Page 2 / 8

Safeyt Instructions

1. The ma hine is designed for through hole

plating of PCBs. Only use the apparatus for

its des ribed appli ation. For any other ap-

pli ation please onta t us.

2. Che k hemi al resistan e of the tanks

against your hemi als. Chemi als supplied

by Bungard are suitable to be used with this

ma hine. Please onta t us if you use differ-

ent kind of hemi als. Mix hemi als outside

of ma hine in a suitable ontainer.

3. To avoid the risk of ele tri sho k, do not

remove the asing or open the ba k. There

are no user servi eable parts inside. Leave

servi ing to the experts! Keep this unit out of

the rain and away from moisture.

Pay attention to the warning signs on the

ma hine.

4. Read all the safety instru tions and all the

operating instru tions thoroughly before us-

ing the unit for the first time. Keep these

safety instru tions and operating instru tions

somewhere safe in ase you need to refer to

them again in the future.

5. In your own interest pay heed to all the

safety warnings on the unit and in the oper-

ating instru tions. Follow the instru tions on

operation and use of the unit in every re-

spe t.

6. Wherever you put the unit, always ensure

there is suffi ient ventilation. For the et hing

and plating units in some ir umstan es an

exhaust system is ne essary. This mainly

depends on the hemi als used.

7. Do not put the unit anywhere near

sour es of heat, su h as radiators, hot air

shafts, oven et ..

8. Conne t the unit only to the power sour e

indi ated in the operating instru tions or on

the unit. We assume that your power sour e

is in a ordan e to the regulations of your

ountry.

9. Follow the manufa turer's re ommenda-

tions for leaning the unit.

10. If you are not going to use the unit for

some time, remove the plug from the so ket.

11. Take great are to ensure that no liquids

or other foreign bodies an find their way in-

side the unit through the openings in the

asing.

12. The unit should only be repaired by qual-

ified personnel. Never try to do more in the

way of maintenan e to your unit than the op-

erating instru tions allow. Beyond that, al-

ways onsult an expert for repair work.

13. Set up apparatus only in a suitable room.

Apparatus filled with hemi als must be

pla ed on hemi al resistant floors. In the

ase of overflow or leakage see safety data

sheets. No hemi als are allowed untreated

in the sewerage. In some ase absorber

tanks are ne essary.

Be ause of possible exothermi rea tions

please mix hemi als in a suitable ontainer

outside of the ma hine. We re ommend to

use sulphuri a id 36% instead of the 98%

on entrate.

The use of the apparatus is not allowed in

the residential area; keep away from hil-

dren.

14. Only run the unit with tanks ompletely

filled. Control the liquid level daily.

15. Close the drain valves before refilling the

ma hine.

16. Personal safety regulations:

The following safety pre autions should al-

ways be observed when handling hemi als

(et hing agent, a ids, lyes, et .):

a) Wear goggles and prote tive gloves for all

w o r k .

b) If ne essary only work under an extra tor

hood or at least in well ventilated rooms.

) Avoid onta t with skin, eyes and mu ous

membranes at all osts.

d) Take off lothing soaked in austi sub-

stan es immediately.

e) Rinse splashes on skin immediately with

opious amounts of water.

f) In the event of a idents or feeling unwell,

always onsult a do tor.

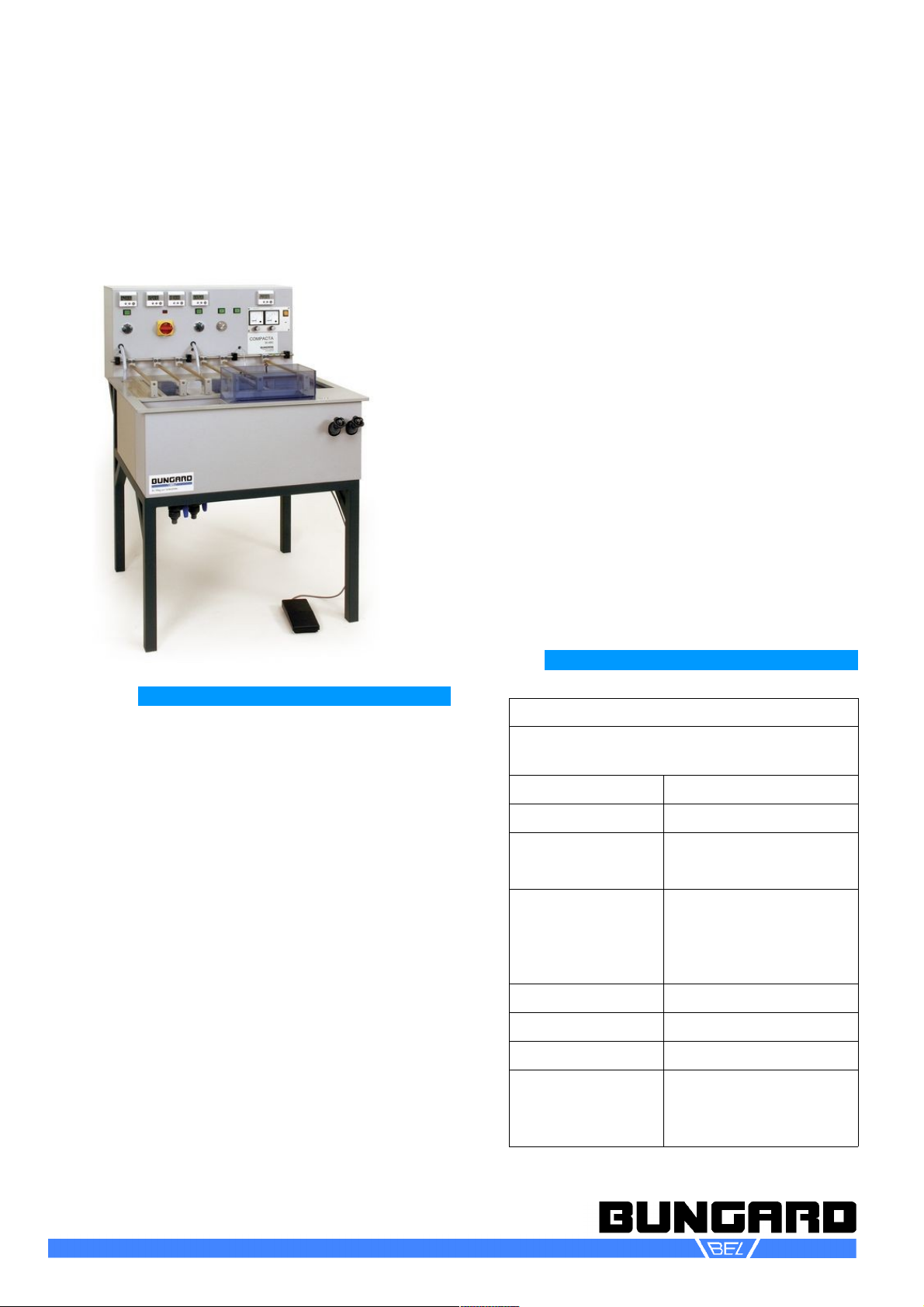

COMPACTA 30

Through hole plating ma hine

Instru tions for use