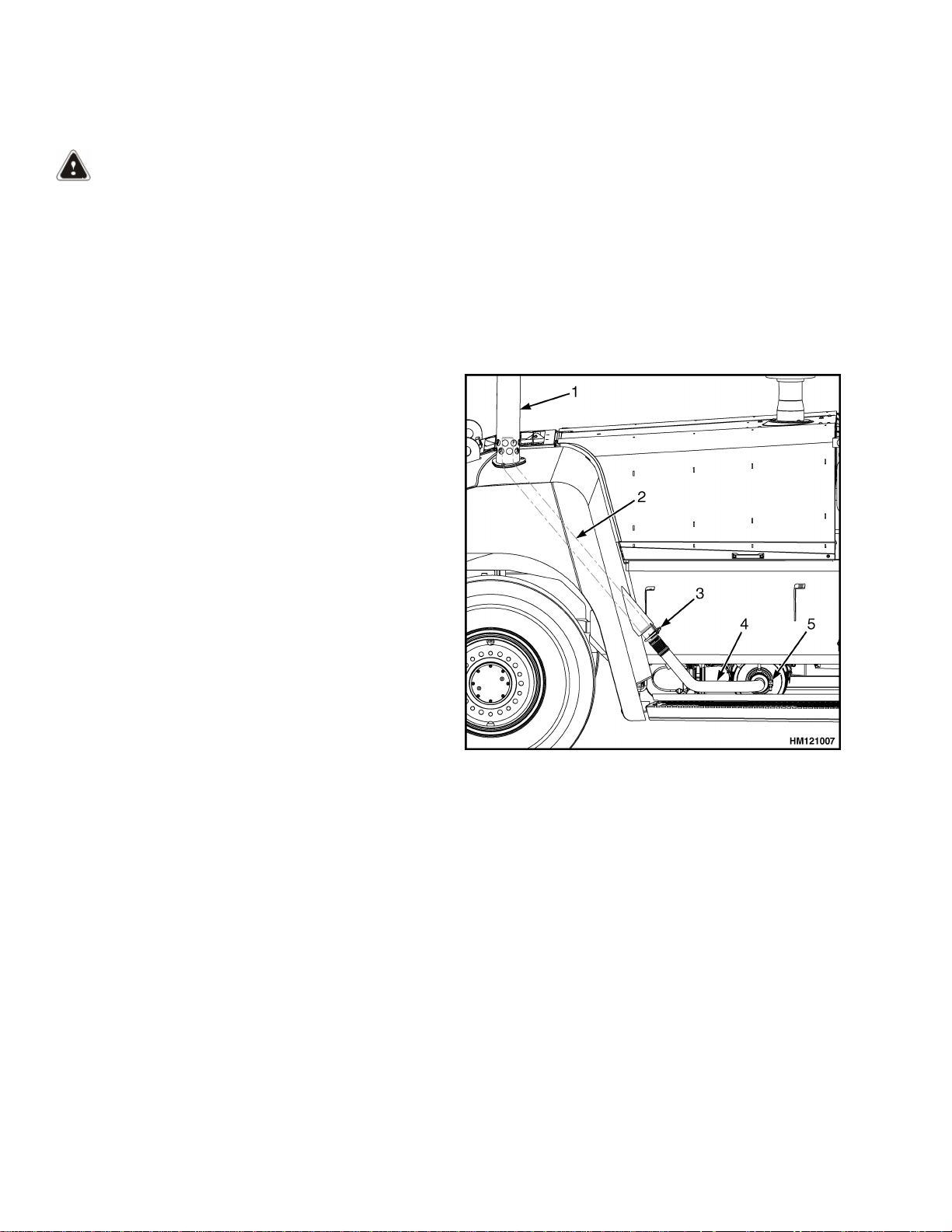

Running Boards, Steps and Mud Flaps ...........................................................................................................14

Hydraulic Tank .................................................................................................................................................16

Remove ..........................................................................................................................................................16

Inspect ...........................................................................................................................................................18

Clean ..............................................................................................................................................................18

Steam Cleaning Method ...........................................................................................................................19

Chemical Solution Cleaning Method .......................................................................................................19

Repair ............................................................................................................................................................19

Small Leaks ..............................................................................................................................................19

Large Leaks ..............................................................................................................................................19

Inspection after Repair .................................................................................................................................20

Install ............................................................................................................................................................20

Fuel Tank ..........................................................................................................................................................22

Table of Contents

i