2

TM

Adjusting Spinner Zero Settings

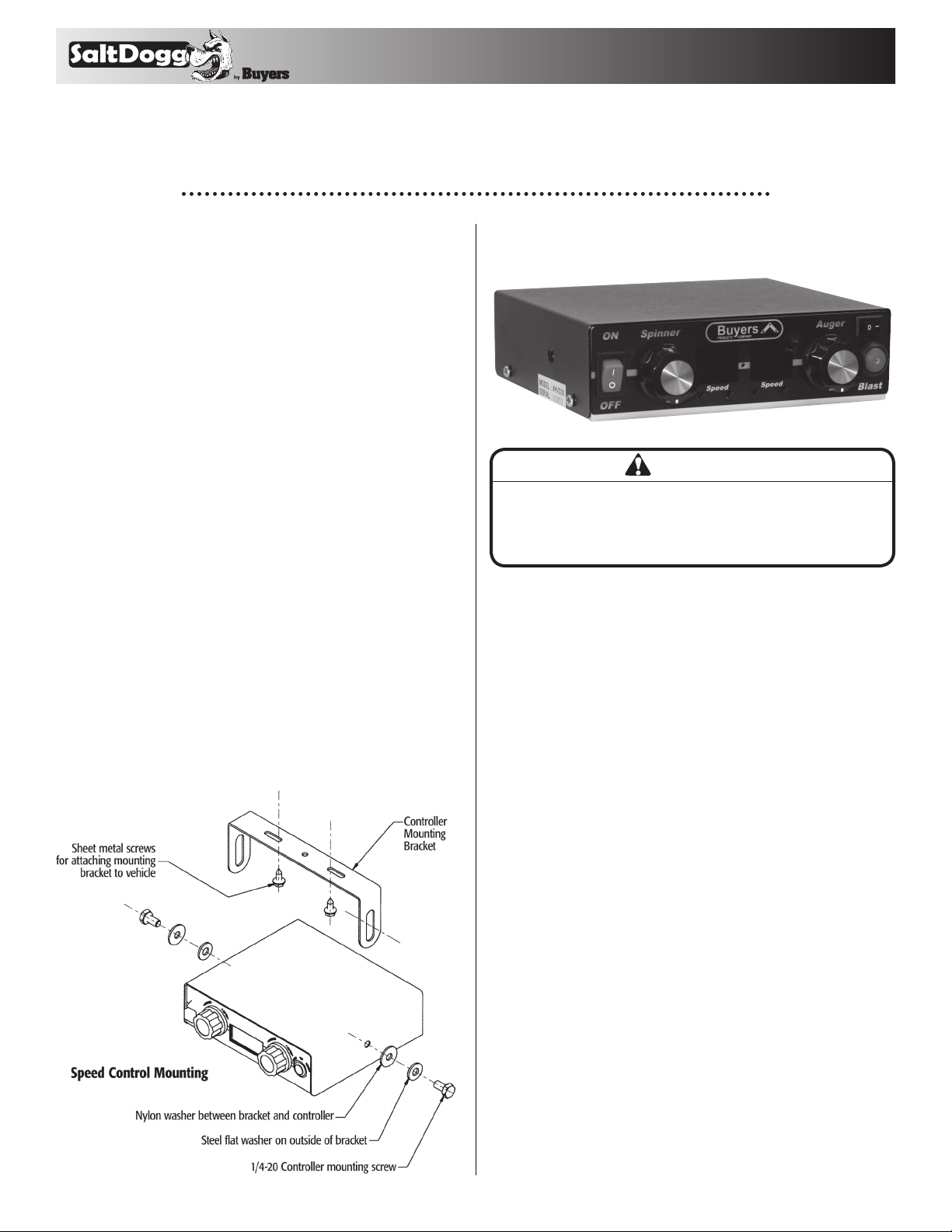

1. Verify that the spinner knob is turned completely

CCW to the zero position before beginning

adjustments.

2. Make sure that spinner disk has stopped, if it is

rotating, see step #3

3. Using a paperclip (that has been straightened

out) depress the "set" button that is located

between the two led displays on front of controller

to put controller into "adjustment mode".

4. Using the "speed" buttons below the spinner

display, press the "Right" speed button to decrease

the output to the spinner disk.

5. After spinner stops rotating, use the paper clip

to depress the "set" button to lock-in setting.

Adjusting Spinner Span Settings

1. Verify that the spinner knob is turned completely

CW to the max speed position you want before

beginning adjustments.

2. Check to see that spinner disk is spinning at

desired speed then proceed to step #3

3. Using a paperclip (that has been straightened

out) depress the "set" button that is located

between the two led displays on front of controller

to put controller into "adjustment mode".

4. Using the "speed" buttons below the spinner

display, press the "Left" speed button to increase

the output to the spinner disk if it is rotating to

slow.

5. After spinner is rotating at desired speed, use

the paper clip to depress the "set" button to lock-in

setting.

Adjusting Auger Zero Settings

1. Verify that the Auger knob is turned completely

CCW to the zero position before beginning

adjustments.

2. Make sure that Auger is stopped, if it is moving

proceed to step #3

3. Using a paperclip (that has been straightenened

out) depress the "set" button that is located

between the two led displays on front of controller

to put controller into "adjustment mode".

4. Using the "speed" buttons below the Auger

display, press the "Right" speed button to decrease

the output to the Auger motor.

5. After Auger stops moving, use the paper clip to

depress the "set" button to lock-in setting.

Adjusting Auger Span Settings

1. Verify that the Auger knob is turned completely

CW to the max speed position you want before

beginning adjustments.

2. Check to see that auger is moving at desired

speed then proceed to step #3

3. Using a paperclip (that has been straightened

out) depress the "set" button that is located

between the two led displays on front of controller

to put controller into "adjustment mode".

4. Using the "speed" buttons below the Auger

display, press the "Left" speed button to increase

the output to the auger until desired speed is

achieved.

5. After Auger is moving at desired speed, use

the paper clip to depress the "set" button to lock-in

setting.

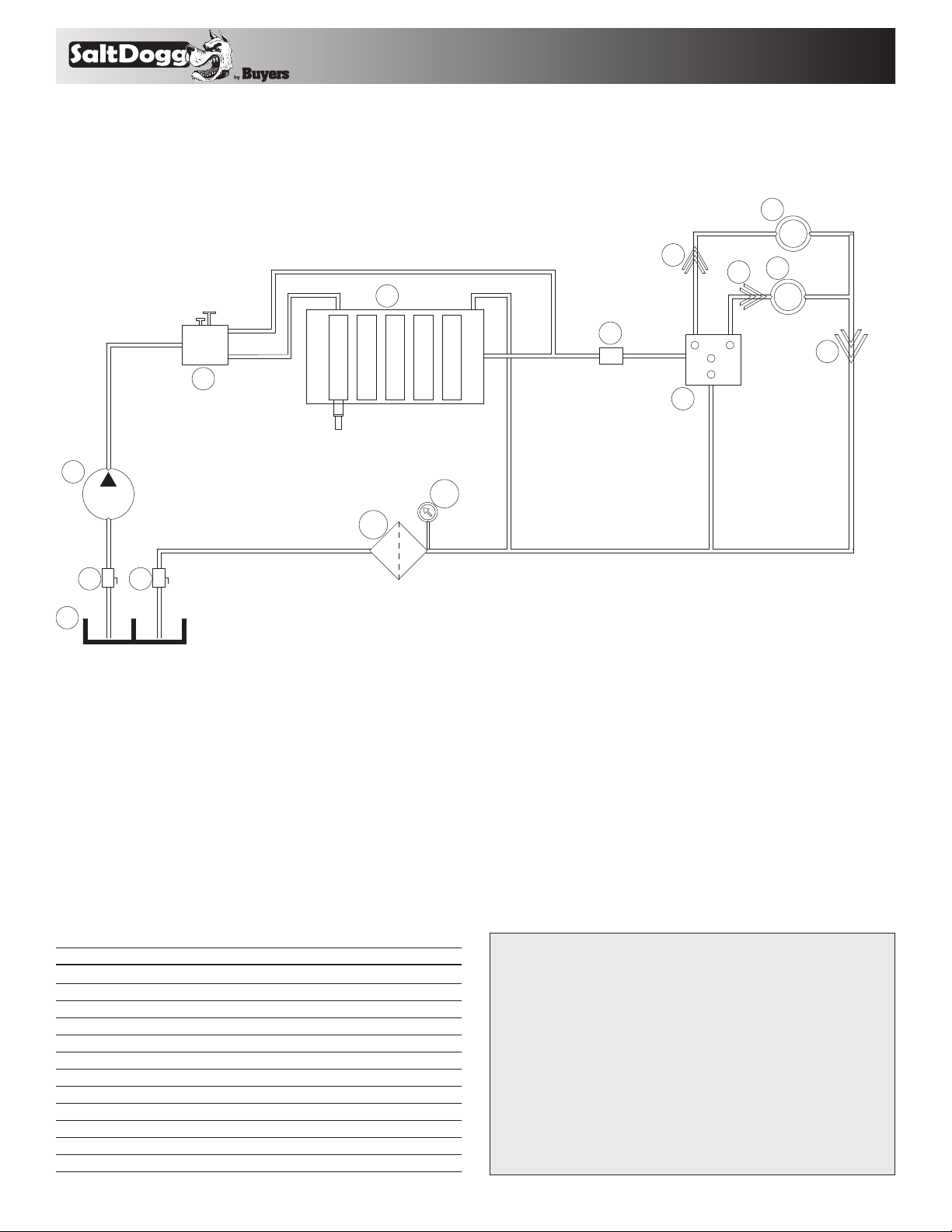

Setting Blast Time

1. Check to make sure the Auger speed knob is

NOT turned to full speed before beginning blast

time adjustment.

2. Press the " blast button" on the front of the

controller to initiate the "blast" function.

3. Using the same paper clip that was used for

spinner and auger adjustments, depress the "set"

button between the two led displays to enter

setting mode.

4. The auger display will show "BT", using the

"speed" buttons below the auger display, press the

"left" button to increase the blast time or press the

"right" button to decrease the blast time.

5. Use paper clip,press the "set" button again to lock

in value.