Table of Contents

2 / 24 Instruction Manual VACTEST DTP 400_EN_en

Table of Contents

1 Safety .......................................................................................................................................3

2 Product Description ..................................................................................................................4

2.1 Interface Illustration ......................................................................................................... 4

2.2 Product Identification ....................................................................................................... 4

2.3 Delivery Content .............................................................................................................. 4

2.4 Proper Use ....................................................................................................................... 4

2.5 Improper Use ................................................................................................................... 4

3 Transport and Storage...............................................................................................................5

4 Installation................................................................................................................................5

4.1 Installation Conditions...................................................................................................... 5

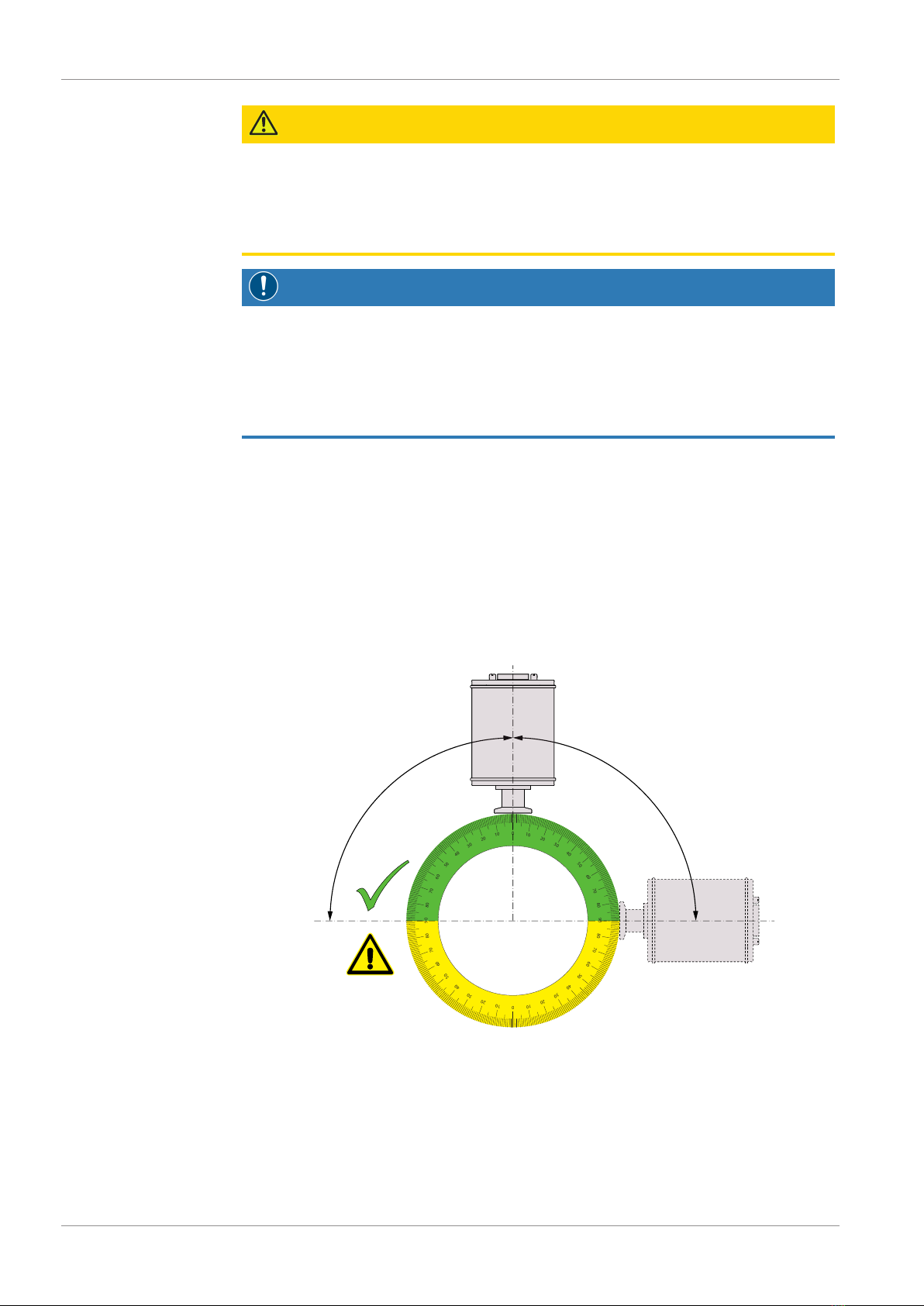

4.2 Vacuum Connection......................................................................................................... 5

4.3 Electrical Connection ........................................................................................................ 7

4.3.1 Connecting to the Active Sensor Controller ........................................................... 7

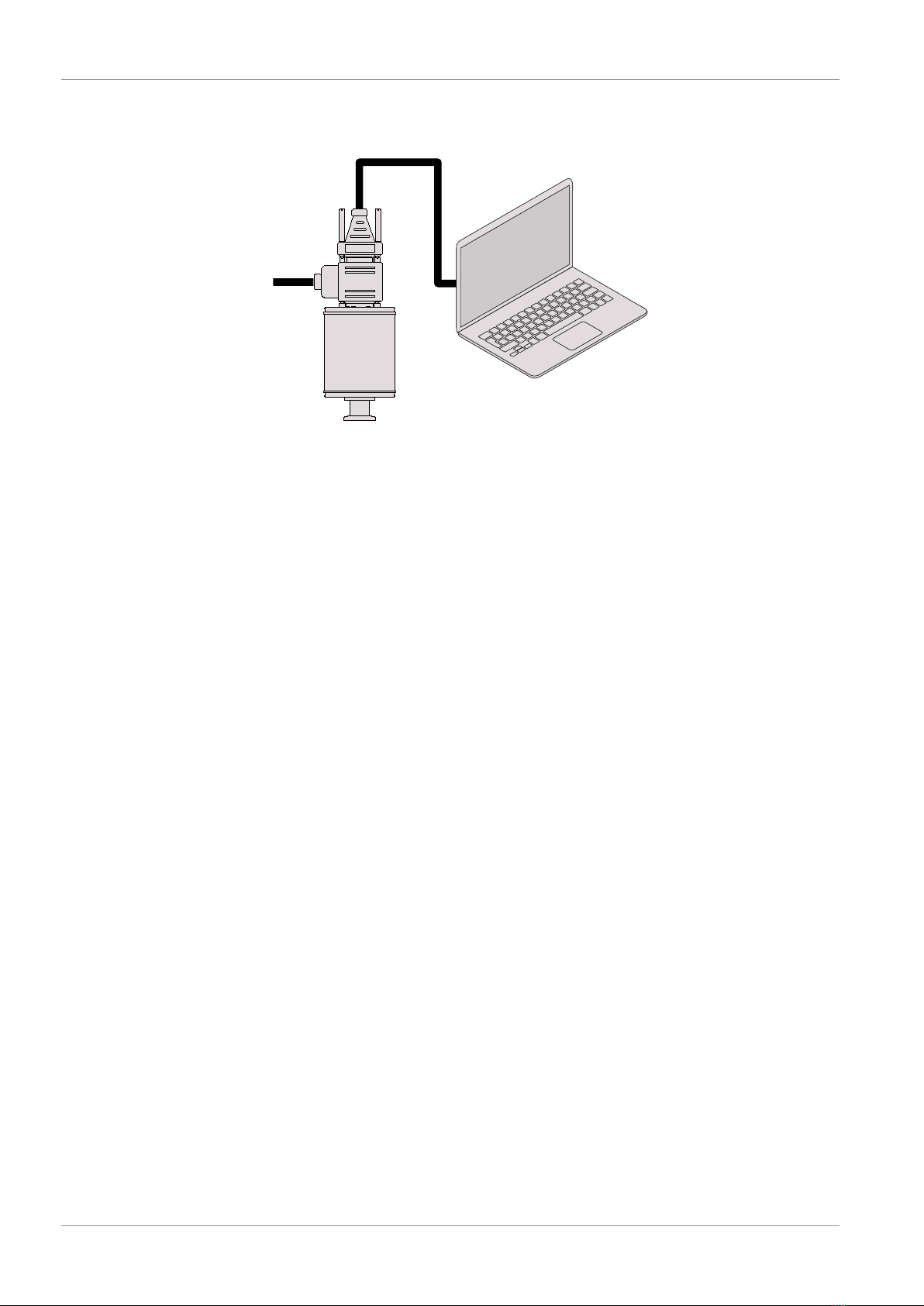

4.3.2 Connecting to the USB/RS485 Converter .............................................................. 8

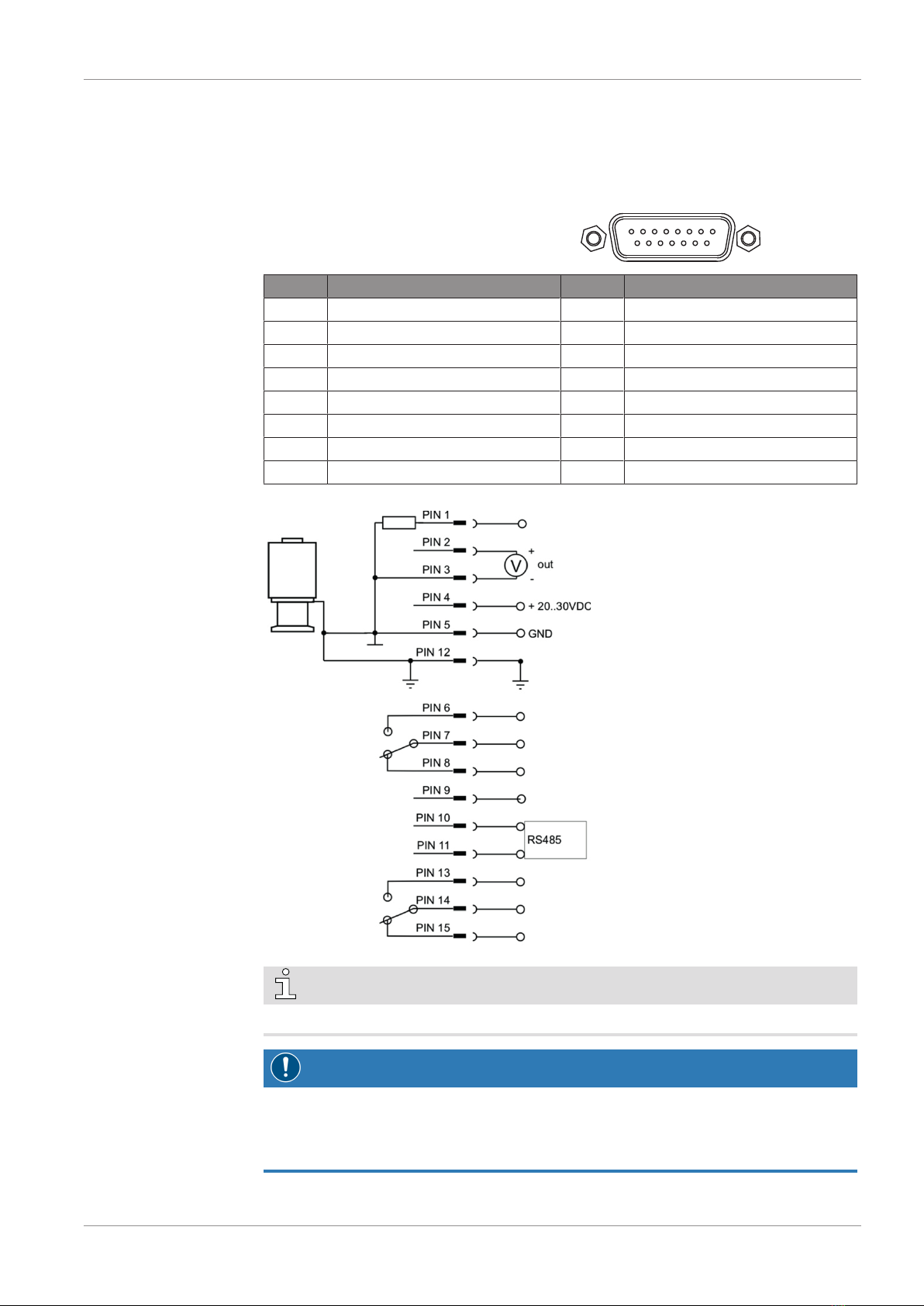

4.3.3 I/O and Communication Port Schematic ............................................................... 9

4.4 Change Display Unit and Orientation (Display version only)............................................. 10

5 Operation .................................................................................................................................10

5.1 Before Operation ............................................................................................................. 10

5.2 Operating the Gauge ....................................................................................................... 11

5.2.1 Operating Flowchart ............................................................................................. 11

5.3 Setpoints .......................................................................................................................... 12

5.4 Bake-out .......................................................................................................................... 13

5.5 Readjustment ................................................................................................................... 13

5.5.1 Readjustment by Pushbutton................................................................................. 13

5.5.2 Readjustment via Software Command...................................................................14

5.5.3 Readjustment via Controller .................................................................................. 14

6 Communication ........................................................................................................................14

6.1 Setting RS485 Address ..................................................................................................... 14

6.2 Commands Overview....................................................................................................... 15

6.2.1 Setpoints ............................................................................................................... 17

6.2.2 Readjustment ........................................................................................................ 17

6.3 VacTest Explorer Software................................................................................................ 18

7 Maintenance and Service..........................................................................................................18

7.1 Replacing the Sensor Head............................................................................................... 18

8 Troubleshooting .......................................................................................................................19

9 Spare Parts and Accessories......................................................................................................20

10 Technical Data..........................................................................................................................21

10.1 Gas Correction Factor....................................................................................................... 22

11 EU Declaration of Conformity...................................................................................................23