8

4 Putting into operation BÜCHI Mini Spray Dryer B-191

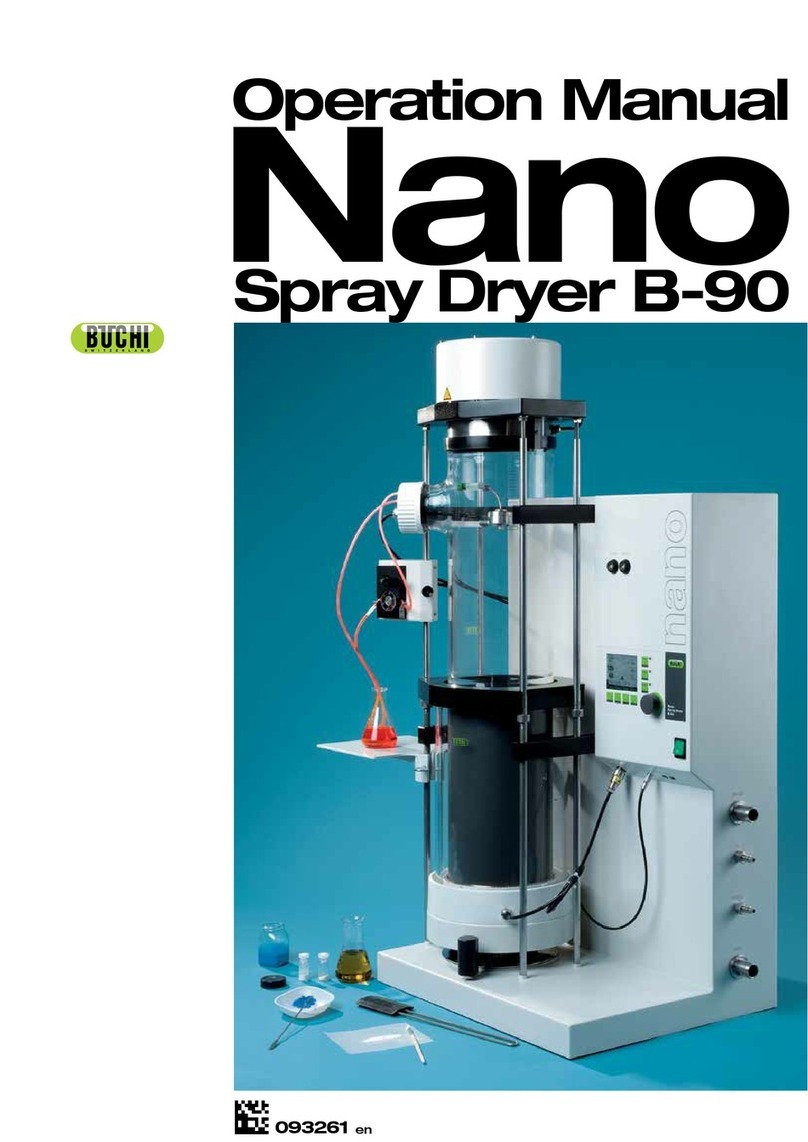

Figure 5a: Glass assembly

4.3 Installation of glass parts

Care is to be taken that only glassware in perfect condition is

used, which shows no cracks, stars or other damage. The

glassware is to be checked visually before the initial putting

into operation of the apparatus.

The glass parts are already mounted on the apparatus in the

packaging.

1. The spray cylinder 햲is held in position by means of the

sprung clamping device 햳.

2. Care is always to be taken that the rubber gasket 햴is fit-

ted correctly during the installation of the cylinder.

3. The temperature probe PT-100 햵must be inserted in the

opening provided in the coupling 햶.

4. The support 햷must be pushed upwards in such a way

that the complete spray cylinder rests on top. The screw

joint for fixing the support in position should be lightly tighten-

ed by hand.

5. The separator 햸is bolted down to the bottom end of the

spray cylinder with an SVL 42 screw cap.

6. The cyclone must be screwed onto the coupling with a

flange screw joint.

7. The glass elbow, which is attached manually, is located

on the cyclone.

8. The product receiving vessel is fastened on the bottom

end of the cyclone. The anchor clamps provided are suffi-

cient as mounting.

9. The earthing cable must be installed in the socket connector

provided on the cover of the product receiving vessel and

connected to the housing.

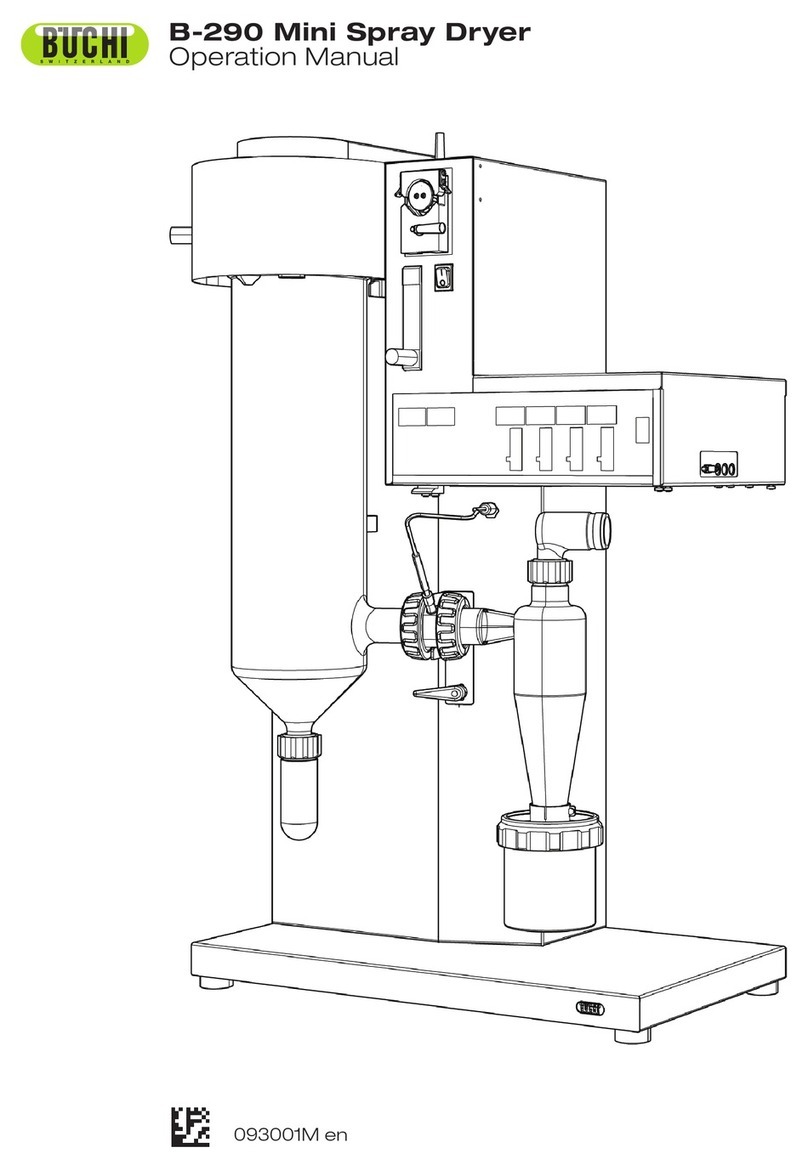

10. When assembling the coupling part, the teflon piece 햹is

inserted with the rectangular shoulder and the fitted contact

ring 햺first. The slanting shoulder is connected to the spray

cylinder. The centering bolt is supplied in order to fit the

flanged nut tight.

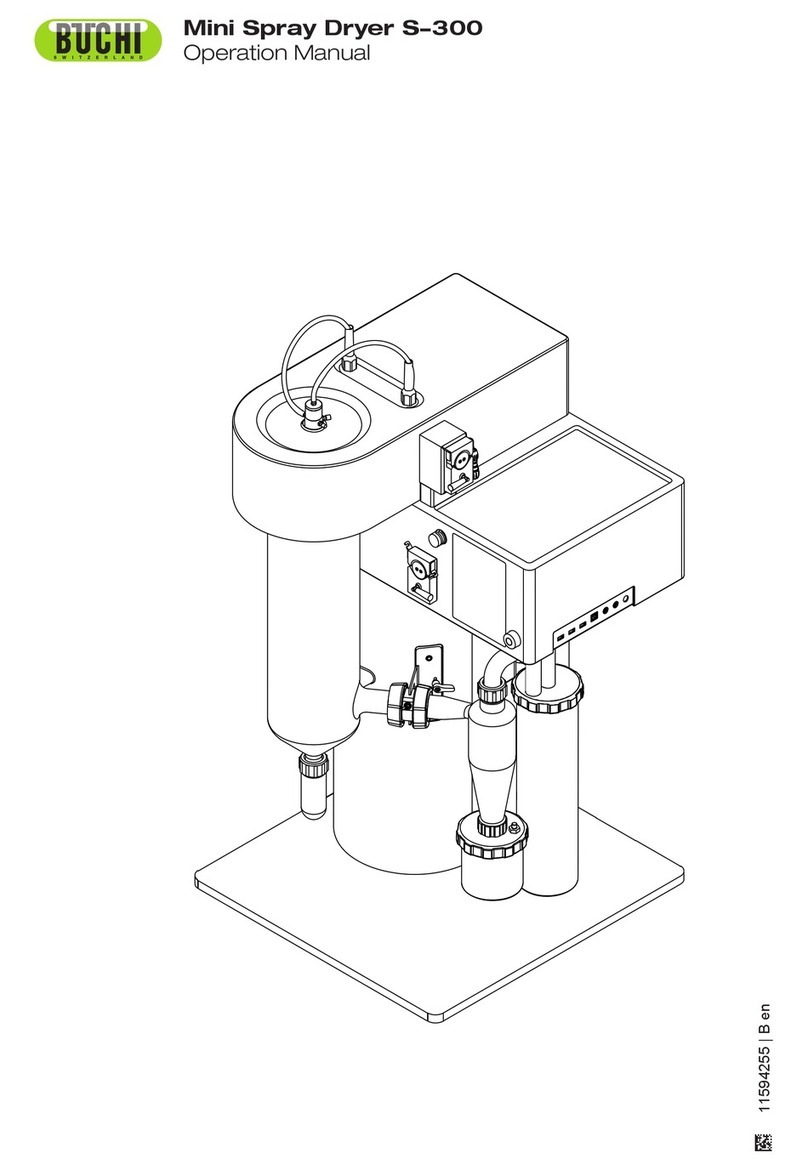

4.4 Installation of the product feed hose

1. In or to be able to install the product feed hose, the rollers

of the hose compression pump (peristalsis pump) must be

raised from the working surface. This is possible by opening

the holding device with the tilting lever.

2. The product feed hose (silicon hose 4x2 mm) is now pulled

through the holder until the nipple integrated in the hose is

at the opening.

3. The hose is now laid between the rollers and the working

surface without tautening.

4. The working area is pressed to the rollers by lifting the

orange tilting lever.

5. The observation window must now be installed in front of

the pump for the safety of the operator.

6. The pump bed (working area) should be lowered by opera-

tional interruption and stoppages in order to protect the

hose.

Figure 6: Product feed hose and peristalsis pump

햲

햳

햴

햵

햶

햷

햸

햶

햹햺

Figure 5b: Coupling part, complete