NICHIYU NTF200P 56 Series User manual

OPERATOR'S MANUAL

ELECTRIC LIFT TRUCK

Unsafe use of this lift truck may cause serious injury or

death. Operators and maintenance personnel must read this

manual and be sure that they understand its contents before

operating, inspecting or carrying out maintenance on this lift

truck. This manual should be kept near the lift truck for

reference and periodically reviewed by all operators and

maintenance personnel who come in contact with it.

WARNING

NTF200P

NTF360P

56 SERIES

ELECTRIC FORKLIFT TRUCK

OPERATORʼS

MANUAL

ELECTRIC

LIFTTRUCKS

OPERATORʼS

MANUAL

ELECTRIC FORKLIFT TRUCK

DANGER

WARNING

CAUTION

NOTE

Indicates an extremely hazardous situation which, if not avoid-

ed, will result in death or serious injury.

You shall observe this instruction.

Indicates a potentially hazardous situation which, if not avoid-

ed, could result in death or serious injury.

You shall observe this instruction.

Indicates a potentially hazardous situation which, if not avoid-

ed, may result in minor or moderate injury.

You shall observe this instruction.

Indicates suggestions, tips and hints related to the safety of a

operator and maintain of a tractor.

¡This operator’s manual provides for the proper operation, easy maintenance and periodical

inspection.

¡Prior to operation, read this manual carefully for safe and efficient operation.

¡Specifications and equipment in this manual are subject to change without any notice by the

manufacturer for further improvement and modifications.

¡Make sure these important instructions in this manual are available for the operator on each

delivery or transfer of tractor. Keep this manual after reading.

¡If you have any questions, please feel free to contact your local NICHIYU dealer.

and are very important for you and others for safety. Follow these

instructions.

INTRODUCTION

CAUTION

The operator should read and understand

the safe operation contained in this manual.

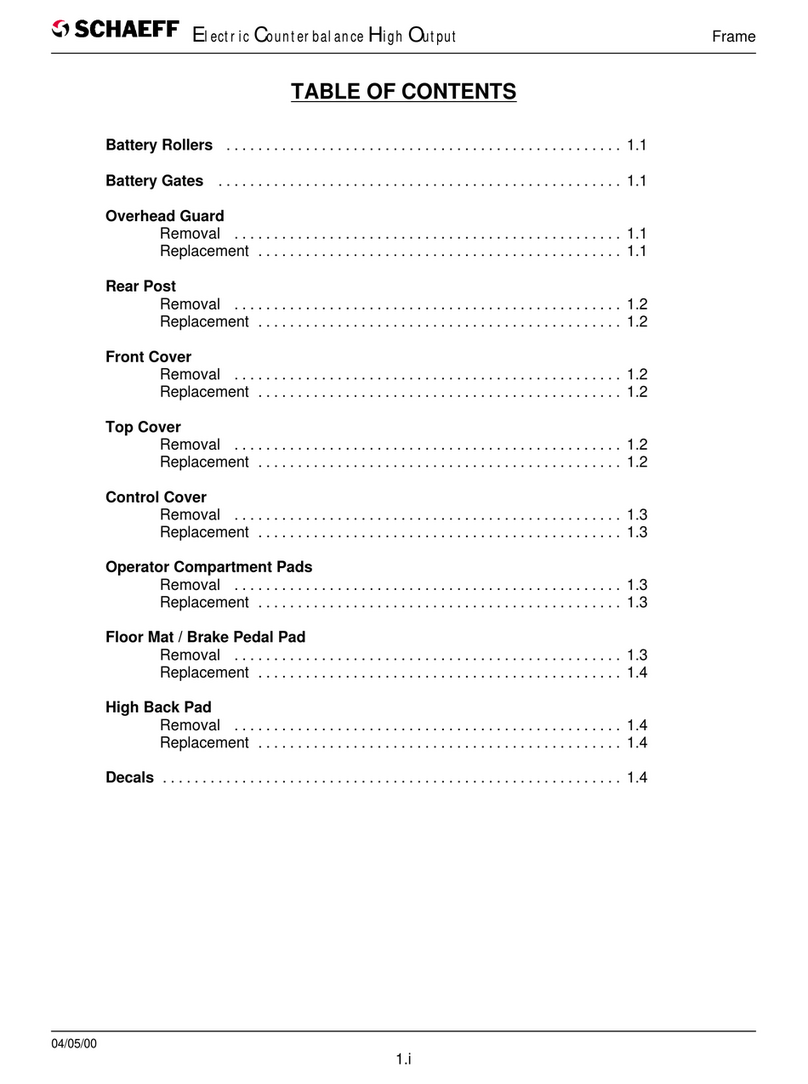

CONTENTS

zSAFETY OPERATION ............................................................................... 1

Information for safety operation .......................................................................... 1

xPARTS NAME AND FUNCTION ............................................................ 4

Name of parts ..................................................................................................... 4

Driving system .................................................................................................... 4

Indicator panel .................................................................................................... 5

Operation ............................................................................................................ 6

cDRIVING AND OPERATION .................................................................... 8

Preparation of start ............................................................................................. 8

Traveling ............................................................................................................. 9

vBATTERY AND CHARGER .................................................................... 11

Battery .............................................................................................................. 11

Precautions for charging the battery ................................................................ 14

Charger ............................................................................................................. 16

Charging method .............................................................................................. 17

Level of electrolyte and specific gravity ............................................................ 21

b

INSPECTION PRIOR TO OPERATION

......................................................... 23

Check points and contents................................................................................ 23

Inspection procedure ........................................................................................ 23

n

INSPECTION OF AFTER OPERATION

........................................................ 26

Inspection after working .................................................................................... 26

mPERIODIC SERVICING ........................................................................... 27

Precautions of maintenance ............................................................................. 27

Weekly (50-hour) servicing ............................................................................... 29

Monthly (200-hour) servicing ............................................................................ 31

Lubrication points and recommended oil .......................................................... 32

Every three-month (600-hour) servicing ........................................................... 32

Semiannually (1200-hour) servicing ................................................................. 33

Replacing parts and trouble shooting ............................................................... 33

,QUICK FAULT FINDING AND PARTS CHANGING ..................... 34

.PERIODICAL REPLACING PARTS .................................................... 36

⁄00 SPECIFICATIONS...................................................................................... 37

1

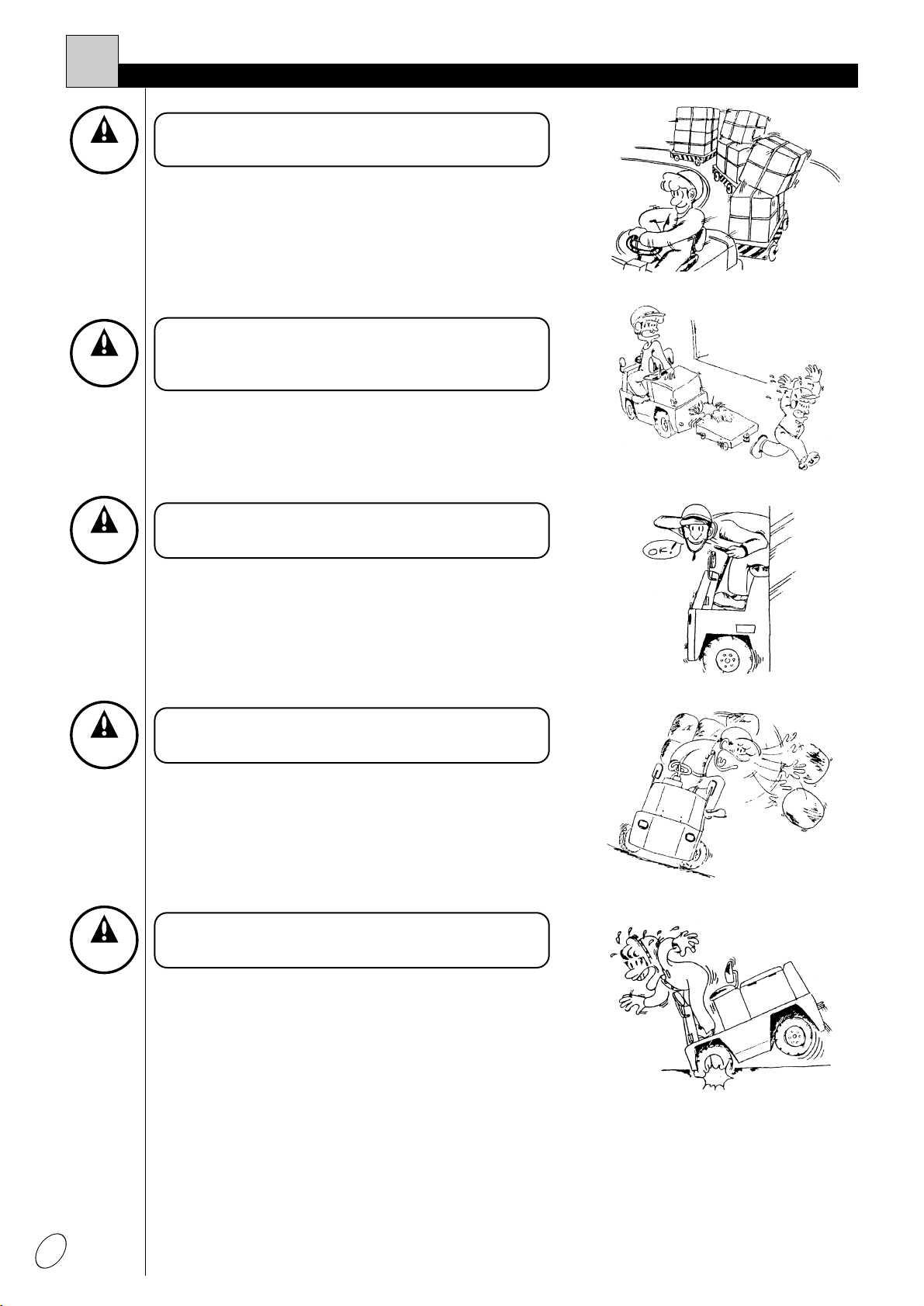

SAFETY OPERATION

■Information for safety operation

1

CAUTION

Only a trained and authorized operator shall

operate the tractor.

CAUTION

The operator is recommended to wear a hel-

met, safety shoes and working clothes.

WARNING

Do not operate the tractor while taking

drugs and/or alcohol; otherwise, an acci-

dent may occur which can cause serious

injury or death.

CAUTION

Do not use a tractor in the following circum-

stances.

qWhere the temperature is less than –10°C

or more than 40°C.

wWhere the explosive gas (thinner, gaso-

line etc.) may exist.

CAUTION

Keep the operator's compartment clean at all

times.

CAUTION

Do not operate the tractor with greasy or wet

hands.

CAUTION

Do not modify the tractor.

CAUTION

Carry out the daily inspection before operation.

CAUTION

Prior to handling, confirm the weight of a load.

¡Modifications and additions shall not be performed

without the written approval of NICHIYU. Contact

NICHIYU

’

s qualified facility for details.

¡Do not install any parts blocking visibility from oper-

ating position.

¡Prohibit to draw over the rated drawbar pull.

2

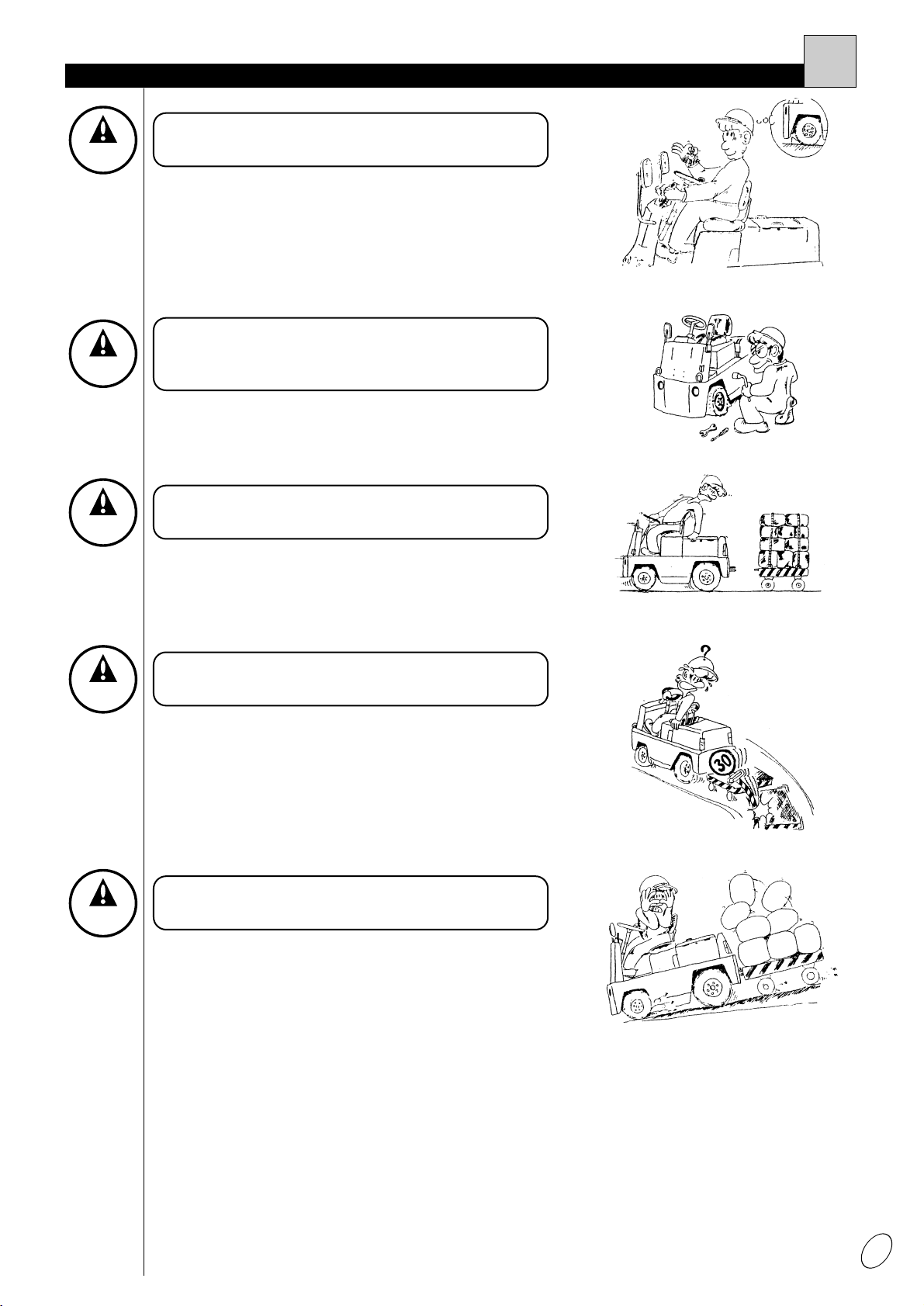

1SAFETY OPERATION

CAUTION

Refrain from a sudden start, quick braking and

quick turn.

CAUTION

Be careful about the condition of road surface,

and not couple while the tractor is leaned and

is on and incline.

CAUTION

When turning, be sure to confirm safety

around the truck, and travel slowly.

CAUTION

Do not either run sideways or change the

direction along the inclined surface.

CAUTION

Do not run over an obstacle on the road.

3

1

SAFETY OPERATION

CAUTION

When leaving the truck, remove the key.

¡Refrain from parking on an incline. If parking on an

incline should unavoidably be obliged, be sure to

apply buffer-stops.

CAUTION

When coupling the trailer, approach slowly.

CAUTION

When turning, the trailers draw near to the

inside. So make large turn considerably.

CAUTION

Refrain, from turning and quick braking on an

incline as it is dangerous.

CAUTION

When the truck is damaged, immediately repair

and never operate the truck until the repair is

finished.

■Name of parts

■Driving system

2

PARTS NAME AND FUNCTION

4

qIndicator panel

wParking brake lever

eHead lamps

rFront hood

tTurn signal lamps

yFront axle

uRear axle

iRearview mirror

oSteering wheel

!0 Center hood cover

!1 Seat

!2 Battery

!3

Stop, Tail & back lamps

!4 Coupler

q w e r t y u i o !0 !1

qParking brake lever

wSteering wheel knob

eSteering wheel

rHorn button

tFloor plate

yHour meter (Option)

uSwitch for turn signal lamp

iBrake pedal

oAccelerator pedal

!00 Directional switch

!1 Indicator panel

5

■Indicator panel

qSave energy switch

The switch adjusts peak current flowing to the traction

motor. When turning the switch clockwise, starting

power and gradeability are reduced.

This results the soft acceleration and save the battery

energy consumption.

When turning the switch to the left end (“P” position),

the acceleration and gradeability are maximum.

The forcible by-pass circuit can activate at this “P”

position only.

When starting is difficult, set this switch to “P” (click is

heard) and depress the accelerator pedal fully. After

three to five seconds, the by-pass contactor is activat-

ed and the tractor start moving.

When turning the switch to the right end (“SE” posi-

tion), the acceleration becomes soft.

wHour meter (Option)

The hour meter indicates the operational integrating

hour. it is useful to know the operational hour efficiency

and periodical inspection for the better management

and schedule of materials handling.

eBattery capacity indicator

The battery capacity indicator measures the state of

charge of the battery. when the key switch is turned

on, the five green lamps will light, one at a time from

left to right to indicate the state of charge of the bat-

tery. With fully charged battery, all five will light. As the

battery energy is used, the lights will go out one at a

time from right to left. When red light begins to flash,

battery needs to be recharged.

2

PARTS NAME AND FUNCTION

q w e r yt

BATTERY 48V

qSave energy switch

wHour meter (Option)

eBattery capacity indicator

rParking lamp (red)

tSwitch for head lamp and tail lamp

yKey switch

6

rParking lamp (red)

The parking lamp indicates parking brake applied. The

parking lamp warns against starting while parking

brake is applied.

tSwitch for head lamp and tail lamp

Switch position :

Tilt up : Turn on the head lamps and the tail

lamps.

Neutral : All lamps are turned off.

Tilt down : Turn on the tail lamps.

yKey switch

OFF : This is the position to insert or remove a key.

ON :

Preparation for operation is completed by turning

the key switch clockwise, and at the same time,

the opreration lamp (green) on the battery

capacity indicator is put on.

■Operation

qParking brake lever

Pull the parking brake lever fully when parking. Push

the parking brake lever forward when releasing the

parking brake.

2PARTS NAME AND FUNCTION

CAUTION

Turn off the key switch while stopping opera-

tion or charging the battery.

OFF ON

q w e r t y u i

qParking brake lever

wSteering wheel knob

eSteering wheel

rHorn button

tSwitch for turn signal lamp

yBrake pedal

uAccelerator pedal

iDirectional switch

when parking

7

wSteering wheel knob eSteering wheel

When steering the wheel, grasp the steering wheel

by the right hand and the left hand are put on the

steering wheel lightly.

rHorn button

Horn button is equipped on the left side of the post for

steering wheel. Horn sounds by pushing button.

tSwitch for turn signal lamp

Lamp at either right or left hand side is put on when

the switch is either pushed or pulled. Move the switch

by finger lightly.

yBrake pedal and uAccelerator pedal

Depress the accelerator pedal gently. The travel

speed is adjusted by depressing angle of the pedal.

iDirectional switch

When the switch is pushed forward, truck is ready to

go forward. When it is pulled, truck is ready to go

backward.

Seat

Operator restraint type seat is equipped as standard.

It is adjustable for the best position to forward or back-

ward.

Adjust the seat for proper operating position. The

operator

’

s manual can be stored in the box behind the

back of the seat.

Adjustable position of the seat

Forward : 60mm

Backward : 60mm

2

PARTS NAME AND FUNCTION

Left

Right

Forward

Backward

Neutral

CAUTION

Do not depress accelerator pedal before turn-

ing on key switch and putting directional

switch either direction.

Adjust lever

Reclining knob

(option)

Forward

(60mm)

Backward

(60mm)

3

DRIVING AND OPERATION

■Preparation of start

1)

Check the directional switch is in the neu-

tral position and the parking brake is

applied.

2) Turn on the key switch

Grasp the steering wheel knob and then turn on the

key switch.

3) Operation of the directional lever

Operate the directional lever to the moving direction.

Forward : Push the lever forward.

Backward : Pull the lever backward.

4) Release the parking brake

Depress the brake pedal.

Push the parking brake lever forward fully to release

the parking brake.

Grasp the steering wheel knob by the left hand, put

the right hand lightly on the steering wheel.

8

CAUTION

¡Do not operate the tractor prior to daily

inspection.

¡Be sure to confirm safety around the tractor

when operating.

Forward

Backward

Neutral

9

■Traveling

1) Start

Release the brake pedal and depress the accelera-

tor pedal gradually, then the tractor will begin to

move.

Acceleration varies in accordance with the

depressing of the accelerator pedal.

2) Slow down

Reducing depression of accelerator pedal slows

down travel speed.

3) Traveling with stipulated speed

Observe an appropriate stipulated travel speed in

the working place when the truck operates at facto-

ry or indoor.

4) Turning

When turning corner, slow down and turn the

steering wheel and taking care the trailers not to hit

the corner and so on. When towing the trailer, tak-

ing enough care the turning.

5) Stop

Slow down and apply the brake slowly.

6) Towing

Approach to the trailer, confirming the position of

couplers, so as to be in one line and connect the

couplers between the tractor and the trailer.

Confirm that the individual loads on the trailers are

put on securely and drawbar pins are inserted into

the coupling devices securely.

Start to drive slowly so as to decrease the loose-

ness of coupling device and drive at constant

speed. On turning at a corner, slow down before-

hand and make a large turn. On arriving the desti-

nation, loosening depression of accel pedal and

brake gradually. Avoid a sudden brake so as not to

hit the trailers each other and fall down the cargo

from the trailers.

3

DRIVING AND OPERATION

CAUTION

Slow down at the next areas.

¡At a corner

¡Approaching to load or pallet.

¡Approaching to loading area.

¡Narrow aisle area.

¡On a rough floor.

CAUTION

Do not apply brake suddenly.

10

7) Parking

When parking the tractor,

¡When getting off the tractor, correctly apply the

parking brake lever.

¡Do not park the tractor on a slope.

3DRIVING AND OPERATION

CAUTION

Remove the key swith when operator leaves

truck.

■Battery

sKeep away from fire (Explosive gas)

sPay attention to an electric shock

sConnect correctly

sKeep tools away

4

BATTERY AND CHARGER

11

CAUTION

¡This section explains NICHIYU's genuine

battery (GS made) and charger.

¡When the lift truck is equipped with another

type battery and/or charger, please follow the

instructions provided by that manufacturer.

WARNING

¡Never allow open flame to come near

the battery.

¡Explosive gas is always present within

the battery.

¡Smoking, flames, or sparks will result

in battery explosions.

CAUTION

Do not make a short circuit.

The battery has high voltage and power.

CAUTION

When servicing the battery, wear the safety

goggles, rubber gloves and boots.

CAUTION

Do not swap the positive and negative terminals.

¡It can cause sparking, burning

and/or explosion.

WARNING

Keep tools away from terminals to avoid

sparks or shorting.

12

sDo not over-discharge

sKeep clean

sWear safty clothes

sBe careful the electrolyte

4BATTERY AND CHARGER

CAUTION

Do not use the forklift truck until no longer run,

it will shorten the battery life.

¡When the battery discharge indica-

tor shows empty, charge the bat-

tery as soon as possible.

¡Electrolyte of the battery is sulfuric acid.

WARNING

¡Keep the upper surface of the battery

clean.

¡Do not use a dry cloth when cleaning,

as it may produce static electricity.

WARNING

Clean the battery before charging.

CAUTION

Wear safety goggles, rubber gloves and boots

to protect yourself.

WARNING

Be careful the electrolyte does not touch

the skin.

13

sEmergency first aid

sClose vent caps securely

sWashing

sAbnormal battery

sDo not disassemble the battery.

4

BATTERY AND CHARGER

CAUTION

The battery contains sulfuric acid which caus-

es severe burns if touched.

If an accident occurs, receive emergency first

aid and consult your physician immediately.

¡Spilled on skin:

Wash down with water for 10 to 15 minutes.

¡Splashed in eye:

Wash down with water for 10 to 15 minutes.

¡Swallowed:

Drink large amounts of milk or water.

¡Splashed on clothes:

Take off clothes immediately.

If you do not follow these instructions, you will

be seriously injured or killed.

CAUTION

Make sure all vent caps are closed securely.

Failure to close the caps can cause leaking of

electrolyte.

CAUTION

If the battery shows the following situation,

contact NICHIYU's qualified service facility or

battery manufacturer.

¡The battery stinks.

¡The electrolyte is muddy.

¡The electrolyte decreases fast.

¡The temperature of electrolyte is too high.

CAUTION

Do not drain the electrolyte, disassemble and

repair the battery.

CAUTION

Do not wash the battery on the forklift truck. It

causes damage to the truck.

14

sStorage

sDo not dispose of used batteries.

■Precautions for charging the battery

sCheck electrolyte level

¡Failure to keep proper level of the electrolyte can

cause overheating or burning of the battery and

electrical components of the forklift truck.

¡Check electrolyte level once a week.If the level is

low, add distilled water to the specific level.

sDo not over-charge.

sPay attention to an electric shock

¡

The charger has high voltage and power when working.

sCharge in well-ventilated areas.

4BATTERY AND CHARGER

CAUTION

Please contact NICHIYU's qualified service

facility or the battery manufacturer for disposal.

CAUTION

Do not use the forklift truck if the electrolyte

level is low.

CAUTION

Do not over-charge the battery.

CAUTION

Do not touch the terminal or transformer when

charging.

DANGER

¡Charge batteries only in approved and

well-ventilated areas.

¡Explosive gas comes out of the battery

while charging.If you use the local sup-

ply charger, follow its manufacturer's

instruction.

CAUTION

¡When storing the battery, store in a well-ven-

tilated and dry place.

¡

Keep the battery away from open flames or ignitions.

15

sCheck cable and plug

sCheck specific gravity

sInterruption of charge

sKinds of charge

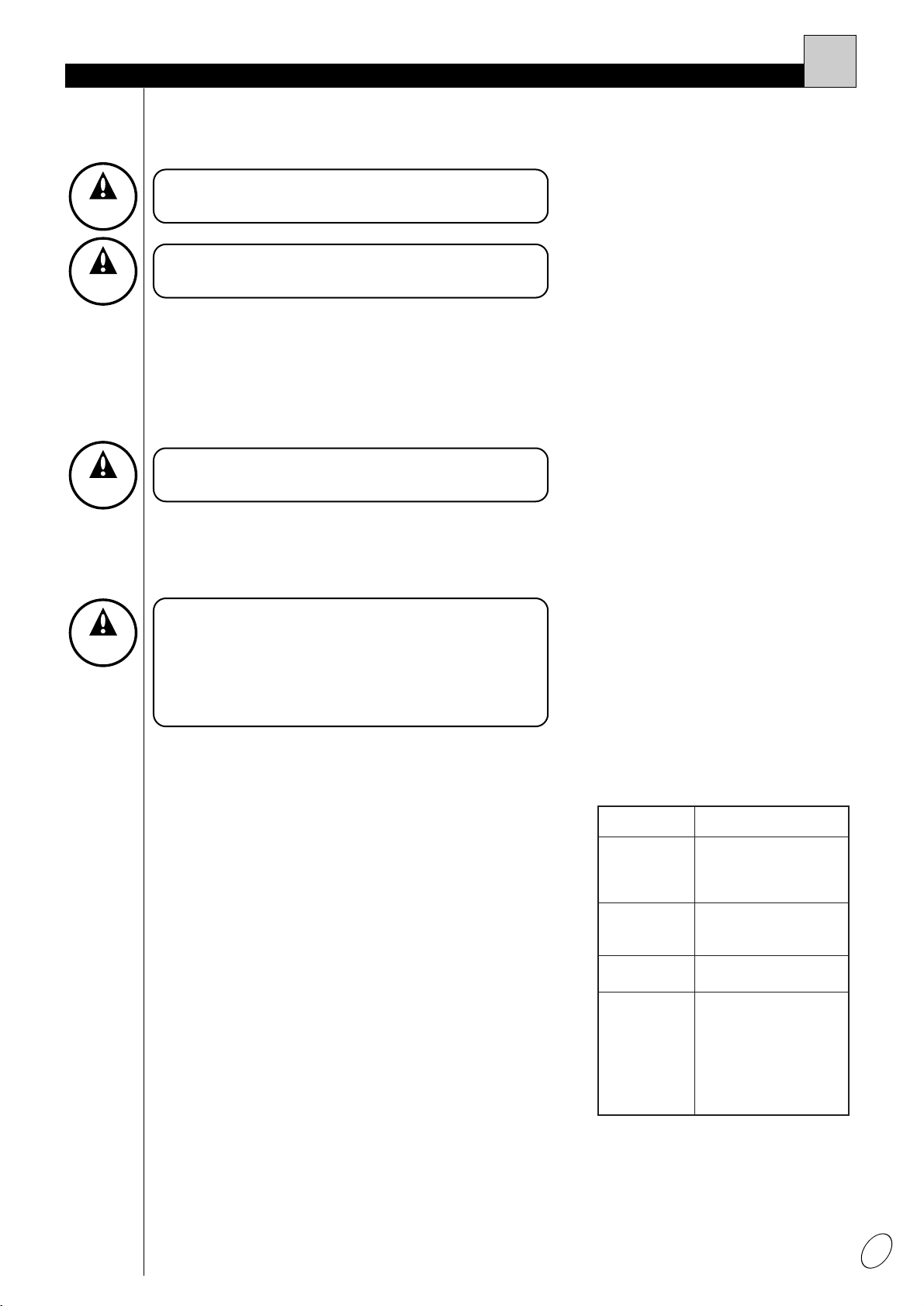

™There are three kinds of charge.These charges are

a normal charge, a balancing charge and a supple-

mentary charge.

™Charging time depends on the discharging condition

and capacity of the battery.

™Generally, 8 to 10 hours are required to charge the

battery fully.

4

BATTERY AND CHARGER

CAUTION

Prior to charging, check the condition of the

cable and plug.

CAUTION

Do not charge the battery if cable or plug is

damaged.

CAUTION

¡When interrupting the charge, push the

STOP button of the charger before discon-

necting plugs.

¡Failure to observe this instruction can cause

a hazardous electrical shock or explosion of

the battery by sparking.

ApplicationClassification

After daily operation or

when the “ E” segment

of the battery discharge

indicator is lit.

Normal

charge

Every two weeks

(Check electrolyte level

and specific gravity )

Blancing

charge

In a recess

Supplementary

charge

Carry out the blancing

charge before storing

the battery for an

extended time. (Peri-

odical charge for

every 15 to 30 days

during storage is re-

comended.)

Charge for

storage

CAUTION

Measure the specific gravity of all cells before

charge.

This manual suits for next models

1

Table of contents

Other NICHIYU Forklift manuals