C-Tech DKZ-5000 User manual

I

CEMENT FLEXURAL TESTING MACHINE DKZ-5000

I

CONTENTS

I. Application .......................................................................................................................................................1

II. Technical specifications .................................................................................................................................1

III. Structure ..........................................................................................................................................................1

IV. Operation .........................................................................................................................................................2

V. Maintenance ...................................................................................................................................................3

VI. Trouble and Solution ......................................................................................................................................4

VII. Circuit diagram ................................................................................................................................................5

-1 -

I. Application

The cement electric bending resistant testing machine is the necessary device to conduct test on

strength of bending resistant in the cement mortar. The device can also be used to test the bending

resistant strength of other cements and nonmetal fragile material.

This machine uses horizontal maximum output 1000N, using the parallel bars, maximum output

5000N, tester scale is designed to cement practice flexural strength of mortar and resistance of soft

conversion scale, maximum output is 1000N, the sensing accuracy of 0.4N and 0.001Mpa, the

maximum output is 5000N, read accuracy of 1N and 0.005 Mpa.

II. Technical specifications

Maximum flexural strength (N)

Single level: 1000 N

Double lever:5000N

The output ratio

Single lever: 10:1

Double lever: 50:1

Load speed

Single lever: (10±1)N/s

Double lever: (50±5)N/s

Load roller and support roller diameter

Φ10mm

Distance between the roller

100mm

Relative error value

<±1%

Lever Angle

>1/50

Dimensions

1075mm×250mm×760mm

Net Weight

85kgs

III. Structure

- 2 -

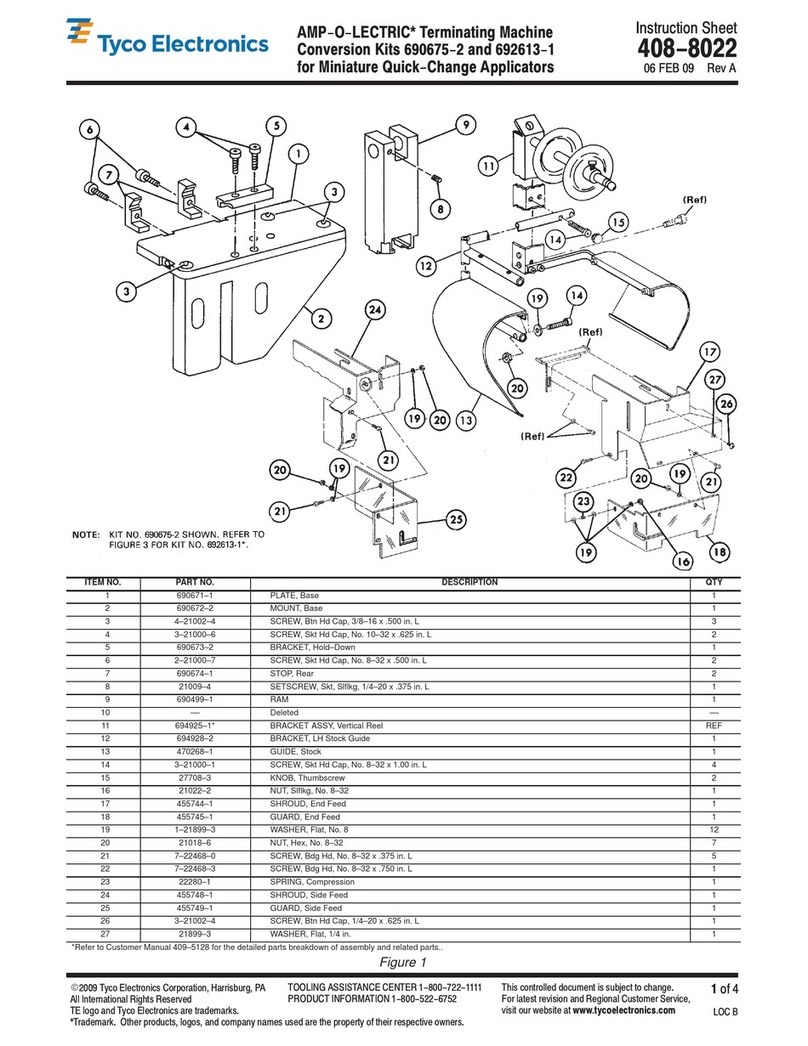

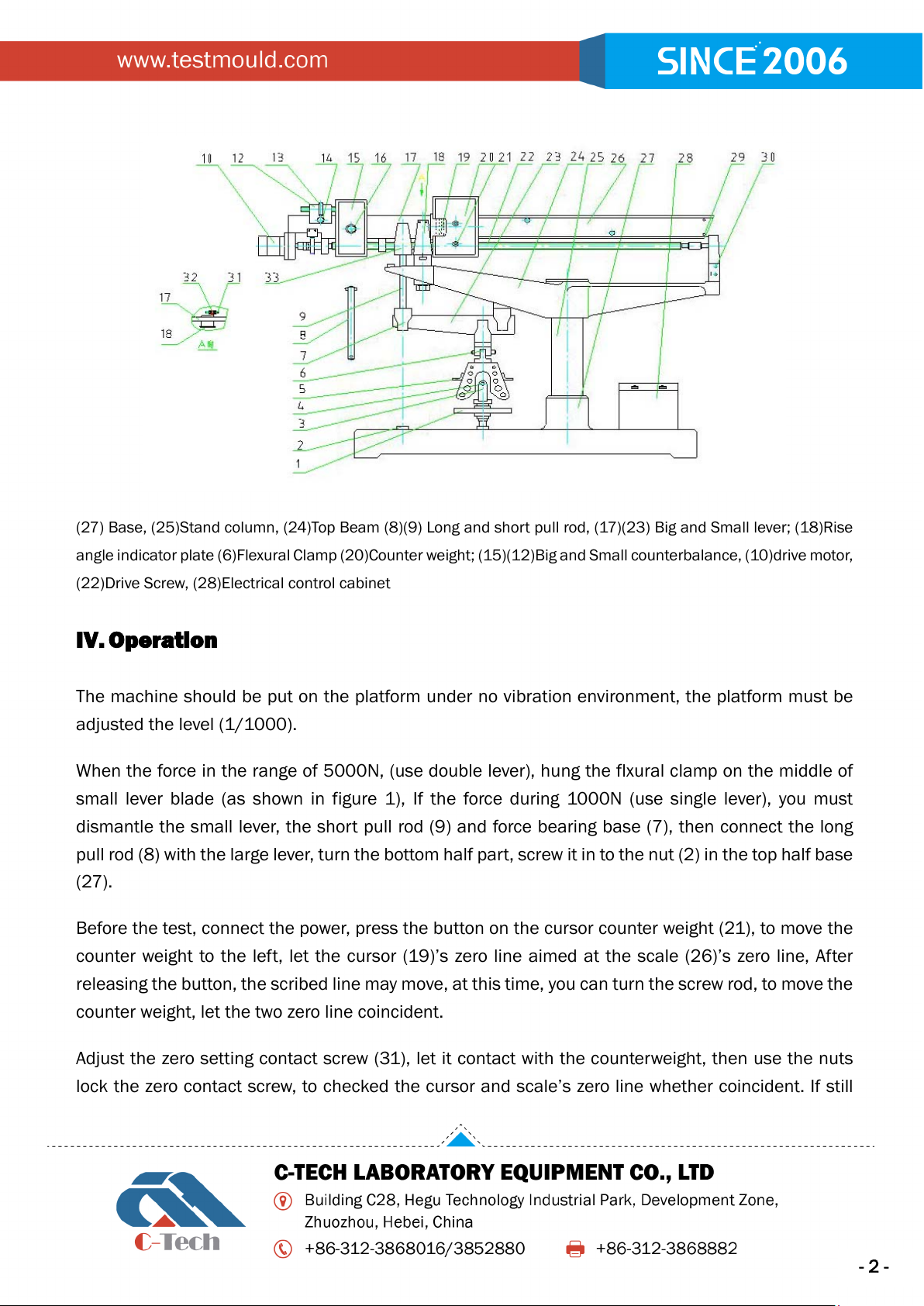

(27) Base, (25)Stand column, (24)Top Beam (8)(9) Long and short pull rod, (17)(23) Big and Small lever; (18)Rise

angle indicator plate (6)Flexural Clamp (20)Counter weight; (15)(12)Big and Small counterbalance, (10)drive motor,

(22)Drive Screw, (28)Electrical control cabinet

IV. Operation

The machine should be put on the platform under no vibration environment, the platform must be

adjusted the level (1/1000).

When the force in the range of 5000N, (use double lever), hung the flxural clamp on the middle of

small lever blade (as shown in figure 1), If the force during 1000N (use single lever), you must

dismantle the small lever, the short pull rod (9) and force bearing base (7), then connect the long

pull rod (8) with the large lever, turn the bottom half part, screw it in to the nut (2) in the top half base

(27).

Before the test, connect the power, press the button on the cursor counter weight (21), to move the

counter weight to the left, let the cursor (19)’s zero line aimed at the scale (26)’s zero line, After

releasing the button, the scribed line may move, at this time, you can turn the screw rod, to move the

counter weight, let the two zero line coincident.

Adjust the zero setting contact screw (31), let it contact with the counterweight, then use the nuts

lock the zero contact screw, to checked the cursor and scale’s zero line whether coincident. If still

- 3 -

can’t coincident, re-adjust the contact screw according to above method. Until the two zero line

coincident.

Release the lock nut (14) and (16), move the small and big counter-balance, let the big lever (17) in

the balance as far as possible, then turn the lock screw, lock the big counter-balance (15) on to the

big lever, move the nut (13), in order to move small counter-balance (12), Until the big lever in balance,

then lock the screw, lock the small counter-balance on to the big lever.

Note: the big and small counter-balance must lock reliable, to avoid the adjusted balance damaged

during the test.

Put the specimen in to the flexural clamp, aimed at the alignment plate, turn the hand wheel under

the clamp(1), let the load shaft (4) contact the specimen, and continue to turn a certain angle, let

the big lever have a rise angle, the data determined by the deformation when the specimen fracture,

the principle is that to keep the big lever in balance when the specimen at breaking, rise angle value

can be read from rise angle indicator plate (each cell is 2°). Press the “start” button in the electric

control cabinet, the motor (10) turns the screw rod to drive the cursor counterweight move to right,

the machine start to load, the big lever sink gradually, When the big lever close to balance, the

specimen fracture, the limit switch bump plate (29) push the limit switch, disconnect the motor power,

the motor stop work, at this time, you can read the flexural strength value from cursor scribed line

and scale.

Press the button (21), shift the cursor counterweight to the left, reset the cursor counterweight, you

can do the second test.

V. Maintenance

Keep the machine clean and day, especially, to avoid rusting, so as not to reduce the sensitivity

and accuracy.

The blade and blade bearing can’t have any lubricating oil, in order to avoid sticking dirt, block

the lever movement, impact the sensitivity, dust cover should be put after use.

The right limit switch bump plate in the big lever must be adjusted to let the limit switch start to

work when the big lever fall to the bottom, avoid to adjust it to let the limit switch work location

too early, so as not to damaged the limit switch.

- 4 -

The cursor counterweight shouldn’t have too big moving before press the button , after long term

use, the cursor counterweight on the screw rod have obvious vibration phenomenon, you can

replace the half-nut.

When the cursor counterweight moving, you can pack some light paper on right shaft of the

screw rod

VI. Trouble and Solution

Trouble

Reason

Solution

After the sample rapture, can’t stop load

automatically.

1.The right travel switch damaged

2.The left boring block not depressed the

travel switch

1.Change the travel switch

2.Adjust the boring block Location.

After the sample rapture, the

counterweight forward a section of

distance

The half nut in the counterweight wear

out

Replace the half nut(Code No.:500-01-

03)

The big lever lost balance 1.Counter-balance location move .

2.The cursor counterweight did not

return the original zero

1.lock tight after re-adjust

2.Turn the screw rod , adjust it to zero

location.

Cursor counterweight button did not

return

1.there have dirt or burrs in the button

hole

2.Spring failure

1.Clean up

2.Replace the spring

Cursor counterweight stagnation There have dirt in screw rod and large

lever flat surface , or in counterweight’s

rolling bearing .

Clean up the screw rod and rolling

bearing in the counterweight.

he motor can’t start 1.the screw rotating part locked dead .

2.The motor or electrical components

damaged

1.Clean

2.Replace the components

The big lever swing one times namely

stop

1.the big lever support blade damaged

2.there have dirt between the blade

Replace the blade or clean it

- 5 -

VII. Circuit diagram

With this , is motor number .

Code

Name

Model

Quy.

Note

C Capacitor CJ41-2A 1UT/630V 1

LX Travel Switch KWX 1

J Middle Relay JH1806 24V 1

B Rectifier transformers BKZ-25 ,1101 , 220V/-24V,-6.3V 1

D AC servo motors SD-75 110V 1

- 6 -

Table of contents

Other C-Tech Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Glunz & Jensen

Glunz & Jensen Flex-i-Line 520 XP Pre-installation guide

Shodex

Shodex IC SI-90 4E Operation manual

entegris

entegris NOWPak user manual

SAMES KREMLIN

SAMES KREMLIN Nanogun+ Airmix instruction manual

Electrolux

Electrolux FSF3 Installation, use and maintenance instructions

Burkert

Burkert 6516 operating instructions