Table of Contents

2 | 88 Instruction Manual COBRA NX 0950 A PLUS_EN_en

Table of Contents

1 Safety ..................................................................................................................................................................... 4

2 Product Description ............................................................................................................................................. 5

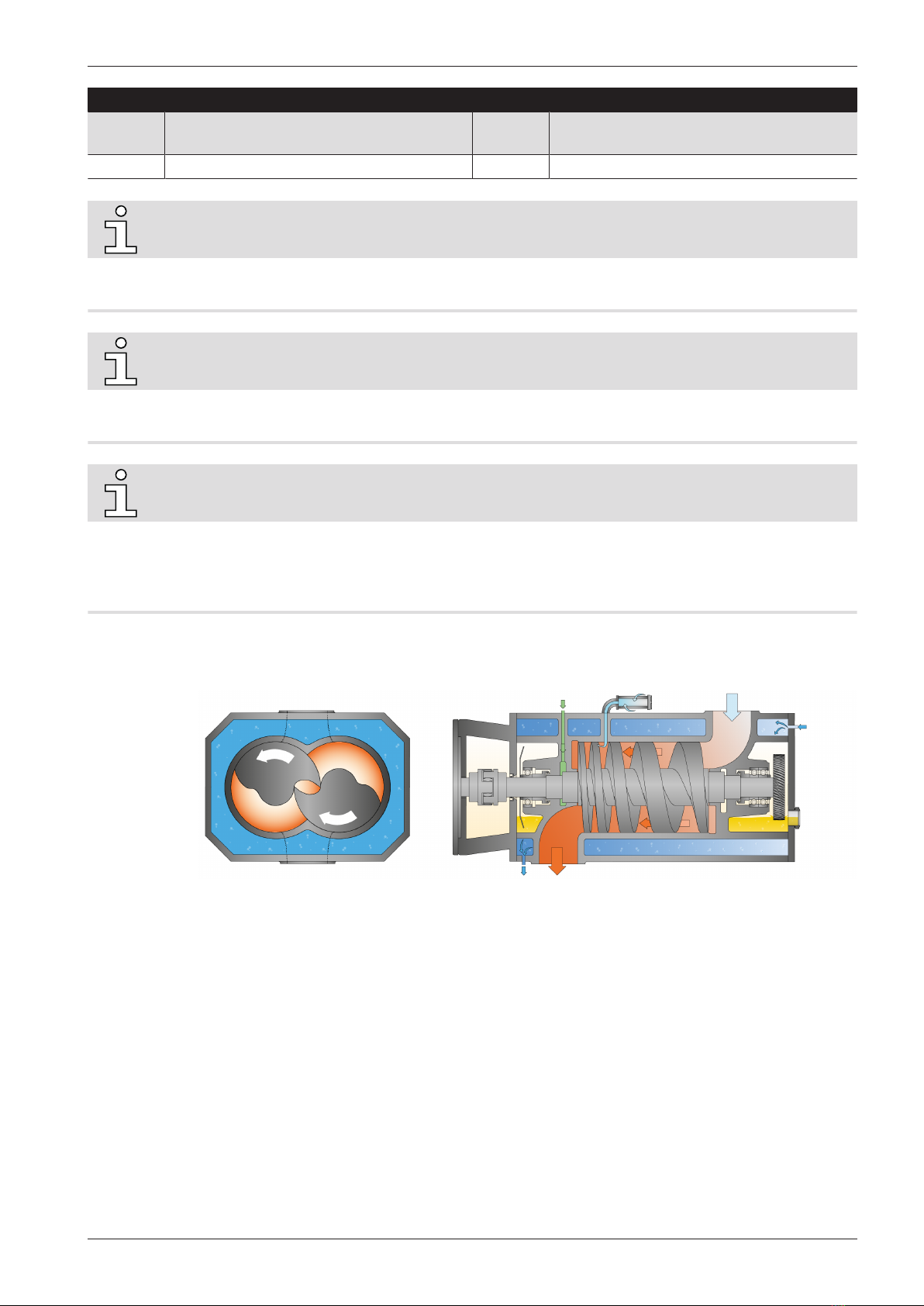

2.1 Operating Principle............................................................................................................................................. 7

2.2 Intended Use ....................................................................................................................................................... 8

2.3 Standard Features............................................................................................................................................... 8

2.3.1 User Interface ....................................................................................................................................... 8

2.3.2 Acoustic Cabinet ................................................................................................................................... 8

2.3.3 Control Unit........................................................................................................................................... 8

2.3.4 Monitoring Devices .............................................................................................................................. 9

2.3.5 I/O and Communication Port.............................................................................................................. 9

2.3.6 Gas Ballast Valve................................................................................................................................... 9

2.3.7 Inlet Check Valve .................................................................................................................................. 9

2.3.8 Water Cooling ....................................................................................................................................... 9

2.3.9 Sealing Systems .................................................................................................................................... 9

2.3.10 Silencer .................................................................................................................................................. 10

2.3.11 Barrier Gas System............................................................................................................................... 10

2.3.12 Oil Level Switches ................................................................................................................................. 10

2.3.13 Exhaust Pressure Sensor..................................................................................................................... 10

2.4 P&ID "Piping and Instrumentation Diagram" ................................................................................................. 10

2.5 LED Indicators...................................................................................................................................................... 11

2.6 Description of User Interface Functions .......................................................................................................... 11

2.6.1 Menu Overview..................................................................................................................................... 12

2.6.2 Bottom Bar ............................................................................................................................................ 12

2.6.3 Navigation ............................................................................................................................................. 13

2.6.4 Roles and Users .................................................................................................................................... 13

2.6.5 System Settings .................................................................................................................................... 15

2.6.6 Machine and Software Identification................................................................................................. 16

2.6.7 Ethernet Settings.................................................................................................................................. 16

2.7 Web Visualization ................................................................................................................................................ 17

3 Transport............................................................................................................................................................... 21

4 Storage................................................................................................................................................................... 23

5 Installation............................................................................................................................................................ 24

5.1 Installation Conditions ....................................................................................................................................... 24

5.2 Connecting Lines / Pipes .................................................................................................................................... 25

5.2.1 Suction Connection .............................................................................................................................. 25

5.2.2 Discharge Connection.......................................................................................................................... 26

5.2.3 External Inlet Pressure Sensor ........................................................................................................... 26

5.2.4 Cooling Water Connection .................................................................................................................. 27

5.2.5 Barrier Gas System Connection.......................................................................................................... 28

5.3 Filling Oil............................................................................................................................................................... 29

5.4 Gas Ballast Opening and Closing...................................................................................................................... 31

6 Electrical Connection ........................................................................................................................................... 32

6.1 PLUS Machine ...................................................................................................................................................... 32

6.2 Wiring Diagram Control Unit............................................................................................................................. 34

7 Commissioning ..................................................................................................................................................... 36

7.1 Prerequisites Before Use.................................................................................................................................... 36

7.2 Configuration....................................................................................................................................................... 37

7.3 Start Up................................................................................................................................................................. 38

8 In Operation.......................................................................................................................................................... 40