AAS 2.0 interlock user manual Ver:1.0

7. Interlock Function Description

7.1 Working procedure

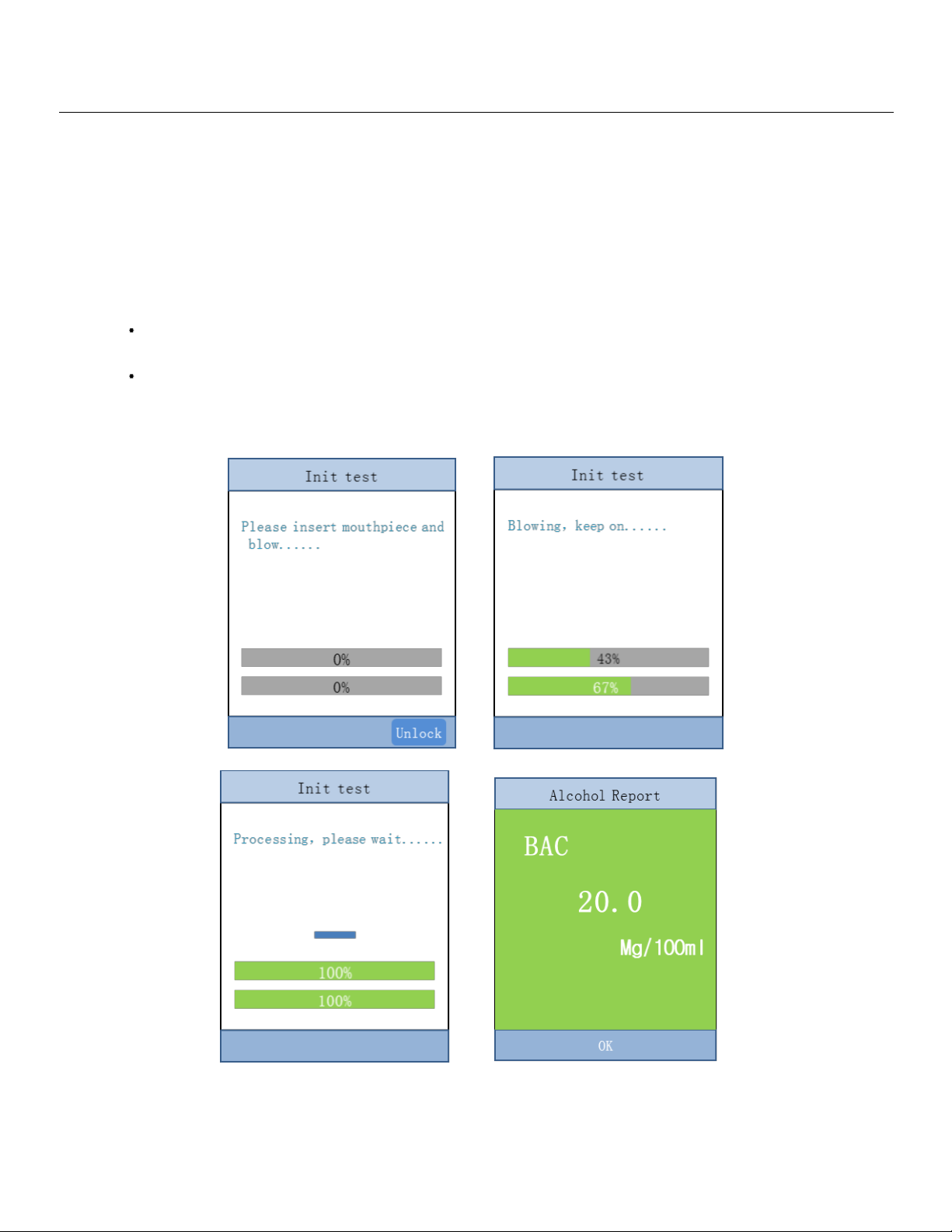

7.1.1 Initial testing process

If the door of the vehicle is unlocked/opened or the car ignition key is turned to the on

position, the initial testing process is started automatically. The tester will at first need to conduct

the initial testing and violation record query. The tester can then conduct the alcohol test (deliver

a blow into device). After passing the test, the device is unlocked and the vehicle can be started.

If the test is failed the instrument stays locked and gives out a beep continuously and pops up

voice warning to require for another test.

7.1.2 Ignition awaiting process

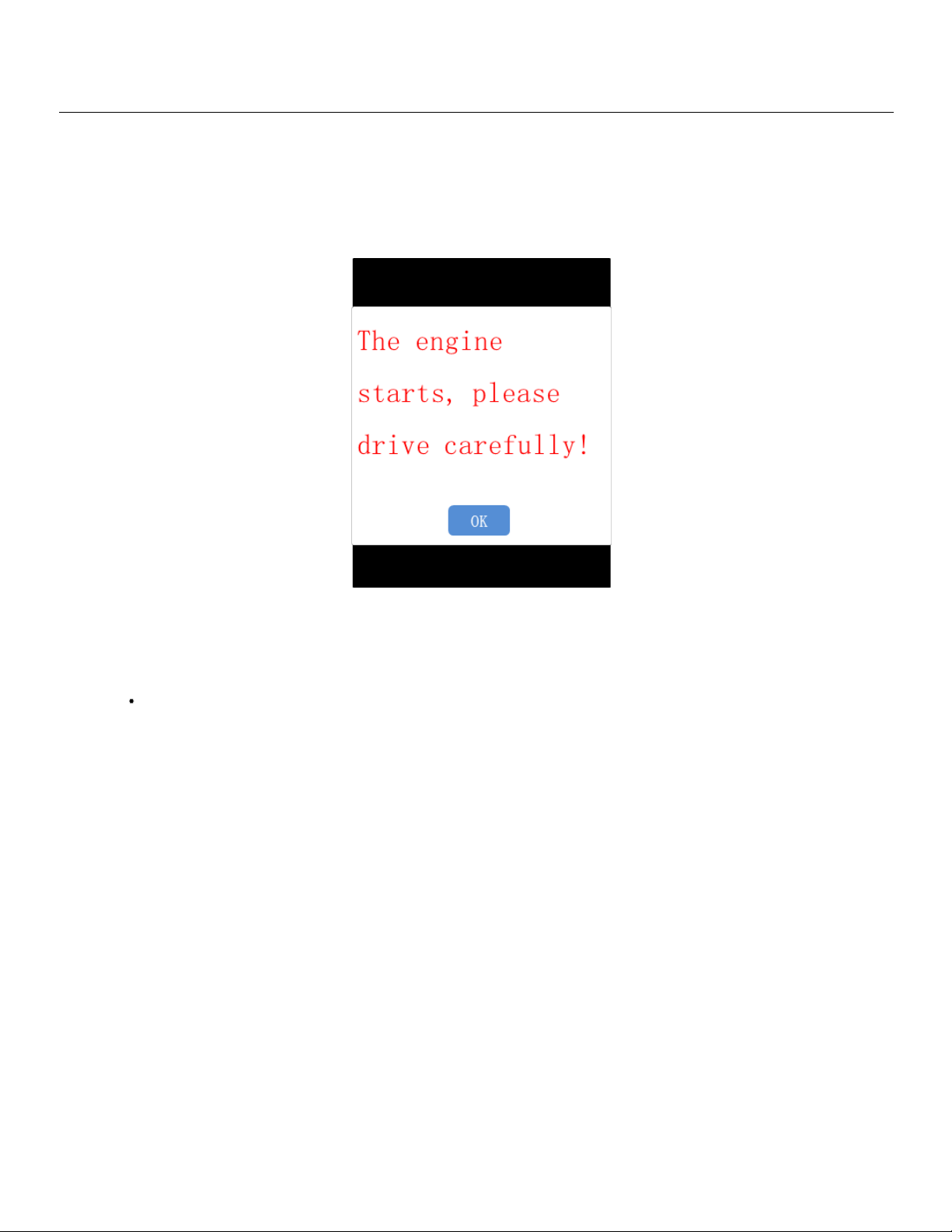

After passing the test allowing the engine to start, the control box automatically proceeds

into the ignition waiting process. The vehicle must be started within the set time or another

breath sample will be required. Once the vehicle has been started the handheld will start the

countdown to the first rolling retest.

7.1.3 Rolling retest process

The Rolling Retest process enables random alcohol tests to be conducted in a specified time

span (set up in Manager Tool or handset, e.g. minimum 10 minutes, maximum 30 minutes) after

the vehicle is started, the handheld will beep or a voice warning will be given out when a rolling

retest is required. Once the test is completed and passed, the device will proceed into a waiting

status for the next rolling retest. If the rolling retest is failed or the driver refuses to take the test,

an indication will be displayed on the screen, the alarm lamp will blink and the horn will sound

(where required) and the violation will be recorded on the data recorder as well as being sent to

the Manager Tool through the cellular network (GPRS) where available. The number of rolling

retests required can be set by the administrator.