Table of contents

4V-850/855 Operation Manual, Version A

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Setting up the Rotavapor with the Vacuum Controller V-850/855 . . . . . . . . . . . 19

5.1.1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1.2 Cable connections to the Rotavapor . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 Communication of Rotavapor and Vacuum Controller V-850/855 . . . . . . . . . . . 20

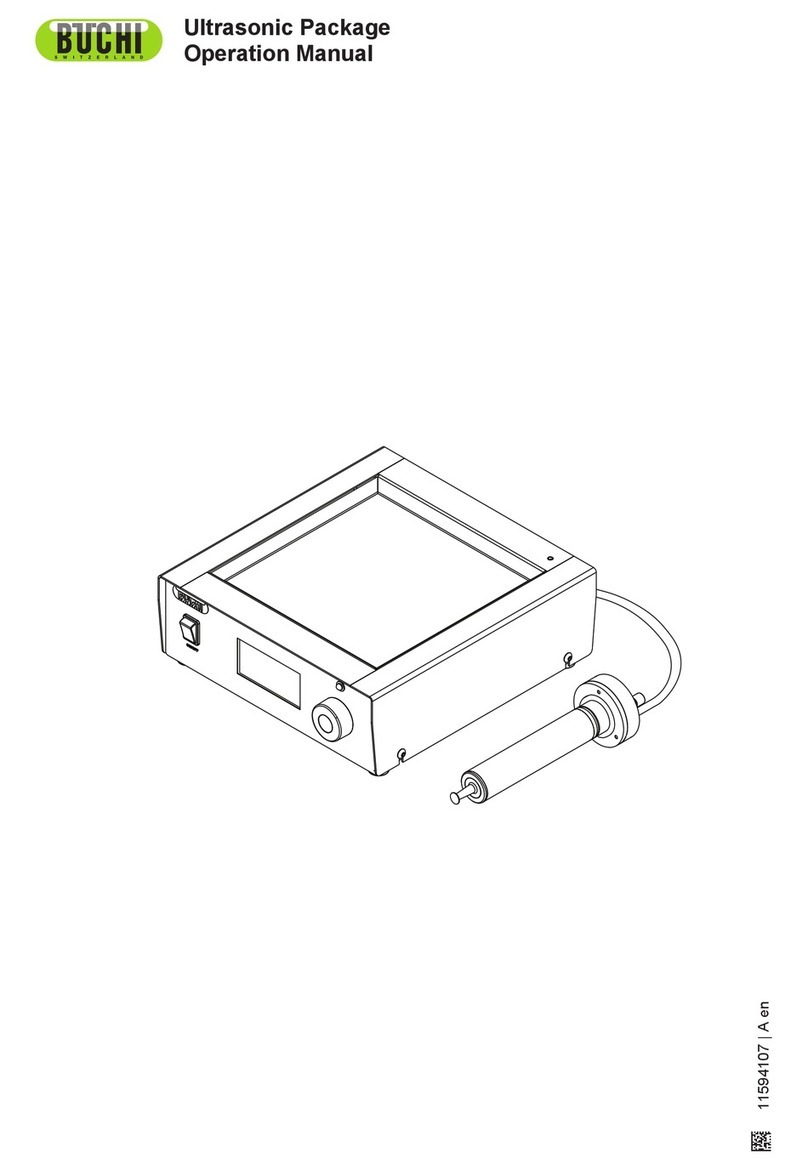

5.3 Installing the AutoDest probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Initial software settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

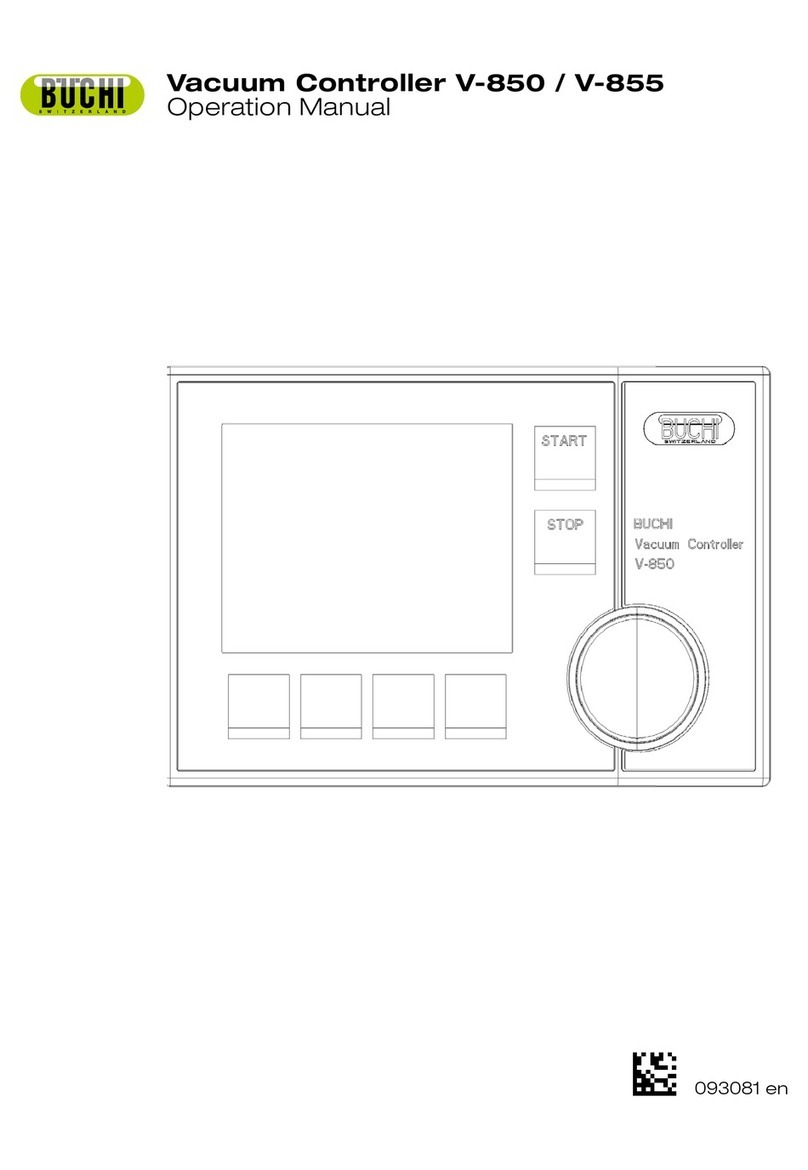

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 Menu structure of the Vacuum Controller V-850/855 software. . . . . . . . . . . . . 25

6.2 Vacuum Controller V-850/855 main screen in Manual mode. . . . . . . . . . . . . . 26

6.3 Selecting the distillation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4 Starting a distillation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4.1 Quick start of manual destillation . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4.2 Advanced settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 Vacuum Controller V-850/855 main screen in Gradient mode . . . . . . . . . . . . . 30

6.6 General information on buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.6.1 Control buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.6.2 Menu buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.7 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.7.1 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.7.2 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.7.3 Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.7.4 Solvent library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.7.5 Extra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.8 Calibrating the pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.8.1 Offset calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.8.2 Simple calibration (without temperature compensation) . . . . . . . . . . . . . . . . 38

6.8.3 Complete calibration with temperature compensation . . . . . . . . . . . . . . . . . 39

6.9 Tips and tricks for a distillation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.9.1 What to do when the solvent starts foaming? . . . . . . . . . . . . . . . . . . . . . 41

6.9.2 How to find out the distillation conditions for a solvent? . . . . . . . . . . . . . . . . 41

6.9.3 How to start a distillation without determining a pressure setpoint? . . . . . . . . . . 41

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2 Functional test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.1 Malfunctions and their remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Health and safety clearance form . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.1 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . . 48

11.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49