ASSEMBLY INSTRUCTION

Table of Contents

GENETAL INFORMATION ....................................................................................................3

1.

STRUCTURE VARIANTS. ..............................................................................................3

2.

SAFETY INFORMATION ................................................................................................3

3.

PRODUCT USE .............................................................................................................4

a. Maintenance.................................................................................................................4

b. Cleaning.......................................................................................................................4

4.

PACKAGING, STORAGE AND TRANSPORT ...............................................................4

5.

ASSEMBLY. GENERAL INFORMATION .......................................................................5

a. Tools ............................................................................................................................5

ASSEMBLY INSTRUCTION ........................................................................................................ 6

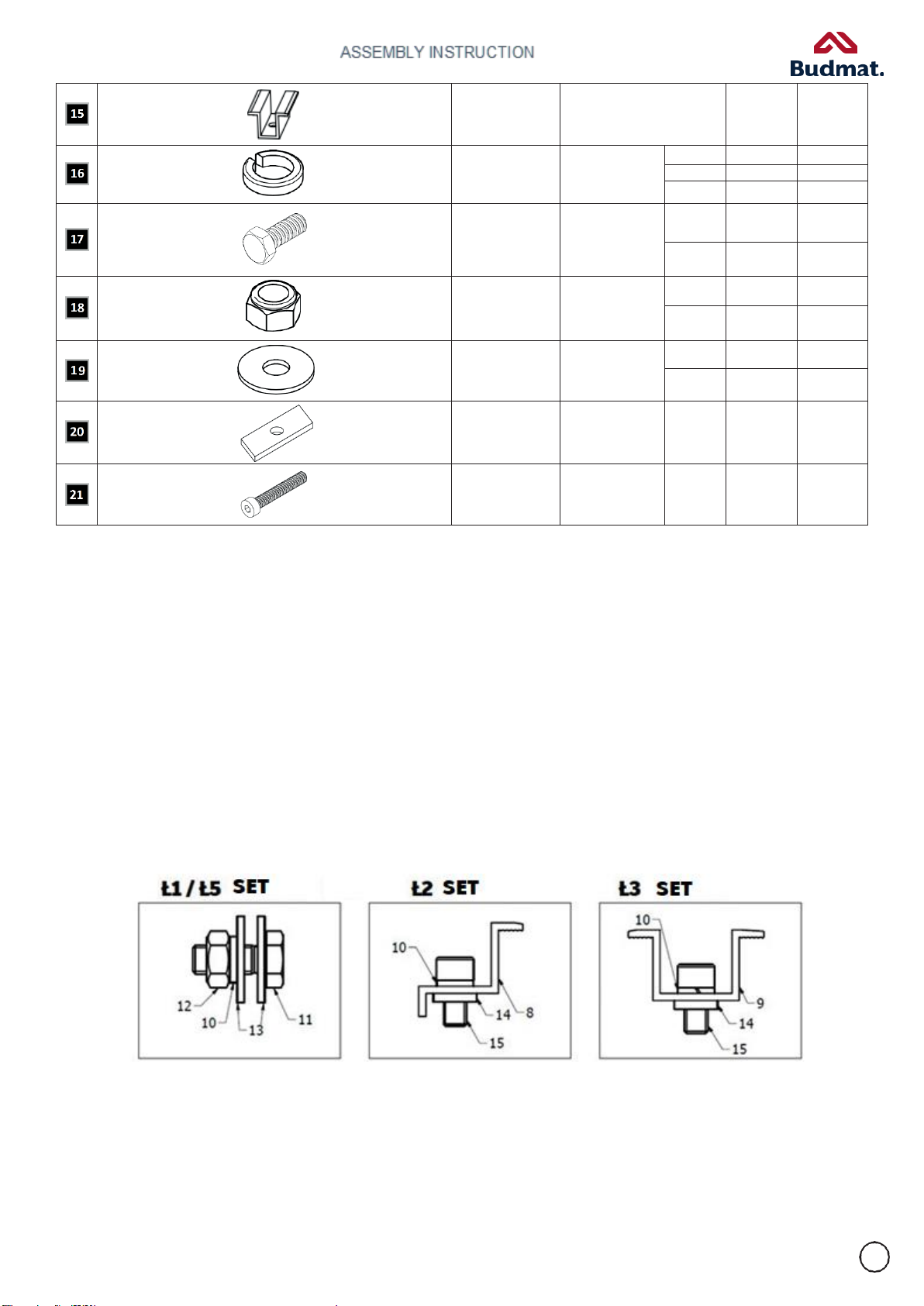

1. COMPONENTS....................................................................................................................... 6

1.1. BASIC STRUCTURE COMPONENT KIT ..................................................................... 6

1.2. CONNECTING SETS ..................................................................................................... 7

1.2.1. CONNECTION PATTERNS .................................................................................... 7

2. ASSEMBLY ............................................................................................................................. 8

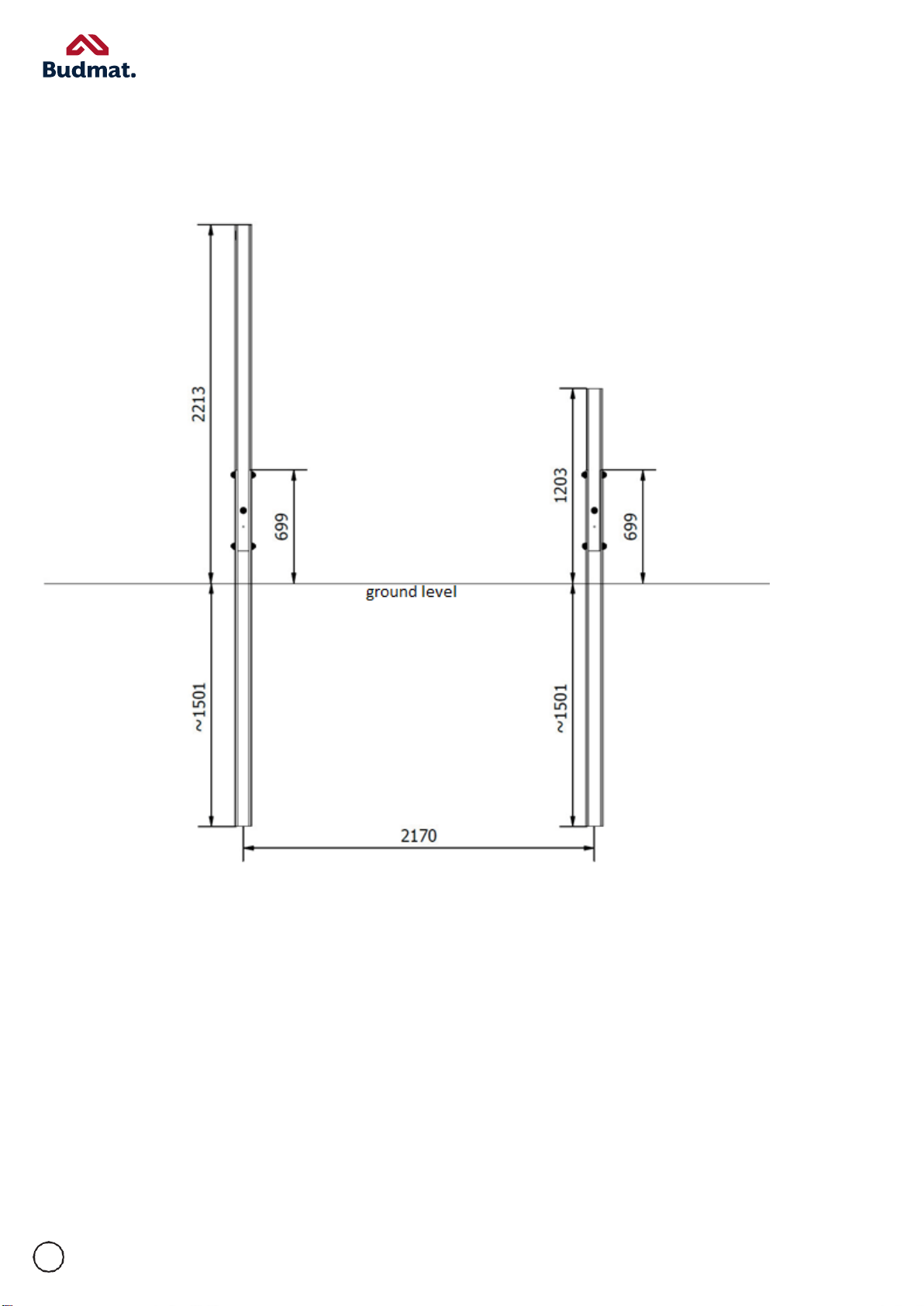

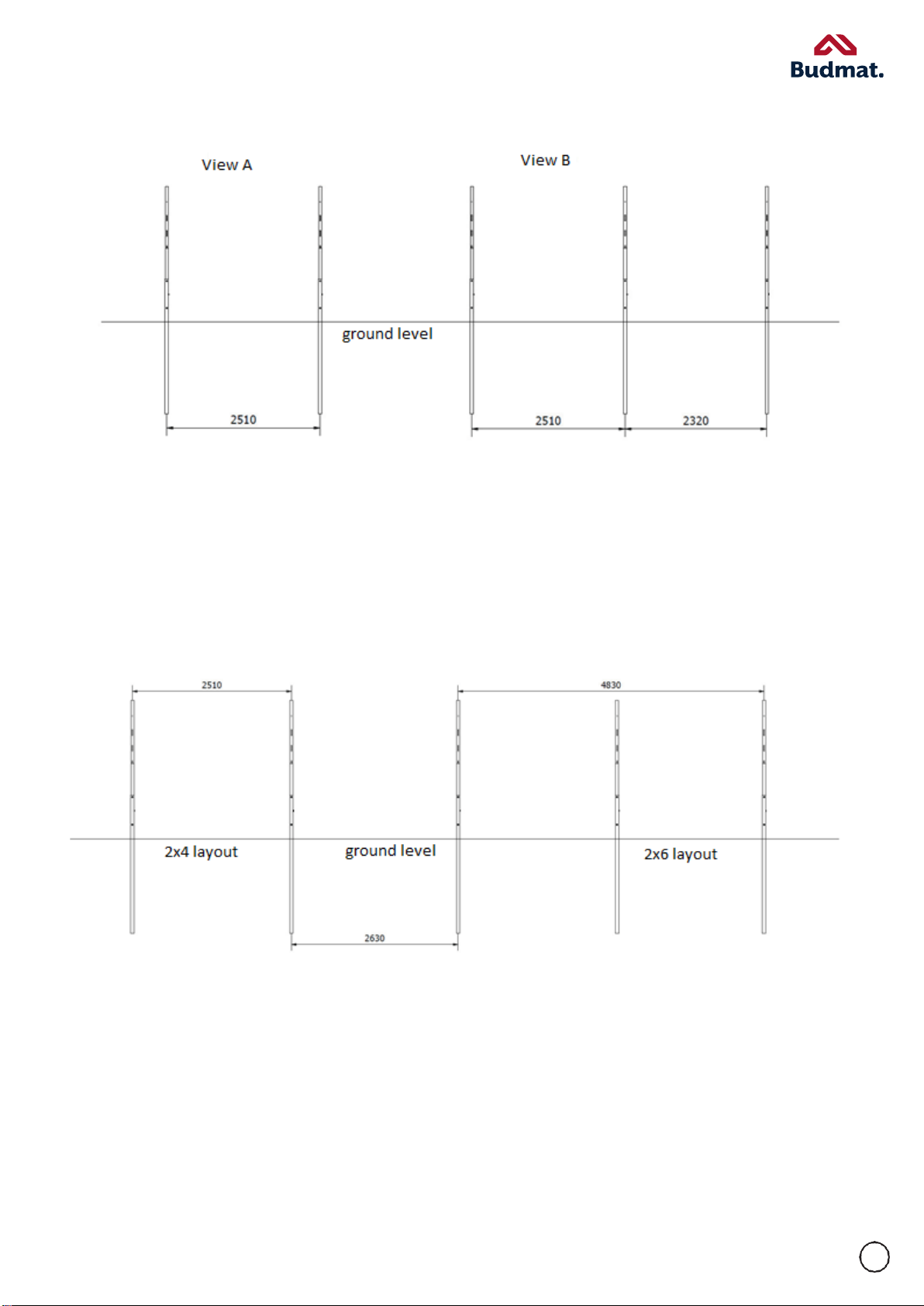

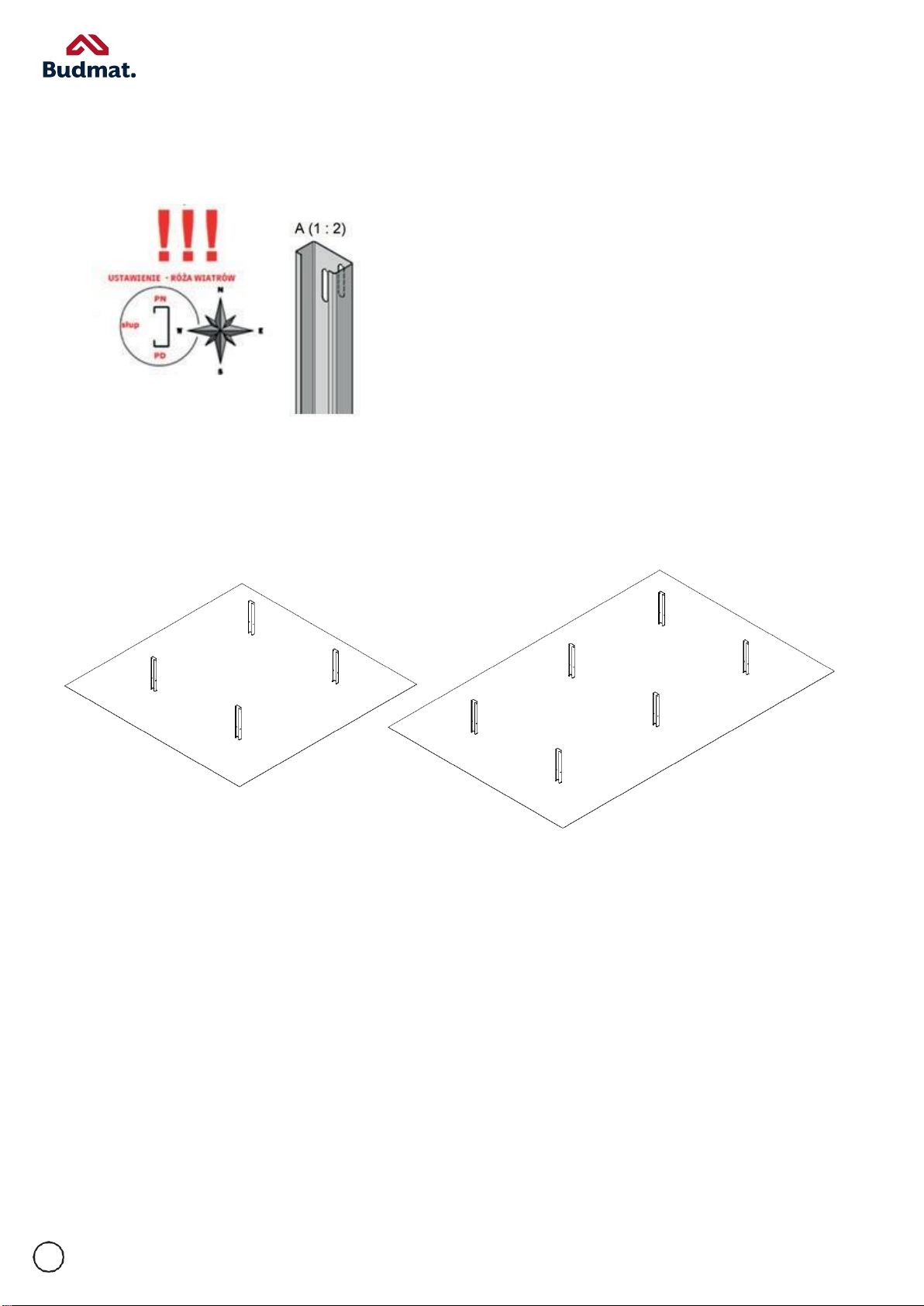

2.1. POST LAYOUT ............................................................................................................... 8

2.1.1. POST MOUNTING .................................................................................................10

2.2. BINDER ASSEMBLY .....................................................................................................11

2.3. RAFTER ASSEMBLY ....................................................................................................13

2.4. BRACE ASSEMBLY ......................................................................................................15

2.5. PV PANEL ASSEMBLY ................................................................................................16

2.6. INVERTER MOUNTING ASSEMBLY .............................................................................16

TABLE OF FIGURES ...................................................................................................................17