Leak-Free Load-Control Valves NS 32

Qmax = 1000l/min [265 gpm],pmax = 420bar [6000 psi]

Seat-valve, two-stage hydraulic, cartridge design

Series CINDY 32-B-C...

1/9

Reference: 300-P-9050099-EN-02

Issue: 10.2016

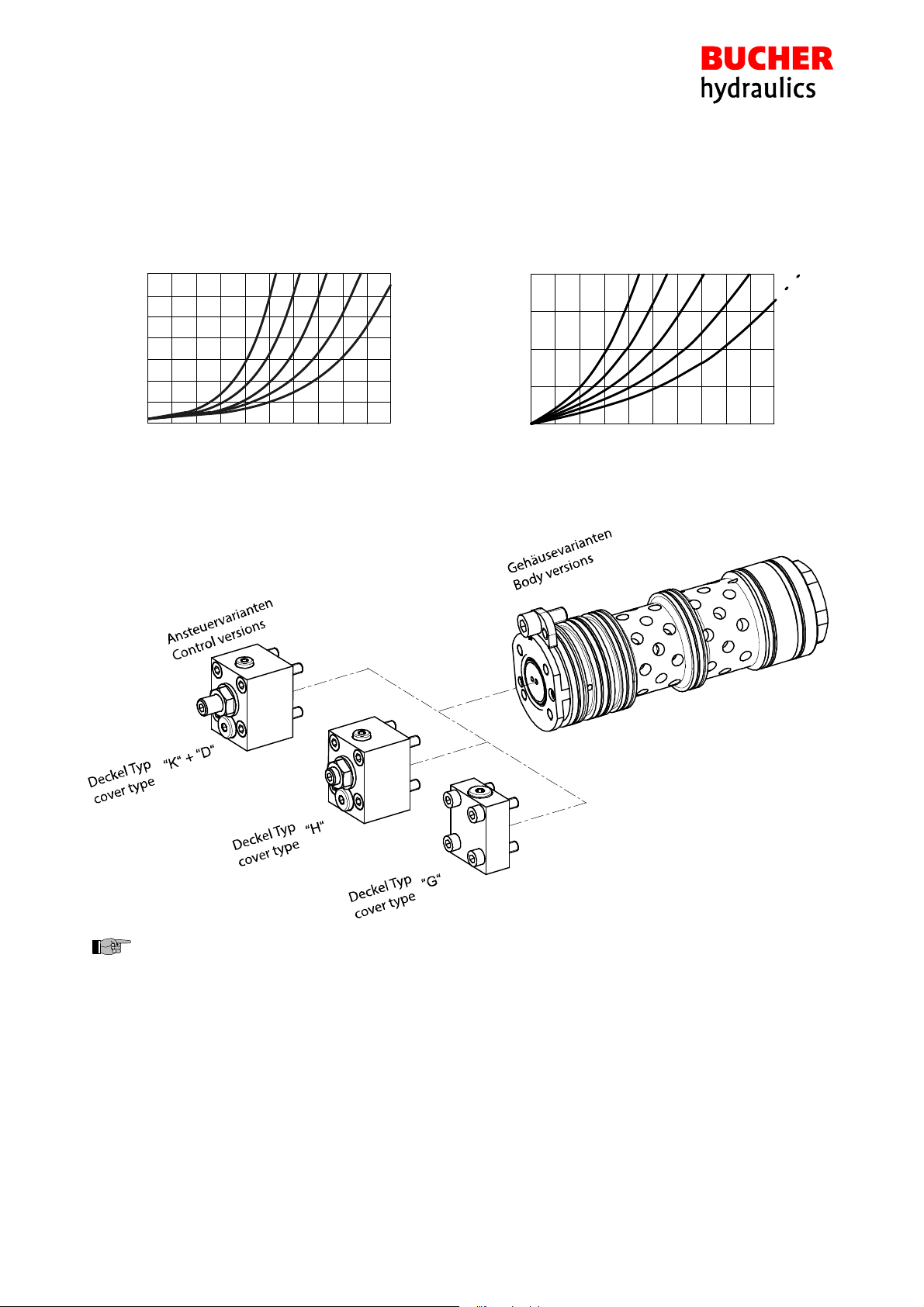

STwo-stage load-control valve and bypass check valve

are functionally combined in one coaxial valve assembly

SLeak-free load holding

SPilot ratio 1:113

SThe control assembly is guaranteed to close

→it closes even with a broken spring

SVarious pilot-pressure ranges can be chosen

SAll exposed parts with zinc-nickel plating

SVarious types of pilot control, matched to your system,

can be supplied

SLow-noise operation thanks to specially shaped control

grooves

1 Description

Whenever large loads are to be precisely moved, placed

and held, when work access platforms must maintain their

position, or when hydraulic presses gates need to withstand

high forces, then CINDY load-control valves from Bucher

Hydraulics are the right solution.

Load-control valves in this series prevent hydraulic actua

tors from running ahead of the available oil supply.

In one valve, they combine the functions of load-holding,

safety and pipe-rupture protection. Leak-free load-control

valves in this series are ideally suited for use in high pres

sure applications up to 420 bar (6000 psi) with a safety fac

tor of at least 3.

With a variety of optional components, the range can be ex

tended and adapted to the requirements of the system.

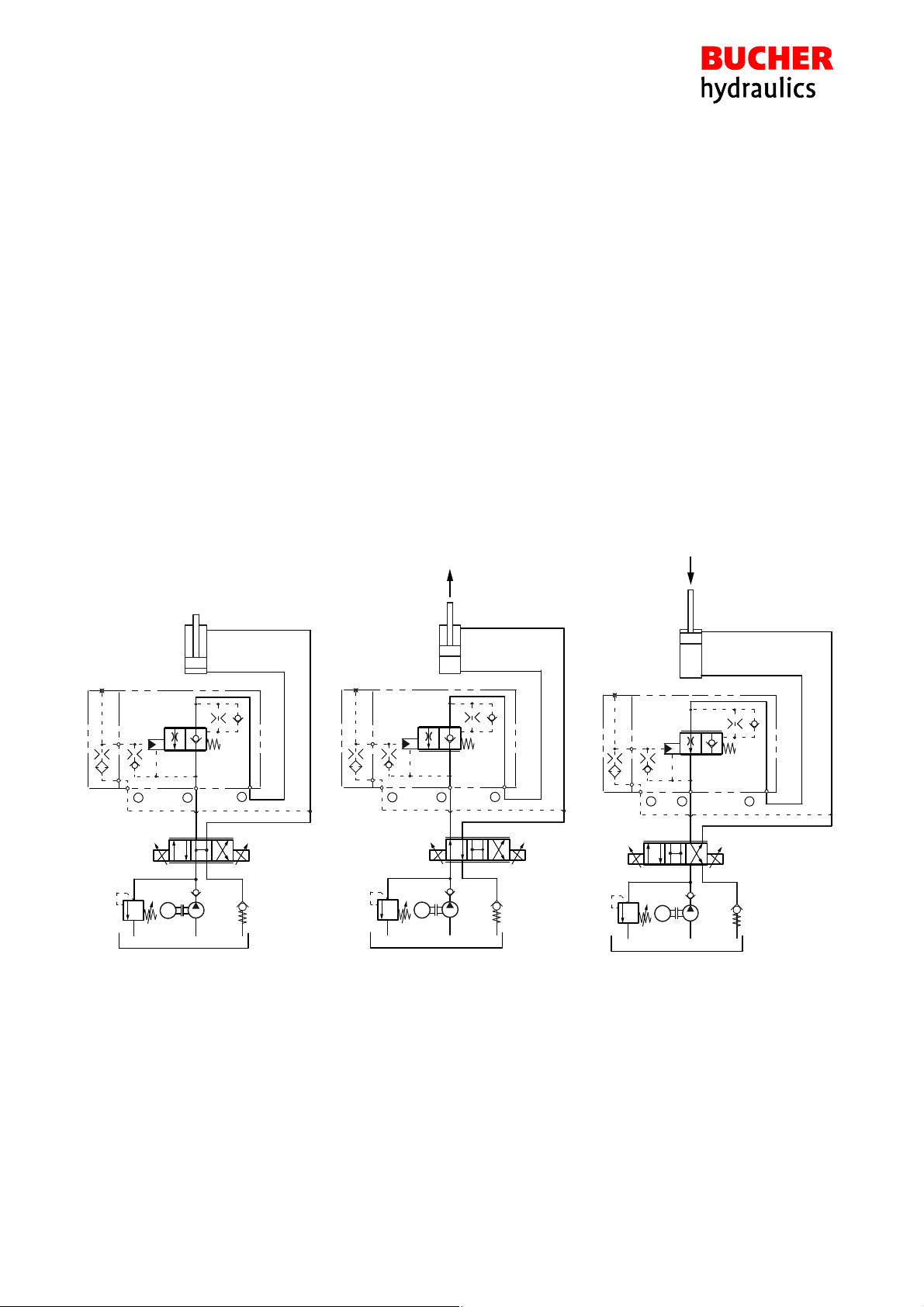

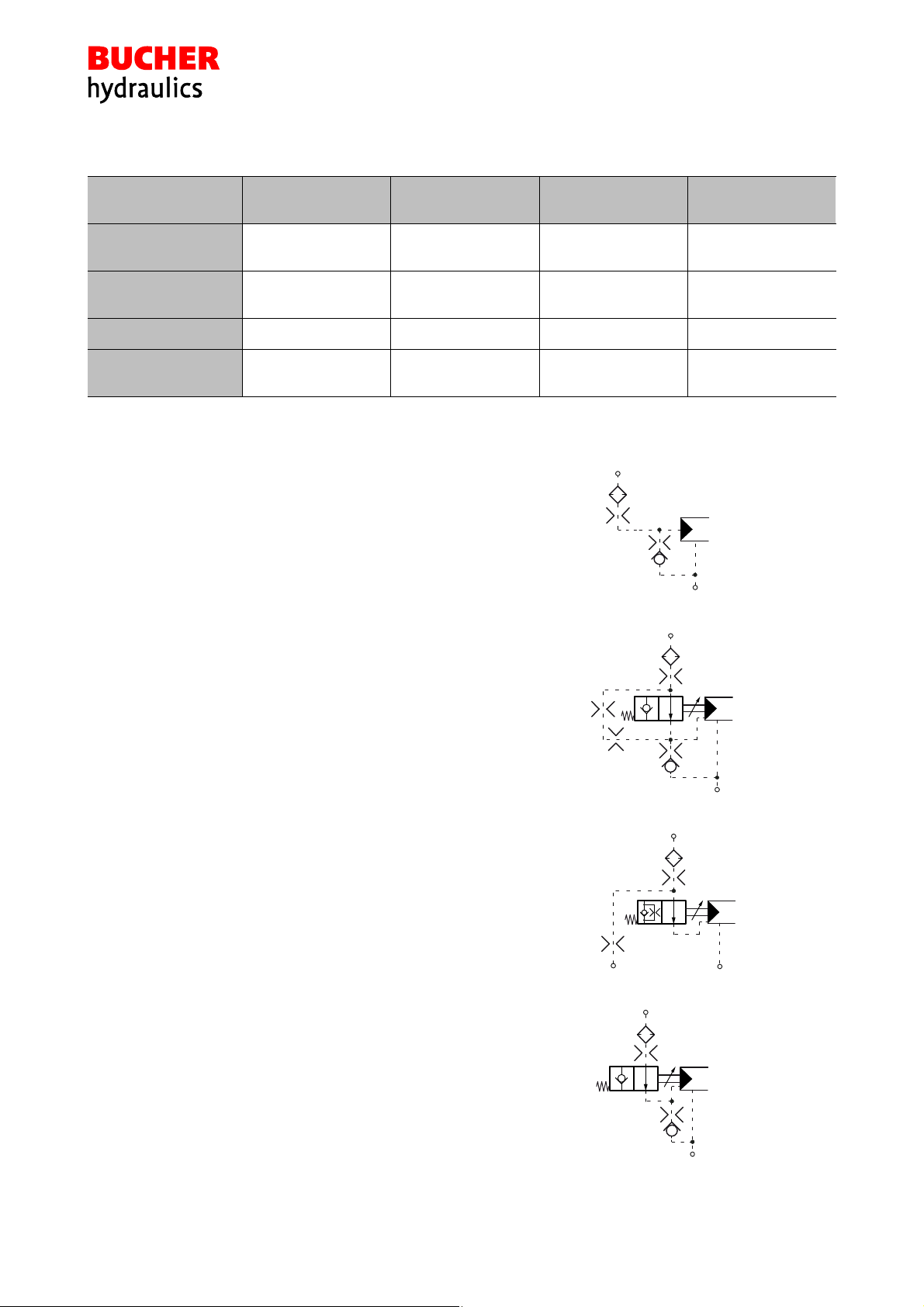

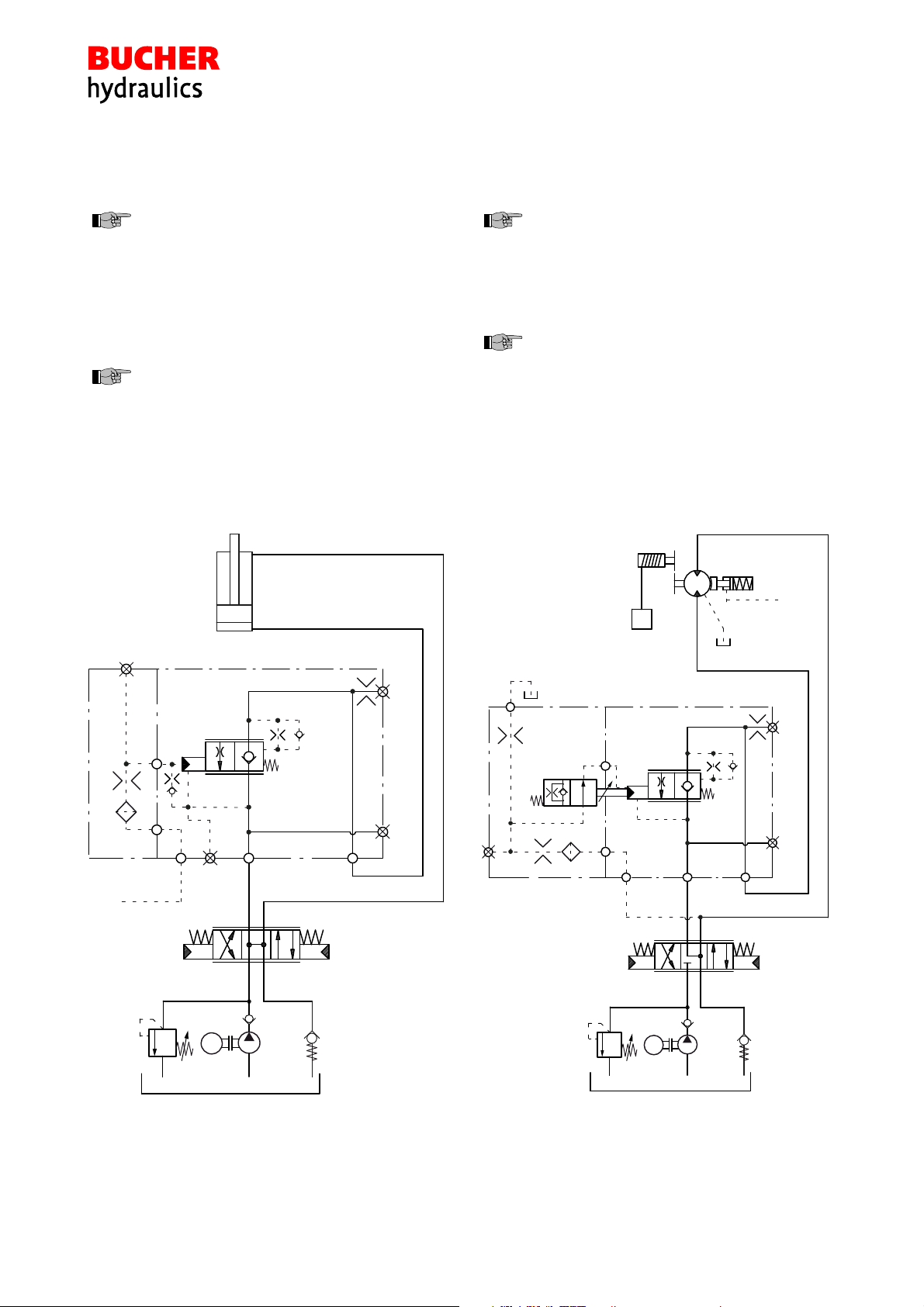

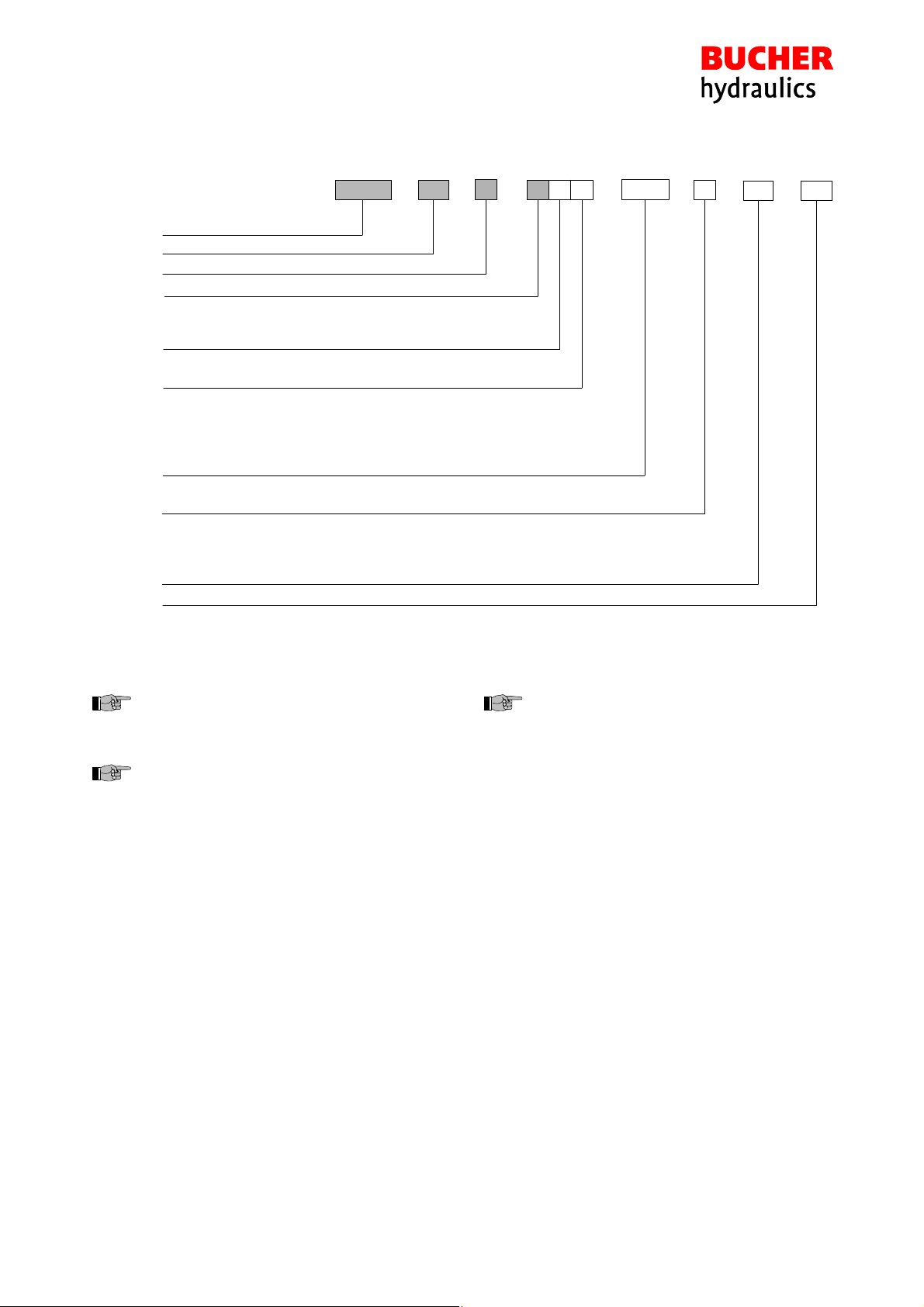

2 Symbol

Variant A

Influenced by return-line pressure

(pressure in A is additive to opening pilot pressure).

ABX

siehe Ansteuerungsvarianten

see types of pilot control

Variant L

Not influenced by return-line pressure

(drain line is required).

ABX L

siehe Ansteuerungsvarianten

see types of pilot control