BÜCHI Labortechnik AG Contents

Operation Manual Vacuum Pump V-100 iii

Contents

1 About this document...........................................................................................................5

1.1 Warning notices in this document........................................................................................................ 5

1.2 Symbols............................................................................................................................................... 5

1.2.1 Warning symbols .....................................................................................................................5

1.2.2 Mandatory directive symbols ...................................................................................................6

1.2.3 Other symbols..........................................................................................................................6

1.3 Available languages............................................................................................................................. 6

1.4 Trademarks.......................................................................................................................................... 6

2 Safety....................................................................................................................................7

2.1 Intended use........................................................................................................................................ 7

2.2 Use other than that intended ............................................................................................................... 7

2.3 Staff qualification ................................................................................................................................. 7

2.4 Residual risks ...................................................................................................................................... 8

2.4.1 Dangerous vapors.................................................................................................................... 8

2.4.2 Faults during operation ............................................................................................................8

2.5 Personal protective equipment ............................................................................................................ 8

2.6 Modifications........................................................................................................................................ 8

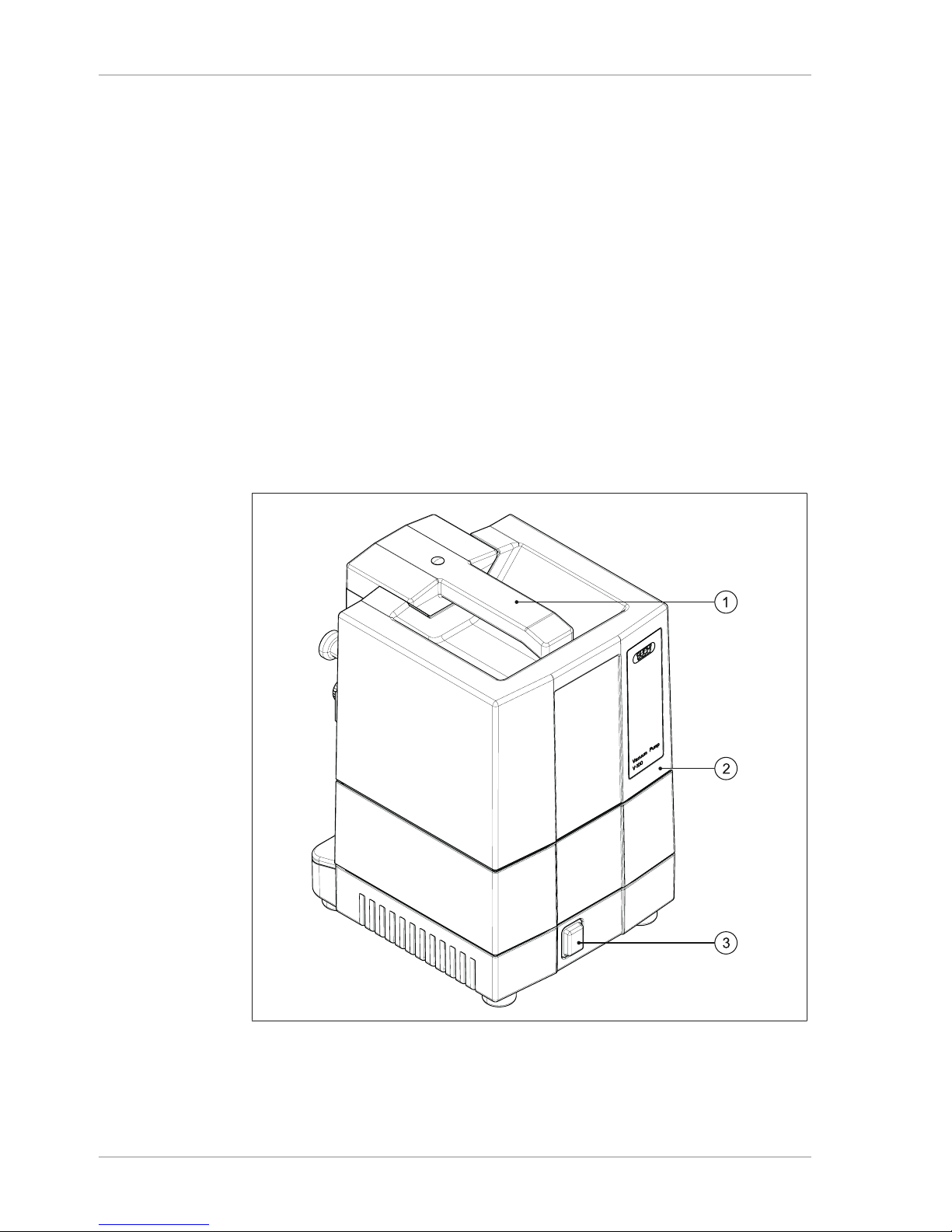

3 Product description...........................................................................................................10

3.1 Description of function ....................................................................................................................... 10

3.2 Configuration ..................................................................................................................................... 10

3.2.1 Front view ..............................................................................................................................10

3.2.2 Rear view ...............................................................................................................................11

3.2.3 Internal view...........................................................................................................................12

3.2.4 Typical application .................................................................................................................13

3.2.5 Type plate ..............................................................................................................................14

3.3 Specifications supplied ...................................................................................................................... 14

3.4 Technical data ................................................................................................................................... 15

3.4.1 Vacuum Pump V-100.............................................................................................................15

3.4.2 Ambient conditions.................................................................................................................15

3.4.3 Materials ................................................................................................................................15

4 Transport and storage ......................................................................................................16

4.1 Transport ........................................................................................................................................... 16

4.2 Storage .............................................................................................................................................. 16

4.3 Removing transit fixings..................................................................................................................... 17

5 Installation..........................................................................................................................18

5.1 Important considerations prior to commissioning .............................................................................. 18

5.2 Installation site................................................................................................................................... 19

5.3 Connecting laboratory equipment...................................................................................................... 19

5.4 Connecting the silencer ..................................................................................................................... 21

5.5 Connecting a Woulff bottle................................................................................................................. 23

5.6 Connecting a secondary condenser .................................................................................................. 24

5.7 Connecting a secondary cooling cold trap......................................................................................... 26

5.8 Electrical connections........................................................................................................................ 27

5.9 Fitting and connecting the Interface I-100 ......................................................................................... 28

5.9.1 Fitting an interface unit to the Vacuum Pump V-100 .............................................................28

5.9.2 Connecting interface unit to Vacuum Pump V-100................................................................ 29