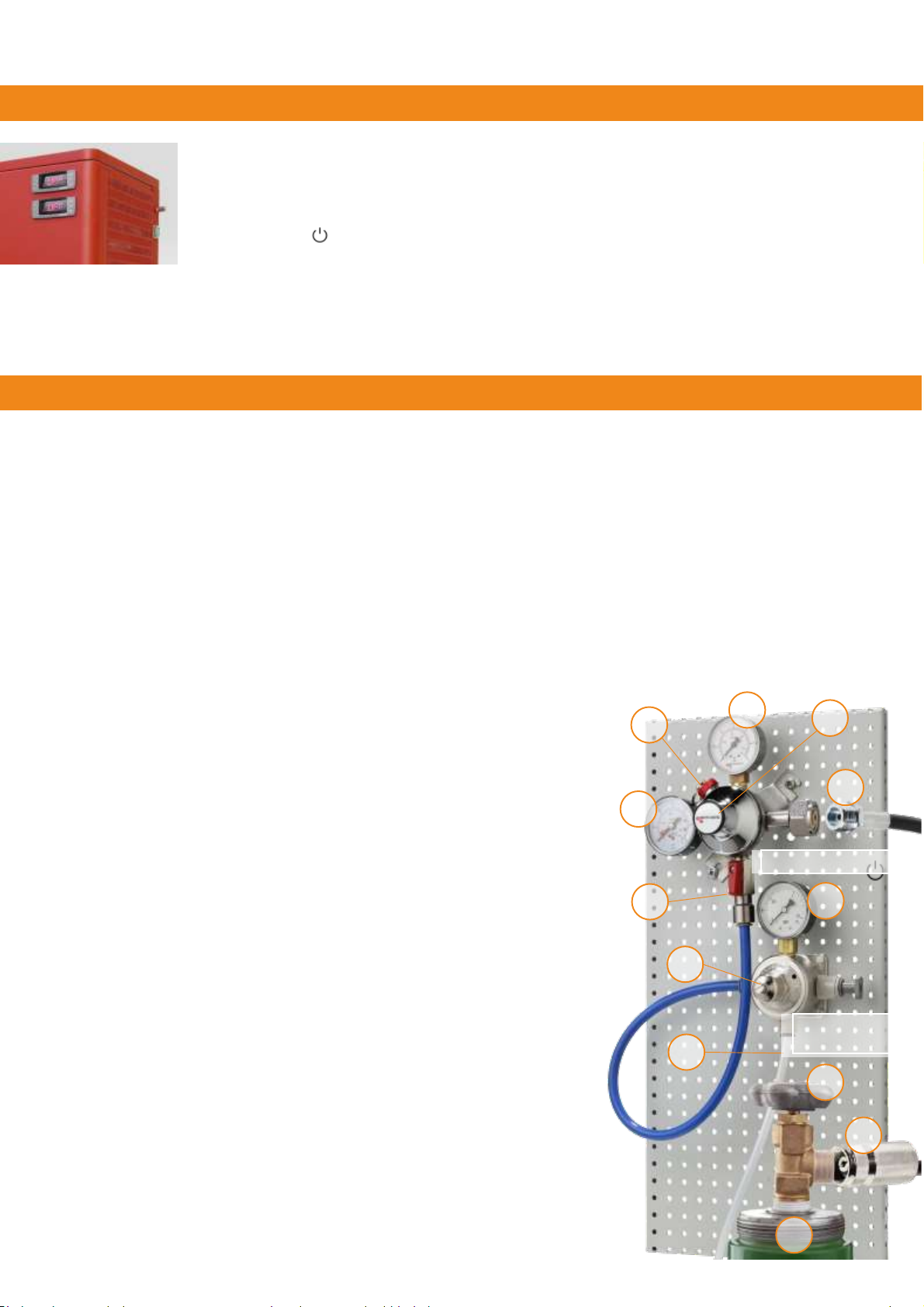

•Mount the supplied pressure regulators accessibly and easy to read on a wall or

in the appropriate furniture piece. When choosing the mounting location, make sure

that the lines can be connected with the least possible torsion, so that they are

not under tension and move as little as possible during operation.

•Connect the high-pressure hose (8) to the high-pressure regulator. The thread

must be screwed very strongly and durably, to ensure tightness. Use two

matching wrenches, to avoid damaging the pressure regulator.

•Connect the quick coupling of the high-pressure hose (9) to the gas bottle. The

quick coupling has a safety mechanism that prevents the releasing of the

connection when under pressure. To release the connection, you must first close

the lever of the gas cylinder (11), and then release the pressure by means of the

manual release valve (4). (See also Para. 12 "Exchanging the Gas Cylinder".)

•Connect the low-pressure line of the Wine Dispenser (10) to the precision

pressure regulator. For this, pull off the red locking ring, and insert the tube all the

way into the plug-in connection. Secure the connection again with the red locking

ring.

•Close the shut-off valve (6) on the pressure regulator (horizontal position), and then

slowly open the cock of the gas cylinder (11). First, check whether the connections on

the high-pressure regulator (8) and the cylinder (9) are audibly proof.

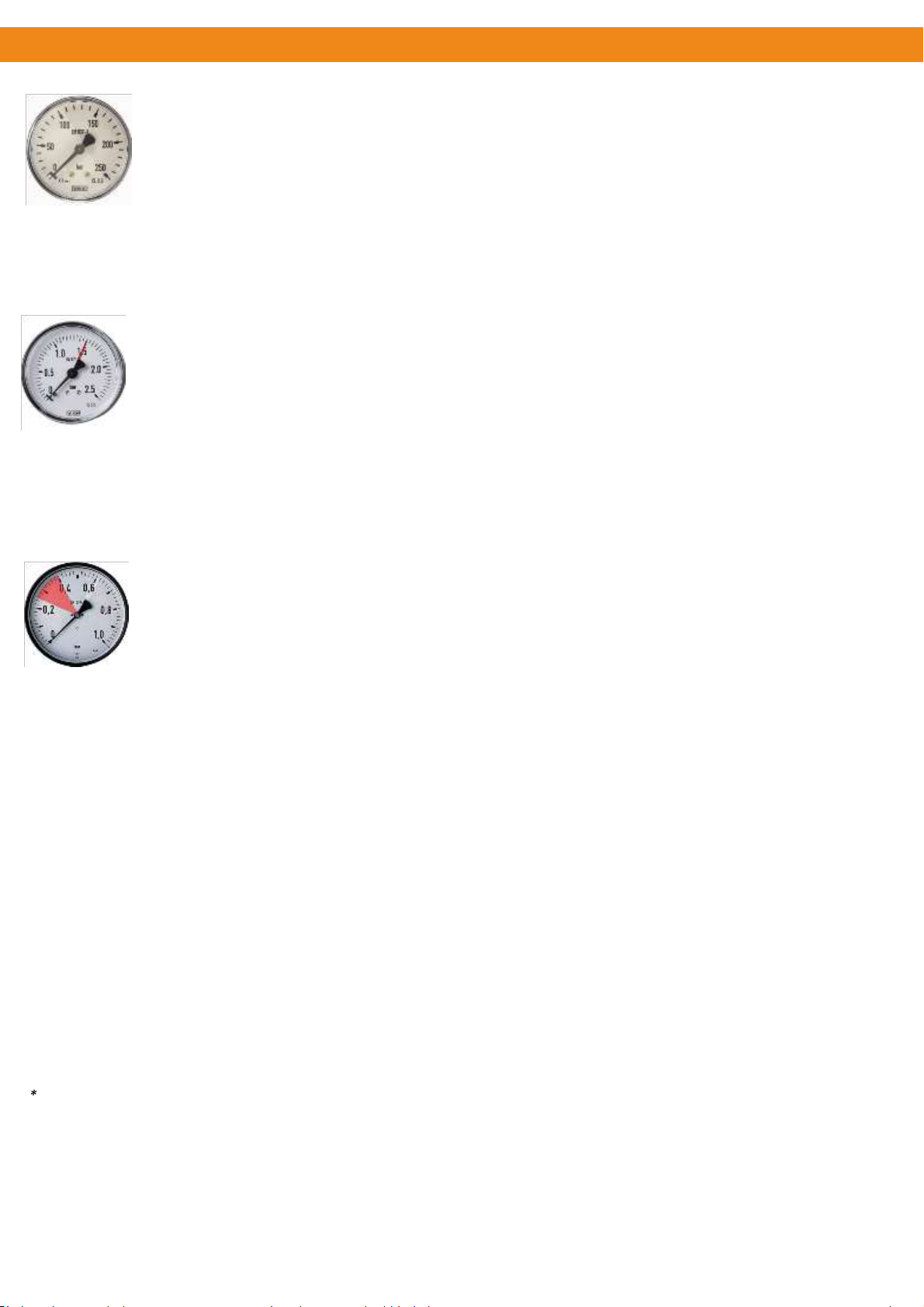

•Now set the transition pressure (2) with the adjustment screw (5). Upon delivery, the

valve is closed, and the display shows “0”. Turn the Allen screw under the cover in

clockwise direction until the indicator (2) shows 1 to max. 1.5 bar. If the pressure

exceeds 1.5 bar, turn the screw backwards. For the indicator to drop, you must first

let out gas manually via the release valve (4).

•Now open the red lever (6), and adjust the discharge pressure (3) with the

adjustment screw (7) on the precision pressure regulator provisionally. Upon

delivery, the valve is closed, and the display shows "0". Keep turning the adjusting

screw clockwise, until the display shows a pressure between 0.25 and 0.4 bar (see

Para. 11 for subsequent fine adjustment of the discharge pressure).

•First check the tightness of the system. You can test the tightness reliably by closing

the gas cylinder again (11), while keeping an eye on the pressure gauge for the inlet

pressure (1). If even after several minutes, the manometer for the inlet pressure

doesn't drop, the system keeps the built-up pressure and is therefore tight.

•If, however, after closing the gas bottle, the inlet pressure drops after a few minutes,

this indicates a leak. The check for possible leaks at the joints can be performed with

a leakage spray by looking for bubbles forming.

7

Warning:

Always open the gas cylinder slowly and not abruptly, to prevent damage to

the lines and the pressure reducers.