Risk of injury from incorrect use!

– Never neglect the general requirements for safety and due diligence. If in

doubt, personally ensure that there are no people or obstacles in the danger

zone of the carrier vehicle.

– Only use fork carriers in carrier vehicles that have been designed to accom-

modate fork carriers and only use them in a technically perfect condition.

– Never mount fork carriers on a tool change device if the device is incompat-

ible with the fork carrier. Observe the relevant operating manual for the

respective tool change device installed on the carrier vehicle.

– Never exceed the maximum load capacity of the carrier vehicle, the fork car-

rier and fork arms used.

– Never use fork carriers in conjunction with incompatible fork arms or with

fork arms that have not been approved by the manufacturer.

– Never use the fork carrier and fork arms at temperatures outside the tempera-

ture range of -4 °F (-20 °C) to +122 °F (+50 °C).

– Never use the fork carrier and fork arms if they are excessively dirty, greasy,

or covered in ice.

– Never use the fork carrier and fork arms in areas subject to explosion haz-

ards.

– Never use the fork carrier and fork arms to lift or transport living beings, espe-

cially people. Transport in conjunction with the fork carrier in so-called

workman baskets is also not permitted.

– Never use the fork carrier and mounted fork arms for demolition work.

– Never mount the fork arms on the fork carrier as reversible fork arms (blade

on top).

– Never use the fork arms individually or load them unevenly.

– Never use the fork arms on a rotary device or on a pallet handler.

– Never expose the fork arms to lateral forces. It is not permitted to drive into or

out of the pallet/load at an angle, or to push the pallet/load from the side.

– Never use fork carriers with auxiliary equipment on fork carriers or fork arms

(e.g., snow clearing equipment, slings).

– Only use the fork carrier with mounted fork arms for road transport with an

approved warning system (e.g., warning bars) in accordance with traffic laws,

and without a load.

– Never allow insufficiently qualified persons to carry out maintenance or repair

work.

– Never skip a maintenance interval.

– Never modify the fork carrier and fork arms independently.

– Never use fork carriers with fork arms without an engaged locking device or

shaft safeguard.

– Never operate the fork carrier and fork arms without safety markings.

– Never allow unauthorized persons access to the carrier vehicle.

Incorrect use of the fork carrier and fork arms could lead to life-threatening sit-

uations and serious injuries.

L WARNING

Safety

Intended use

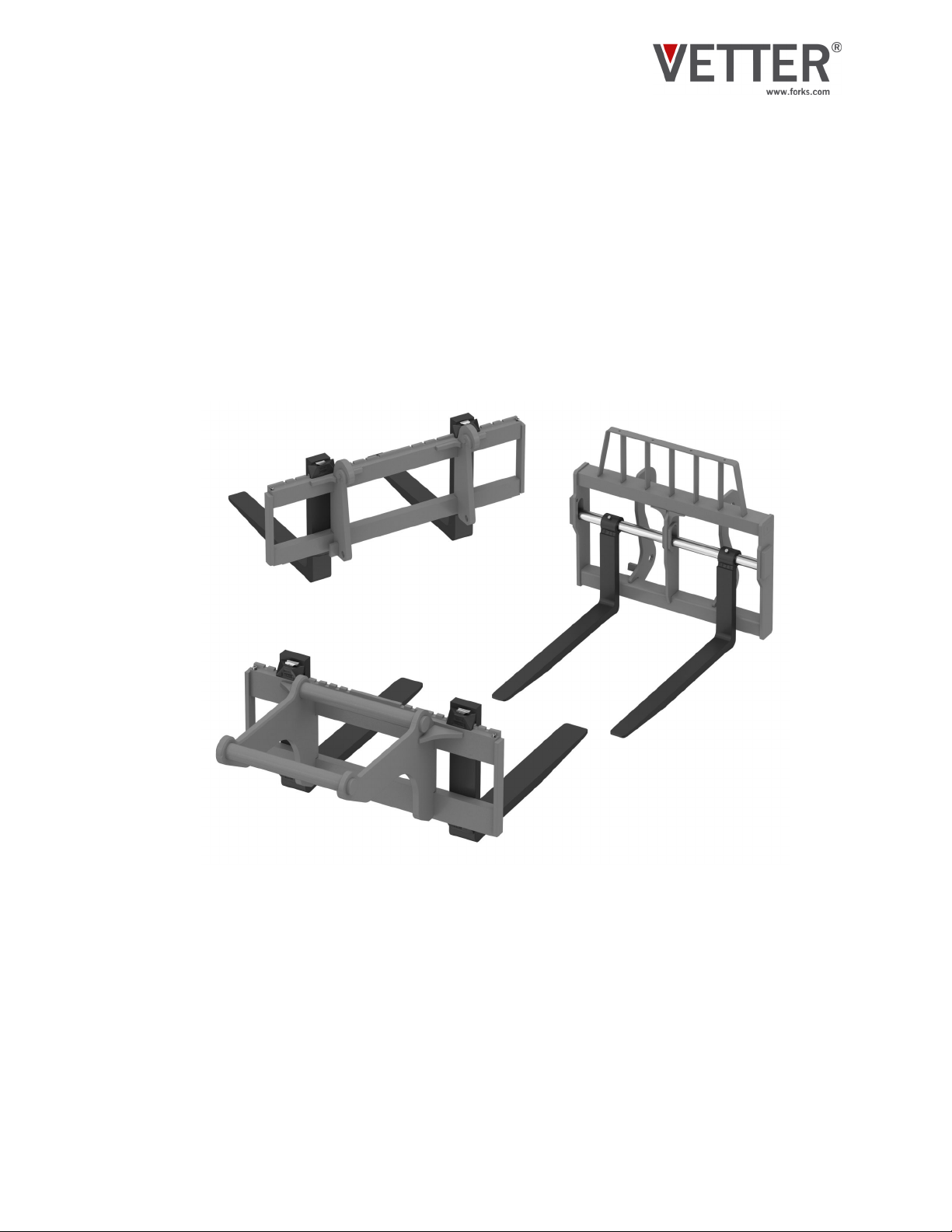

Fork carrier with fork arms

8