C.M.O FL Series Instructions for use

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 1

17/09/2014

INSTRUCTIONS AND

MAINTENANCE MANUAL

SERIES: FL

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 2

THEFLPENSTOCKCOMPLIESWITHTHEFOLLOWING:

MachineryDirective:DIR2006/42/EC(MACHINERY).

PressureEquipmentDirective:DIR97/23/EC(PED)ART.3,P.3.

PotentiallyExplosiveAtmospheresDirective(optional):DIR94/9/EC(ATEX)CAT.3ZONE2and22GD.

TheFLpenstockcomplieswiththeDirectiveonEquipmentandProtectiveSystemsforPotentially

ExplosiveAtmospheres.Inthesecasesthelogowillappearintheidentificationlabel.Thislabelshows

theexactclassificationofthezoneinwhichthepenstockcanbeused.Theuserisresponsibleforitsuse

inanyotherzone.

HANDLING

Payspecialattentiontothefollowingpointswhenhandlingtheequipment:

SAFETYWARNING:Beforehandlingthepenstock,checkthatthecranetobeusediscapableof

bearingitsweight.

Donotliftthepenstockorholditbythearm.Liftingthepenstockbythearmcanleadtooperating

problemsasitisnotdesignedtowithstandthepenstock’sweight.

Whenliftingthepenstock,takecarenottodamagethesealingjoints,asthismayleadtoleakage

duringtheoperationofthepenstock.

Topreventdamage,especiallytotheanticorrosiveprotection,itisrecommendedtousesoftstrapsto

lifttheCMOretentionpenstocks.Thesestrapsmustbesecuredinthetoppartofthebody,usingthe

holesfittedtosecurethepenstockandwiththehelpofshackles.

Iftheequipmentispackedinwoodenboxes,thesemustbeprovidedwithclearlymarkedholding

areaswheretheslingswillbeplacedwhensecuringthem.Intheeventoftwoormorepenstocks

beingpackedtogether,separationandsecuringelementsmustbeprovidedbetweenthemtoprevent

possiblemovements,knocksandfrictionduringtransport.Whenstoringtwoormorepenstocksinthe

sameboxyoumustensuretheyarecorrectlysupportedtopreventdeformations.Inthecaseof

dispatchesbyseawerecommendtheuseofvacuumbagsinsidetheboxestoprotecttheequipment

fromcontactwithseawater.

Payspecialattentiontomaintainingthecorrectlevellingofthepenstocksduringloadingand

unloadingaswellasduringtransporttopreventdeformationsintheequipment.Forthispurposewe

recommendtheuseofmountsortrestles.

INSTALLATION

Inordertoavoidpersonalinjuryandothertypesofdamage(tothefacilities,thepenstock,etc.),we

recommendfollowingtheseinstructions:

Thestaffresponsiblefortheinstallationoroperationoftheequipmentmustbequalifiedandtrained.

UsesuitablePersonalProtectiveEquipment(PPE)(gloves,safetyboots,goggles,etc).

Shutoffalllineswhichaffectthepenstockandputupawarningsigntoinformabouttheworkbeing

carriedout.

Completelyisolatethepenstockfromthewholeprocess.Emptytheconduitorline.

Drainallthefluidfromtheconduitorlinethroughthepenstock.

Usenon‐electricalhandtoolsduringinstallationandmaintenance,inaccordancewithEN13463‐1(15).

ASSEMBLY

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 3

Beforeinstallation,inspectthepenstocktoensurenodamagehasoccurredduringtransportorstorage.

Ensurethatthepenstocksealingareaisclean,andcheckthattheflapswivelswithoutanydifficultyon

thelugsofthebody.

‐Ifthepenstockistobeinstalledonaflange,inspectthepipeandtheinstallationflange,ensuring

theyarecleanandtheflangeboreholesstandardcoincideswiththepenstockboreholesstandard.

‐Ifthepenstockistobewall‐mounted,inspectthewalltoensureitiscleanandflat.

ASPECTSTOBECONSIDEREDDURINGASSEMBLY

Whenmountingthepenstock,itisvitallyimportantthattheturning

pointoftheflap(bodylugs)are,whateverthetypeofattachmentor

typeofpenstock,intheupperpartofthepenstock,inordertoensure

thattheforceofgravityclosestheflap.

fig.1 fig.2fig.3

TheFLpenstockisunidirectional,andisalwaysinstalledinsuchamannerthatthefluidwhichcomes

fromaconduitorlinefirstpassesthroughthebodyofthepenstockandthenpushesontheflap.

Physicallyitcannotbemountedinanyotherway,withthesingleassemblyoptionthereforeguaranteed

tobethecorrectone.

Turningpoint

ConduitFlap

Body

fig.4

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 4

Sinceeachofthesepenstocksisdesignedtocomplywiththeoperatingconditionsofeachinstallation,

thereareseveraloptionstoinstalltheFLpenstock.

Themostnotablearethetwomostcommonoptions:oneisboltedtoanexistingflangeandtheotheris

mountedonawallandsecuredwithanchors.

Eachoftheseoptionsisdescribedindetailbelow.

Tomountthepenstockboltedtoaflange(fig.5),thesestepsshouldbefollowed:

‐Positionthepenstocksupportedontheflangeoftheinstallation,checkingthattheboreholes

coincidewiththepenstockbodyboreholes.

‐Afterensuringthattheboreholecoincides,removethepenstockfromtheflange.

‐Cleanthefaceoftheflangewherethepenstockistobemounted.

‐Positionasealtightjointontheflange,inordertoensuretherearenoleakagestotheoutside

wheretheflangeandthepenstockcometogether.Thesealtobeinstalledwillbeselectedinline

withtheworkingconditionsinsidetheline(temperature,pressure,typeoffluid,etc).

‐Checkthatthepenstock,theinsideofthebodyand,aboveall,thesealingareaareclean.

‐Cleanthefaceofthebodysupportedontheflange.

‐Positionthepenstocksupportedontheflange.

‐Positionthepenstocksotheturningpointoftheflap(bodylugs)remainsintheupperpartofthe

installation.

‐Ensurethatthesealtightjointbetweentheflangeandthepenstockiscorrectlypositioned.

‐Aftercorrectlypositioningboththesealtightjointandthepenstock,fastenthejoiningbolts.

Theseboltsandnutsmustbesuitablefortheoperatingconditions.

‐Oncealltheboltsareinplace,tightencrosswisewithalowinitialtorque.

‐Finally,completethefinaltorqueinaccordancewiththeapplicablestandard.

‐Aftercarryingoutallthesestepsandbeforefinishingtheassemblyprocess,checkthattheflap

swivelswithoutanydifficultyontheturningpoint.

Installationpiping

fig.5

Turningpoint

Body

FlangeSealtightjoint

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 5

Inordertoinstallthepenstockmountedonawallandsecuredusingchemicalorexpansion

anchors(fig.6),thesestepsshouldbefollowed:

‐Checkthatthewalliscompletelyflat,otherwisethebodymaybecomedeformedandproduce

irreparabledamagewhentighteningtheanchoring.

‐Placethepenstockonthewall,ensuringthepassageofthepenstockcoincideswiththewall

orifice.

‐Usingtheholesofthebodyofthepenstockasaguide,maketheboreholesnecessaryinthewall

forthechemicalorexpansionanchors.

‐Removethepenstockfromthewallwhereitistobelocatedandapplysealingpastesuchas

SIKAFLEX‐11FCorsimilarinordertopreventleakagesbetweenthebodyandthewall.

‐Returnthepenstocktoitslocationabovethesealingpasteandintroducethechemicalor

expansionanchors.Theseanchoringsshouldalsobesuitablefortheoperatingconditionsand

theirmeasurementsinaccordancewiththeapprovedplans.

‐Onceallthechemicalorexpansionanchorsareinplace,carryouttheinitialtighteningwithlow

torqueandcrosswise.

‐Oncealltheanchorsareslightlytightened,continuewithfinaltorqueincrosswisemode.Usea

flatruletocarryoutthistightening.Supporttheruleonthebodyandbegintotightenthe

anchors,andstoptighteningassoonasthebodybeginstoloseshape.Usetheflatruleto

preventexcessivetightening.

‐Thefinaltorquemustbecorrectwiththeapplicablestandard.

‐Aftercarryingoutallthesestepsandbeforefinishingtheassemblyprocess,checkthattheflap

swivelswithoutanydifficultyontheturningpoint.

fig.6

Body

SIKAFLEX‐11FCcord

Wall

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 6

Thesearethemostcommonattachmentoptions,although,asmentionedonotheroccasions

throughoutthismanual,thedesignoftheseFLpenstocksisdefinedinaccordancewiththecustomer's

requirementsineachspecificproject.Inconsequence,ifyourequireadifferentattachmentoption,

contactCMO'stechnicalsalesdepartmentforabespokeprojectinlinewithyourneeds.

Thepenstockcanbeinstalledsecuredtoawallwithanchorsorboltedtoaflange;inallcasesthe

followingmustbetakenintoaccount:

Theequipmentmustbefirmlysecuredintheinstallation.

Asregardsscaffolding,laddersandotherauxiliaryelementstobeusedduringassembly,followthe

safetyrecommendationsindicatedinthisdossier.

Oncetheequipmenthasbeenassembled,makesurethattherearenoelementswhichcaninterfere

withtheflapmovement.

Theassemblyoftheequipmentmustbecoordinatedwiththesite’scontrolandsafetystaffandno

modificationsarepermittedintheequipment’sexternalindicationelements(limitswitches,

positioners,etc.).

ASSEMBLYPOSITIONS

Thistypeofpenstockscanbemountedonaverticalflange(fig.7)locatedattheendofahorizontal

pipe,ormountedonaverticalwall(fig.8)inwhichthereisasquare,roundorrectangularorifice.

Whateverthetypeofinstallation,thepositionofthepenstockisvertical.

ThisFLpenstockisaretentionpenstockwhichisdesignedforuseasendofline,meaningitisalways

assembledattheendofafacility.

Thesearethemostcommonattachmentoptions,although,asmentionedonotheroccasions

throughoutthismanual,thedesignoftheseFLpenstocksisdefinedinaccordancewiththecustomer's

requirementsineachspecificproject.Inconsequence,ifyourequireadifferentattachmentoption,

contactCMO'stechnicalsalesdepartmentforabespoke

projectinlinewithyourneeds.

fig.8fig.7

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 7

Oncethepenstockhasbeeninstalled,checkthatallbolts,nutsandanchoringshavebeencorrectly

tightened.

AllCMOpenstocksaretestedatitsfacilities,althoughthepenstockmayhavebecomedamagedduring

transportorassembly.Onceinstalled,itisveryimportanttocheckthatthepenstockworkscorrectly,

makingsurethattheflapswivelsonitsturningpointwithoutanydifficulty,thatitsitsperfectlyonthe

sealwhenthepenstockisclosed,etc.

IfthepenstockhaselectricalaccessoriesoryouareinanATEXzone,earthconnectionsmustbemade

oncethepenstockisinplacebutbeforeoperatingit.

IfyouareinanATEXzone,checkthecontinuitybetweenthedifferentelementsofthepenstock(EN

12266‐2,annexB,pointsB.2.2.2.andB.2.3.1.).Checktheearthconnectionofthepenstock.

TheseFLpenstocksdonothaveanactuatorsystem,butratherareautomatic.Itisthefluidwhichopens

orclosesthepenstock.

Whenthefluidcomesfrominsidethepipetotheoutside,itpushesontheflapwhichswivelsonthe

turningpointandopensthepenstock.Thedegreeofopeningwillbeproportionaltothepressureofthe

fluid:thegreaterthepressure,themorethepenstockwillopen(fig.9).

Whenthefluidcomesfromtheextractortowardsthepiping,itpushestheflapagainstthebody,

pressingontheelastomersealinordertoachievesealtightintegrity.Thegreaterthefluidpressure,the

moretheflappressesagainstthebody,thusensuringsealtightintegrityatalltimes(fig.10).

ACTUATOR

fig.9fig.10

GateopenGateclosed

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 8

CMOwillnotbeliableifthepenstockssufferanydamageduetoimproperhandlingorwithoutproper

authorisation.ThepenstocksmustnotbemodifiedexceptunderexpressauthorisationfromCMO.

Thefollowinginstructionsshouldbefollowedinordertoavoidpersonalinjuryormaterialdamagewhen

carryingoutmaintenancetasks:

Thestaffresponsibleforthemaintenanceoroperationoftheequipmentmustbequalifiedand

trained.

UsesuitablePersonalProtectiveEquipment(PPE)(gloves,safetyboots,goggles,etc.).

Shutoffalllineswhichaffectthepenstockandputupawarningsigntoinformaboutthework

beingcarriedout.

Completelyisolatethepenstockfromthewholeprocess.Emptytheconduitorline.

Drainallthefluidfromtheconduitorlinethroughthepenstock.

Usenon‐electricalhandtoolsduringmaintenance,inaccordancewithEN13463‐1(15).

Theonlymaintenancerequiredinthistypeofpenstocksistochangetherubbersealingjoint.Itis

recommendedtocheckthesealregularlyevery6months,althoughtheworkinglifeofthesealswill

dependontheoperatingconditionsofthepenstock,suchas:pressure,temperature,numberof

operations,typeoffluidandothers.Thesejointsareboltedwithflanges;boththeflangesandthebolts

aremadeofstainlesssteel,andcanbereusedseveraltimes.

InanATEXzone,electrostaticchargesmaybepresentinsidethepenstock,whichcancauseariskof

explosion.Theuserwillberesponsibleforcarryingoutappropriateactionsinordertominimisethe

risks.

ThemaintenancestaffmustbeinformedabouttherisksofexplosionandATEXtrainingis

recommended.

Regularcleaningofthepenstocktopreventaccumulationofdust.

Avoidre‐paintingtheproductssupplied.

IMPORTANTSAFETYASPECTS

Inordertoworkinidealsafetyconditions,boththeelectricalandmagneticelementsmustbeidle.

Theelectricalcontrolcabinetsmustalsobeoutofservice.Themaintenancestaffmustbeuptodate

withthesafetyregulationsandworkcanonlystartunderordersfromthesite’ssafetystaff.

Thesafetyareasmustbeclearlymarked,avoidingtheuseofauxiliaryequipment(ladders,

scaffolding,etc.)inmovingparts,inordertoproducethemovementoftheflap.

Beforestartingmaintenanceworkonthepenstock,securetheflapinopenpositionusingmorethan

onesystem,thusensuringitwillstayinplaceintheeventoffailure.

Takingintoaccounttherecommendationsindicated,themaintenanceoperationscarriedoutinthis

typeofequipmentareshownbelow:

MAINTENANCE

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 9

REPLACINGTHESEALINGJOINT

1. Makesurethereisabsolutelynopressureorfluidinthefacility.

2. Placetheflap(2)incompletelyopenposition.

3. Securetheflap(2)inthispositionusingmorethanonesystem.

4. Unscrewandremovethescrews(8)fromtheflange(4)andtheseal(3).

5. Removetheflangeseal(4)andfinallythedeterioratedseal(3).

6. Cleanthesealhousing(3).

7. Fitanewsealingjoint(3)withthesamedimensionsastheoldone.

8. Returntheflange(4),checkingthatitiscorrectlyfittedandtheseal(3)hasnotbeendamagedin

theprocess.

9. Removethesystemstosecuretheflap(2)inopenposition,andcarefullypositionitinclosed

position.

10. Beforestartinguptheinstallation,checkthattheflap(2)swivelsfreelyonitsturningpoint;also

checkthattheflap(2)sitsperfectlyontheclosingseal(3)whenthepenstockisclosed.

Note:Thenumbersinbracketsrefertofig.11.

Note:Duringtheassemblyofthenewsealingjoint,itisrecommendedtoapplypetroleumjellytothe

jointtofacilitatetheassemblyprocessandthecorrectoperationofthepenstock(donotuseoilor

grease);table1belowshowsdetailsofthepetroleumjellyusedbyCMO:

PETROLEUMJELLY

SayboltColour ASTMD‐156 15

Meltingpoint(ºC) ASTMD‐12760

Viscosityat100ºC ASTMD‐4455

Penetration25ºCmm./10ASTMD‐937165

Siliconecontent None

PharmacopeaBP OK

table1

fig.11

RETENTION PENSTOCK FL SERIES

C.M.O.

AmateguiAldea142,20400Txarama‐Tolosa(SPAIN) MAN‐FL.ES00

Tel.National:902.40.80.50Fax:902.40.80.51/Tel.International:34.943.67.33.99Fax:34.943.67.24.40

[email protected]http://www.cmo.es page 10

LUBRICATION

Theonlypointofthepenstockwhichrequireslubricationistheturningpoint,whichwerecommend

greasingabouttwiceayear.

AfterthemaintenanceandinanATEXzone,youmustchecktheelectricalcontinuitybetweenthepipe

andtherestofthevalve’scomponents,suchasthebody,flap,stem,etc.StandardEN12266‐2,AnnexB,

pointsB.2.2.2.andB.2.3.1.).

STORAGE

Toensurethepenstockisinoptimumconditionsofuseafterlongperiodsofstorage,werecommend

storingitinawell‐ventilatedplaceattemperaturesbelow30ºC.

Itisnotadvisable,but,ifstoredoutside,thepenstockmustbecoveredtoprotectitfromheatand

directsunlight,withgoodventilationtopreventhumidity.Thefollowingaspectsmustbeconsideredfor

storagepurposes:

Thestorageplacemustbedryandundercover.

Itisnotrecommendedtostoretheequipmentoutdoorswithdirectexposuretoadverseweather

conditions,suchasrain,wind,etc.Evenwhentheequipmentispackaged.

Thisrecommendationisevenmoreimportantinareaswithhighhumidityandsalineenvironments.

Windcancarrydustandparticleswhichcancomeintocontactwiththepenstock’smovingpartsand

thiscanleadtooperatingdifficulties.

Theequipmentmustbestoredonaflatsurfacetoavoidlossofshape.

Iftheequipmentisstoredwithoutsuitablepackagingitisimportanttokeepthepenstock’smoving

partsgreased,forthisreasonitisrecommendedtocarryoutregularchecksandlubrication.

Likewise,ifthereareanymachinedsurfaceswithoutsurfaceprotectionitisimportantforsomeform

ofprotectiontobeappliedtopreventtheappearanceofcorrosion.

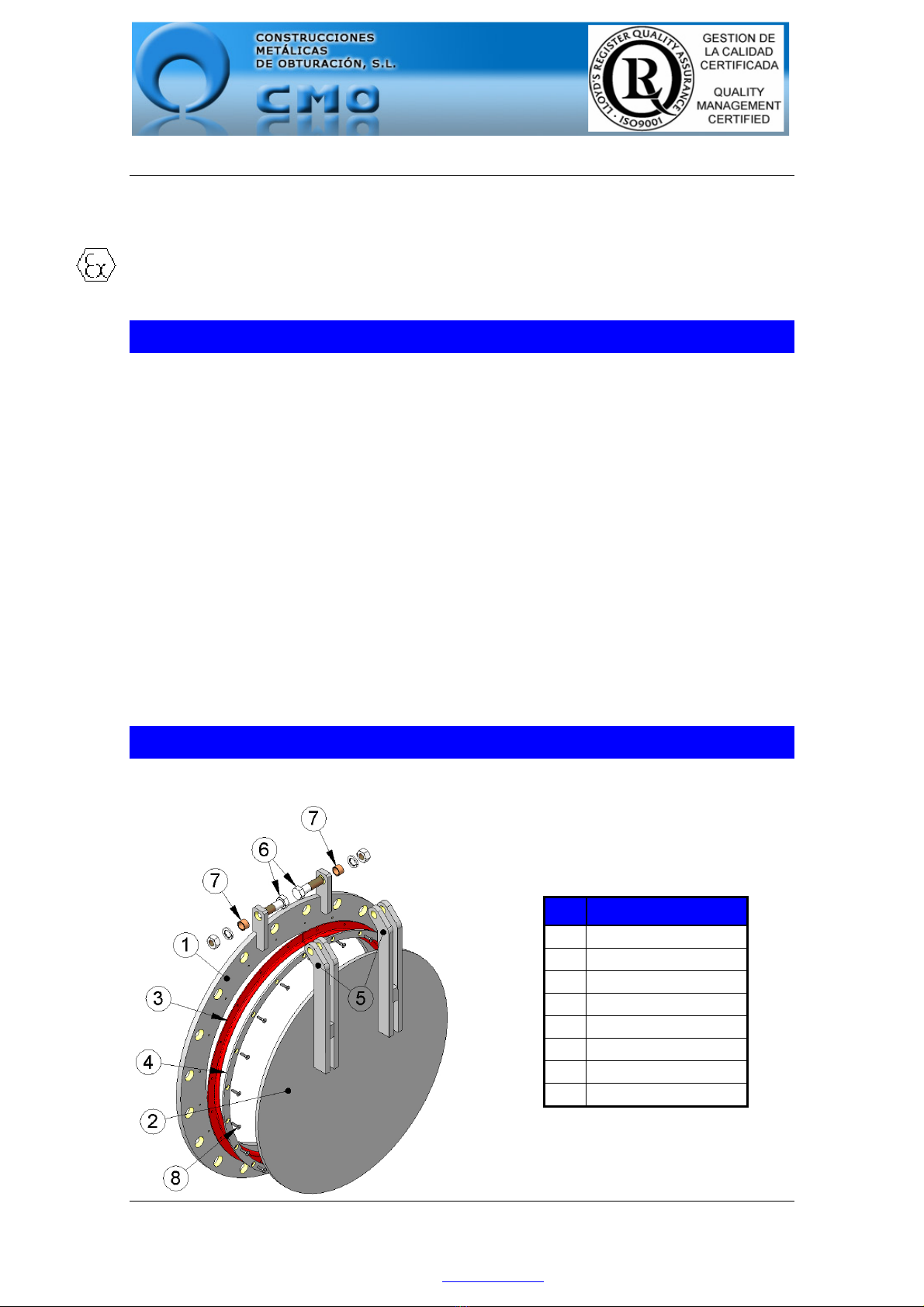

COMPONENTSLIST

table2

POSDESCRIPTION

1BODY

2FLAP

3SEAL

4FLANGESEAL

5ARM

6SHAFT

7 BUSHING

8SCREWSANDBOLTS

fig.12

Table of contents