2

1 Safety instructions ............................................................................................................................................3

1.1 Possible dangers............................................................................................................................................3

1.2 Notes on safe operation ................................................................................................................................3

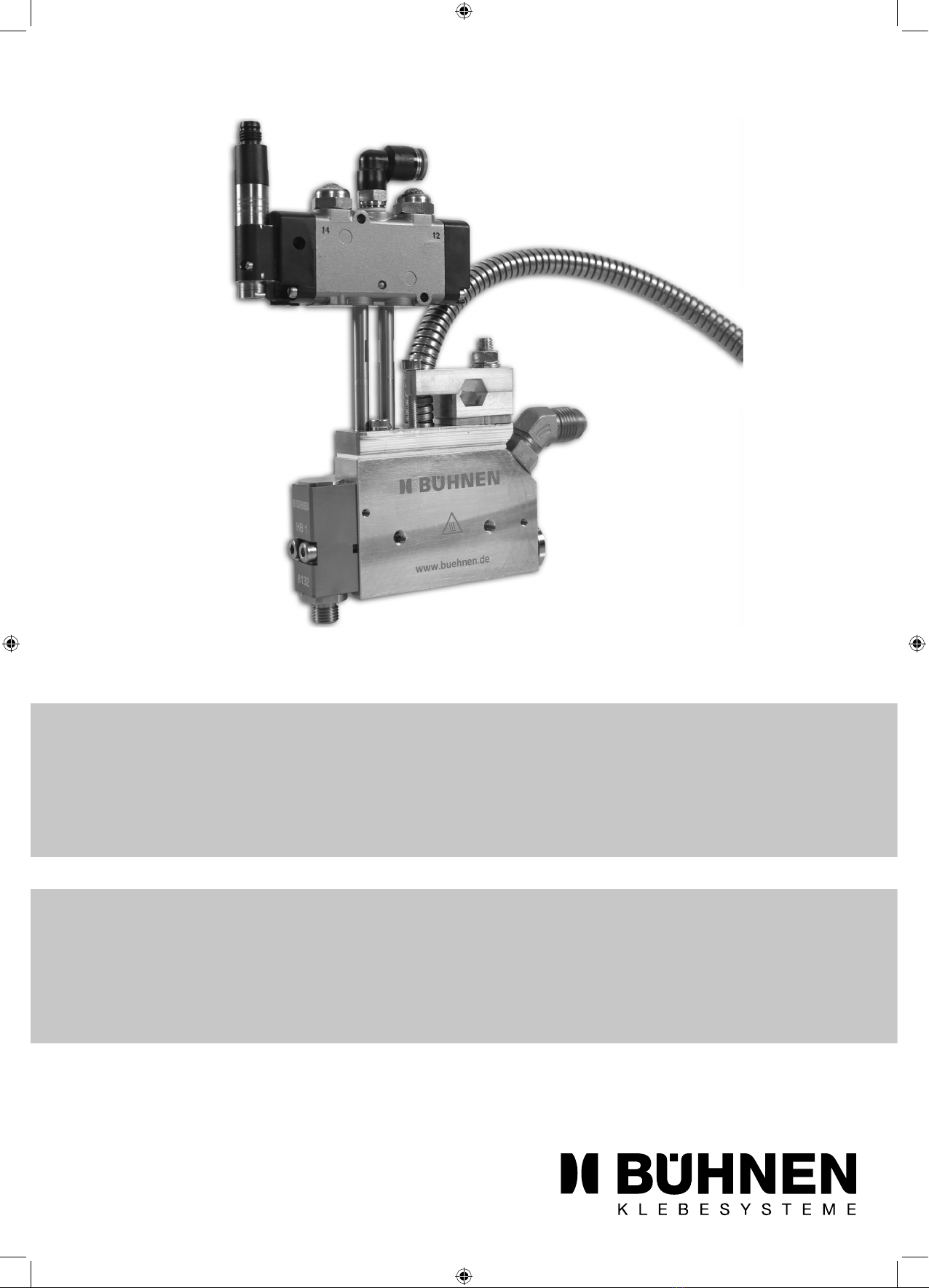

2 General ...............................................................................................................................................................4

2.1 Operative range .............................................................................................................................................4

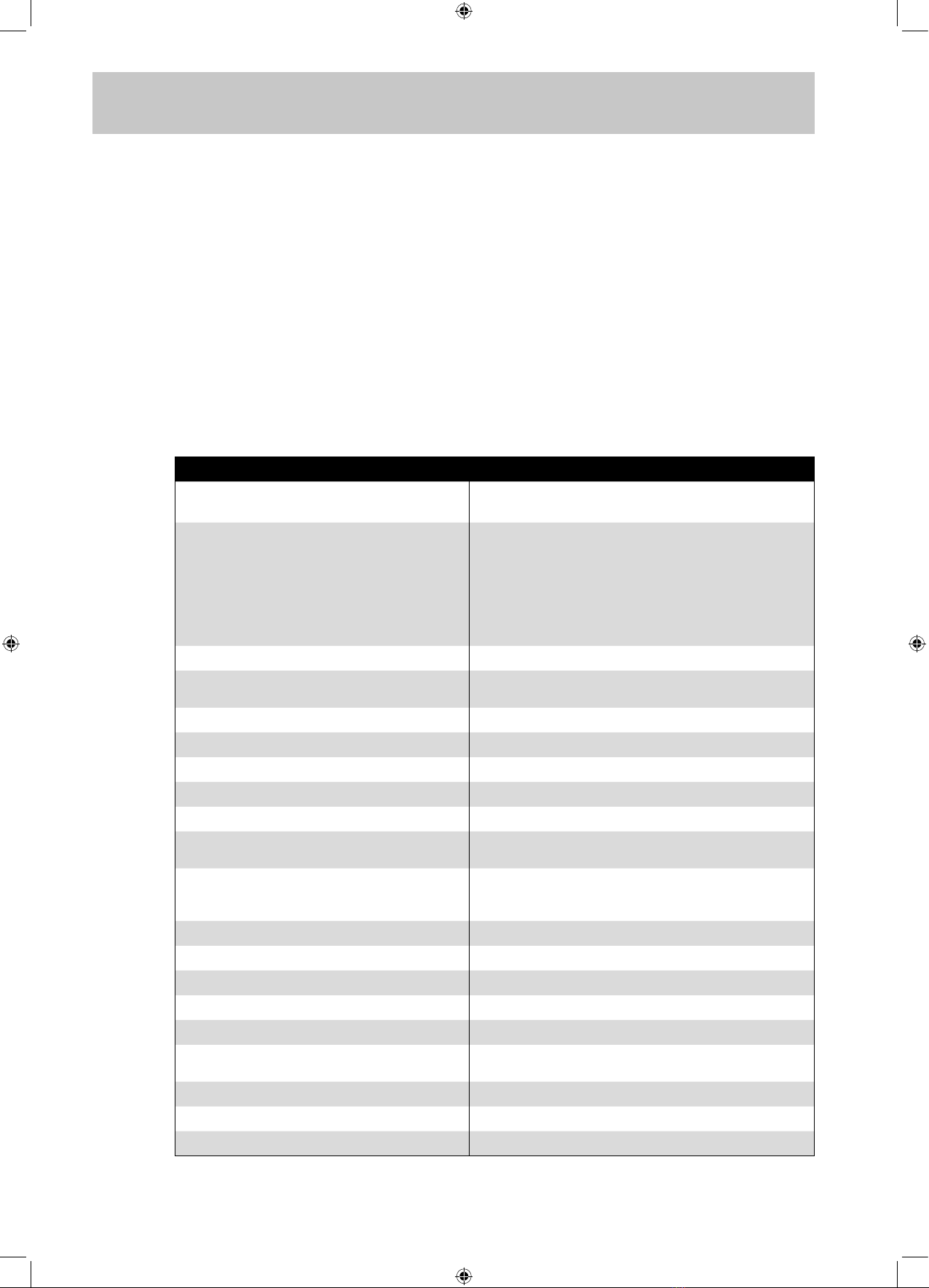

2.2 Technical data ................................................................................................................................................4

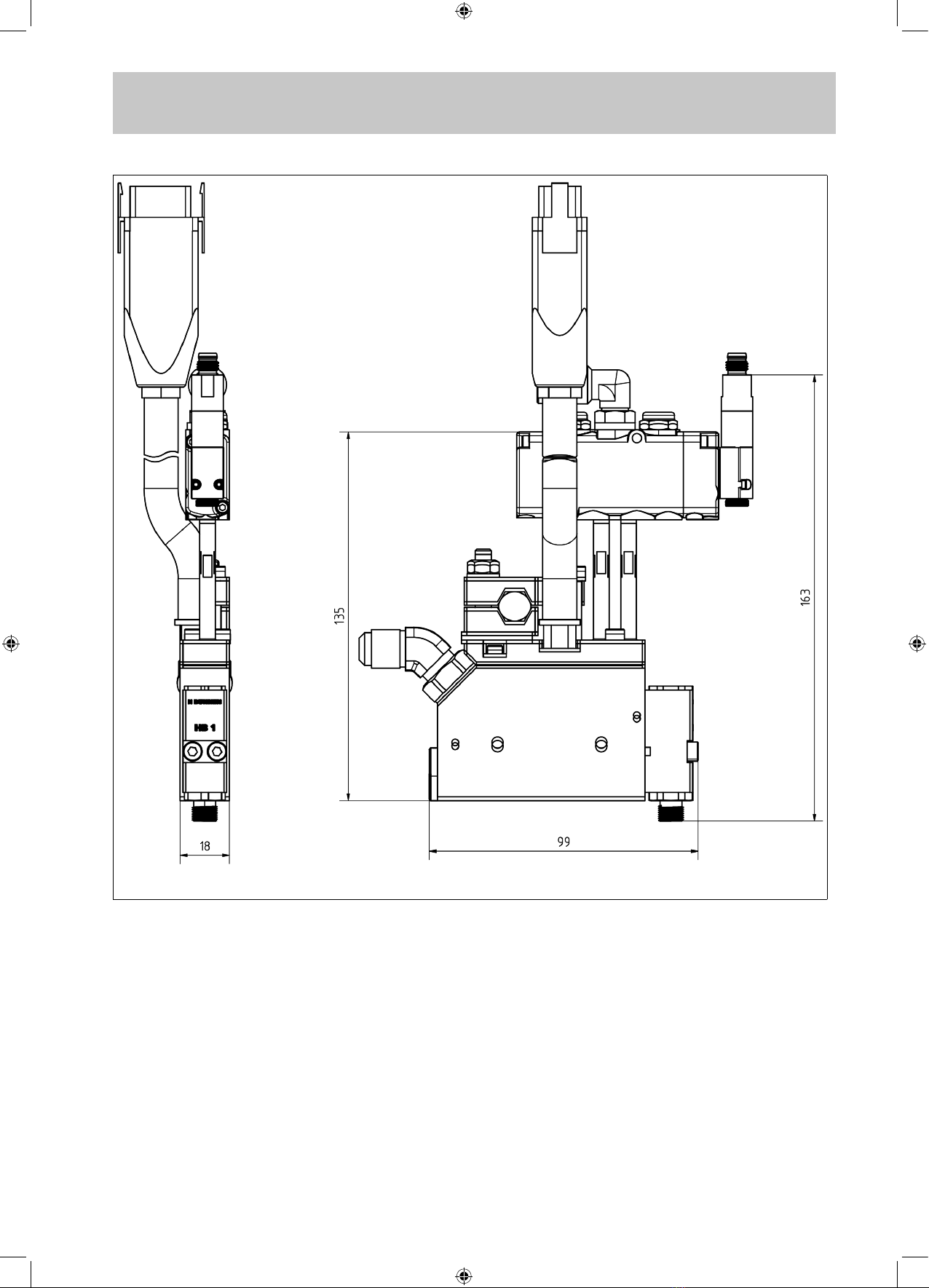

2.3 Dimensioned drawing.....................................................................................................................................5

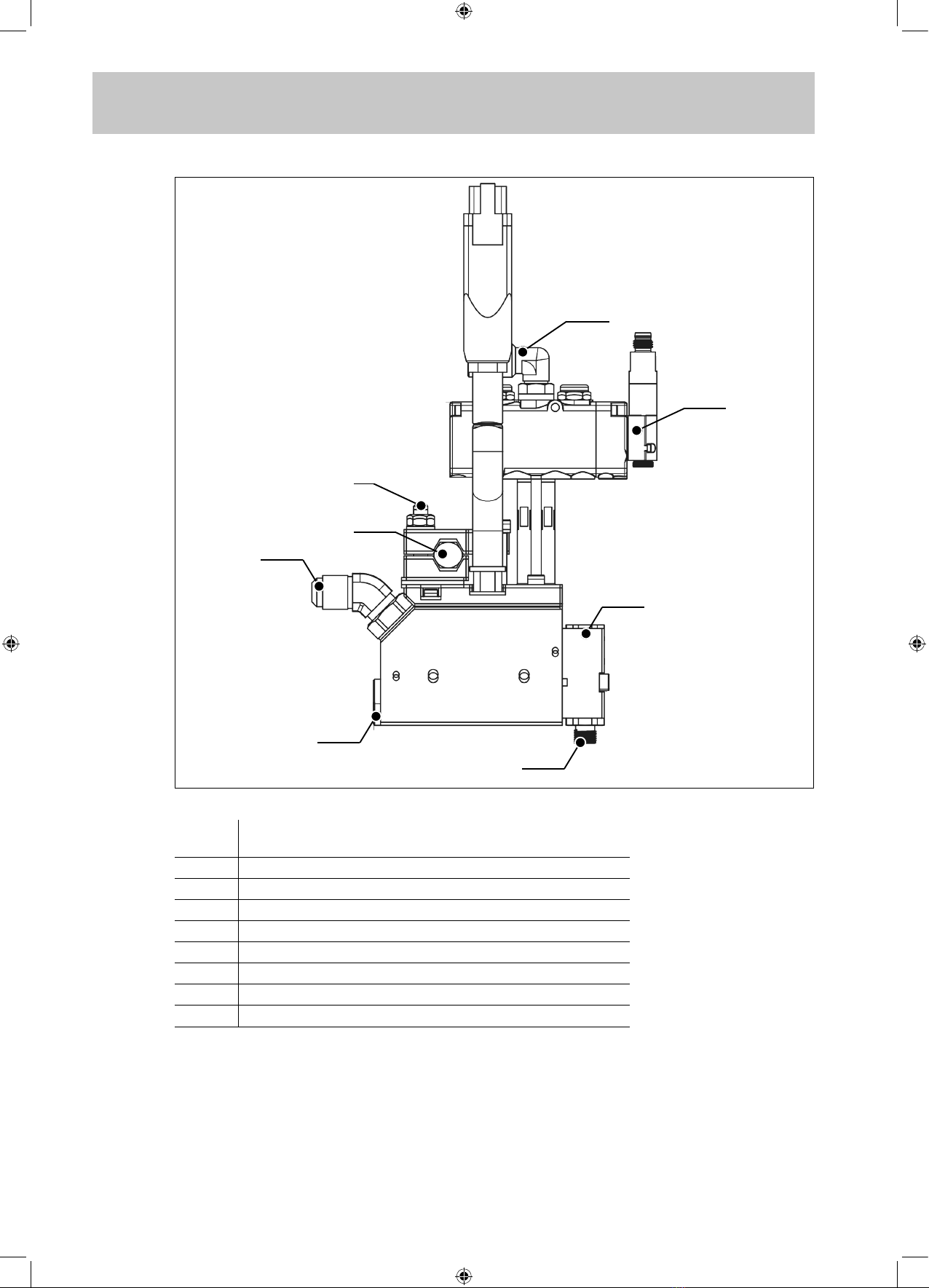

3 Assembly............................................................................................................................................................6

3.1 Electrical connection ......................................................................................................................................7

3.2 Compressed air connection ...........................................................................................................................8

3.3 Heatable hose................................................................................................................................................8

4 Operation............................................................................................................................................................8

4.1 Initial operation...............................................................................................................................................8

4.2 Adjusting the adhesive dosage ......................................................................................................................8

4.3 Interruptions in work/End of shift....................................................................................................................8

4.4 Processing PU hot melt adhesives ................................................................................................................8

5 What happens if… .............................................................................................................................................9

5.1 Troubleshooting and repair ............................................................................................................................9

6 Maintenance/servicing ....................................................................................................................................10

6.1 Maintenance intervals ..................................................................................................................................10

6.2 Cleaning.......................................................................................................................................................10

6.2.1 Clean nozzle ...............................................................................................................................................................10

6.3 Replace module HB 1 .................................................................................................................................. 11

7 Repairs..............................................................................................................................................................12

8 Warranty ...........................................................................................................................................................12

9 Disposal............................................................................................................................................................12

10 Spare parts .......................................................................................................................................................13

Declaration of Conformity...............................................................................................................................14

FCH0479-2XM_EN_191107.indd 2 07.11.19 14:03