The TS-1 Dial Line Transient Suppressor provides transient voltage surge suppression for

equipment connected to a dial telephone line with standard RJ-13 or RJ-11 connectors.

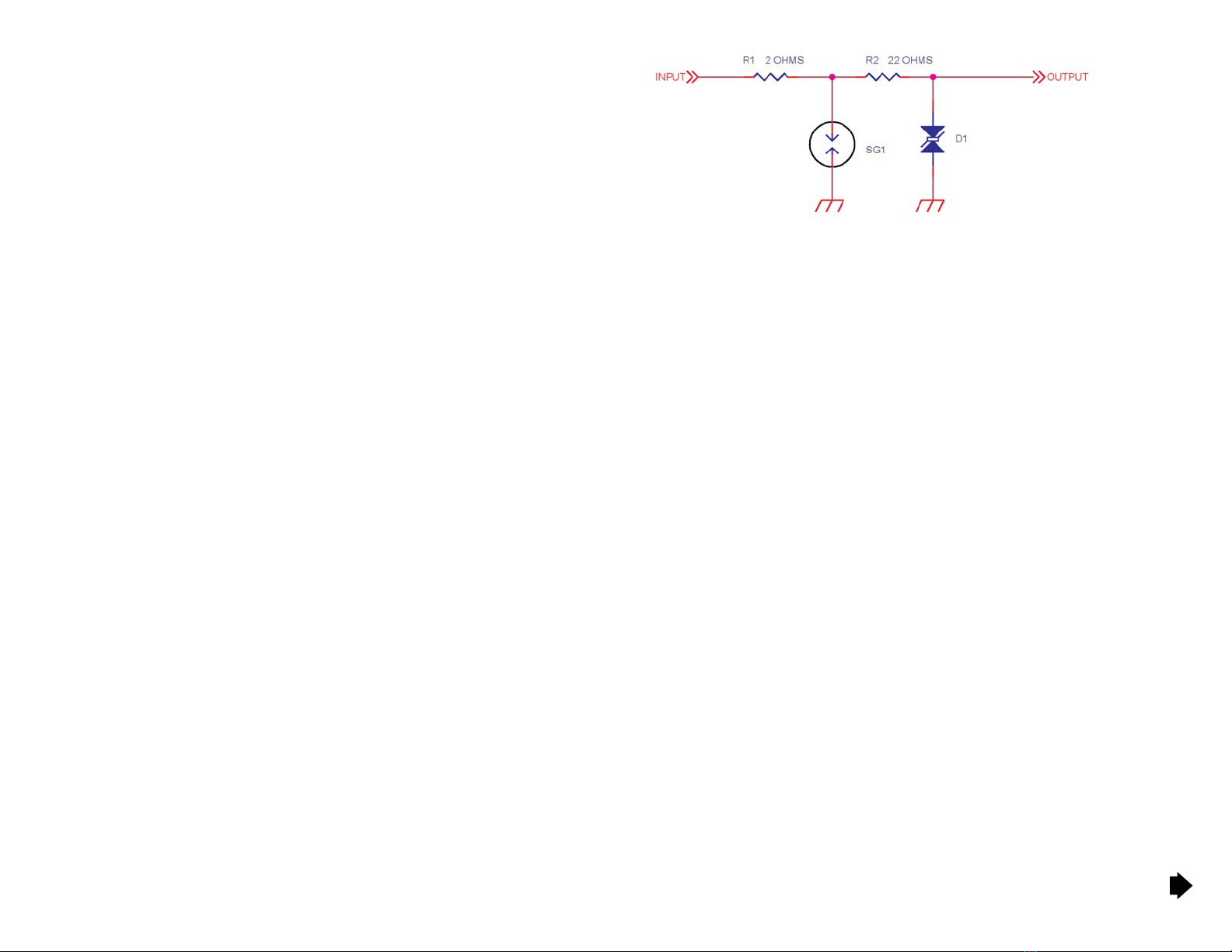

The high quality die cast aluminum enclosure houses a passive, three-stage protection

device designed to conduct destructive energy safely to ground.

Both pairs in the RJ-13 standard configuration are afforded protection, while allowing the

normal ring voltage, and voice or data to pass unimpeded. Studio or transmitter audio

equipment connected to a two-pair dedicated stereo telco circuit may also be protected

with the TS-1.

The TS-1 must be connected to an adequate station ground to provide a path for

destructive energy to be shunted away from the protected equipment. Ideally, the TS-1

should be mounted on the copper strap directly connected to station ground. The integral

clamping system on the TS-1 affords easy mounting on strap up to four inches wide and

ensures a low-impedance path to ground. Alternatively, the TS-1 may be connected to earth

ground using the ground lug on the side of the enclosure.

INSTALLATION

Position the TS-1 near the telco service entry. In the event of a catastrophic lightning strike

to the phone line, this location prevents destructive energy from entering the facility.

Installation of the TS-1 is straightforward:

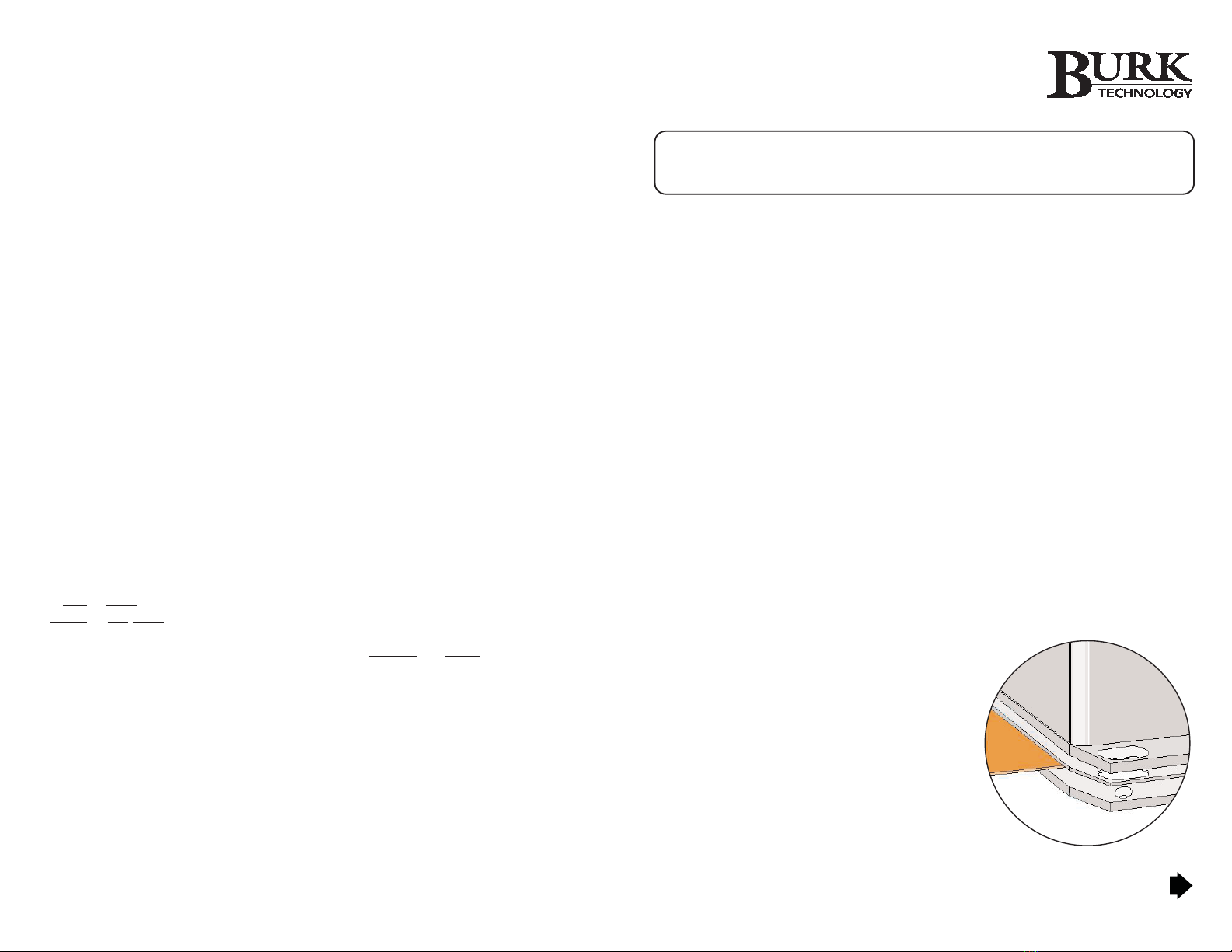

1. The preferred mounting scheme is to secure the

TS-1 to the station ground bus. First, remove the

machine screws from the TS-1. Beneath the

aluminum enclosure, you will find a thin

stainless steel shim on top of the stainless

steel backing plate. Clamp the ground bus

between the backing plate and shim, as

illustrated. Then attach the aluminum

enclosure so that it is flush with the stainless

steel shim and not touching the ground bus.

Secure the TS-1 by tightening the machine

screws (Phillips #8 x ½”).

TS-1 Dial Line

Transient

Suppressor

WARRANTY

Burk Technology, Inc. warrants the TS-1 Transient Voltage Surge Suppressor to be free of

defects in materials and workmanship for a period of 24 months from the date of purchase.

Equipment will be repaired or replaced at the option of Burk Technology and returned

freight prepaid to the customer. Damage due to abuse or improper operation or installation

of the equipment or caused by fire or flood or harsh environment is not to be covered by

this warranty. Damage in shipping is not the responsibility of Burk Technology. A return

authorization must be obtained before returning any equipment. Materials returned under

this warranty must be shipped freight prepaid and insured in the original shipping carton or

suitable substitute to Burk Technology, 7 Beaver Brook Road, Littleton, MA 01460. Repairs

not covered under this warranty will be made at prevailing shop rates established by Burk

Technology, Inc.

THE WARRANTY SET FORTH ABOVE IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. BURK

TECHNOLOGY, INC. SHALL NOT BE LIABLE TO ANY PARTY FOR ANY INCIDENTAL,

SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

THIS EQUIPMENT.

GETTING HELP

The Burk TS-1 is designed to protect indefinitely against multiple surges. If a catastrophic

strike disables the TS-1, the device breaks the line circuit so there is no loss of protection.

Therefore, if an otherwise functional telephone line is inoperative when connected to the

TS-1, the unit may need factory repair.

For assistance with the TS-1, please contact Burk Technology customer support:

Phone: 978-486-3711

Web: www.burk.com

Email: support@burk.com

Contact the sales department toll free at 800-255-8090, or email sales@burk.com.

TS-1 USER GUIDE, REV D

Copyright © 2015 Burk Technology, Inc. All rights reserved. No part of this manual may be reproduced in any form

or by any means without written permission from Burk Technology. Information in this manual is subject to change

without notice.

User Guide